Dumpling business, homemade handmade dumplings. How to start a dumpling business at home

Read also

In this material:

Dumplings are tasty, fast and nutritious. In an age when people save their time as much as possible, home cooking food went by the wayside. This is especially true for dumplings, the making of which takes most of the day. Previously, this dish was enjoyed on weekends or holidays for obvious reasons, but today everything has changed. The counters are filled with frozen semi-finished products, allowing each consumer to taste their favorite dish 10–15 minutes after boiling water in a pan. The dumpling business requires serious investments, but this does not take away from it such features as high profitability and demand.

Production of dumplings: relevance of the idea

Dumpling counters in shops and supermarkets are simply bursting with an abundance of goods. It seems that there are so many manufacturers that it is impossible to wedge between them. On the one hand, this is true; high competition causes big problems. But if you look from another point of view, namely from the price segment, it becomes clear that people always lack something average. Cheap dumplings are practically dead weight, while too expensive ones take an extremely long time to be sold. There is always a shortage of dumplings that are not inferior in quality to expensive ones, but have an average price.

It is also worth noting that the products presented in the stores are almost all imported. There is very little local production, since it is extremely difficult to break into a chain supermarket. High-quality dumplings made in the workshops of entrepreneurs are most often sold in small pavilions, where the markup on the product exceeds the cost of elite products.

The relevance of dumplings on the market is as follows:

- popularity of the product;

- affordable price;

- ease of preparation;

- satiety;

- taste.

Dumplings are in demand and will remain so for a long time, but for the production and retail sale of the product it is necessary to draw up a detailed business plan with financial calculations and stage-by-stage organizational measures.

Advantages and disadvantages of business

Positive sides:

- demand - despite the abundance of types of dumplings on the market, each of them is in demand;

- quick payback – an average workshop for the production of dumplings can pay for itself in 6–8 months;

- the possibility of expanding the assortment - in the future it is possible to produce other frozen products (dumplings, filled pancakes, pasties for heating);

- simple technology for manufacturing the product.

Negative sides:

- high requirements for the premises;

- competition;

- serious start-up capital.

The requirements for the premises are serious, but still they are standard for food production, and therefore feasible. Start-up capital only involves the purchase of equipment, which is really expensive, as well as the hiring of a large number of personnel.

Description of the list of goods and services

At the start of a business, you can limit yourself to only the production of dumplings. At the same time, it is worth understanding that it is impossible to understand how successful or unprofitable a business is by just one type of product.

Initially, it is necessary to produce 2–3 types of dumplings:

- domestic;

- classic;

- children's.

Thus, the manufacturer will not only understand which taste is closer to the buyer, but will also expand the boundaries of the target audience.

A common stereotype among the population is that store-bought dumplings do not contain meat, the ingredients are unnatural, and therefore the product is harmful for children.

Psychological technique of the manufacturer - if you name one of the types of products “Children’s”, then the parents’ attitude towards the product will immediately change, which means sales will increase.

As an additional service, you can develop a special sauce for dumplings, which comes with the pack. This will have the least impact on production costs, and will attract maximum attention.

Market analysis: assessment of the level of competition and risks

For a novice businessman, competition comes from everyone – both regional and federal manufacturers. The first ones practically do not need advertising, because they are known to buyers for many reasons:

- “word of mouth” – friends, relatives, acquaintances always recommend this or that locally produced product;

- seller's recommendation - buyers often ask for locally produced goods;

- personal search - attentive people independently study the manufacturer, focusing on the regional representative.

Federal companies producing dumplings are known to everyone - their products are widely advertised on television and are widely represented in stores in every city in the country. There is one “but” - the quality of the product is lost due to mass production, so the consumer is wary of dumplings of this kind. Undoubtedly, they sell well, but not as much as the manufacturer himself would like.

To assess competitors, you should visit several large supermarkets, retail pavilions and specialized stores selling semi-finished products. When comparing prices and products, you should pay attention to the production time of dumplings. For example, if a product was produced a long time ago, but the packaging has not yet been sold, there is a high probability that this brand will not be popular.

The risks in the dumpling production business are small. This mainly concerns the purchase of cheap or defective equipment, which directly affects the quality of dumplings. Before purchasing equipment, you need to read reviews online and also make sure you have a certificate of conformity from the manufacturer.

Dumpling production technology

Main stages:

- Preparation of ingredients - defrosting meat, peeling and slicing onions, sifting flour, disinfecting eggs, diluting saline solution.

- Kneading the dough - the procedure is carried out on the basis of an agreed upon recipe.

- Minced meat - the ingredients are passed through a meat grinder and then mixed for 20 minutes in a special machine with the addition of water and spices. At small production and manual sculpting, the procedure is carried out by hand.

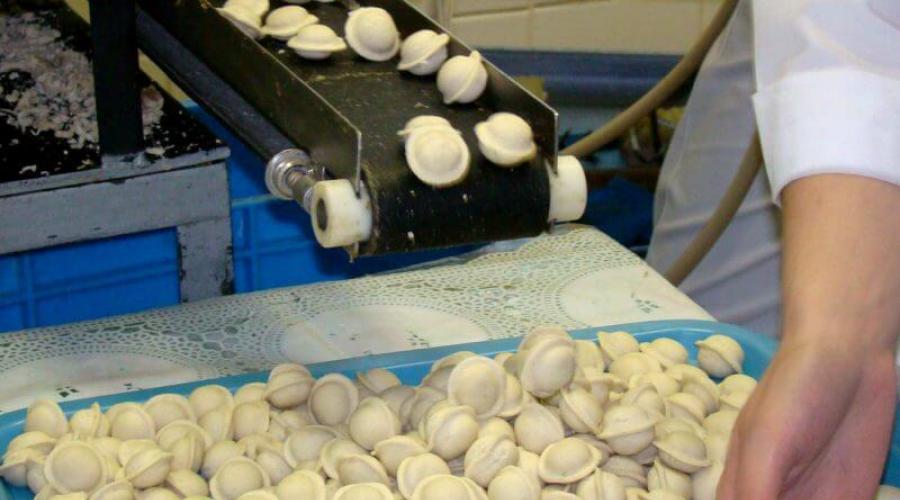

- Forming - minced meat and dough are placed in a special device, which produces ready-made dumplings at the output.

- Freezing – products are placed in the freezer no later than 20 minutes after preparation.

- Packing and packaging – frozen products are packaged by weight and packaged using a special device. The package must indicate the production date, expiration date and shift number.

Help: packaging material costs a lot of money, so a businessman must decide for himself whether he needs a stylish package or a transparent option with a label inside. Often the second solution is more successful, because the product is clearly visible, and the very fact of such packaging inspires more confidence than “machine compaction”.

How to open a dumpling shop step by step

First of all, you need to take care of registering your business activity, otherwise the business will turn out to be illegal. Next, the entrepreneur will need equipment, premises, formulation development and hiring staff.

Registration of production

For a small or medium-sized workshop, it is enough to open an individual entrepreneur - visit tax service at the place of registration, submitting an application with a passport and TIN, waiting for a decision. The state duty is 800 rubles.

In the future, when the business gains large-scale momentum, you can close the individual entrepreneur and establish an LLC. The sequence of actions is exactly this, and not a transition from the status of an entrepreneur to entity, which is legally impossible.

