Roof duct ventilation units

The ventilation system of buildings is most often equipped with an air duct outlet through the roof. According to a similar principle, an aerator was made on a metal roof from corrugated board or metal tiles, designed to ventilate the under-roof space. In the places where the ventilation pipe joins the roofing pie, a passage unit (UE) is formed. Each type of roof has its own ventilation passage through the roof, which differs in shape, size and functionality.

Types of penetrations

It is not easy to make a passage through the roof of the duct, because the integrity of the coating, and sometimes even the truss system, is violated. The resulting knot at the point of docking with the roof requires careful protection against moisture penetration. To simplify installation, penetrations that differ in design depending on the purpose help:

- Penetrations for arranging the point of withdrawal of air outlets are without a valve or with a valve. Simple models without a valve are the cheapest. They equip the duct passage through the roof of private houses. The design with a valve provides for the use of a damper that blocks the outlet if necessary. Such penetrations are mounted on the roofs of industrial and administrative buildings, where the ventilation system does not work constantly.

- The production of insulated penetrations and without thermal insulation allows you to choose the right product depending on the place of its installation. Non-insulated penetrations are used when the duct is located near the ridge. It is allowed to make a ventilation passage through the roof without thermal insulation in regions with a hot climate. Penetrations insulated with basalt insulation are used with bends that extend far from the ridge and rise strongly above the roof. The insulation prevents the formation of condensate in the pipe due to the difference between the external and internal temperatures.

- The use of penetrations with automatic and mechanical control depends on the type of ventilation system where they will work. Mechanical models are designed for manual control of permanently operating ventilation systems, where it is not necessary to frequently close and open them. Adjustment of air circulation is carried out using a cable. Automatic penetrations are designed for ventilation systems controlled by an electronic controller.

Many inexperienced owners of private houses believe that arranging the exit of the chimney and the air duct through the roof is one and the same. This is a gross mistake, since inside the chimney the air temperature can reach 800 ° C, which requires the arrangement of a box made of non-combustible materials around the pipe. In the pipe passing through the ventilation roof, the air temperature is a maximum of 1 ° C higher than the room temperature. Installation of air outlets does not require fire protection measures.

The main characteristics of the passage nodes according to GOST

The domestic manufacturer manufactures a roof passage assembly in accordance with GOST 15150. The document displays all the dimensions of the product, the material of manufacture, and also indicates the observance of gaps during the installation of the elements.

UEs are produced that differ in shape and size, and the main requirements are imposed on all products:

- the thickness of the metal used to make the passage must not be less than 1.19 mm;

- the diameter range of a round product is allowed from 100 to 125 mm;

- the dimensions of rectangular UEs are unlimited;

- all walls of the product must be coated with an anti-corrosion compound;

- the support ring should be 300–400 mm larger than the section of the branch pipe;

- the entire assembly of the ventilation passage through the roof, excluding the valve, should not be longer than 1 meter;

The ventilation system of the building works on the principle of an aerator. Before choosing a specific design of the UE, calculations of humidity, gas contamination, temperature, dust content and other parameters of the room are made.

UE marking

At the moment, 11 varieties of products with standard sizes are produced to help equip the duct passage through the roof, and they all have their own marking:

- After the letter designation of the UE, there are always numbers. The first digit 1 and following from 01 to 10 indicate the standard dimensions of the product, not equipped with a valve, as well as a condensate ring. An example of such a marking is UP1-01.

- The first digit 2 and all the following from 01 to 10 indicate the same standard product dimensions without a condensate ring, but with a mechanical valve. Marking example - UP2-02.

- The first digit 3 and all following 11-22 indicate the standard sizes of products with a mechanical valve and a condensate ring. Marking example - UP3-22.

If the ventilation passage through the roof has non-standard dimensions, individual production of the UE according to the customer's dimensions is allowed.

