The node of the passage through the roof and the node of the junction of the roof to the wall - what are they for

For the effective functioning of the roof, the quality of all its elements is of great importance. Some of them, at first glance, may seem unimportant. It should be remembered that there can be no secondary structures in the roof. The nodes related to the adjoining of the slopes to the walls, as well as to the exits to the surface of technological communications, play an important role. Let us consider in more detail what are the nodes of the roof, which provide the passage of communications through it, as well as the nodes of the junction of the roof to the wall.

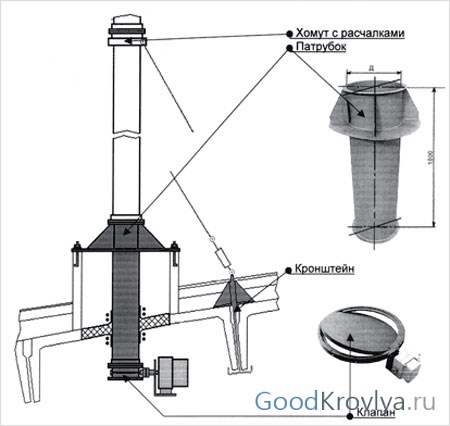

Many industrial, residential and civil buildings are equipped with ventilation systems. When installing them, it becomes necessary to install a passage through the roof. This element is a metal structure consisting of a hole in the ceiling and a metal pipe inserted into this hole. Their main purpose is the transportation of a chemically inactive air stream at a temperature not exceeding 80 degrees and a relative humidity of not more than 60%. Passage nodes are subject to GOST-15150. This design is also used for chimneys.

A roof passage node is required in houses equipped with ventilation systems.

Varieties of elements

If the choice of a ventilation system for which a roof passage assembly is installed is influenced by a number of conditions (humidity, air temperature, etc.), then only two parameters are required when calculating the passage assembly: the angle of inclination of the roof and the distance from its ridge.

There are several variants of this design with typical dimensions:

- design that does not have a valve and a condensate ring;

- manual control design with valve and with or without condensate ring;

- design with an actuator, insulated valve, can be with or without a condensate ring;

- with or without condensate ring;

- manually operated, with intrinsically safe valve, with or without ring;

- with manual control and insulated valve, spark-proof, with or without ring.

Various options for passage nodes with typical sizes are used

In addition to the listed standard designs, non-standard designs are produced in some cases.

The manual drive is applied at the stable operating mode which is not demanding repeated switching.

For the manufacture of UE is used:

- black steel, 1.5-2 mm thick;

- stainless steel, 0.8 mm thick;

- stainless steel, 0.5 mm thick.

The shape and dimensions of the duct passage nodes depend on the type of ventilation and the roof itself. In form they are:

- round;

- rectangular;

- oval;

- square.

The advantage of domestic products is that they are better adapted to our climate.

Node markings:

- The letter designations UE and the numbers from 1 to 10 indicate designs that do not have a valve and a ring.

- Numbers from 2 to 10 indicate the presence of a valve operating on manual control without a condensate ring.

- UP3 designate designs with a valve and a platform for the actuator.

How is the installation of the passage through the roof

For each type of roof, its own version of the passage node is used with one or another installation scheme. The structure is fixed on reinforced concrete cups with anchor embedded bolts and nuts provided in the cups themselves. Mineral wool is used as thermal insulation, which is protected from the outside by an additional layer of fiberglass. The ventilation units of the passage are equipped with protective valves of automatic or manual control.

A specific feature of the passageway is the presence of a branch pipe. The spigot has a lower end flange used for attaching valves or air ducts, as well as an upper flange with which a circular section shaft is attached. The braces are fastened with brackets and clamps.

It looks like a design that provides the passage of the ventilation pipe through the roof

When installing the system, a skirt is also used, which acts as an additional waterproofing agent. In case of loss of moisture from the air or gas mixture, the use of a condensate collector welded to the nozzle will be required. The mechanical control of the valve is carried out by means of an actuator regulated by the “open” and “close” commands.

It is important to know ! For the safety of the actuator, it is forbidden to install it near the ring coupling or condensate trap.

The shape and dimensions of the duct passage nodes depend on the type of ventilation and the roof itself.

Some features of the installation

It is preferable to mount the passage roof units before installing the roof. First, they must be installed on the ventilation system itself, and then the roofing must be installed, regardless of the materials used. After installation, sealing is recommended. With the same sealant, go through all the joints on the roofing. Such actions will ensure the safety of heat and waterproofing.

For additional sealing, you can do the following:

- Clean the surface of the pipe and part of the coating adjoining it.

- Glue foil paper so that it covers the bottom of the pipe and the adjoining part of the roofing.

- Finally, fill all holes with sealant.

This will increase the tightness of the roof and increase its service life.