Recipe development

Everyone knows the recipe for dumplings - dough, minced meat and spices. Why then is the product of one manufacturer tastier than another, some dumplings retain their shape, while others fall apart? initial stage cooking The answer lies in the recipe.

To create tasty and high-quality dumplings, you will need the services of a technologist who will calculate the exact proportions of ingredients and also “work magic” on the taste. It would not be superfluous to try to launch the unique taste of dumplings through additional food additives (allowed by law) or the introduction of new ingredients.

For the average consumer the best option There will be a taste of home, which is much easier to obtain than it seems. It is enough to follow standard proportions and use quality products without trying to save money. The price of dumplings in stores is initially inflated due to a large staff, packaging and delivery from other regions. For a mini-workshop within the city, these factors do not play a role, so you can maintain high quality at an affordable cost.

Workshop premises: SES requirements

The building is best rented. The location does not matter if it provides for the sanitary zone of the settlement.

SES requirements:

- availability of water supply and sewerage;

- ventilation equipment and natural movement indoor air;

- washable wall and floor cladding;

- sufficient lighting of the work area, the presence of lamp shades;

- utility room for employees;

- at least one bathroom;

- stock.

In addition to the SES, the premises are checked by the fire inspectorate for compliance with safety standards. In particular, this applies to electrical wiring, required quantity fire extinguishers and fire evacuation plan.

Purchase of equipment

To produce dumplings you will need:

- Meat grinder.

- Dough mixer.

- Device for mixing minced meat.

- Apparatus for making dumplings.

- Fridge.

- Freezer.

- Packaging machine.

- Kitchen tools.

In addition to everything, you will need to purchase cleaning products with disinfectant properties.

Staff

Minimum staff:

- technologist – 1 person;

- worker – 6 people;

- driver – 1 person;

- loader – 2 people;

- accountant – 1 person;

- sales representative – 1 person.

Assortment compilation

At the start of production, 3 different positions of dumplings are enough price category. After a couple of months, as soon as the state of affairs can be assessed, product expansion is recommended:

- dumplings with various fillings;

- spring rolls;

- cutlets;

- meatballs.

Each type of product requires the purchase of additional equipment, so costs should be taken into account based on the profit of the enterprise.

Search for product sales channels, advertising

The marketing campaign for the introduction of a new type of dumplings involves, at most, launching a video on local television. The effect of such advertising will be up to 30%, but this is necessary so that people at least learn about the brand and pay attention to it in the store.

Rest marketing moves are practically ineffective because the consumer is more focused on the cost and appearance of the product.

The sales representative is responsible for searching for sales channels. If at the initial stage the employee is singular, then you can share responsibilities with an entrepreneur who will deal with contracts for supplies to supermarkets, and the TP will deal with the introduction of products into the retail pavilions of the city, and then the region.

Financial calculations

The dumpling business is considered a rather expensive undertaking, but despite this, the markup on products reaches 50% or more. Using the example of a small mini-workshop, calculations will be made for opening the production of dumplings.

Investments in the project

Spending at the start (in rubles):

- premises rental – 50,000;

- repair work and bringing the premises to the standards of regulatory organizations - 100,000;

- purchase of equipment – 700,000;

- purchase of products – 100,000.

Result: 950,000 rubles.

Current expenses

Monthly expenses (in rubles):

- employee salaries – 360,000;

- transport and fuel maintenance – 80,000;

- utilities - 20,000;

- additional expenses – 30,000.

Result: 490,000 rubles.

Income and profit calculation

The profitability of a business directly depends on the volume of products sold. Modern dumpling machines produce from 50 to 250 kg of product per hour, but this does not mean that there will be demand for such a volume.

As an example, we will consider an inexpensive device with a productivity of 60 kg per hour of goods. 300 kg of dumplings are produced per shift. Per month – 9,000 kg.

The market value of a kilogram pack of dumplings is 130 rubles. Gross income – 1,170,000 rubles.

Net profit – 1,170,000 minus 490,000.

Result: 680,000 rubles.

Evaluating the efficiency of dumplings

It is unrealistic to achieve such a profit in the first month, because it is typical for production with established distribution channels. This will take 2–3 months, during which production will earn no more than 20–30% of the calculated amount.

With high-quality and affordable products, supply volumes increase, so payback occurs closer to 6–8 months with a sharp increase in net profit.

The dumpling business is widespread throughout the country. Upon careful observation, you will notice that the brands that existed 10 years ago have not gone away, but at the same time, “newcomers” are successfully conquering this niche. This means only one thing - there is demand, and, accordingly, there is also profit from production. A competent business plan and high-quality products are the key to the success of an enterprise producing dumplings and frozen semi-finished products.

Dumplings are one of the most popular dishes in our country, and their production is quite profitable business. It would seem that all the niches in the manufacture of these products are occupied, and with the current competition it is impossible to break into the market with a new brand. Is there a chance of success in the dumpling business? Where to start and how to beat your competitors? Our next interlocutor will answer all these questions.

Reconomica I talked to a dumpling manufacturer who, with a limited budget and in a short period of time, managed to conquer part of the market in his city. A young entrepreneur from Astrakhan started his career from the very bottom, working as a loader at grocery market, and currently occupies a worthy place among manufacturers working on quality.

The businessman told us his success story, and revealed to us some secrets, what things should be paid attention to when choosing frozen semi-finished products (and many other interesting things about the quality of products on the Russian food market). Readers will also have the opportunity to take an inside look at the production of dumplings, which for some will be a discovery, and for others this information will shock.

There is nothing to do in business without experience working with your hands! Where did I start

Greetings to all. My name is Marat, I am 27 years old and I live in Astrakhan. I am engaged in the production of frozen products instant cooking. My products are of high quality and affordable prices.

This is how my career began.

In this article I will tell you how I managed to go from an ordinary loader to an entrepreneur who owns a small production workshop equipped with the most modern equipment. Currently I employ 8 people who are happy with their workplace.

I started as a loader, and I’m not ashamed of it!

He began his career at the local city market, as a simple loader. I came back from the army, there was no work, and I decided to temporarily work as a loader. I loaded everything, from cereals to meat. Didn't look very prestigious this profession, but I earned my thousand or one and a half a day. Often I had to stay for night loadings, and this was additional income. Little by little I got involved in this business, and I even began to manage to save some money.

I worked as a loader for a little over a year. I did not draw up employment contracts with the market administration, but negotiated directly with entrepreneurs. I worked for several retail outlets at the same time. It was hard, but I always managed. I also worked for two trade pavilions selling meat.

From loaders to cutters

One day, the owner of one of the meat pavilions called me and asked me to come quickly. It turned out that on the eve of the May holidays, her hewer fell ill with another bout of drunkenness and did not go to work. This often happens in trading. She asked me to chop the meat, since there was a line at the counter and there was no one to work.

I’ve tried chopping meat before, but I’ve never been able to do it at this pace. Buyers demanded to let them go. I had to put aside doubts and just do the work. I started a new job in my life - chopping meat.

The first cuts I made were uneven, but within two hours I got the hang of it, stopped dropping the ax and the meat from my hands, and something even started to work out.

The first day of working as a hewer pleasantly surprised me

Since the meat was good, and there were many buyers on this pre-holiday day, all four carcasses were sold before the evening.

