Methods for splicing rafters along the length

Read also

Proper splicing of the rafters along the length guarantees the safety of the system in various operating conditions.

Using the methods described in the article for splicing, you can build a roof of any, even the most complex structure, spending a minimum of money on materials and using timber of standard sizes.

The nuances of lengthening roofing lumber

The main element of the gable roof frame is the rafters themselves, or, as roofers call them, rafter legs.

The rafters are fixed in the desired position using a system of spacers, girders, puffs and braces.

For the construction of truss frames that cover significant gaps between walls, and for the construction of roofs of complex shape, it is necessary to use timber of atypical size.

If there is no timber or other lumber of the right size at hand, then you have to splice the elements until their total length reaches the required value.

The material of a standard size becomes thicker with increasing length - this is not always convenient and technologically advanced.

Splicing makes it possible to increase the length of the truss elements without changing their thickness and thus achieve the design parameters.

The order of splicing the rafters in length, which can be used, mainly depends on the preferences of the master.

All methods are equally reliable and allow you to get rafters of given geometric and physical parameters.

Before proceeding with the combination of rafters, you need to learn a little about the physical properties of the materials used in different parts of the rafter structure.

Structural parts located in its different parts have to endure mechanical loads of different intensity.

In some knots, splicing of rafters in length cannot be used at all, since spliced lumber does not have the strength of a single piece.

Moreover, in certain places it is advisable to reinforce even solid lumber with additional details.

In any case, after splicing, the rafter legs and the entire roof frame must be guaranteed to be protected from breakage.

As a rule, splicing rafters in length reduces the rigidity of the structure, since a semblance of a plastic hinge is formed at the splicing site.

In order to reduce the stiffness as little as possible to affect the strength of the truss system, splicing of the rafters must be carried out at the points of the least bending load. Such places of the truss system are located near the supports.

The main rule when splicing in length is as follows - the junction of the lumber should not be located from the support at a distance greater than 15% of the span.

In addition, the place where the lumber joins along the length depends on what part of the truss frame they will subsequently be used as.

When combining lumber going to the construction of runs, it is necessary to ensure the same strength of the future part along the entire length.

Another task is when splicing the ridge run. Here, a certain deflection size is required, since only in this case the height of the ridge bar will be the same throughout its entire length.

The order of splicing rafters

In the construction business, there are several ways to splice timber in length. The choice of splicing technique is influenced by the distance between the rafters and the available fasteners and building materials.

The fastest way to connect timber and thus increase their length is docking.

For docking, the ends of both boards or beams must be cut at an angle of 90 degrees.

The ends should fit exactly to each other - this will ensure maximum strength of the rafters after splicing.

On both sides of the joint, wooden planks are placed on the lumber and fixed with nails, driving in fasteners in a diagonal order.

Instead of wooden linings, you can use metal plates with holes pre-drilled in them in a checkerboard pattern.

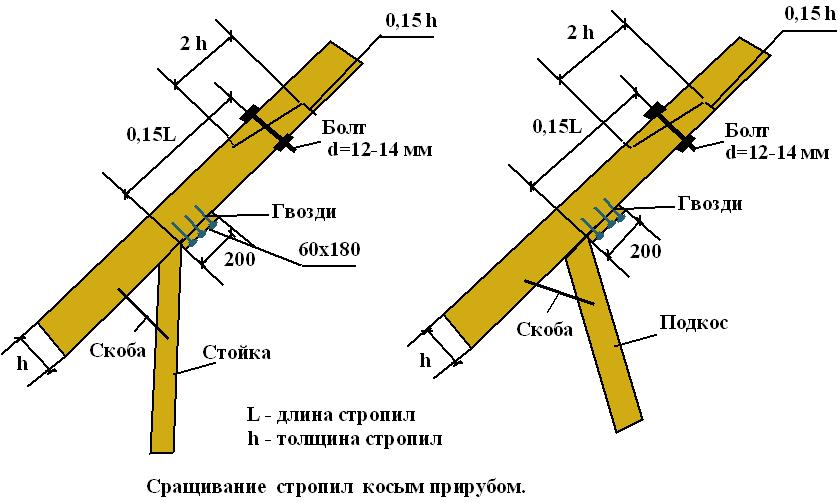

The next method that can be used to splice rafters is the oblique cut method. Basically, this method is used to connect square-section lumber.

