Wind bar for metal tiles - varieties, functions

A roof covered with modern metal tiles is a practical solution for a private cottage, country house or townhouse. Contrary to the beliefs of homeowners, the durability of such a roof is not entirely dependent on the quality of the roofing material. The additional elements used for installation have a great influence on durability, water tightness, reliability, despite the fact that their area is less than 5% of the roof surface. In this article, we will tell you what a metal tile windshield is, what it is for, and how it is fixed.

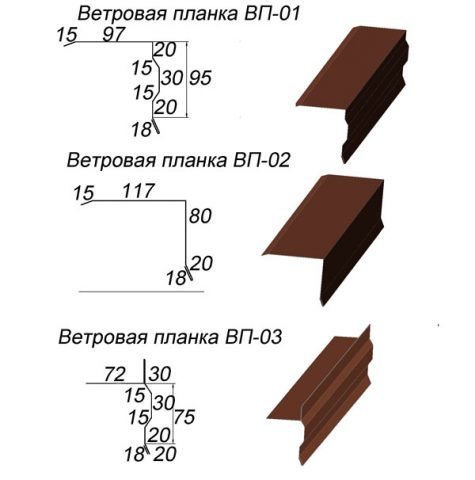

Wind bar - one of the additional elements used for roofing from metal tiles. It is a corner made of plastic or galvanized metal and performs protective and decorative functions. There are the following types of wind bars:

Important! The wind bar is a corner with 2 mounting shelves, the wider they are, the more reliably this additional element for the roof protects the overhang from the penetration of moisture and wind. The installation of the end element is often performed in combination with seals that follow the shape of the waves of the coating for more efficient operation.

Materials, dimensions

For the manufacture of cornice wind strips, materials are used that are highly resistant to atmospheric phenomena, as well as mechanical strength. The service life of a roof made of metal is at least 20-25 years, which means that additional elements should serve no less. The following bars are most often used:

- Steel. The most popular models of additional elements for protecting the ends and cornices are steel. Galvanized steel, which is coated with a layer of paint, pural or polyester during the production process, withstands water, does not corrode, while it is quite light and strong.

- Plastic. Polyvinyl chloride is a thermoplastic plastic used for the manufacture of eaves and end strips. The advantages of this material are light weight and a variety of colors. However, plastic elements are subject to thermal expansion, in addition, it is not recommended to install a heat cable on them to heat the roof.

Please note that the dimensions of the models of the cornice strip for metal tiles are very different. This additional element usually has a length of 1.5-2.5 m, the width of the mounting shelves is 15-30 cm. Steel products are made to order according to the buyer's size.

Functions

Additional elements in the composition of a roof made of metal, depending on the complexity of the design, make up 2-5% of the area, but their importance cannot be overestimated. Installation of roofing without wind strips leads to the penetration of moisture and wind into the rafter frame and, as a result, accelerated wear of the material. The cornice and wind bar perform the following functions:

- Protective. The main task of the cornice strip is to prevent the penetration of atmospheric moisture and cold wind under the roofing material. Due to high humidity, the wooden frame becomes damp and rots, which negatively affects the life of the roof. Blowing cold air into the attic increases the cost of heating the house.

- Decorative. Installation of wind slats allows you to neatly and aesthetically sheathe the frontal board, as well as hide the “insides” of the truss system from the eyes. Additional elements are selected to match the color of the metal tile, so the slopes look holistic and harmonious.

Experienced craftsmen say that additional elements for metal tiles can be made by hand. Wind slats are made of sheet metal with a thickness of 0.4-0.5 mm. However, homemade trims will not look so neat.

Installation

Wind bars are elements of simple design, so models from different manufacturers differ only in the type of coating and the thickness of the metal used. The effectiveness of these devices depends on the correct use. Installation of eaves and end strips is carried out as follows:

- Eaves strips are fixed on the eaves board to the flooring of the roofing material. Before installing this additional element, brackets for the gutter are fixed on the eaves. After that, the wind plank with an overlap of 10-15 cm is fixed on the cornice board using nails or self-tapping screws in increments of 30-50 cm.

- Wind strips are fixed on the frontal board after the roofing is made of metal tiles. They must cover the roofing material for 1 wave. The overlap between these elements can be more than 50 cm. Each plank is fixed to the board with 4 nails or self-tapping screws to avoid deformation in strong winds.

Important! The joints between the windshields must be airtight and not let water through. To do this, they are treated with a silicone-based sealant.