Roofing from ondulin - features of euroslate installation technology

Onduline has become a truly “popular” roofing material in recent years. Ondulin roofing is generally simple, but has a number of features.

Onduline traces its history back to 1950, when the founder of the company, Gaston Gromier, first introduced low-cost corrugated sheets of cellulose impregnated with a bitumen-mineral composition to the French building materials market. For more than 60 years, the production technology has been significantly improved, and today the Onduline trademark is popular and in demand in many countries of Europe, Asia and America.

By the way, Soviet engineers spied on the wavy shape of domestic asbestos-cement sheets from the French: before that, asbestos-cement products for roofing were produced in the form of rectangular tiles resembling stone slate in shape and color. From here it went among the people - "slate", although modern wavy asbestos-cement sheets are completely different from real slate.

Ondulin is not much more expensive than asbestos-cement corrugated sheets, but it lasts longer and looks better.

Onduline Group is not the only company that produces such products; products from other European manufacturers are also represented in Russia. However, the French were the first to become interested in the possibilities of the vast Soviet market after the opening of the Iron Curtain. Today, the company's products are manufactured for Russia at a large modern enterprise located in Nizhny Novgorod. Since the Russians first got acquainted with the products of the French company, now ondulin has become a household name, often spelled with a small letter and denotes a class of similar roofing materials in general. The term "Euroslate" is also used. In fact, both definitions are incorrect, but have taken root.

Onduline offers four color options and one completely clear.

Comparative characteristics of the material

Onduline is one of the cheapest roofing materials available. Only domestic corrugated asbestos-cement sheets are cheaper. More expensive than "euro-slate" is a Russian-made metal tile with a budget polyester coating. Bituminous shingles cost slightly more than metal, but require more serious base preparation and are more difficult to lay, which puts them in a higher price category.

Ondulin serves up to forty years, which is even more than that of a cheap metal tile, but less than that of a bituminous one. An asbestos "slate" 4.8 mm thick will last 15 years. The most powerful 7.5 mm, subject to regular cleaning and painting, can also last 40 years in a year. Unlike fragile asbestos sheets, Onduline is flexible and ductile.

They can cover complex curved and simply not very even roofs, the sheets are able to withstand fairly large deformations of the supporting structure. The material forgives some negligence during work: the roof does not leak, only the appearance suffers. Unlike metal tiles, ondulin does not form condensate (there is no need for a roofing film), does not make noise, heats up less and does not become electrified.

Roofing from Onduline with "branded" extensions looks neat

In the minus of ondulin, you can put its flammability. Although, subject to mandatory fire safety rules, there are no problems. Another property of the material: it has a rough outer surface. Because of this, plant pollen and dust can linger on the roof. But this is also an advantage: there are no avalanches in winter, as with a slippery metal roof.

The environmental friendliness of ondulin, which sellers talk about, is at least doubtful. What can be the environmental friendliness of a material made partly from petroleum products? However, compared with asbestos "slate", the release of which has long been banned in developed countries, ondulin wins significantly.

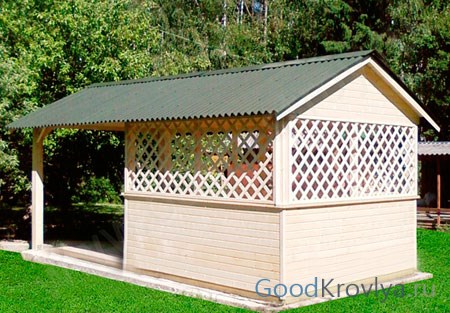

The gazebo covered with ondulin looks pretty

Issue price

The cost of asbestos-cement corrugated sheets with a thickness of 4.8-7.5 mm is an average of 80-200 rubles / m 2. Onduline will cost 200 rubles / m 2. Budget metal tile - from 220 rubles / m 2. This is the cost of the material without work and additional elements. The complexity of installing ondulin and asbestos "slate" is minimal, it is more difficult to work with metal tiles. With cheap sheets, the euroslate extensions are expensive. With a large number of them, you can replace the complete bitumen-cellulose elements with metal ones. It’s not a problem to get into the color, it doesn’t affect the tightness, but it will cost a little cheaper.

