Why do I need a wind bar for corrugated board and how to install it correctly

Currently, roof structures made of metal profiles are considered quite popular. They are great for covering buildings for industrial, household, garden and country purposes. Below we will talk about such a metal profile roof assembly as a wind bar for corrugated board.

Why do you need a wind bar on the roof

A wind bar is an additional element used in the process of building a roof from corrugated board. This is a special corner in which one mounting shelf is fixed to the crate, and the second is designed to protect the roof overhang from strong winds, rain and snow. Wind bars are made on the roof of high quality galvanized, covered with pural or polyester. A number of procurers sell shaped elements coated in the form of stone chips.

This roof unit serves the following purposes:

- Protection of the roof and gable overhang from moisture ingress. The outer part of the roof is protected by a roof covering, but water quite often enters the truss system from below. As a result, the supporting structures along with the crate get wet, they are damaged, even if the tree is treated with an antiseptic. The wind bar retains water, thereby increasing the life of the roof and its wooden elements.

- Protection against gusty winds. Strong side winds in regions with harsh climatic conditions quite often tear off and damage the roofing. Excessive load on the roof at such a moment causes the edges of the corrugated board to break without protection. The wind bar helps to avoid damage to the roofing material, as well as blowing cold wind under the crate.

- The roof structure takes on a complete and elegant look.. Chosen in the same tone with the roofing, the planks hide all the irregularities of its edges. In addition, later it will be possible to produce high-quality and even filing of overhangs with spotlights or siding.

It is worth noting that for the manufacture of a wind bar, you can take a cheaper bent metal profile, which can be found in any hardware store, but there may be problems when choosing a shade and size.

Technical characteristics and types of elements for corrugated board

Guided by building codes, during the construction of a roof made of corrugated board or tiles, the installation of wind strips must be carried out without fail. They are mounted around the entire perimeter of the roof to prevent precipitation from falling on the rafters and lathing and blowing strong winds.

There are such types of windshields on the roof:

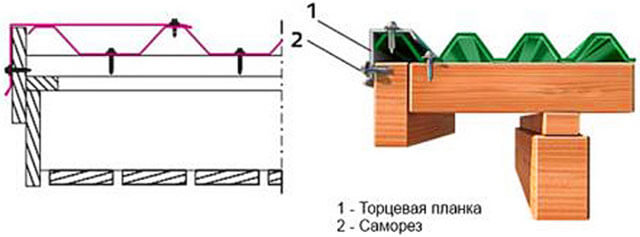

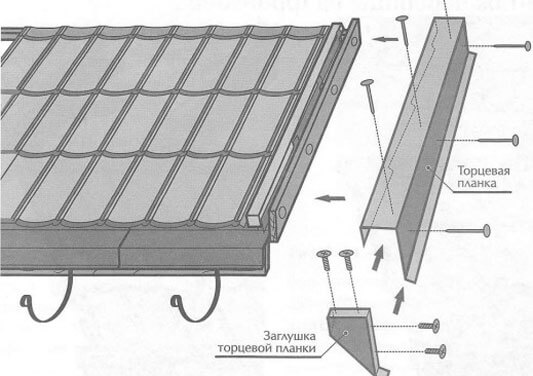

- Frontal. It is made in the form of a corner, in which one mounting shelf is made straight, and the second one duplicates the wavy relief of the corrugated board. Such a bar is fixed to the roof overhangs, which are installed from the gable side. This knot covers one or two corrugated board waves and the entire end board. Some models have a hood to remove moisture.

- Cornice. Such a bar is installed on the roof lathing along the entire length of the overhang to the roofing and installation of the drain. The cornice strip is made in the form of a galvanized corner with a polymer coating, with straight mounting shelves.

- ridge. To organize protection between the joints of the corrugated board, where the slopes are connected, to ensure waterproofing, a ridge bar is installed, which can be oval, rectangular or straight. In addition, there are models with ventilation gaps that contribute to normal air circulation in the roof structure.

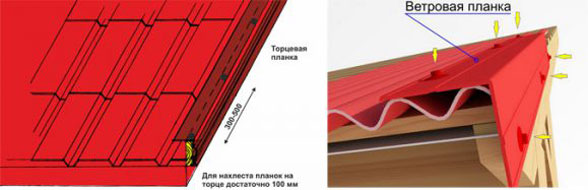

Wind shaped devices for corrugated board have a length of 200 centimeters, however, their useful length is only 190-195 centimeters, since they are installed with a gap of 50-100 mm. Planks are produced with dimensions of 40×60 and 90×150 mm.

Experienced roofers advise mounting a 40-60mm wind bar on flat roofs and in areas with light winds. A wide bar can be used for pitched roofs with any slope.

How to install a wind deflector on a roof

The windproof bar for the roof can be mounted on its own, since this stage does not require special building skills or special tools from the master. For installation, you will need roofing screws with rubber seals - 5-6 pieces for each plank; screwdriver; hacksaw for metal; sealant.

The sequence of fastening the nodes will depend on the place of assembly:

- Installing the cornice strip. It is mounted on the eaves of the roof before laying the roofing material using self-tapping screws with indents of 40 cm, while the overlap should be 5-10 cm. In the process of fixing, the waterproof film covering the crate is lifted and spread on the planks. In order for the design to turn out to be of high quality, the wind cornice must be pressed against the inside of the drain. In some cases, you may need planks made to special sizes.

- Installing the gable. The last step is to install it. Next, you will only need to equip the roof ridge. The dimensions of the upper mounting shelf are determined based on the profile and height of the roofing waves - as a rule, it is 13.5 or 14.5 cm. This unit is fixed in the upper part through the roofing material to the crate every 30-50 cm. take self-tapping screws with a rubber washer.

It is worth noting that sealants, sealants or construction tape can be used as additional insulation for the joints between the roofing and the windshields. According to the statements of experienced craftsmen, the sealant that duplicates the relief of the corrugated board is the most effective, because it has an unlimited service life.

We hope that our material on how to fix the wind bar on the roof was useful to you, and you will do all the roofing work correctly.