Evening came, the meat was sold, the counters were empty, and it was time to pay for my work. The fact is that a meat chopper receives 7 rubles for every kilogram chopped. I ground four carcasses, and the total weight was 465 kilograms. The salary per day was 3225 rubles. This is more than good. Of course, I was very tired that day, my hands hurt from being unaccustomed to it, but it was worth it.

So I decided on my future profession - working with meat products

Then I firmly decided to learn how to chop and cut up meat. I began to often replace hewers at different points and earn more. On normal days, less meat was sold from the point, about 100 to 150 kilograms, but at the same time I could serve several retail outlets at once. My income on the market began to consistently exceed 2,000 rubles a day, given that I could go home after three o’clock in the afternoon.

Gradually I turned into a professional hewer. The meat business sucked me in completely, and I even started my own small business. I studied market life very well, and knew exactly where to buy, when and how to sell meat. All I had to do was open my own store.

The meat outlet at the city market is my first business.

First steps in the meat business

To rent a retail space and a refrigerator, I needed documents, and I... It cost me 3,500 rubles. The sanitary record and some other papers cost another 2,700 rubles. The necessary equipment - a cart, a cutting block, an ax and scales - cost me another 16,000 rubles. I purchased all equipment used.

I tried to work so that I wouldn't have any problems

Renting a retail space at the market cost 6,000 rubles, and renting a small refrigerator cost another 3,000 rubles per month. Accounting services cost another 4,000 rubles per quarter. Deductions ranged from 6,000 to 8,000 per quarter.

For tax reporting I did not miss a large number of goods, and allocated approximately no more than 10,000 rubles per quarter. Everyone is trying to avoid taxes. Tax audits are rare, and they are mainly carried out based on customer complaints, or when someone snitches on a competitor. I tried to work in such a way that I would not have any problems.

My first business was relatively successful. I tried to sell at least 100 kilograms of meat a day and my earnings were 3,000 rubles for such sales. I specialized in selling beef. The retail markup for this meat is 30 - 50 rubles per kilogram (in our region, at least). I cut and sold myself, so I saved on hiring a seller and a cutter. Moreover, I also served neighboring points and received additional income from them. Things progressed, the business developed, and I made new acquaintances.

I noticed someone else's business and began to analyze it

One day I met the so-called dumpling makers. This was a caste of entrepreneurs who produced dumplings. These dumpling makers bought meat every day for their products. But not tenderloin, as many might think, but the cheapest thing on the market.

The horrors of our town

For some, this will be a revelation, but on Astrakhan shelves, and in other cities, I think, too, dumplings made from meat waste are sold.

No matter how scary it may sound, the filling includes exactly what is not sold on the counter, gets weathered and loses its presentation. The filling of dumplings includes such “delicacies” as head meat, flank meat, films, everything that is not sold from the counter for several days and is discounted due to the fact that it may go to waste.

Poor quality dumplings flood store shelves.

If these people are given free rein, they will put whatever they want in dumplings.

But this is not the worst thing. The worst people are butchers who try to deceive dumpling makers and sell them already spoiled meat, having first washed it with potassium permanganate to remove the smell. These tricks very often work, and inexpensive store-bought dumplings turn out to be something that, according to all sanitary standards, should be in the trash.

What you need to know about semi-finished meat products. A short excursion into large productions

And I’m even afraid to imagine what’s going on at those enterprises where food chemicals are used. Meat can be replaced there with another substance. This is widely practiced in Food Industry, and this is easy to prove by comparing the price of sausage or sausages with the purchase price of meat.

Raw materials cannot be cheaper than the final product. If the price of sausage, sausages or cutlets is lower than the price of meat, then you need to be prepared for what you eat toilet paper mixed with pork skins and flavor enhancers. And for information, I’ll also say: if the sausage is chicken or with poultry meat, this does not mean at all that the bird will be deboned and the meat separated from the bones before being processed into minced meat. This procedure is expensive. It is easier for the manufacturer to turn minced meat into paste using triple distillation through an industrial meat grinder. This explains the presence of a paste-like substance in dumplings instead of meat.

But our dumpling makers do not use chemicals - due to their lack of education, but simply sweep away everything that should soon be disposed of.

Planning a new business. Business plan for a dumplings production enterprise

I watched dumpling producers for a very long time and tried to calculate their benefits. Their dumplings sold on average price segment and came after those sold in large chain stores.

If we think about it (and call a spade a spade), then the online dumplings have paste-like chemicals instead of filling, and those sold under the guise of homemade ones still contain meat, of course, the worst, but still meat.

Homemade dumplings not because they are made with love, but because there is no equipment

These dumplings are called homemade because they are made by hand by people from Central Asia. This is also beneficial for the employer; he saves on the purchase of expensive equipment, and hand-made dumplings can be passed off as homemade dumplings.

This state of affairs is the case in almost all mini-workshops at the local level. The quality of the products leaves much to be desired. Maybe entrepreneurs are happy to produce high-quality products and be proud of them, but sometimes a bad product, by default, suits everyone - manufacturers and end consumers.

Logical inference

Having found out enough information, I began to think about expanding my business. I reasoned like this: I have meat suppliers, a refrigerator for storing meat products and a distribution point. I could buy raw materials cheaper and of acceptable quality. I will not have any waste, because I could sell all the residual production products from my point. The profitability of such workshops ranged from 30 to 70%. I was able to maintain this profitability but significantly improve product quality by being able to purchase raw materials directly.

I set about writing a short business plan and this is what came out of it.

The dumpling machine is the main unit in my workshop.

Cost of equipment for a dumpling shop. Specific numbers

Necessary equipment:

- Gazelle with a used thermal booth – 160,000 rubles.

- Dumpling machine JGL-120 – 130,000 rubles.

- Professional meat grinder, capacity 100 kg. per hour – 32,000 rubles.

- Dough mixer for hard dough brand L4-HTV, capacity 60 kg. per hour – 84,800 rubles.

- Freezer POZIS FV 115, 4 units. – 60,000 rubles.

- Refrigerator compartment – 22,000 rubles.

- Blast freezing chamber, equipment with installation – 110,000 rubles.

- Stainless steel tables – 4 units. – 14,000 rubles.

- Cutting tables and other equipment – 15,000 rubles.

- Sinks, plumbing, etc. – 13,000 rubles.

- Electronic scales, large and small – 19,000 rubles.

- Other expenses, furniture, cabinets, changing rooms - 20,000 rubles.

- Video surveillance system – 44,000 rubles.

- Repair and equipment of the premises to bring it into proper sanitary condition - 150,000 rubles.

I calculated the amount that I planned to spend on renovating the premises for an area of 150 square meters. This included tiling, plastering in places where it was needed, and painting walls and ceilings with water-based paint.

The amount of one-time expenses amounted to 873,000 rubles. This is a normal amount, since several dumpling shops were sold in the region, and their price tag exceeded 1,000,000 rubles.

True, I didn’t have a filling and packaging machine, but I decided that I didn’t need one yet. The point is that registration trademark It costs around 400,000 rubles, and I couldn’t afford it yet.

Good staff is half the success of an enterprise

Next, we had to focus on planning the staff of workers necessary for the normal functioning of the dumpling shop. My highlight was that I decided to hire a technologist who would understand the task at hand. And the task was this: to keep the quality of the products stable high level constantly.

As an experienced butcher, I know that everything meat products appearing on the market are popular because the manufacturer does his job conscientiously at the initial stage of production.

A good team is half the success.

You should never let the work of the workshop take its course!

In general, the entire food business is very simple. If the product is edible and tasty, then people will take it. It will be taken as long as the manufacturer controls the entire technological process and the product remains of stable quality. Nobody wants to experiment with food. If a person likes a product once and does not let him down again, then this product will always be sold until the quality deteriorates.

It would seem that this is an idyll, and nothing can stop you from making money, but practice shows otherwise. When production starts flowing, other factors intervene - .

If, for example, 500 kilograms of meat are processed on a working day, and 50 of it is stolen by workers, this means that the dumplings will have a 10% underweight of filling. The buyer will immediately feel this. If they don’t add it to the dough mixer required quantity eggs, then instead of broth in the pan the buyer will have a sticky liquid, and such dumplings cannot be added to the soup.

A good dough should be yellowish in color. This means that it is involved in technology.

After such incidents, sales will always fall.

Therefore, a person responsible for output products is necessary in production. Many people make the mistake of appointing one of the workers responsible for the production process. A simple worker, even the best one, will not cope with this responsibility.

I tried to form a staff according to all the rules of good production

- Technologist, who is also the production manager – 35,000 rubles.

- Driver – forwarder – 20,000 rubles.

- Meat deboner, minced meat procurer – 23,000 rubles.

- Dough preparer – 23,000 rubles.

- Procurer of onions and carrots for minced meat, laborer – 18,000 rubles.

- Dumpling machine operator – 26,000 rubles.

- Packer - 18,000 rubles.

- Accountant – 22,000 rubles.

The amount of monthly expenses was supposed to be 185,000 rubles. To this amount was added the rent for the premises of 20,000 rubles per month. Total, to start the project, with the first monthly payment, the amount was 1,078,000 rubles, excluding the cost of electricity and other expenses. The amount is quite serious, and if I were an investor who did not know this business, I would have thought about it, but I had already worked with meat products for several years and knew exactly what I could do.

A little about the profitability of the production of dumplings and semi-finished meat products

Ideally, the profitability of fresh frozen products ranges from 30 to 70%. For the normal functioning of the dumpling shop, I needed to produce at least 600 kg. dumplings a day. This amounted to 12,600 kilograms of product per month, taking into account a five-day working week.

The raw material cost of a kilogram of dumplings using my technology is 146 rubles - taking into account the use of first-grade beef and pork. Another 2 rubles per kilogram was spent on packaging and labeling. Sales wholesale cost of a pack of dumplings weighing 0.5 kg. was 90 rubles. It turns out that from a kilogram of dumplings, I had a profit of 34 rubles. It was dirty profit, and they also had to pay wages.

How much of the proceeds remains net profit?

If the entire monthly batch is fully sold, the profit should be 428,000 rubles. Since the calculation was made based on the raw material cost of the product, all that remained from this amount was to pay wages to the workers, which amounted to 185,000 rubles monthly, and taxes, transportation costs, rent and electricity were also paid from it. Additional expenses were added by about 60,000 rubles monthly.

By my calculations, a dumpling shop should bring in between 150 and 180 thousand rubles. This is a good result, because the workshop should work autonomously, without my participation. My participation should only be in the first six months of the workshop’s operation, and then the staff should also include two sales representatives to sell products and expand the distribution network.

Launch of dumpling production

After all the calculations, I decided to organize a business. It took me two months to do this. I decided to open the workshop in October. At this time, the vegetable season is already ending, and good sales of meat products begin.

As planned, the workshop, equipped with equipment and staff of workers, was ready to open.

About marketing - how to find sales for new products

I started worrying about sales early on. I visited many stores and retail chains in order to negotiate the sale of products. There was only one offer for sellers - they would receive goods that would not sit on the shelves, and the price of the products would be the same as that of other entrepreneurs. Many agreed to these conditions and decided to purchase a trial batch.

First batch of products

The opening day arrived, the equipment was tested, and production began. On the first day we produced 350 kg. dumplings. There were several stoppages during the production process due to equipment adjustments.

On the second day we already reached the working target of 600 kg. This was the daily norm, and there was no need to exceed it. Almost a ton of product has accumulated in freezers.

Delivery of goods and waiting for orders

I stopped production for several days to distribute goods and wait for the first orders from stores. I delivered the first batch to more than 25 stores. Almost all the goods had to be distributed for sale. An agonizing wait ensued.

I was confident in my product, because, in addition to the good quality of the dumplings, cooking spices were added to each package. It looked attractive and was also very convenient for the buyer. This packaging method was suggested by the production technologist. This, of course, resulted in certain costs, but also gave an advantage over competitors.

A quality product is the key to the success of any business.

As I expected, almost all the stores placed orders for the product. Production was resumed and began to operate as planned.

The start of a new business went without surprises

Everything turned out just as I planned. My experience in the market helped me start earning money right away. I knew everything about competitors and used all the accumulated knowledge against them.

Expansion of production

For more successful sales and to eliminate the distribution of goods to stores, I decided to rent a retail outlet at a food wholesale center. This step required additional investments of 90,000 rubles. This money was needed for the purchase chest freezers and necessary equipment.

I raised the plan to 800 kilograms per work shift. This was almost the maximum power of the unit.

Sales also came close to these indicators.

It's simple in food production

After three months of work, the whole city knew my dumplings. This has become quite a popular product. I’ll tell you a little secret of my success - by producing products you either make money right away or you don’t. If the product is tasty, it will immediately become popular, and therefore will immediately sell. It’s quite easy to make a name with good quality and an inexpensive price, but then it’s difficult to maintain this level. Buyers will not forgive if for some reason the product one day appears on the shelves in an inedible form.

What you should absolutely not do

If the product turns out to be defective - due to human factor, or due to equipment failure, then it is better to throw it away. You can’t be greedy in these moments and sell it at a discount.

Several times I took large quantities of dumplings to a dog shelter. This is very expensive, but it is better to lose 50,000 rubles once than the trust of customers.

Correct calculation - successful business

Now my business is stable. Product output is going according to plan, and sales are keeping pace with production. I increased the salaries of my employees, as the production plan increased, and consequently, the workload on the staff increased.

Now I’m thinking about acquiring a brand and entering other markets in the region.

Dumplings are a very affordable, quick and tasty product for lunch or dinner. Hence the constant demand, which does not depend on the time of year and social status, everyone eats dumplings. There are many important disadvantages that dumplings that are produced on factory equipment have. Often such companies add too much soy to minced meat, which alienates consumers from the classic taste of minced meat. In this regard, the home-based dumpling business can pose serious competition to manufacturers supplying their “soy” dumplings to the shelves of city stores. After all, the taste of homemade dumplings is something that is familiar to us since childhood and is radically different from store-bought options.

Advantages and disadvantages of opening a dumpling production

In the table below, we consider the advantages and disadvantages of opening a dumpling shop that produces dumplings. It can be noted that the main target audience is people who want a satisfying and at the same time inexpensive meal.

Dumpling production business: documents for tax registration

To register a dumpling shop with the tax authorities, an individual entrepreneur or LLC is created. In the table below we analyze the main advantages. In addition, let's consider necessary list documents for registration of each legal form property. When registering, select the OKVED code:

- 10.13.4 - production of semi-finished meat products,

- 10.73.1 - production of semi-finished products, dumplings, etc., boiled and uncooked, with and without filling.

| Form of business organization | Benefits of use | Documents for registration |

| IP ( individual entrepreneur) | Used to open a small pet business (50-80m²). Number of personnel from 1 to 3 |

|

| OOO ( limited liability company) | Used to open large network pet stores, borrowing Money, as well as scaling. |

According to the law, the authorized capital of an LLC cannot be less than 10,000 rubles! |

The most optimal organizational form a workshop for the production of dumplings can be an ordinary individual enterprise (IP). The most favorable tax regime for an enterprise will be the simplified taxation system (STS), 6% of revenue or 15% of enterprise profit.

Own workshop: SES requirements

For the first time after opening a business, you can build your first premises in your personal home kitchen, which already has all the necessary equipment. But it is worth keeping in mind that for making dumplings even on your own kitchen you should have: a large number of sockets or an extension cord, a spacious and comfortable table, a sink with a constant supply of water, good lighting fixture and, of course, a large freezer for storing finished products. If you are planning to rent such a premises, possible success in this field can turn it into a full-fledged dumpling production workshop.

In the future, if you leave your home kitchen and rent premises, it must comply sanitary requirements Rospotrebnadzor(SES). In addition to the SES, you must obtain a conclusion on the premises for a workshop in Gospozharnadzor. To do this, it is necessary to install a fire alarm and fire extinguishing equipment (fire extinguishers).

Below is a list for obtaining a basic permit from Rospotrebnadzor, after which you can begin production.

Equipment for a dumpling shop

To organize this workshop indoors or at home, you will need a certain list of equipment that is necessary for this type of activity. We are not talking about new equipment; used household appliances are quite suitable:

To organize this workshop indoors or at home, you will need a certain list of equipment that is necessary for this type of activity. We are not talking about new equipment; used household appliances are quite suitable:

- Refrigerator compartment with sub-zero temperature function. Such a chamber will accommodate about 100-1500 kg of finished products; its dimensions can easily fit in a kitchen or balcony. The issue price is 7000-12000 rubles;

- Manual or automatic meat grinder for preparing the filling. The price of this device ranges from 2000 to 7000 rubles. The approximate productivity of an automatic meat grinder is 1.5 kg of meat per minute, and a convenient loading tray and increased power can increase production time quite significantly;

- A device for making dumplings – a dumpling maker. It can be mechanical or automatic. An ordinary mechanical dumpling maker costs about 1000 rubles and has a productivity of 10-12 kg per hour. An automatic dumpling maker will cost you 7,000 rubles, but it will speed up the process of making dumplings significantly, as it has many additional and very convenient functions: molds for dumplings, rolling out dough, producing noodles and ravioli, and a measuring spoon.

In addition to the above equipment, you can additionally buy: Flour sifter (about 15,000 rubles), dough sheeter (about 30,000 rubles).

Where to start production?

To begin with, you will need a great recipe, preferably with an exclusive signature, so that your dumplings stand out from the crowd of your competitors. But it’s worth considering the preferences of your future customers, for example, should you make dumplings from beef or pork? Or maybe mixed minced meat or chicken? Or even cook dumplings with non-traditional fillings of vegetables or fruits? The answers to these questions can create good demand, which will provide you with a large turnover and an influx of profit.

To begin with, you will need a great recipe, preferably with an exclusive signature, so that your dumplings stand out from the crowd of your competitors. But it’s worth considering the preferences of your future customers, for example, should you make dumplings from beef or pork? Or maybe mixed minced meat or chicken? Or even cook dumplings with non-traditional fillings of vegetables or fruits? The answers to these questions can create good demand, which will provide you with a large turnover and an influx of profit.

Next, having decided on the desired filling, we proceed directly to the process of making dumplings. Dumpling makers have several molding options for future products. So besides delicious filling can be picked up interesting shape, which can also work favorably into your hands. Automatic dumpling makers have a mode for rolling out dough from 0.2 to 3 mm thick. This can seriously affect the taste, and it is better to strictly determine the future thickness of your dough. Next, the resulting dough is placed in the dumpling chute, the required amount of minced meat is applied, and all this is turned into a finished dumpling product.

You can reduce the cost of dumplings produced by adding potatoes to the meat. Meat and potato dumplings taste no worse than pure meat dumplings, but the cost is the same.

You can reduce the cost of dumplings without losing quality by increasing the percentage of water content in the dough and minced meat. Technologically, it is possible to increase the percentage of water content in minced meat to 20%, while the taste of dumplings only becomes better.

Video review of dumpling production

The video shows the production of dumplings in detail.

Market for your products

Most often, the first batch of finished products is distributed among close friends, acquaintances and neighbors. But these are only initial reviews, and, as a rule, you can’t start a business with your family; you need to look for the main places for selling such products - public catering and convenience stores. To introduce your products to these places, you will need a number of documents to carry out trade. In fact, these are 2 declarations of conformity, but to obtain them you will need registration of technical production conditions, which includes the following documents:

- lease contract;

- product recipe;

- label.

The development and registration of specifications will take you 10 working days, and receiving a declaration of conformity will take about several weeks. The paperwork may seem difficult, but it's worth it. In order to make sure of the success of your company, it is best to test the first batch in some cafe or among friends. If the party receives good feedback and receives approval, then there is no point in delaying the documents. After all, an honest entrepreneur is a trusted supplier.

Assessment of the attractiveness of a business by the magazine website

| Business profitability |      (3.0 out of 5) (3.0 out of 5) |

Business attractiveness

|

| Project payback |      (3.0 out of 5) (3.0 out of 5) |

|

| Ease of starting a business |      (3.8 out of 5) (3.8 out of 5)

|

|

| The dumpling production business is a highly profitable and competitive business. The difficulty arises in the marketing of manufactured products. Therefore, you need to think about searching for sales agents immediately after registering with the tax office. | ||

Dumplings are considered instant products and are in great demand among the population regardless of the season, so their production will always be in demand. Often businessmen combine the production of these semi-finished products with the production of dumplings, manti, pancakes, cutlets and other products, which allows them to expand the range and increase profits from the operation of the enterprise.

The production of dumplings at home can be organized by anyone who wants to open their own business without large investments. Despite great competition, this type activity is profitable, but the enterprise will be required to produce tasty and high-quality products, as well as the optimal selling price.

Pros and cons of a home-based dumpling business

The great popularity of dumplings is easily explained, because anyone can buy them inexpensively and quickly prepare them. Let's look at the main advantages and disadvantages of this product, which will allow novice entrepreneurs to understand the needs of customers and the intricacies of production.

To begin with, we note that in the consumer market today there is a huge demand for high-quality semi-finished products, so entrepreneurs should not have any difficulties with sales. In addition, dumplings bring significant income to many retail outlets, and their managers are interested in manufacturers who do not skimp on raw materials. The advantages of doing business in the production of dumplings also include:

- the possibility of organizing an enterprise with minimal investment;

- high profitability of the dumplings business;

- a wide range of manufactured semi-finished products;

- year-round demand for the product;

- moderate costs of production, depreciation of equipment and advertising;

- long shelf life of finished products.

Starting a business is quite simple, since at the start you do not have to rent production premises and purchase expensive equipment. You can make dumplings at home at first, and for preparing minced meat, every kitchen has knives and a meat grinder.

Despite the obvious advantages of this business, there are still some negative sides. First of all, they include great competition, because with a certain skill, anyone can make dumplings.

It is also worth considering that premises for the production of semi-finished products are subject to requirements from the sanitary and epidemiological station, fire inspection and other structures: special requirements, which must be observed for the smooth operation of the enterprise.

Since this type of business has many advantages, the production of dumplings should be considered as a promising business. In addition, it is important to know that with a certain amount of effort and high quality products, income will not be long in coming.

Over time, you can expand production by increasing the range of semi-finished products produced. Effective marketing and competent business management are the main components of success.

Dumpling making technology

Let's consider the features of the technology for producing dumplings at home and in the workshop. In the first case, they can be made in the kitchen using hand modeling, and the output is about 8-10 kg per 1 working day.

Preparing semi-finished products at home does not require special preparation and equipment of the production premises, as well as the purchase of expensive equipment. The technology for making dumplings in a home mini-workshop consists of several main stages. These include:

- processing of ingredients;

- dough preparation;

- minced meat layout;

- making dumplings;

- freezing of products;

- packaging of finished semi-finished products.

At the raw material processing stage, meat is cleaned and washed, eggs are disinfected, after which a water-salt solution is prepared. Then peel the onions and garlic and start preparing the minced meat. To do this, a meat grinder is used, through which meat preparations, onions and garlic and other vegetables (for example, potatoes) are passed. To ensure that the filling has a uniform consistency, the crushed ingredients must be thoroughly mixed. This is done using an electromechanical stirrer or manually (the use of rubber gloves is mandatory) for a quarter of an hour.

Important: To reduce the cost of production, a large amount of onion is added to the minced meat. Potatoes are also used to compose the minced meat, which gives the dumplings a good taste.

The dough should be prepared by first sifting the flour. This can be done manually or using a dough mixer. When all the ingredients are ready, proceed directly to sculpting the dumplings. The minced meat is wrapped in dough by hand or a machine is used to make dumplings. Prepared semi-finished products are laid out on trays and placed in freezing chambers. If you use a machine, you can prepare a much larger quantity of products at home.

Dumplings are packed in colorless plastic bags weighing 1 and 0.5 kg. If you plan to produce small volumes of products, you will not need to purchase a filling machine. Dumplings of various colors are in great demand among consumers, especially if there are several of them in one package. Juices of spinach, beets, black currants and other natural ingredients are used to color semi-finished products.

The technology for making dumplings in workshop conditions has some difficulties. This is primarily due to the significant volumes of products that require a certain amount of raw materials. Meat for production can be purchased in frozen blocks or prepared manually through special processing, for which trimming and deboning are used. To prepare the dough in a workshop, use flour with at least 30% gluten. In addition, the dough must have a strictly defined humidity, which ranges from 38-42%.

All components are thoroughly mixed using an automatic dough mixer for at least 20 minutes, while, depending on the technology, the dough can mature from several hours to a day at a temperature of +3°C.

To prepare minced meat, the meat is cut into small pieces, after which it is crushed mechanically (special cutters are used for this). After this, salt, onion, garlic, spices, vegetables and water are added to the resulting mass, then everything is mixed for 10 minutes. The finished minced meat is unloaded into steel tanks, from where it is removed for further sculpting.

The workshop uses machines for making dumplings with a certain productivity. Such equipment has bunkers for loading finished minced meat and feeding dough, which are sent to the production conveyor automatically. Ready dumplings are packaged using special equipment. There are certain requirements for packaging in accordance with GOST R 51074-2003. It must include information such as:

- name and location of the manufacturing company;

- production date of semi-finished products;

- name of the finished product;

- compound;

- best before date.

Finished products are packed in transparent plastic bags in cardboard boxes. The manufacturer's label must be present on the container. It indicates total weight containers and number of packs.

How to open a dumpling shop at home?

To open a dumpling shop at home, you will need minimal equipment. To do this, you should get a meat grinder (preferably electric), a freezer and a dumpling maker (a mold for making semi-finished products). As production increases, it will be necessary to invite assistants to work.

If you use a machine for making dumplings, in 1 hour of work you can prepare 10-12 kg of ready-made semi-finished products. Availability small equipment for the production of dumplings, ravioli and homemade noodles will expand the range of the enterprise and increase profits.

The purchase of automatic devices will make it possible to increase production volumes. So, with the help of 1 piece of equipment you can sift flour, knead dough and form dumplings, while in 1 work shift you get about 350-400 kg of semi-finished products.

For such a quantity of dumplings, you also need to purchase a packaging machine. Beginning entrepreneurs should know that to open a small home workshop, it is enough to select compact equipment with which you can make about 100-150 kg of workpieces per hour.

Business registration

The process of registering an enterprise for the production of dumplings and other semi-finished products does not present any difficulties. To legalize his activities, an entrepreneur must contact the tax office and submit an application for registration of an individual entrepreneur. There you can clarify the OKVED code, which will be required for maintaining records and statistics in the Federal Tax Service. You will also need to obtain the following documents:

- license to start production of products Catering;

- permits from the fire inspection and Rospotrebnadzor;

- SES certificate;

- permission to use a cash register.

If production is initially planned with the involvement of hired employees, they will be required to have a health certificate. This legalizes their access to the production of food products. You should be prepared for the fact that it will take several months to register your business. Its cost will be about 7-10 thousand rubles.

Preparing the premises

For a full-fledged operation, it is important to choose production premises that will comply with sanitary standards and fire safety, and are also equipped with proper communications (water supply, electricity, ventilation, etc.). To organize the work of a mini-workshop, you will need to find production space from 50 m². If you plan to open an enterprise with a medium-capacity production line, then you should look for premises of 250 m².

The sanitary station places special requirements on production premises, which, in addition to cleanliness, must have clearly defined areas or separate areas for storing raw materials and finished products. Also, the enterprise needs to allocate a separate place for the installation of freezing equipment. This should also include the presence of a room for cutting meat products. The floors and walls must be tiled tiles, which can be easily cleaned.

The enterprise should allocate a room for staff, as well as equip a sanitary room and showers. Please note that the equipment for the production of dumplings operates on an alternating power supply, so it must be possible to connect to 220 and 380 V. The workshop must be equipped with a supply and exhaust ventilation system, sewerage and powerful lighting.

While searching suitable place for the production of semi-finished products and dumplings, you should pay attention to public catering establishments (kitchens, public canteens), which are initially adapted for the production of products and comply with the standards of state regulatory authorities.

If you try to convert inappropriate areas into a dumpling shop, this venture will be too expensive. You should also pay attention to the presence of a good transport interchange, which is a necessary condition for unhindered delivery of raw materials and export of enterprise products.

Equipment purchase

How to decide on equipment and equip production with it? Beginning entrepreneurs should know what they will need to purchase:

- automatic dough mixer – 70 thousand rubles;

- machine for rolling out dough – 35 thousand rubles;

- equipment for sifting flour – 20 thousand rubles;

- electric minced meat mixer – 30 thousand rubles;

- industrial meat grinder – 28 thousand rubles.