General rules and procedure for mounting the node

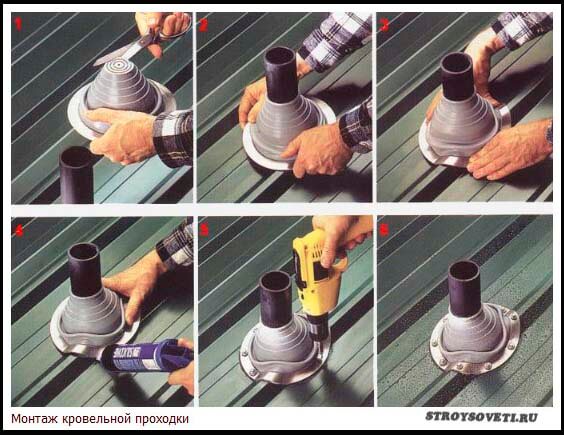

The output of the air duct through the roof from the building begins after the assembly of the entire ventilation system inside the building. Installation of a standard passage assembly is carried out in the following order:

- The installation of the UE begins with determining the exit point of each duct. According to existing building codes, it is recommended to install ventilation pipes between the rafters as close to the ridge as possible.

- Having decided on the exit point, a place is marked on the roofing for the future hole. It should be 30 mm wider than the pipe diameter. In order to avoid making mistakes, a template can be cut out of cardboard, and markings can be made on it on the roofing material.

- The following steps require caution. It is necessary to accurately cut the hole according to the marking. On a soft roof, this is easy to do, but the roof of a metal tile or other hard coating will first have to be drilled. It is enough to make several holes in a row along the marked contour so that the blade of a hacksaw for metal fits in and cut out the entire circle. All remnants of the roofing pie, including the elements of the crate, are removed from the hole made.

- A penetration with a rubber seal is put on the duct, taking into account that it should be on the roof surface. Steam and waterproofing layers are fixed to the pipe with construction tape. For reliability, joints can be treated with sealant. The rubber seal of the penetration to the soft roof is glued with a sealant. Fastening to hard metal coatings occurs with the help of self-tapping screws.

- When it is fully fixed, a cap is put on top to protect the ventilation duct from rain, birds and debris.

A correctly installed node for passing through the roof around itself should not have a cavity, otherwise in winter a snow pocket will form in it, and melt water will penetrate under the roofing.

Installation of complex passage nodes

In some situations, it is impossible to use standard UE, which is associated with the elevation of the air duct above the roof of more than 600 mm, its large weight and the presence of a thick layer of insulation. Some roofing material, such as tile or slate, has a profiled surface that does not allow the UE flange to be tightly laid.

The way out of the situation will be the manufacture of a metal sleeve with a supporting part. To install it, cut a hole in the same way. Waterproofing is placed under the supporting part, after which the UE is installed. In this case, the rubber seal is run under the roofing and fixed with a sealant. The contact area of the air duct with the upper part of the metal sleeve is similarly treated with a sealant.

Highly elevated air outlets are reinforced with an additional overlay made of waterproof material, such as OSB. Holes with a diameter of 8.5 mm are drilled in the corners of the cut-out lining and the supporting part of the metal sleeve. Further, these 2 parts are pulled together with studs with a diameter of 8 mm. Gaskets are placed under the nuts located outside, plus they are additionally treated with sealant. From the inside, the lining is insulated with basalt wool and sewn up with ordinary plywood.

Heavy air ducts of large diameter are fixed with additional stretch marks from a cable or wire. As an option, props are made from 3-4 bars.

Installation of UE on a concrete roof

The process of installing a penetration in a concrete roof is no more difficult than it is on a conventional roof. Most often, the concrete base is covered with soft roofing material such as euroroofing material, etc. Holes in the floor slabs are provided at the project development stage. The optimal arrangement of the UE involves the use of a plastic sleeve. It is inserted into the hole of the concrete slab, fixing it from the inside.

The plastic support is lubricated with sealant and glued to the roof waterproofing. Moreover, it is necessary to glue with precise centering of the marking under the ventilation pipe. The air duct is inserted inside the plastic sleeve and wooden spacers are driven into the gaps between their walls. To extend the life of the node, the wood is pre-treated with an antiseptic.

Next, there is a process of warming and sealing the node. If a plastic sleeve was used for penetration, it is covered with insulation and sealed with polyurethane foam. However, in concrete floors, metal or asbestos-cement bushings can be used for penetrations. They are sealed with hot bitumen.

In a concrete slab, the pipe passage through the roof is difficult to seal. Although the joints of the supporting part are well treated with sealant, the possibility of its delamination is not ruled out. For 100% protection of the assembly, an outer cap is put on it, covering all joints from water ingress. In addition, the cap-nozzle is able to replace the stretch marks that contribute to the stability of the duct.