Planks for a fence from a professional flooring

To give the fence a finished look and protect it from negative factors, you should install strips for the fence. The closing bar is most often made of galvanized metal with a polymer coating and is used for fences made of concrete blocks, corrugated board, brick, metal picket fence.

It looks like a plank for a fence made of corrugated board

Unpretentious at first glance, the fence strips perform several useful functions.

Extending the life of the fence

The fence, protected by planks, will not lose its original appearance and strength characteristics for a long time. Brick fences and poles quickly crumble from constant exposure to water and snow, and fences made of metal euro picket fence and corrugated board begin to rust.

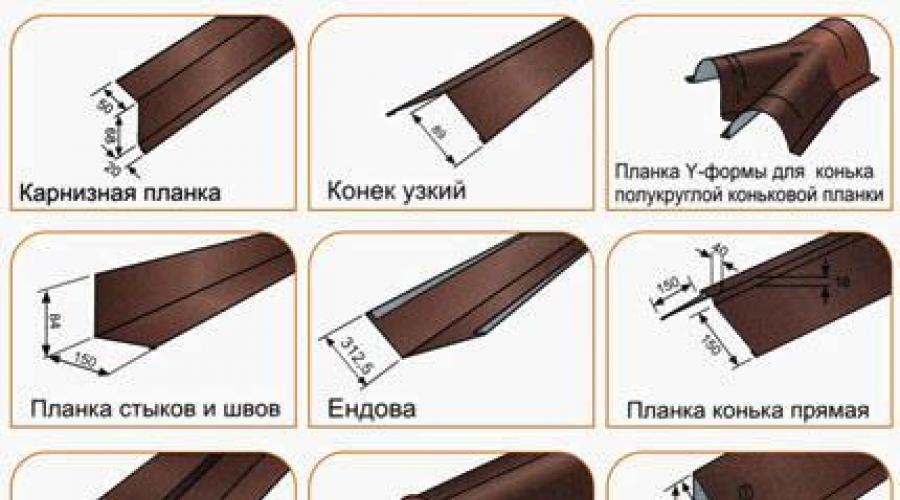

Various types of planks for a corrugated fence

Water, getting into the microcracks of wood, concrete or brickwork, expands when freezing, destroying the material from the inside. Fence strips will minimize the ingress of moisture on the fence and protect against premature destruction and from ultraviolet rays.

Additional web stiffness

The top lath provides additional durability of fences from a professional flooring. The corrugated sheet is a steel sheet with ribs of various heights.

The thicker the steel and the higher the corrugation of the metal profile, the better the rigidity and stability of the fence canvas.

However, corrugated board has a slight rigidity when bent in the direction of the waves. To compensate for this shortcoming, it is recommended to increase the number of horizontal power parts, that is, the crossbars of the fence.

Installing additional lags is an increase in installation time and unjustified expenses.

Scheme of a fence made of corrugated board with lag dimensions

With the help of a horizontal bar made of the same material as the corrugated board, you can add strength to the fence without unnecessary material and labor costs. The reinforcing top bar can have different sizes, depending on the height of the corrugated board ribs. Made from the same material as the corrugated board, the plank provides maximum rigidity of the sheet and is a very important element of the fence.

Additional strength is also necessary for fences made of euro picket fence. It is quite easy to bend or damage the upper edges of the picket fence, so a plank in the color of the fence is a must.

External attractiveness

Edging the top of a railing or parapet is also essential, as is a suitable picture frame. Without a fence profile, the fence looks unfinished. Planks for the upper part of the fence, parapets to protect the foundation and finials on the pillars give the overall appearance of the fence a harmonious look, visually align the fence, making it beautiful and neat.

The colors of the hedge trims are presented in a wide variety. You can choose options in the color of the fence from corrugated board or under the roof of the building. The fence strips are covered with a colored polymer layer, which is resistant to fading in the sun, corrosion and retains a presentable appearance for a long time.

Materials for the manufacture of fence slats

For the production of additional elements for fencing, cold-rolled galvanized steel sheet with a polymer coating is used.

Zinc coated steel sheet has excellent anti-corrosion properties.

The application of an additional polymer layer enhances the protection of the finished product. The most common types of polymer coating are polyester and pural. They are suitable for all climatic conditions and are highly resistant to mechanical and atmospheric influences.

The shape of the classic fence strip

The polymer layer of polyester and pural is elastic and has good color fastness.

Advantages of pre-painted steel

Fence strips made of steel with a polymer coating have the following advantages:

- durability - warranty period of service is not less than 10 years;

- rust resistance;

- resistance to temperature extremes, moisture and ultraviolet;

- decorative;

- wide palette of colors;

- light weight with good mechanical strength;

- affordable price.

Fence Plank Models

Types of fence slats differ in configuration, purpose, color and size.

Drawing with dimensions of various planks for a corrugated fence

Fence strips for metal profiles

Fence strips for profiled sheets are made of galvanized rolled sheet steel with a polymer coating of 25 microns. It is necessary to select the color of the fence coating in accordance with the color scheme of the fence. The standard length of the slats is 2 m.

Each type of profiled sheet has its own type of plank of a certain size:

- for C8 corrugated board, a bar with dimensions of 20x8x20 mm is used;

- for C10, the bar parameters are 20x10x20 mm;

- for C20, the dimensions of the fence strip are 20x20x20.

Depending on the configuration, additional elements for corrugated board are:

U-shaped planks have the most elementary structure and are used for simple fencing sheets. They are especially popular due to a number of advantages:

- low cost;

- average strength;

- light weight;

- ease of installation.

The U-shaped product also has its drawbacks:

- low aesthetics;

- poor protection against moisture, unlike strips with drip ebbs.

Planks for metal picket fence

The top of the metal picket fence needs increased rigidity, and the fence bar does an excellent job of this task. For eurostudent, the most popular are planks twisted in a spiral on one side and bent on the other.

This form performs an aesthetic function, giving the top of the fence a clear shape and original appearance, and also enhances the mechanical stability of the fence due to additional horizontal rigidity.