Since raw materials for preparing dumplings and other types of semi-finished products, as well as finished products require certain storage conditions, it is necessary to install refrigerator(for raw materials), a blast freezer and a freezer for storing finished products. You will have to spend about 170 thousand rubles to purchase them.

To reduce costs when purchasing equipment for a small workshop, you can purchase a table-top flour sifting device. It is compact in size and allows you to quickly obtain a lot of raw materials for qualitative test. You should not save on purchasing an industrial meat grinder, since the smooth operation of the production process depends on its quality. It is worth paying attention to those models that are equipped with reverse, which allows you to quickly remove stuck cartilage and tendons.

As for devices for mixing minced meat, there are tabletop and floor type. Their cost varies depending on the type of drive, which can be electrical or mechanical. If you plan to independently deliver products to customers, you need to spend about 600 thousand rubles on the purchase of a used refrigerator.

Purchasing ingredients

To ensure uninterrupted operation of production, it is necessary to organize the supply of raw materials. In addition, you should calculate the supply of ingredients for making dumplings. To minimize costs, it is recommended to purchase raw materials from supermarkets, wholesale warehouses and markets.

As for meat, different varieties are allowed and it must always be fresh. You cannot use by-products to reduce costs, as well as cartilage, tendons and other production waste. Please note that some entrepreneurs use poultry and animal skins to make minced meat. This should not be done, since dumplings with such filling are not in demand among buyers.

To purchase fresh meat, please refer to the guide livestock farm and enter into a supply agreement with him. This option ensures the availability of always fresh products, the quality of which will be confirmed by appropriate quality certificates.

If farms are located far from the production location, you can purchase meat in large supermarkets at wholesale prices. To do this, you need to find out when fresh batches are delivered and buy them strictly at a certain time.

Attracting working personnel

Often, the production of dumplings is a family business, where all work responsibilities are distributed among all relatives. However, specialists who are well versed in the specifics of the process may be required:

- shift adjuster of electromechanical equipment;

- production technologist;

- accountant;

- director.

Depending on the volume of production, kitchen workers will be required who will be involved in the process of preparing minced meat and dough. It is imperative to hire cleaners, loaders and a storekeeper, as well as a sales department manager.

Important: if family members work in production, its head can take on the responsibilities of the head of the company, accounting and master the distribution channels (sales) of finished products. This will allow you to save on employee remuneration costs.

Conducting an advertising campaign

How to advertise your products to a large number of consumers and build a marketing campaign correctly? First of all, you should understand that the start-up enterprise is unknown to anyone, and the quality of dumplings and semi-finished products will be a big question for many.

It makes sense to contact a professional advertising agency, whose specialists will develop a strategy for promoting the company’s products. Quite often in populated areas fairs are held where you should take part and introduce consumers to the quality of their dumplings and other products.

To independently promote your company’s products, you can use various effective methods. First of all you need to create an online information resource company where the entire range of products will be presented. You should also indicate prices, contact information and commercial offer for buyers. It is very important to place high-quality photographs on the site, which can present samples of dumplings and other products in all their glory. In addition to the above methods of promoting your own brand, the following will be effective:

- placement of advertisements on television and other media;

- promoting products through personal communication with potential consumers;

- sending commercial offers to public catering establishments, supermarkets, markets, shops.

Please note that before launching sales, you should carefully analyze competitors' prices. Typically, a trade margin of 20% is applied to products. The purpose of the advertising campaign is to convince customers to buy the product and evaluate the quality of the products offered. The main thing is to keep the brand, and information about the product will spread among people instantly, which is guaranteed to attract a large flow of regular customers.

Sales of finished products

The issue of selling finished products is relevant for every entrepreneur who has decided to organize a business in the production of dumplings and semi-finished products. Sales mechanisms can be very different, and their effectiveness depends directly on the volume of production.

So, if dumplings are prepared at home and their quantity is relatively small, they can easily be sold to private buyers, as well as individual requests can be fulfilled. As a rule, such methods are good if the enterprise produces about 10-12 kg during the day.

Excellent results can be achieved if you sell semi-finished products using advertising in in social networks, as well as by posting offers for users on free message boards.

If you open your own store, you can easily sell finished products through it, and besides this method will allow you to quickly attract a large number of regular customers. To do this, the entrepreneur will need to register a food trading enterprise with the Federal Tax Service and hire a salesperson. You can find a lot interesting offers for rental trade pavilions and small shops. As practice shows, such outlets bring good income, if located in residential areas, near shopping centers, educational institutions, large production associations and other places with big amount of people.

Cafes and fast food outlets readily buy frozen food. Particular attention should be paid to inexpensive canteens and catering establishments located at train stations and markets. When communicating with managers of catering enterprises, it is worth emphasizing the fact that homemade recipes are used in the production of dumplings. Cooperation with a network of small stores that operate under a single brand and with wholesalers gives good results.

Business plan for the production of dumplings

Let us give an approximate calculation of the estimate, which will allow us to present the approximate amount of profit, provided that the dumpling shop will produce 700 kg of products in 1 working day. So, the volume of investment will be:

- purchase of equipment – 350 thousand rubles;

- repair of production premises - 40 thousand rubles;

- costs for advertising campaign– 30 thousand rubles;

- business registration – 7-10 thousand rubles;

- purchase of raw materials – 65 thousand rubles.

Also, the production enterprise will have mandatory monthly expenses. These include:

- rental of industrial premises – 40 thousand rubles;

- utility bills - 10 thousand rubles;

- employee salaries – 100 thousand rubles;

- purchase Supplies– 20 thousand rubles.

The cost of 1 kg of dumplings is 65 rubles, and the average selling price on the market is 92 rubles. The profit from 1 kg of product is 27 rubles, and the income per shift is 18.9 thousand rubles. If we take into account that the enterprise will work seven days a week, the total amount for the month will be 567 thousand rubles. Now it is necessary to subtract the costs of staff salaries, purchase of consumables and rental of premises in the amount of 170 thousand rubles, and we get a profit of 397 thousand rubles.

How to withstand competition with other enterprises?

Unlike factory-made dumplings, homemade products have a unique taste, since they are made using a unique recipe, as well as high-quality and fresh ingredients.

The best way to produce delicious dumplings that will be in great demand among customers is to cook them the way it is done in every family - with special love. Under production conditions, soybeans are added to minced meat (to reduce costs and increase profits), which significantly reduces the quality of the product. To compete with other companies, you should offer the buyer dumplings highest quality. An honest entrepreneur will always find a way to intelligently minimize production costs and the cost of dumplings. For example, you can expand the range by releasing new types of semi-finished products with open application natural ingredients.

In conclusion, we note that the return on investment in business development for the production of dumplings occurs after 1 year of operation of the enterprise. If the company remains afloat during this period, it means that its organization and marketing were carried out correctly, and the possibility of expanding production capacity can also be considered.

Lately, our company has started to very often receive questions from aspiring entrepreneurs regarding the organization and launch of a dumpling shop. In this article I will try to explain what a dumpling shop is, what equipment you need to purchase to get started, and, accordingly, what financial investments will be required at the initial stage.

