Metal tile roofing - pipe bypass technology

Roof - the top element of the entire roof, designed to protect the structure from precipitation. The device of a roof from a metal tile will allow not only to resist atmospheric precipitation, but also to resist other adverse environmental factors. To perform its functions, such a coating must meet certain requirements, and its device must be carried out in strict accordance with the technology.

Why metal tile - rationale for choice

The choice of material for the roof device is always associated with the degree of fulfillment of the basic requirements for the roof.

These main requirements are:

- resistance to precipitation;

- resistance to low temperatures (in winter) and high (summer) - the choice of material depending on climatic conditions;

- solar radiation;

- precipitation from acid rain;

- high level of resistance to mechanical stresses during operation and repair.

The roofing material must meet the requirements of maintainability, be reliable and durable.

Sheets of a metal tile satisfy all listed requirements in full. Corrugated corrugated profiled sheets imitate the surface of ceramic tiles, inheriting its main technical properties and characteristics. The metal tile is made from a hot-dip galvanized sheet 0.5-0.7 mm thick with a polymer coating in accordance with GOST R 52146 and TU 14-1-4792. The choice of such a base allows to achieve a high level of strength and reliability of the material.

The production technology provides for the production of profiling by the rolling method, which makes it possible to guarantee the correctness of the shape of all finished products without exception.

The composition of the metal sheet includes special layers of substances and chemical elements that provide a high level of protection against corrosion. In addition, the use of modern polymers allows you to perform a decorative function.

Roofing from metal tiles is used for arranging pitched roofs (slope more than 12 °).

The main advantage of this material is its own weight. Despite the insulation and waterproofing, the weight of the roof will remain the lightest compared to the use of other roofing materials.

Metal tile roofing– basic rules for selecting elements

For the installation of the roof, the main material is used - sheets of metal, as well as component parts. An obligatory element of technologically correct installation is the use of anti-condensate films and heat-insulating material.

The main criteria for the selection of metal tiles is the height of the corrugations, the size of which, according to the standard, is in the range of 10 - 25 mm.

The height of the corrugation, as well as the type and color of the polymer coating on the front side of the building material surface, are chosen based on aesthetic tastes and architectural design requirements.

When choosing a metal tile, special attention should be paid to the thickness of the sheet. In order to prevent deformation during operation, a material with a thickness of at least 0.5 mm is used when constructing a roof made of metal tiles.

Among the modern heat-insulating materials provided for the implementation of such tasks, slabs are most often used, consisting of fibrous and foam materials, on a cement binder. In addition, backfill heat-insulating materials can be additionally used - shungizite, expanded clay, vermiculite, perlite.

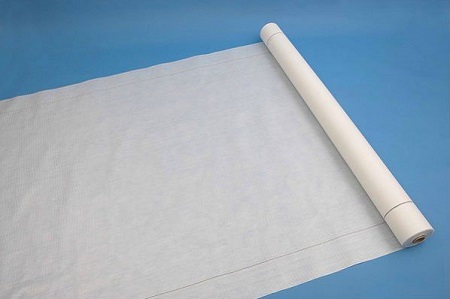

Anti-condensation films are usually made of a vapor-tight, moisture-absorbing material.

To protect the attic from moisture that can penetrate from the outside of the building, the anti-condensation film is made from a moisture-absorbing non-woven material. The film is laid under the roof and its main purpose is to prevent condensate from flowing onto the thermal insulation. The mechanism of action is based on the properties of a moisture-absorbing, quick-drying material.

To protect the thermal insulation of buildings with high humidity from condensation, anti-oxidant films from a vapor-proof material are chosen.

The device of roofing anti-condensate films is mandatory. Specifications for the choice of material are specified based on local conditions at the stage of project adjustment.

Roofing accessories are used at the joints (combinations) of metal tile sheets, at the places of passage, as well as at the exit of the chimney, on the formed sections of the coating material. Additional elements are designed to hide the raw edges of the metal, the resulting cracks and gaps. When using roofing components, the technical characteristics of the integrity of the coating (reliability and strength) are maintained, and the aesthetics of the appearance (attractiveness and neatness) are significantly improved.

The device of a roof from a metal tile assumes a set of the following additional accessories:

- ridge, cornice, end strips, for seams, external and internal corners, joints, etc.;

- snow retainer;

- valleys;

- passing elements;

- sheet for covering external recesses;

- outlet pipe.

