Technique for applying decorative plaster

The time of monotonous wall decoration in the form of wallpapering has sunk into oblivion. It was replaced by a period when surface finishing turned into a creative process that allows you to create a unique design of a room or building facade from the same material. Decorative plaster serves as a platform for the manifestation of aesthetic taste and artistic talents. Various techniques of its application contribute to the formation of an individual interior. What includes the preparatory stage, and what methods of decorating walls and ceilings with decorative plaster exist, we will consider in detail. The proposed videos will help to deepen knowledge on the topic being studied.

Varieties of material

Before describing the technology of applying a finishing material, a brief excursion into the variety of its types should be made. There are several parameters by which the classification of decorative plaster is carried out. Depending on the binder, plaster is:

- Acrylic. It is presented in the form of a ready-made mixture having a pasty consistency. Such decorative plaster is extremely convenient for the application of various surface structuring technologies.

- Mineral. Cement acts as the basic component. Inexpensive mixture is optimally suited for outdoor work and in rooms with high humidity. The powder is diluted with water in the indicated proportions before application. From the point of view of environmental safety, it is the most harmless product.

- Silicone plaster, based on synthetic resins. Its many advantages provide a wide range of applications in the conditions of the harmful effects of the surrounding climate.

- Silicate product based on liquid glass. The most reliable material for decorative finishing. Maximum strength and resistance to negative factors are the reason for the high cost of the product.

The composition of decorative plaster affects its final appearance. On this basis, decorative plaster can be divided into the following types:

- structural;

- silk;

- Venetian, etc.

Depending on which technique of applying decorative plaster is chosen, the material is able to imitate various surfaces, from stone or wood to wallpaper. The presence of artistic skills allows you to create exclusive panels on the wall.

Preparatory activities

Preparing the walls before applying decorative finishes is a prerequisite for obtaining a quality coating, regardless of the technique chosen. The process contains steps that are the same for all types of plaster and nuances that depend on the composition of the material. The entire preparatory procedure prior to applying the decorative layer includes the following steps:

- Removal of the old coating, the presence of layers of old plaster that has departed is excluded.

- All fat and oil stains are removed by special means.

- Cracks, chips are carefully repaired, protruding surfaces are knocked off. To eliminate significant damage, you will need a cement mortar, minor flaws are treated with putty.

- After removing dust and dirt, it is recommended to apply a primer.

Advice ! In conditions of high humidity, it is better to use an antiseptic that prevents the appearance of mold.

The technology for decorating the surface with a decorative finishing material includes the preliminary application of a thin layer of plaster. It is not necessary to strive for an ideal surface; in the future, all miserable flaws will be masked. After drying, following the rules of the application technique, it is recommended to re-treat the wall with a deep penetration primer. These measures significantly increase the adhesion of the adjacent layers. The nuances of surface preparation and simple techniques for applying a finishing material are described in the following video:

Variants of surface design with structural plaster

The choice of structural plaster for decorative finishing opens up a wide scope for the manifestation of creativity, even with minimal skills. There are many techniques for applying this material, which can be divided into several groups:

- using textured rollers or stencils;

- spray method;

- using all sorts of available materials.

After familiarizing yourself with several application technologies, choosing the most suitable method will be easier.

Roller work

Decorative plaster should be directly at hand from the material; acrylic-based wax and color scheme are used as a top coat. The main tools for work are a spatula and a roller (textured or with a pile).

The technology for applying decorative plaster using a roller with a pile is quite simple:

- Work on the distribution of the solution begins only after the complete drying of the primer.

- The plaster is tinted in bulk. Please note that as it dries, the shade darkens by approximately two tones. To avoid gaps, the primer composition also needs to be pre-tinted.

- According to the established technique, the solution is partially applied to the surface, the layer thickness is 1-2 mm. Given the rapid setting of decorative plaster, the area of the treated surface should not exceed 2 m 2.

Important! Torn seams are formed between the application areas. This technology will make them almost invisible.

- The direction of movement for the distribution of decorative plaster with a pile roller depends on the texture that is planned to be obtained at the end of the work.

The use of a textured roller slightly changes the technique for applying the finishing material:

- First, the surface is completely decorated with decorative plaster. The layer thickness varies within 1-2 mm.

- Then the drawing you like is applied using a textured roller.

- All movements are made in strict parallelism.

According to the proposed technique, a variant is allowed when a layer of decorative plaster is simultaneously applied with a roller, and a pattern is formed. During the day, the layer of plaster dries, after which they proceed to the application of a protective coating. This role is played by wax, its application is carried out with a roller with a medium pile. In conclusion, the surface is polished with a woolen cloth.

spray method

The end result looks interesting when using the technique of spraying decorative material. This method is applicable both for exterior finishing works and for interior design. The application technique is not difficult and includes the following steps:

- Initially, an even starting layer is formed with a spatula. Only after the complete drying of the first layer proceed to the next stage.

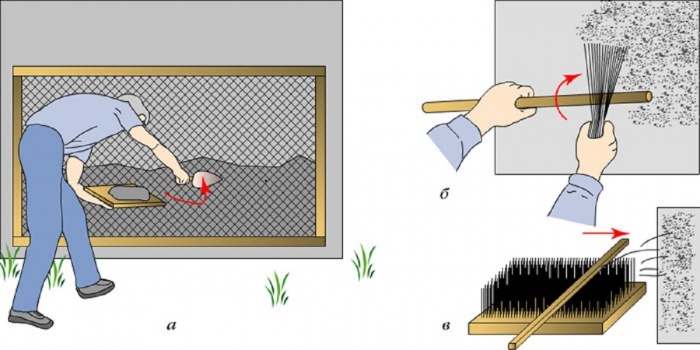

- To apply the second layer, various devices are used. It can be a brush, a stiff-bristled brush, or even a mesh.

- When choosing a brush, it is dipped into a solution of decorative plaster, and then the mixture is distributed by tapping the tool on a stick.

- The technique of applying decorative material with a brush is a kind of cleaning of the tool from the solution with a stick.

- To finish the facades, I use a mesh, through which a solution of decorative plaster is thrown with a spatula onto the wall.

The described technique is clearly shown in the figure below:

If you want to improve the process, the first layer can be made a little darker, and for the final distribution, take a decorative material of a lighter shade. A slightly different texture is obtained if the surface is treated with a second layer, without waiting for the starting finish to dry.

The use of improvised materials

There are many options for decorating surfaces with decorative plaster using improvised means, most of them can be mastered even by a novice master.

Applying Venetian plaster

The desire to decorate the wall with Venetian plaster requires the skills to apply decorative finishes. It will be difficult for beginners to master the technique right away. Of the materials you must have:

- primer for Venetian plaster;

- directly the decorative mixture itself;

- wax;

- container with warm water.

A trowel and fine-grained sandpaper are the main tools for applying and processing. The essence of the whole process lies in the alternate application of layers on top of each other, with the alternation of these actions by grinding the surface.