Do-it-yourself foam concrete house: pros and cons - Technology + Photo

Read also

Today, the construction of houses from foam concrete is gaining great popularity. This is due to the fact that this material has a number of advantages. Foam concrete should not be confused with aerated concrete, because they are completely different materials. The first is softer than the second, but also more moisture resistant. The price of foam blocks is lower. For this reason, when building houses, foam blocks are more popular than gas blocks.

The foam block is a block, 0.6 x 0.2 m in size, made of foamed concrete.

- It is cheaper to build a foam concrete house than a wooden or brick house, and if you build it yourself, the savings will increase several times. Having a low cost, houses made of this material have most of the characteristics that houses made of brick and wood have.

- They are environmentally friendly, as they do not contain chemicals that adversely affect human health, and have excellent sound insulation.

- The surface of the foam block is easily processed and significant efforts will not be required to process the walls.

- Also, due to its porosity, it passes air. Therefore, in the house, there will be practically no high humidity.

- The simplicity and speed of construction from foam concrete is due to its large size and the fact that a special adhesive composition can be used instead of a cement-sand mortar.

- Foam blocks are fire-resistant, they will not burst or split at high temperatures, unlike concrete, so they can protect the reinforcement from heating for a long time.

Cons in construction

But, like any material, foam concrete has its drawbacks, which include not very high strength, which, firstly, does not allow creating a strong load on the walls, and secondly, it requires mandatory facade cladding or plastering.

Instruction. How to build a house of foam concrete with your own hands?

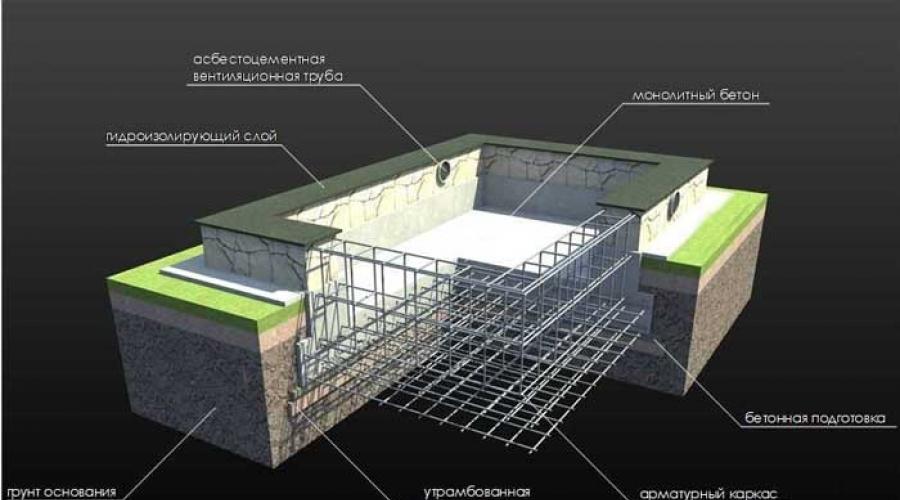

You can see the foundation scheme in the photo

You can see the foundation scheme in the photo Foundation

Foam blocks weigh less than a brick, so there is no need to make a powerful one. We are not talking about the fact that you can save on the foundation, just huge costs will not be required.

- We calculate the width and depth of the formwork system. The width is equal to the cross section of the future structure, and the depth depends on the local climate and degree.

- We dig a trench, about 2 m deep. We lay sand on the bottom, moisten it with water and tamp it well. To give the correct shape, we set, and fix the stripes. Along the entire length of the trench for fixing, we install a belt of reinforcement.

- Now we fill the foundation with a solution consisting of 5 parts of crushed stone, 3 parts of sand and 1 part of cement and gradually build it up, periodically compacting it.

- The foundation must stand and "mature" within a month. At this time, cover it from sunlight and periodically moisten with water.

- Next, we roll out roofing material on a concrete structure to prevent moisture from entering.

Wall masonry

See the photo for the layout of the walls

See the photo for the layout of the walls - We start laying blocks in the corners, from the highest corner of the house.

- Pulling the cord over the corners, we begin to lay the first row. Jointing large sizes between blocks reduces heat saving and sound insulation to a minimum, therefore, if a block does not fit to complete a row, we saw it, apply glue and install it in the resulting gap.

- We are laying foam blocks, strictly observing the correct levels horizontally and vertically. Irregularities immediately clean and remove dust.

- We lay the reinforcement along the entire perimeter of the masonry in a specially cut strobe filled with glue. During masonry, we comply with all building codes and reinforce places for door and window openings with fiberglass weaves. Upon completion of the laying on the top of the walls, we make a reinforcing belt of concrete, for the subsequent installation of the roof.

- Externally, we produce glass wool insulation with a width of 50 mm. From above we fix the wind and material.

overlap

We design the floor according to a well-known scheme, which gives an idea of how the load of the beam, the dimensions of the span and the sections of the beams interact. You can use boards connected with screws, processed.

![]()

First we lay the end beam beams, then the rest. We fix a metal crate above the bars, apply a mesh of fiberglass and mineral insulation.

Roofing and slate

![]()

We build a rigid structure, using a bar and supplementing it with roof trusses.

- We fasten the boards at an angle of 90 degrees to the rafter legs. We cut off the corners of the slate sheets so that there is no layering in the docking places.

- We make holes in the slate, the diameter of which should be larger than the diameter of the nail.

- We fasten the slate with nails, nailing it from the bottom row into pre-prepared holes.

Finishing a house from foam blocks

When the construction is completed, it must be completed with finishing, both from the outside and from the inside. To finish the house from the inside, board, plaster and much more are suitable.

For exterior decoration, plaster with subsequent painting or facing brick is suitable.

Video

In this video you can learn about the technology of facing a house from foam concrete blocks.

We calculate the cost of construction

For calculation, let's take a one-story house measuring 10 by 10 m, 3 m high and calculate the cost.

- First, let's calculate the perimeter of the walls: 10 + 10 + 9.40 + 9.40 = 38.8 m (round up to 39 m). The total length along the perimeter is 39 m.

- Then we calculate the area of \u200b\u200bthe walls: 39 x 3 \u003d 117 square meters. m. Further from this number we subtract the area of window and door openings. For example, it is equal to 15 square meters. m. 105 - 15 = 90 sq. m. We calculated the net area of the walls without window and door openings.

- Let's find out how many foam blocks we need per square meter. We calculate the area of one foam block: 0.6 x 0.2 = 0.12 sq.m. That is, for 1 sq. m. wall we need: 1 / 0.12 = 8.3 foam blocks.

- Now let's determine how many blocks it will take to build the outer walls of the house: 90 x 8.3 = 747 blocks.

- Using the same formula, we determine the number of blocks required for the main wall: its length is 9.40, its height is 3 m. 9, 40 x 3 = 28.2 square meters. - the area of the main wall. Subtract the door area, let it be 6 square meters. m = 22.2 sq. m. round up to 23. 23 x 8.3 = 190.9 pieces.

- Now we add the number of blocks required for the construction of the outer and main walls: 747 + 191 = 938 pieces. Thus, it turns out that for the construction of our house 10 x 10 m, 938 foam blocks will be needed.

- The approximate price of foam blocks is about three thousand rubles per 1 cubic meter. m. In 1 cu. m. - 27.7 pieces. So 938 is about 34cc. meters. Now 34 x 3 thousand = 102 thousand rubles. Thus, 102 thousand rubles. must be invested to build the walls of our house.

Not very expensive, is it?