In order to fix sheets of metal tiles, the following types of slats and parts are used:

- ridge bar on Monterrey profile;

- end on a ridge plank (for a hipped roof, end on a ridge plank and a U-shaped plank for the end of a hipped roof);

- end plate 50x50 mm (103x115 mm);

- cornice strip for metal tiles;

- plank for internal seams and joints;

- for outside corners;

- for internal corners;

- with inner and outer corners;

- for seams and joints;

- top bar;

- lateral;

- groove plate.

Components for metal roofing are used in full, without fail. Refusal of accessories and additional elements can lead to improper installation of the roof, and therefore to a reduction in its service life.

Metal roofing: technologydevices

Roof projects

Roofing is a complex and time-consuming process, which is quite difficult to carry out without the advice of specialists and the help of an experienced partner.

Installation work begins by measuring the slopes. At the same time, the perpendicularity of the ends of the roof is established with respect to the lines of the cornices and the ridge.

The crate is made of boards with a section of 32x100 mm. The distance between the ribs of the crate should be 350 mm (equal dimensions between the ribs of the metal tile). The distance from the outer edge of the cornice board is about 300 mm.

If the size of the transverse ribs of the metal tile differs from the standard, then the crate is also arranged according to the new dimensions.

The technology of roofing from a metal tile assumes compliance with the following conditions:

- Boards of ribbed sheathing, as well as wooden material on the end sections (extreme on the cornices) are placed above other boards.

- The edges of the sheets of metal tiles are covered with solid sheathing boards.

- Installation of sheets of metal tiles begins with the end sections.

- All overlaps are performed at the transverse border of the sheet, subject to a length of approximately 250 mm.

- The ridge is closed with special additional accessories - ridge elements with a seal. The semi-cylindrical shape contributes to a more dense laying on the upper ends of the profile sheets of metal tiles.

- On the cold inner surface of the metal tiles create conditions for ventilation under the roof. To prevent the formation of condensate from the eaves to the ridge, roll material is placed under the crate.

- Roof valleys are made using a special grooved element. To do this, an intermediate structure is mounted on the skin, on which a grooved element is attached.

- The gaps under the ridge, between the sheets of metal tiles and the grooved element are sealed using special sealing tapes, or silicone or any other curing sealant.

- Metal tiles are fastened with bolts or screws in accordance with the diagrams.

When carrying out any installation work, you should walk in shoes with soft soles. It is important to try to step only into the deflection of the wave and in the places of the crate.

The device of a roof from a metal tile must be carried out in strict accordance with all stages of the work.

To prepare the roof for installation, it is necessary to assess the integrity and evenness of the surface. In cases where defects and irregularities are identified, measures are first taken to eliminate them. They also check the correct dimensions of the roof and shape, for this, measure the diagonals of the slopes. If the skew cannot be technically corrected, then the metal tile is laid, aligning the lower edge of the crate with the overhang line of the building material.

Roofing material is laid from the bottom up, while the top sheet should overlap the bottom one. Roof installation starts from the lower left corner. And in order for the cornice line to be even, during installation work, special attention is paid to laying the first sheet.

Features of installation of additional structural elements

The technology for strengthening additional accessories and roofing elements with a metal tile device has its own characteristics that must be taken into account.

The cornice strip for metal tiles is attached to the last board of the batten, while the length of the overlap of the strips is 100 mm. This fastening is carried out before the installation of the base material.

End strips are attached along the gables from the bottom up. A feature of this type of installation work is that the strips must cover the end edges of the sheets.

Ridge strips should be installed after the installation of the roof, end strips, fixing the sealant.

Roofing pie - structure and features of the device

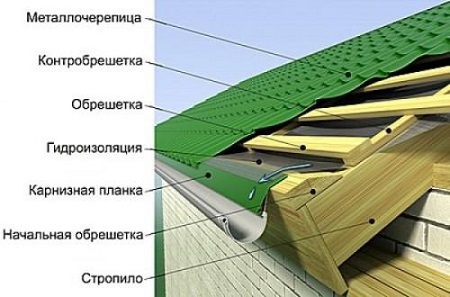

As you know, a roof is a structure consisting of a different number of layers that perform various types of tasks. Such a set is called a roofing pie. A roofing cake for metal tiles, in most cases, consists of the following set of layers and elements:

- metal tile;

- crate (unedged board 25x100mm or timber 40x50);

- counter-batten (board 25x100mm, unedged);

- waterproofing (diffusion membrane);

- vapor barrier;

- insulation (basalt slab 150mm);

- rafter (wooden beam 50x100 or 100x150);

- connecting tape (double-sided tape);

- the spillway is round;

- hook for fixing the gutter;

- frontal board (wooden 30x150 edged);

- wind bar;

- skate;

- ventilation "horse" in waterproofing;

- ventilation holes in the profile seal;

- ventilation gap between the waterproofing.

The option of a roofing cake is determined individually depending on the type of roof and is fixed in the project documentation.

Roofing cake for various types of roofs

For a cold roof, a roofing pie for a metal tile consists of load-bearing structures, a metal tile, a control batten and a gyro-insulating film. The installation of such a film has some features. It is fastened with staples of a stapler (construction) and pressed with self-tapping screws to the fastening boards of the counter-lattice.

When attaching the film, it must be given some sagging (15 - 25 mm). Such a condition will help to ensure ventilation of the underside of the metal tile sheet during operation.

If this condition is violated, then moisture will accumulate in places where the film fits snugly, as a result of which the corrosion process will begin quite quickly.

Such a cold version of a roof made of metal tiles is rarely used in the construction of residential buildings, this is due to the increased echo (sound conductivity) of the material.

In addition, this option of a cold roof has a number of the following disadvantages:

- low air permeability due to the obstacles created by the crate;

- difficulty with fixing the waterproofing film on the rafters;

- the impossibility of installing a “ventilation ridge” in the waterproofing layer;

- increase in wood consumption per crate.

In order to reduce the noise level, as well as to be able to more efficiently use the under-roof space, they arrange a warm roof. Although the cost of construction will be increased, the result of the efforts and investments will be additional space for household and utility rooms.

Roofing cake for metal tiles will include the following layers:

- load-bearing roof structure (longitudinal purlins, rafters);

- vapor barrier (unilateral moisture permeability is provided);

- thermal insulation;

- ventilation gap (space between thermal insulation and rafters and girders;

- waterproofing (waterproof film, or membrane with one-sided permeability to the outside);

- counter-lattice (used to fasten the batten and press the waterproofing);

- crate (beam of a certain calculated section, on which the roof is attached);

- sheets of metal.

The roofing cake under the metal tile has a weak point - a heater. It is quite important to weigh all the features of the material before buying a heater, or consult with a specialist. For example, when choosing foam plastic as a foam plastic, it is necessary to take into account its higher cost compared to rolled thermal insulation (mineral or glass wool). In addition, such material does not have sufficient flexibility, which leads to the formation of additional waste with a non-standard rafter pitch.

The most popular type of thermal insulation materials are technical wool. However, a feature of this version of the material is its hygroscopicity. Such a deficiency is found when moisture is collected. At high humidity, the unprotected layer loses up to 80% of its insulating properties.

In order to prevent violation of the thermal insulation of the roofing pie, the metal tile roof structure includes gaps between the thermal insulation (from 30 to 40 mm) and the upper layers of the roof, as well as between the waterproofing and the metal tile (from 10 to 15 mm).

To remove moisture in the insulation, a natural blowing method is used.

Features of the installation of a roofing pie

Installation work of installation of metal roofing layers is carried out in a certain order, the violation of which will lead to a weakening of performance.

- Installing a vapor barrier. Attaching a vapor barrier film is carried out on the inside of the rafters. In some cases, it is necessary to fasten the film with a gap (provided by a counter rail with a thickness of 30 mm or more).

- Installation is carried out in the direction from the bottom row to the top, while the overlap is 100 mm.

- Formed and longitudinal joints are closed with a vapor barrier film.

- Insulation (gaps) is carefully stuffed into the space between the lags.

- Waterproofing is installed using a similar technology.

The roofing pie must be completely arranged before the immediate start of the installation work of the metal tiles.

Metal roof structure- fastening of individual elements

When installing a roof, it is important to take into account the features of fastening not only sheets, but also individual additional units and elements. Such attention to detail will ensure the reliability of the entire structure and eliminate the risk of “weak” points not only on the surface, but on the entire roof.

When installing the end strips, it is necessary to observe the rule of fastening them to each other (overlap of 2 cm or by flanging)

If the tile is not adjusted to the width of the slope according to the size of the wave, then it may turn out that the lower crest of the wave will fall on the gable. In this case, it is recommended to additionally add a roof lath or adjust the gable overhang.

To improve the fit of materials, it is recommended to lay an additional layer of sealant with a sheet of metal tiles and a plank.

In cases where metal roofing elements are installed independently, typical errors occur. For example, quite often in a rectangular slope, when installing skylights, they are built into a cut of a metal tile sheet. window apron. With this approach, a hole is formed in the roof along the edge of the notch.

When installing dormer windows, roof windows, pipes located below the ridge, it is necessary to strictly adhere to the technology of using metal tiles when covering the roof. In this case, it is recommended to use single-module sheets (two sheets for each element).

Skate bar installation rules

Installing the skate bar also involves following some rules:

- Before mounting the ridge strip, it is recommended to carry out work on the installation of under-roof ventilation.

When carrying out installation work on a roof with gentle slopes, it is necessary to install an aero roller between the ridge strip and the sheets of metal tiles. This design approach will reduce the risk of snow falling under the ridge.

- When installing pinpoint ventilation holes in the ridge, it is mandatory to install a seal.

When carrying out this type of installation work, the skate is mounted on the end strips, and the work is carried out from the end. The protrusion of the edge is 20-30 mm.

- When installing a flat ridge, the parts are overlapped. A semicircular ridge is attached along the profile lines.

- If the roof has an angle of inclination of more than 45 degrees (sharp), it is necessary to accurately calculate in advance the combination of the ridge plank model and the angle of inclination of the roof. It is recommended to entrust such calculations to specialists, because a small mistake in the numbers can lead to the need to purchase a metal tile in full.

- In order to more accurately repeat the angles of inclination of the roof slopes, it is recommended to bend or unbend the ridge shelves as necessary.

- Ridge knots of roofing from metal tiles for trapezoidal and triangular slopes are mounted according to the pattern of fitting the plank to the corner of the ridge. In this case, a straight ridge is recommended to be cut in accordance with the angles. Installation of a semicircular ridge involves the installation of a plastic plug.

- Ridge knots of roofing from metal tiles for trapezoidal and triangular slopes are mounted according to the pattern of fitting the plank to the corner of the ridge.

It is recommended to replace the plastic plug that comes with the kit with a steel one made by craftsmen on their own.

It should be ensured that the axis of the ridge bar corresponds to the axis of the ridge. If the angles of adjacent slopes have the same value, this is not difficult. In another embodiment, specialists use a bright mounting tape or a plastic V-tee to control the corresponding abutments.

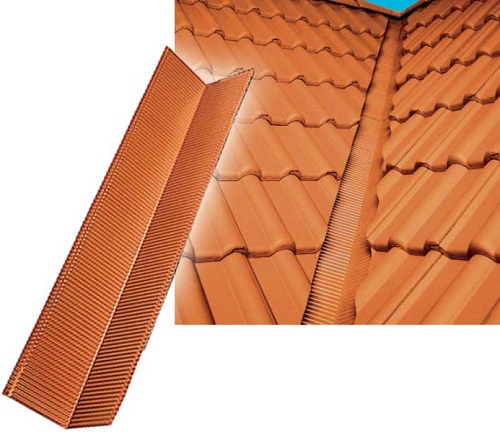

Roof units made of metal tiles- features of the installation of the valley

A special place in the construction of a roof made of metal tiles are the places where the valley is installed. On the roof, this place starts from the ridge and goes down to the eaves.

The technology of the device involves the installation of an additional board for each valley. It is important to remember that the strips must be installed from the bottom up. The overlap with this technique is 20-30 cm.

The gap between the axial line of the valley and the sheets of metal tiles should be at least 6.0-10.0 cm.

Checking the correctness of the assembly of the metal roof structure is quite simple. With the correct performance of all work with strict observance of all requirements at the attachment points, the coating sheet should touch the board. In the event of a miscalculation or error, the metal tile will be fixed at other points, which will lead to the formation of gaps. Such a defect will necessarily lead to leaks already in the first period of operation.

In order to close the cut sheets of the valley, they are decorated with decorative overlays. When implementing this process, experts recommend:

- mount a decorative trim from the bottom up;

- compliance with the size of the overlap (at least 10 cm);

- between the decorative overlay and the metal tile, the installation of a sealant is not provided;

- installation of a decorative lining provides for the accurate installation of self-tapping screws (no damage to the valley plank).

The device of a roof from a metal tile provides various types of designs. Some of them provide for the presence of a valley, which begins and ends on the slopes. If we consider the case of the correct arrangement of the dormer window, then it is not difficult to notice the additional installation of the board under the valley. The technology of such an installation assumes the level of cutting of a sheet of metal tiles is 20 cm higher than the exit of the valley to the slope. Cutouts are made under the front and side walls of the dormer window in the covering building material. Installation work involves the following work processes:

- installation along the walls of the dormer window seal;

- closing the cornice overhang with a plank;

- installation of the valley plank;

- trimming the plank at the exit to the slope and along the eaves.

In order for the edge facing the slope to fit snugly against the metal tile sheet, it is recommended to mold the upper edge of the valley manually. It is also necessary to trim the bottom sheet with a mallet. If necessary, you can lengthen the valley, but on condition that the size of the overlap is 20-30 cm. In most cases, the junction of the valleys to each other is fixed with self-tapping screws with sealant.

Under the flanges of the valley, it is imperative to install a sealant. On the main slope above the valley, the sheets are laid according to a scheme that provides for fixation between the upper and lower rows. In this case, it is more than 20 cm.

Metal tile roofing - pipe bypass technology

Roofing technology involves installation work not only on a flat surface. The roof structure involves the installation of a pipe and other objects.

When installing the covering material, it is necessary to take into account all the features of the correct installation work. For a professional bypass of the pipe, it is necessary to prepare its surface at the junction in advance.

At the preparatory stage, the following types of work:

- the surface of the pipe is completely plastered;

- waterproofing is installed on the sides;

- on a slope at a distance of not more than 80 cm from the back wall, a drainage groove is installed;

- an additional crate is installed above the pipe.

![]()

When constructing a roof, sheets of metal tiles located on both sides of the pipe are cut off above the stamping line. In this case, the cut will take place at a distance of no more than 15 cm from the pipe to the stamping lines.

The upper and lower aprons are measured along the side ones, the height of which is at least 15 cm. The measurement is carried out from the top of the roofing.

In order for the design to meet all the requirements of reliability and integrity, it is also necessary to carefully measure the side of the apron that lies on the slope (at least 20 cm high). A prerequisite is the apron covering the nearest wave crest. Aprons are attached using self-tapping screws with sealant. Be sure to use a sealant.

Following the sequence of actions, you must first connect the lower and side aprons, and then proceed with the installation of the upper one. A prerequisite for installing the top apron is to cover the sheets of metal tiles by 10-20 cm.

The top apron cannot be mounted into the cut of the metal tile. With such a defect in the installation work, water leakage under the roof is inevitable.

If the pipe is located at a distance of less than 1 m from the ridge, then the installation of a metal roof is much easier. In this case, the upper part of the apron is brought under the skate.

The danger of the location of the pipe on the ridge is considered to be an unprofessional approach when sealing the joints of the side aprons of different slopes.

If on the roof there are objects with a width of more than 0.8 m, then the installation of metal tiles is carried out in accordance with the rules, requirements and instructions used when installing the valley. In this case, the nodes of the roof made of metal tiles form a ramp formed by two additional slopes. According to the technology, the slopes are covered with metal tiles and valleys are arranged.

The option, in which the width of the object does not exceed 1.2 m, provides for covering the slope with a flat steel sheet instead of the main covering material.

However, there are also more complex design solutions. In the case when the shape of the pipe is round, then you can’t do without the help of specialists. Bypassing a round pipe when installing a metal roof is a very complex technical process. When turning to specialists for help, it should be remembered that the prices for installation work on this section of the roof are much more expensive than on the rest of the surface.

The device of a round pipe will complicate the process of installing a roof from a metal tile.

Metal roofing - the choice is yours

When choosing a metal tile as the main material for covering your roof, you need to consider that this is a modern covering material with a huge list of advantages.

Technical characteristics, as well as high performance properties, make it possible to maintain a high level of consumer demand in the market of domestic coating materials. Today it is possible to choose the necessary covering material for any type of pitched roofs, corresponding to various requirements. Construction stores are ready to offer the buyer products of various brands and manufacturers.

To make a final decision when choosing this material, its advantages and disadvantages should be considered in more detail.

Benefits of metal roofing:

- compared to other covering materials (ceramic tiles and slate);

- simplicity and ease of installation work on the installation of the roof (the possibility of installation with certain skills);

- wide range of color palette (over 40 shades);

- the presence of stiffeners, which ensures high strength of the material;

- high technical properties and operational characteristics;

- compliance with modern requirements;

- environmental friendliness.

One of the disadvantages we have considered is the noise from hail and rain impacts. In addition, with self-cutting of the roof, a large amount of waste profiled material remains.

With a competent analysis of the main advantages and disadvantages of this material, the conclusion becomes obvious even to a non-specialist. The metal roofing is quite durable and beautiful.

Subject to all the considered structural features of such a roof and the moments of installation work, a roof made of metal tiles is guaranteed to stand for about 50 years.

However, it should be remembered that flat roofs are not covered with profiled metal sheets. The slope of the roof for covering with metal tiles is from 1.5-2 to 11 degrees.