It is important to know ! Elements of the passage nodes are both domestic and foreign production. The advantage of using products from a domestic manufacturer is that they are better adapted to our climatic conditions.

Sealed roofing is the key to the durability of the entire roof structure

Roof to wall junction

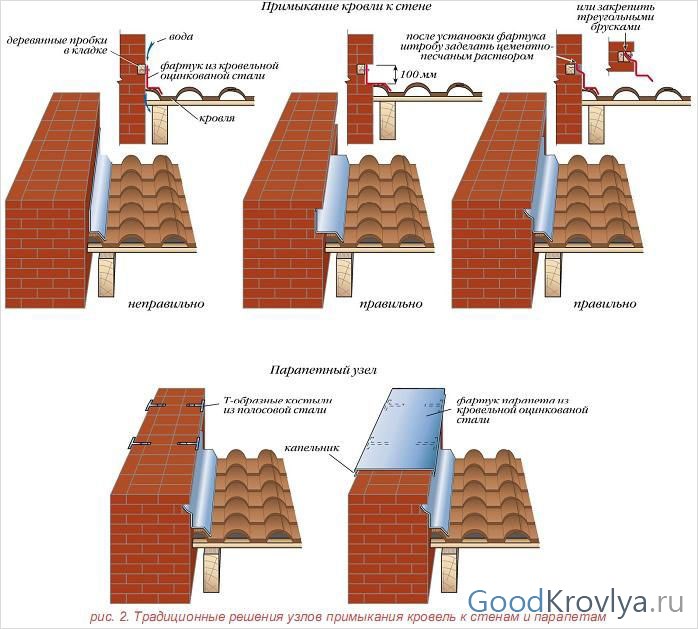

Another important element of the roof is its junction with the wall. It is installed at the points of contact of the roofing with the wall and protects the joint from water penetration. The technology of execution depends on the material of the roofing. The junction of the roof to the wall is mounted according to the same scheme. The difference is only in the methods of additional sealing.

The node is a junction bar fixed on the wall. The other part covers the roof covering. For two main types of junctions - the main and the top, it is advisable to use the butt strips PS-1 and PS-2. Planks produced by modern manufacturers have a shape that allows them to be mounted directly on the wall without arranging an additional strobe. Tightness is ensured by special silicone compounds.

This ensures protection against moisture penetration into the joint between the roof and the wall.

Mounting the junction in a strobe or niche

For greater reliability and tightness during the installation of these units, it is recommended to equip special niches and strobes in the walls into which aprons made of galvanized steel roofing are mounted. Application of aprons from a black roofing tin is possible. Tin before use is covered twice with hot drying oil on both sides and painted at least twice.

When installing an apron without a niche or strobe, its tight fit is not ensured, as a result of which water gets under the metal. This is not only due to uneven walls, but also due to heating by the sun, followed by expansion of the material and its arching between the fasteners.

When installing an apron in a strobe, this problem is eliminated due to the fact that the wall material covers the resulting leaks, protecting it from the penetration of rainwater, but does not provide protection from snow. In this regard, when installing the apron in a niche, it is recommended to make the height of the upper part at least 100 mm, and fill the strobe with a solution of cement and sand. When covering the strobe with a solution, protection is provided from blowing snow into it, which eventually turns into melt water flowing under the metal.

After installing the apron, the strobe is sealed with a solution of sand and cement

As fasteners, nails are used, nailed to wooden antiseptic corks. The plugs are laid into the wall in advance during the brickwork erection with installation steps of up to 1 m. Before installation, wooden bars can be attached to the plugs. In this case, the plug installation step may be larger. Fastening to the bars will provide a tighter fit of the apron. Fastening with a second bar will provide complete waterproofing.

Features of the arrangement of the junction to roofs with different coatings

- For bituminous shingles, the best option is to use an adjoining plank, which will provide a tight hold.

- For a metal-tiled roof, a waka bar is used, under which a wakaflex is laid. From above, everything is covered with sealant.

It is important to know ! Vacaflex is a self-adhesive rolled material used for arranging roof joints with walls, pipes and parapets. The rigidity of the material is provided by reinforcement. Presented in a wide range of colors.

Full tightness is ensured by sealant treatment

- Joints of ceramic tile coverings are sealed with corrugated aluminum tapes, the wavy profile of which will repeat the shape of the tile. The subsequent filling with bitumen will make the seams absolutely tight.

- Corrugated aluminum tapes can also be used for shingles. Due to the wide range of colors, you can choose any color to match the coating.

Modern building materials used for roofing are simple and easy to use. Instructions from the manufacturer simplify the process and allow even non-professionals to use them. At the same time, one should not forget that the safety of the entire structure depends on the condition of the roof, so it is better to trust roofing work, including the installation of its nodes, to professional performers.