It is not very rational to use Ondulin on whimsical roofs, especially with an abundance of triangular and trapezoidal planes. For complex roofs, it makes sense to calculate the cost of flexible tiles: in contrast to large-sheet materials, there is practically no waste in the form of scraps, and extensions are relatively inexpensive.

Foundation preparation

Laying ondulin with a slope of less than 1/11 is not recommended. Such a roof should already be covered with welded roll waterproofing. If the elements of the batten are of the same thickness, a pair of wooden "intervals" will speed up the work, the length of which will be equal to the internal distance between the battens. As for the quality of the lathing, Onduline fits perfectly on roofs with a rather uneven surface, on which the asbestos "slate" would crack. Bitumen-cellulose sheets will form the shape of the roof and perform their function, but a visually poorly prepared roof will remain uneven.

Required Tools

The nuances of mounting sheets

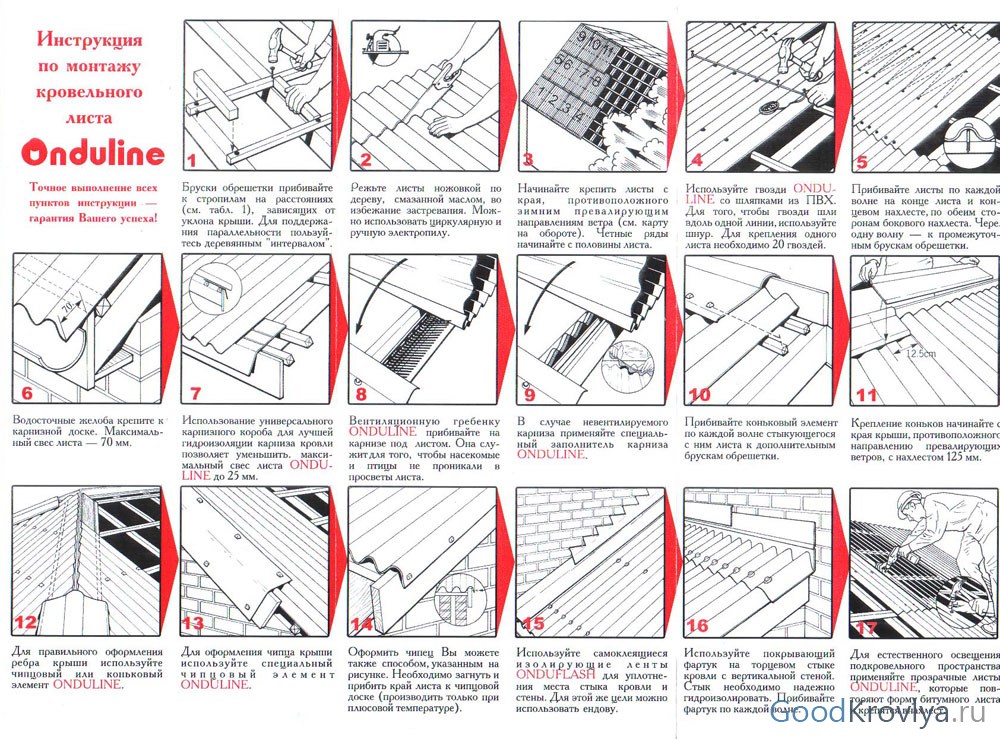

The first sheet is attached on the leeward side. That is, from where the wind blows more often. First, the lower, cornice row is completely mounted, then the second, and so on. In order for the bottom row to come out even, a marking cord must be pulled along the eaves at the level of the lower edge of the roof.

Installation flow chart introduces step-by-step instructions

The first row starts with a single sheet, the last sheet in the row is cut off if necessary. The second row does not start with a whole, but with a cut sheet. The first sheet of the last row is cut according to the pattern of the last sheet of the first row, or simply in half. The third row again starts with a whole sheet. Thus, the joints of the sheets in the vertical plane do not intersect anywhere.

The photo shows that the workers do not start the second row with a whole sheet. This arrangement will avoid the overlapping of the joints of four sheets at one point.

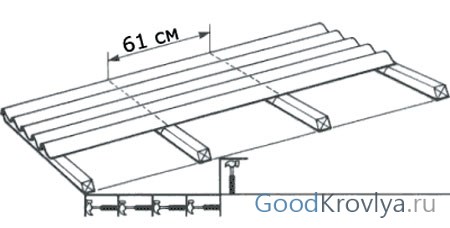

Ondulin is fixed with special nails with a snap-on hat in the color of the main coating. It is undesirable to use ordinary slate nails. Sheets are attached, starting from the bottom row closer to the eaves at the top of each wave. In the same way, they are nailed in each overlap, fixing both sheets at once (lower and upper). But in the middle of the sheet, the fastening is done in a tricky way. The distance between the nails at the ends of the sheet is divided into three parts (step 61 cm). Nails are hammered into each wave, but not in one line, but in two, in a checkerboard pattern. That is in each line through the wave. This is with a crate step of 61 cm. With smaller slopes, the step will be 45 cm, and there will be three lines. With a normal slope, two dozen nails go to the sheet.

This is how the sheets are fixed in the middle: through a row apart. You can mark with a cord or wooden blocks of the right size

To make the roof look neat, the nails must be hammered strictly in line, and not by eye. For marking, you can use a cord or bar of a suitable length. And, of course, the nail must hit the bar or board of the crate. Hammer nails should be without fanaticism, so as not to crush the sheet.

Ondulin can even be laid on the old "slate" roof without dismantling it. Wooden bars of the crate should be antiseptic, they will last longer

Sheet overlap

The overlap, both end (vertical on the short side of the sheet) and side (horizontal on the long side), depends on the slope of the roof:

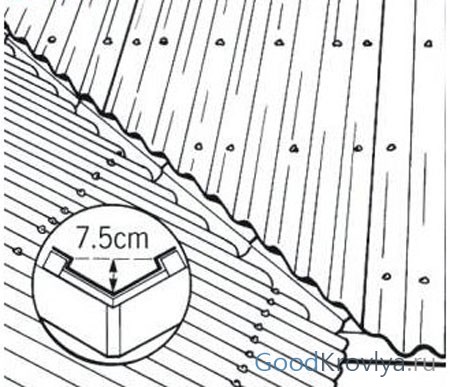

- With a normal roof slope of 1/4 or more (above 15 °), the end overlap is 17 cm, the side overlap is one wave.

- With a slight slope from 1/6 to 1/4 (10-15 °) - 20 cm and one wave.

- If the slope is quite small - from 1/11 to 1/6 (5-10 °) - 30 cm and two waves.

We make the last blow to the nail slightly so as not to dent the sheet. After hammering, we snap the plastic hat.

Installation of additional elements

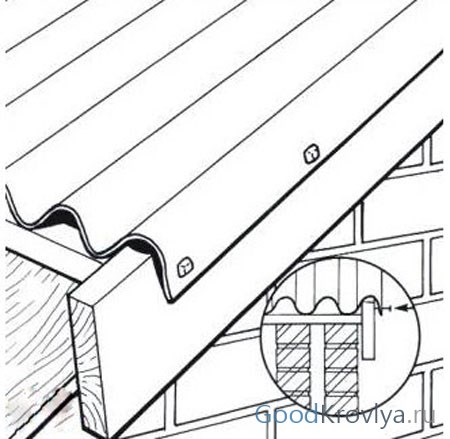

In order not to buy a chip (wind) extension, you can simply bend the extreme wave by 90 °

Onduflash - competent isolation

Soft self-adhesive tape Onduflash will help to isolate the junction of the roof to the pipes. The tape can be used to improve abutment joints and seal the valley.

Onduflash tape will help seal the joint with the pipe. Bends by hand, can be “rolled” to the surface with a wooden block

Onduline is a deservedly popular, reliable and inexpensive roofing material. Covering the roof with ondulin is quite possible on your own. You just need to follow the manufacturer's recommendations, have a set of simple tools and have initial experience in carpentry.