There is a misconception that starting a frozen food business is quite easy. It would seem that there is nothing complicated about buying meat, making minced meat from it, preparing and rolling out the dough, making dumplings, freezing them in the freezer - and you can launch the finished product for sale and make a profit. Indeed, there is nothing complicated. There are, however, a few small “buts”. First, does the buyer need your undoubtedly delicious dumplings? If necessary, then the second thing is immediately – can you provide the required volume of production of your product? And immediately the third question appears - how to organize production and what is needed for this?

Due to the nature of my work, I very often communicate with the owners of small workshops for the production of frozen semi-finished products and asked everyone questions - how did your business begin? And how long did it take you to reach the current production volumes? It is clear that everyone’s answers are different, but some of the most common ones can be identified. Let's look at these answers using several examples of different ways to establish a given business.

Example one. An entrepreneur from a not very prosperous region of our country, who does not have free funds, decides to open the production of semi-finished products. On initial period his activities, there was almost no competition in his region. The first thing he did was buy a Stinol refrigerator with a large freezer on credit. All immediate relatives were involved in the production. The only equipment was an electric household meat grinder for making minced meat. All other operations were done manually. The volume of production was from 30 to 50 kg per day. Over time, when profits appeared, several more refrigerators, a JGL-120 dumpling machine, a dough mixer for hard dough with a bowl capacity of 20 kg, and a minced meat mixer were purchased. The volume of production reached about 700 kg per day. Further on increasing. The premises were rented. A blast freezing chamber was built. Two dumpling machines JGL-120 and JGL-135 were purchased. The volume of production is 1300-1500 kg per day. Over time, when JGL machines began to break down very often, our company purchased an HLT-700XL dumpling machine. On commissioning works your humble servant was leaving, that’s where this example came from.

At the time of writing this article, this production acquired another HLT from our company. The volume of production reached 2500 kg per day. The total development time of this dumpling shop, from the beginning to the current volumes, is 7 years.

Example two (the most common in different variations). Individual entrepreneur, engaged in the trade of meat and dairy products, decides to open a workshop for the production of semi-finished products. Having studied consumer demand and competitors' products, he purchases everything necessary equipment leased and starts working. After a few years, when production begins to bring tangible profits, a decision is made to expand the range of semi-finished products produced. Purchased optional equipment and the production of cutlets and pancakes begins. Today, this company produces about 60-70 tons of all semi-finished products per month. The company's development time is 6 years.

Example three. Big company wholesale trade frozen semi-finished products, which has its own areas for warehousing and storing finished products, as well as well-established sales, asks the question - why do we sell products only from third-party manufacturers? Shouldn't we start producing our own, under our own brand? Funds are allocated and construction of the dumpling shop begins. Repairs are being made existing premises, are installed freezers, production and technological equipment is purchased, personnel are recruited. A year later, the workshop reaches a volume of 60 tons of dumplings per month. When I launched the equipment we supplied to this company, I was able to find out that the volume of investments made in this production amounted to more than 20 million rubles! I think it was worth it!

So. What do we see in these three examples? The first and most important thing is the sale of finished products! If you don’t have well-established sales, then you don’t need a dumpling shop. You will fill the freezers with finished products, where they will safely, over time, become unusable. And second, also important, the speed of reaching large volumes directly depends on how much money was invested at a time at the initial stage. From the first example it is clear that production developed gradually, in parallel with sales. Accordingly, investments in capacity expansion were also made gradually. Yes, it took quite a long time, but the refrigerators were never full of finished products. Those. production developed in parallel with consumer demand (sales).

In the second and third cases, production developed quite quickly. But here, again, sales were already established and the demand was quite high. Therefore, in order to satisfy the high demand, serious cash injections were made into the development of production, which paid off over time.

The issues with demand and sales have been resolved. Let’s say that in your region a buyer is eager to buy only semi-finished products under your brand! And you urgently need a dumplings workshop with a capacity of 200 kg per hour or 1500 kg per day (30 tons per month). What is needed for this? First of all, a room with an area of at least 100 square meters. meters, renovated in accordance with sanitary standards for food production. Secondly, you need to decide what kind of meat you will prepare minced meat from - chilled (carcass or half-carcass) or frozen block? I’ll explain what the difference is now. To make minced meat from FROZEN meat, the following equipment is required:

1. Two refrigerated chests with a volume of at least 1.5 cubic meters. meters. One for raising the temperature of frozen meat before cutting, from minus 18 degrees to minus 10 degrees. The second is for cooling the finished minced meat.

2. Band-saw for cutting blocks of meat into cubes measuring 50x50 mm.

3. Stainless steel bath. After sawing, the meat is placed in a bath for 5–6 hours and defrosted at a temperature of 25–26 degrees.

4. Electric grinder (industrial meat grinder). Designed for grinding completely thawed meat. It is prohibited to throw frozen pieces. If you want to speed up the process of preparing minced meat and throw pieces of frozen meat, you need a more powerful and expensive grinder.

5. Minced meat mixer for mixing minced meat with other ingredients.

6. Cutter. When using cheap, low-quality minced meat with a high water content. It is designed to “drive in” water to reduce costs. This position can be abandoned if you make a premium product.

Now the list of equipment for CHILLED meat:

1. Stainless steel table for deboning (cutting) meat + deboning man - man.

2. Electric grinder (industrial meat grinder).

3. Minced meat mixer for mixing minced meat with other ingredients.

4. Refrigerated chest for cooling the finished minced meat.

As you can see, to produce minced meat from chilled meat, less equipment is needed. But the raw materials themselves are more expensive than frozen meat. What is more profitable is up to you to decide. And most importantly, you need to decide what price category dumplings you will produce.

We've sorted out the meat. Now let's move on to the test. What is needed to prepare it? Here is the list:

1. Flour sifter. Designed for mechanized separation of flour from foreign impurities, loosening and saturating it with air, which improves product quality.

2. Dough mixer for hard dough, with a paddle or Z-shaped kneading body (two shafts rotating towards each other), with a bowl capacity of at least 50 liters.

The minced meat and dough are ready. All that remains is to make the dumplings yourself. To do this you will need a dumpling machine. Of course, I recommend the ANKO HLT-700XL dumpling machine! If the budget is small, then you can get by with Chinese JGL series machines. They are several times cheaper, but there are several times more problems with them. You can read a detailed comparison in my proposal article about HLT on the same blog.

If you want to minimize manual labor, then you will have to purchase a filling and packaging machine, which also costs a lot of money.

Well, let's sum it up! To organize and open a small-capacity dumpling shop, you will need premises, the above equipment, competent technical staff and, most importantly, well-established sales. The first two components will require considerable financial investments. According to my calculations, to open a dumpling shop with the stated productivity, a minimum of 6 million rubles will be required! What would be so difficult about making dumplings?!

However, in different regions New dumpling shops continue to open. It seems that the market for these semi-finished products is already more saturated than ever. Now there is a market selection from large producers by small dumpling shops. Each workshop brings something of its own to the market and occupies its own niche. Or competes in already occupied niches. I think that no one will be left without profit, and competition will benefit us, the consumers.

It's time to say goodbye! I hope this article has helped you understand that such a seemingly simple matter as making dumplings on an industrial scale has many nuances and complexities. But, as one of the ancients said: “He who walks can master the road!” I wish you every success! And see you again on the pages of my resource!