The ends of the two bars must be cut at an angle of 45 degrees. The length of the cut should be twice the width of the beam.

Sharp corners on both parts are ground at an angle of 90 degrees, the depth of the resulting sites should be 15% of the height of the section. Similarly, platforms are made at the other end of the oblique cut.

Having connected both elements, fix the junction with a bolt, twisting it into the middle of the joint. A round opening for the bolt has to be done in advance.

At the same time, it is important that the hole diameter is equal to the diameter of the fastener or slightly smaller - then there will be no backlash, and the bolt will hold firmly in the rafter.

For splicing lamellas, the easiest way is to use the overlap method. Here, the carpenter does not require special accuracy and skill, since the boards are connected with an overlap of 100 cm.

Over the entire overlap area, nails are driven in in a chaotic manner. Bolts and studs are sometimes used instead of nails.

When using such fasteners, it is necessary to pre-drill holes in the boards, but the use of bolts and studs instead of nails increases the reliability of the structure.

When splicing rafters, we must not forget that the junction should fall on the least loaded section of the truss structure.

Finger-jointed lumber cannot be used for installation as diagonal rafters, as this structural element has to withstand increased loads.

At the same time, it should be noted that the strength of legs made from finger jointed lumber can exceed the strength of solid boards or beams.

Double and combined rafters

It is necessary to distinguish splicing from building. Splicing is an increase in the initial length of lumber, building up is an increase in diameter.

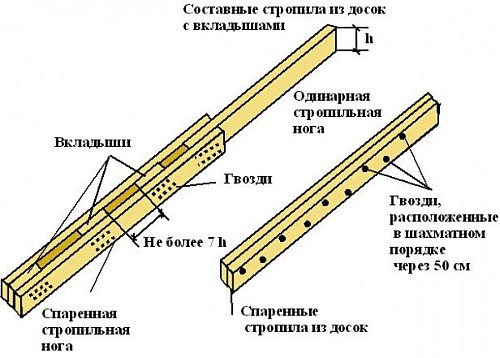

There are ways to simultaneously increase both the length and diameter of the rafter. These structures include paired and composite rafters.

Doubled and combined rafters are elongated beams made of boards and used for specific purposes. For lengthening in this case, the overlap method is used.

Paired rafters are connected from several edged boards, stitching them in a diagonal order with nails.

To increase the length of the paired rafter, it is connected to a similar paired structure.

Lumber in the connection node must overlap each other with an overlap of at least 100 centimeters.

This connection allows you to create a reliable beam of two rows of boards connected to each other with an overlap.

The joints should be placed diagonally so that the joints on the back side overlap with the solid parts of the boards.

Paired rafters are not inferior in reliability to a monolithic beam, which makes it possible to assemble the frame of hip and semi-hip roofs from them.

Combined legs are made from three boards. In this case, a third is laid between two edged boards of equal length and thickness.

An additional board enters the rafter gap by at least one meter, but usually, for greater reliability, it is inserted into a third of its own length.

The result is a rafter, on the one hand consisting of two strips, and on the other hand - from one. All joints are stitched with nails in a diagonal sequence or fastened with self-tapping screws.

The gap between the two planks is filled with inserts from timber scraps and fixed with nails in random order.

Combined rafters are installed with a thin side on the ridge run, and with a thick side - on the support beam.

Combined rafters allow you to save material and achieve the desired diameter, depending on the load on the rafter leg.

The bifurcated lower part of the rafter leg makes it possible to easily connect the rafter to the support beam.

Composite rafters are less durable than paired rafters, they can only be used for the construction of pitched roofs. They are not used in hip roof frames.

If in the process of work you need to lengthen or expand the rafters, then it is not necessary to call specialists.

It is enough to use one of the methods proposed in the article, and in the end you will get a structure that is not inferior in strength to the roof, the rafter system of which consists of solid boards and bars.