Wind bar

In fact, the functionality and visual appeal of the roof consists not only of the quality and correct installation of such large-scale elements as the truss system, the type and quality of the roofing or the arrangement.

Of no small importance in this matter are such seemingly insignificant components as the choice of high-quality fasteners, the arrangement of a cornice strip or an adjoining strip.

The eaves strip for the roof is not an easy decorative element, this part bears a huge functional load. It is she who protects the under-roof space from the penetration of atmospheric moisture and cold air into it.

It should be noted that the wind or end plank, as well as the eaves and abutment plank, are made using the same technology as the corrugated sheets used to cover the roof slopes.

They are made on the basis of a galvanized metal profile with a thickness of 0.4 to 0.5 mm, while the same polymeric materials are used for their coating as for the manufacture of corrugated board.

The wind and end elements can be produced with a polyester or plastisol coating, but for composite corrugated board, the end part is additionally coated with basalt chips.

In the article below, we will carefully consider the existing types of these parts, as well as study the features of their installation.

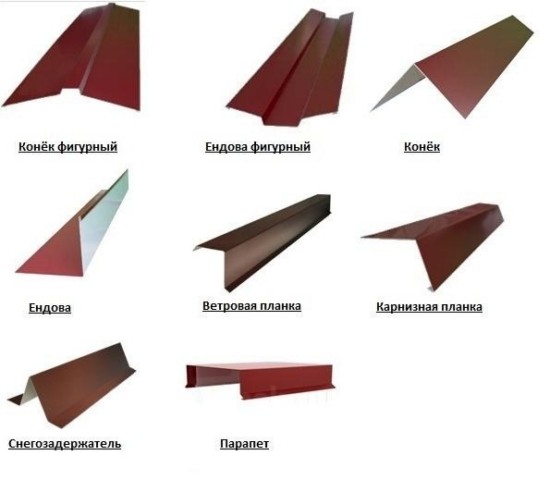

Types of planks

- eaves plank

- End plate

- side plank

- junction bar

- Connecting bar

- Top junction bar

- Docking bar

- Gable plank

The cornice mounting strip is used as a longitudinally located roof element. Its main function is to protect the frontal board from moisture, as well as to prevent it from getting wet and moisture penetrating into the under-roof space. The second name of this element is the frontal bar, it corresponds to its location on the roof.

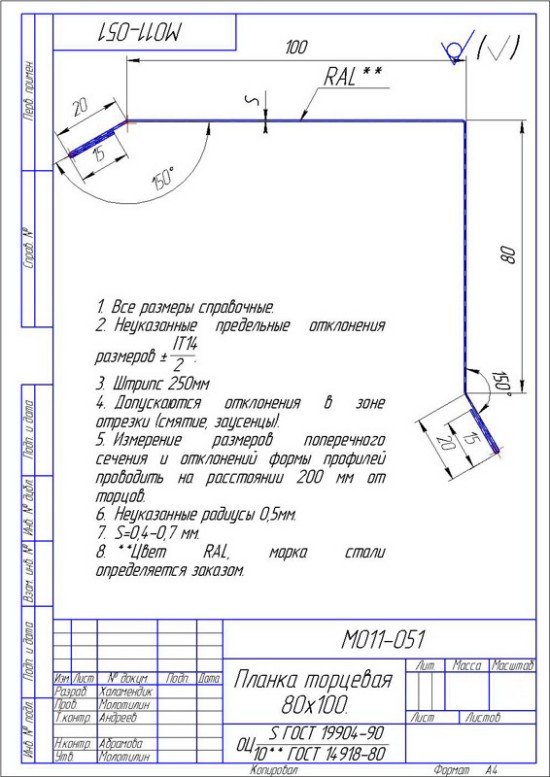

Outwardly, the end plank is no different from the eaves, however, its significant difference from the first is that its fastening is carried out not from below the slope, but on all end parts of the roof. First of all, it is designed to increase the resistance of the roofing pie to wind loads.

Due to the fact that this part completely covers the end of the roof, it provides reliable protection against moisture and wind not only for the under-roofing space, but also for the lathing, as well as for all its other structural elements, both for soft roofs and corrugated roofs.

Thanks to this feature, it got its second name - the wind bar.

The wind bar is an indispensable part not only when used as a corrugated board covering, it is also necessary when arranging a soft roof. It is mounted after the crate has been made, and the waterproofing and roofing material has been laid.

Installation of eaves and end strips

The cornice mounting plate is attached to the frontal board. It should be noted that in this case the frontal board itself is nailed with galvanized nails to the end parts of the rafters. This part has standard dimensions - 100x69x2000 mm. It is very important that the frontal board is positioned as correctly as possible.

Its fastening will not cause difficulties even for novice builders. It is simply nailed to the frontal board with nails in a checkerboard pattern in increments of 300 to 350 mm.

After the first element has been installed, another overlap is nailed onto it. In this case, the size of the overlap should be approximately 10 cm. The last part is carefully cut to size.

The installation of this element for a soft roof is no different from installing it when using metal tiles as a roofing material. Do not forget that the installation of this element can only be started after installation for the drainage system.

After installing this important protective part, you can proceed to laying the roofing.

The end mounting plate is an important element; its installation can only be started after the roofing has been laid. This element, just like the previous one, has standard dimensions - 134 or 145 mm by 2000 mm.

It is mounted above the crate approximately at the height of one wave of the metal profile. Its fastening is carried out using self-tapping screws on the top and side. The upper self-tapping screw presses the part to the corrugated board wave.

The next part will be laid with an overlap of 50 cm and aligned with the roofing, and only after that it will be finally fixed. To increase the sealing end-to-end between the coating and the part, you can lay a layer of some kind of insulation.

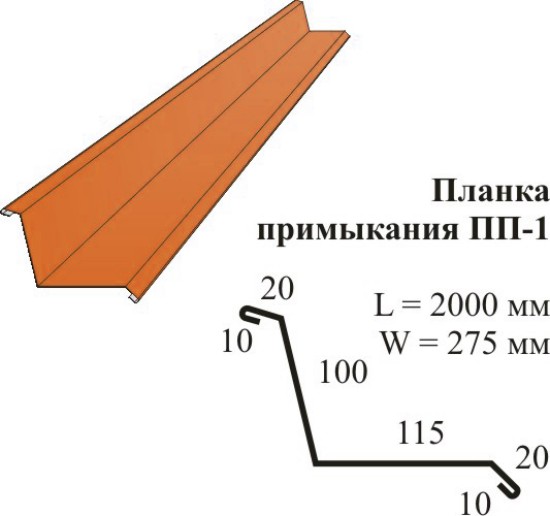

Adjacency bar and its installation

Another name for this part is a clamping bar. It is mounted after laying the roofing and installing the wind bar.

It is intended for mechanical fixation of the valley carpet on a vertical surface, and is also sometimes used to achieve tightness in the area where the roof adjoins the chimneys. Its installation is the final stage in the way of roof installation.

It is installed when the metal tile is already laid and the wind protection part is fixed. Its purpose is to mechanically fix the valley carpet on a vertical surface.

It is also used to create tightness in places where the roof adjoins chimneys or ventilation ducts. The installation of this structural element is the final stage of roof installation.

The cornice strip, like all other protective structural elements of the roof, is necessary to ensure maximum reliability of the future roof. You should not save on the purchase of these structural elements, since their untimely installation will cost much more.

You need to know: