End strip for corrugated board

Frontal, end, wind - these are all the names of one part when installing a pitched roof with corrugated board. Its installation takes place at the final stage of the installation of the roofing. The wind strip for corrugated board is not only a decorative element of the roof, it has a lot of other functional responsibilities.

The end strip, of course, gives the roof a complete look, but its protective function is much more important. She protects the roof from many misfortunes:

- The ingress of precipitation into the under-roof space, which leads to wetting of wood and insulation.

- Strong wind gusts driving debris and snow under the corrugated board. The side wind changes the temperature and humidity conditions inside the attic.

- Penetration under the cover of birds and small animals. They spoil roofing materials, provoke the appearance of an unpleasant odor, increase the likelihood of infection with microbes and fungi.

- A strong wind can completely tear off sheets of corrugated board.

Design features

As a rule, the wind strip is made of the same material as the profiled deck. Producers of corrugated board offer, when ordering materials, to immediately purchase the final parts (additional elements). They have a curved shape and are painted to match the roofing. The end plate is made of galvanized metal with a coloring coating. The following types of coating are used as a coloring layer:

The end plate is made of galvanized metal with a coloring coating. The following types of coating are used as a coloring layer: - Polyester (based on organic polymeric substances).

- Pural (based on polyurethane with polyamide).

- Plastisol (PVC and plasticizers).

- Lacquer.

- PVDF (fluoropolymers).

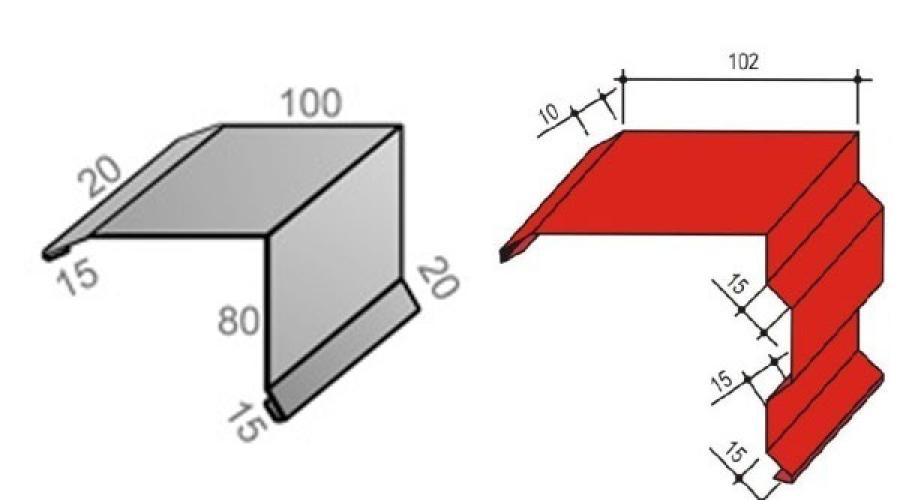

Suggested dimensions of the front bar: length 2–2.5 m, width 250, 312 mm, thickness 0.5–0.55 mm. The shape of the part can be straight or curly. To add rigidity, the edges are double folded. The thickness of the end plate can have different sizes - from 0.4 to 1 mm. But a thickness of 0.5–0.55 mm is the most suitable, since the part is strong enough and, if necessary, can be easily bent.

Suggested dimensions of the front bar: length 2–2.5 m, width 250, 312 mm, thickness 0.5–0.55 mm. The shape of the part can be straight or curly. To add rigidity, the edges are double folded. The thickness of the end plate can have different sizes - from 0.4 to 1 mm. But a thickness of 0.5–0.55 mm is the most suitable, since the part is strong enough and, if necessary, can be easily bent. Installation rules

The wind bar is installed as one of the very last pieces. After framing the ends, only the installation of the skate remains. The installation of the end element is carried out in the following order:

The wind bar is installed as one of the very last pieces. After framing the ends, only the installation of the skate remains. The installation of the end element is carried out in the following order: - An end board 80 mm wide and 25 mm thick is attached to the crate, on which the profiled flooring is laid. The board is mounted using construction nails with a diameter of at least 4 mm and a length of 100–120 mm.

- A wind bar is mounted on top of the end board. Fastening is carried out using roofing screws with a diameter of 4.8 mm. The design of self-tapping screws implies the presence of a sealing washer (rubber gasket). Fasteners should be located in increments of 200–300 mm. Mounting of self-tapping screws is carried out only with a screwdriver.

The following types of sealant can be used to fill the gap:

The following types of sealant can be used to fill the gap: - universal self-adhesive;

- universal self-expanding (PSUL).

Due to their properties, these materials work well in roof construction. They create a barrier to the penetration of moisture, do not collapse under the influence of ultraviolet radiation, tolerate temperature changes from -45 ° C to + 85 ° C well. Special impregnations protect against infection by fungi and mold. In order for the joint between the corrugated board and the plank to be 100% reliable from leakage, the additional element must close two waves of the coating. Summarizing this information, it can be noted that there are three types of nodes and types of installation:

Due to their properties, these materials work well in roof construction. They create a barrier to the penetration of moisture, do not collapse under the influence of ultraviolet radiation, tolerate temperature changes from -45 ° C to + 85 ° C well. Special impregnations protect against infection by fungi and mold. In order for the joint between the corrugated board and the plank to be 100% reliable from leakage, the additional element must close two waves of the coating. Summarizing this information, it can be noted that there are three types of nodes and types of installation: - The use of a front part with a wide horizontal part covering 2 corrugated board waves. Mount on the crest of the second wave with long self-tapping screws.

- The front bar is about 125 mm wide, covers only one wave, but the use of seals is mandatory. Mounting with short self-tapping screws on the end board.

- It is allowed to mount the front part with the device of the end bar. However, such a mount does not seem strong and reliable.

Is it possible to completely do without the end element of the roof? There is no strict guidance in this regard in building codes and regulations. Only for an unprotected coating, the service life is reduced by 2-3 times. We recommend the following videos for your reference:

Is it possible to completely do without the end element of the roof? There is no strict guidance in this regard in building codes and regulations. Only for an unprotected coating, the service life is reduced by 2-3 times. We recommend the following videos for your reference: