The size and weight of a roll of roofing material of standard grades

Roofing material began to be produced in the nineteenth century in America, however, since that time it has undergone many changes. In the process of use, the composition and method of production of this roofing material have improved. After two centuries of searching for the ideal value for money, the construction market offers more than 60 brands of coatings based on cardboard, polyester and fiberglass with different types of toppings. To control the quality of materials, a product standardization system is in place.

This article will tell you what weight and dimensions of a roll of roofing material should be for a material produced in accordance with GOST 10923-93.

Width and length

Requirements for the quality of roofing material are described in GOST 10923-93, this document regulates the main dimensions of the roll: length, width, thickness and weight. However, most manufacturers use specifications for quality control, not GOST. The following parameters are subject to standardization:

- Width. The width of a standard roll of roofing material according to the requirements of GOST is 100 cm, while the technical conditions allow a deviation of 5 cm in one direction or another. Most brands of roofing material are produced in the form of rolls, the width of which meets these requirements, but some enterprises produce products with a sheet of 1.025 and 1.05 m. The minimum width that is on sale is 0.75 m, it is convenient for them to cover the roof of a small area.

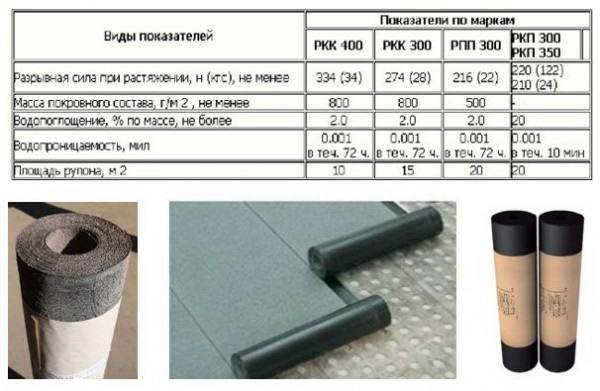

- Roll length. GOST 10923-93 for roofing material requires that the length of each roll be 10 m, allowing a deviation of 0.5 cm in one direction or another. However, the technical conditions used by manufacturers allow the production of rolls with a length of 15 m and 20 m. Usually, lining grades of roofing material are produced in rolls having a length of 15-20 m, which have a smaller thickness and weight.

- Roll area. Roll coverage area according to GOST, if the dimensions of a roll of 1x10 m should be 10 +/- 0.5 m2, if 1x1.5 - 15 +/- 0.5 m2, if 1x20 m - 20 +/- 0.5 m2. These technical characteristics of the material are taken into account when calculating the required number of rolls.

Note! Specifications allow deviations in the dimensions of the roll. It is allowed to produce roofing material with a length according to the buyer's order. Now, when product certification is voluntary, and most manufacturers have their own specifications, it is better to give preference to roofing material from well-known companies.

Thickness, density and weight

The service life and effectiveness of roofing depends on the density and thickness of the roofing material. Lining grades of roofing felt, in the production of which thin cardboard and powdered dressings are used, serve only 2 years, after which they lose their waterproofing properties and leak. Roofing grades "live" longer, withstanding 15-30 years of intense exposure to temperature extremes, moisture and sunlight. To evaluate the durability of a roofing felt coating, the following criteria are taken into account:

- Density. The density of roofing felt is the weight of 1m2 of a base made of roofing paper, fiberglass or polyester. Specifications and GOST 10923-93 allow the production of roofing material with a density of 300-400 g/m2. Bases, 1 m2 of which weighs 300 g, are used for the production of lining grades, and 400 g/m2 for roofing. Modern (Euroruberoid, Rubemast, Steklomast) have a density of 2000-4000 g / m2.

- Thickness. Specifications allow the release of roofing material, the thickness of which is 0.25-5 cm. The grades intended for use as the top layer of a roofing cake have a thickness of 0.5-5 cm, it depends on the density of the base and the topping used. The thickness of the lining marks is 0.25-0.45 cm.

- The weight. The weight of the roofing material depends on the size of the roll and the material from which the base and topping are made. A standard roll has a weight in the range of 25-30 kg. Roofing grades with coarse-grained dressing weigh more, and lining ones weigh less.

Note! The dressing is applied to the roofing material on one or both sides. It prevents the material from sticking together during storage and is an additional barrier to prevent moisture penetration. Roofing grades have a double-sided coating of coarse-grained or flaky dressing, and lining ones have one-sided coating of talc or chalk.

Quality standards

Coming to the store, the buyer has little idea of how a high-quality material should look like, therefore, he often focuses only on the price or the popularity of the manufacturer. To choose a durable coating, you need to pay attention to such indicators:

- Correct marking. The ruberoid is packed in a paper wrapper, on which the marking is applied. This label contains information on which GOST or TU the product complies with.

- Size matching. All rolls must have the same size in accordance with the regulations. If the dimensions noticeably “walk”, you should think about the quality of such products.

- Thickness. During visual inspection, the edge of the roofing material should have the same thickness without thickening or thinning.

- Sprinkle loss. If the powder is easily removed from the surface of the material, you have poor-quality material.

- Edge damage. Regulations allow no more than 2 tears 2 cm or less in length. If there is more damage, this is a reason to reject the material.

- Surface. On inspection, no cracks should be found on the surface. To check this parameter, bend the edge of the product several times in both directions.

Important! In the store, pay attention to how products are stored. This material must not be stored in a horizontal position, as the layers stick together, and then it is difficult to separate from each other. If stored vertically, sticking does not occur.

In order to qualitatively cover the roof of the house, they use certified material that meets the requirements of GOST. It is pointless to use obviously substandard products for the construction of a roof, since it will require repair in 2-3 seasons. To create a reliable hydro-barrier, roofing grades specially designed for such operation are used. Using a cheap lining type, you can achieve the same level of protection against moisture by applying 5-7 layers of roofing.