Adjacency strip, adjoining strip for roofing, installation, useful tips

Experienced master roofers rank the work on arranging the areas where the roof adjoins to other elements of the structure as the most important and complex. In fact, it is at the junctions that leaks most often occur, which is why installation work should be carried out in strict accordance with the rules.

Recommendations for the correct execution of work on the abutment of roof elements

Since it is the roof that is obliged to protect the house from the weather and prevent the possibility of rainwater flowing into the building, then the main condition for its creation should be considered tightness. It is quite easy to provide it on flat sections of the roof, problems begin at the interface segments, which, due to their structure, are a place of accumulation of snow and storm water, debris and create increased pressure on the truss system, which over time can lead to seal failure.

A serious attitude to the requirements for the arrangement of junctions is the only factor that can guarantee the integrity of the roof and its long-term operation without accidents and repairs.

During the construction of a brick building, at the design stage, they provide for the construction of a special visor half a brick wide. It is designed to protect the junction of the roof with the wall. There is another option - when performing masonry, leave a shallow recess, such that it can later be inserted into the corresponding elements of the roof. Any chosen method involves, before starting work, to determine the junctions and the technology for performing their sealing.

Adjoining the roof to the wall and its types

The place of joints on the roofs can be:

- top,

- side.

But this is not all, it turns out to be difficult to design connection lines with:

- chimneys,

- ventilation pipes,

- awnings,

- visors, etc.

It is in them that a large amount of melt and rain water, snow accumulates.

The sealing method is chosen depending on what roofing materials are used in the construction of the roof, they should be considered in more detail.

Top junction bar

It is an element of roof decoration and is designed to decorate the joints of pipes, ventilation and smoke, parapets, house walls with sheets of metal. For the manufacture of junction strips, metal is used, painted in the same shades as the roofing material. Such a bar can be used if the roofing material is:

- corrugated board,

- metal tile,

- flexible tiles.

Scope of use of the upper junction bar:

- at connection points with vertical walls,

- at the junction of the roof with the gable,

- for sealing roof joints with pipes for various purposes, turrets, and other decorative elements,

- when working with siding - for arranging joints with a parapet and a plinth.

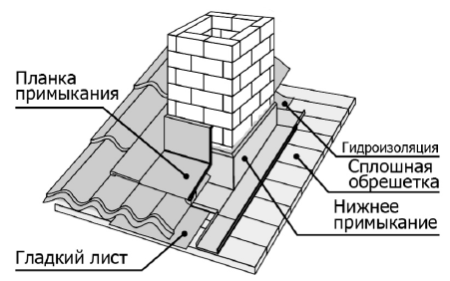

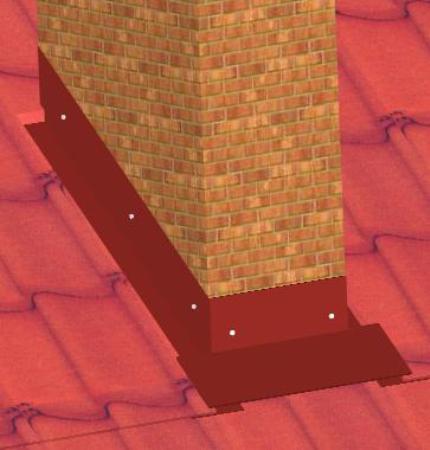

Masters advise to pay maximum attention to the arrangement of the junction with the pipe - this place is most often at risk of leaks. To ensure the tightness of this joint, aprons, internal and external, are equipped on the roof slope.

The installation of the inner apron is carried out using the lower junction bar, then sheets of roofing material are laid and fixed.

Its installation is carried out similarly to the internal one, but the upper edge is fastened directly to the wall, and not to the strobe.

The sequence of installation work is as follows:

- Having attached the lower junction bar to the pipe wall, they beat off the upper edge, along this line with the help of a grinder they make a strobe, while making sure that it does not pass along the masonry seam - this is strictly prohibited!

- After laying the strobe, it is cleaned of dust and washed with water. The depth of the strobe should be about 15 mm, it is desirable to give it some upward slope.

- The next stage is fastening, trimming the planks is carried out in place, fastening is done with self-tapping screws. In the same way, the apron is mounted on all sides of the chimney; the overlap during installation should be about 150 mm. This will prevent leaks. A heat-resistant sealant can be used to seal the edges of the plank.

The use of upper joining strips gives each processed joint a more decorative look. The installation of these elements is carried out on top of the laid roofing material, the overlap must be at least 100 mm. The strap is fastened with self-tapping screws, the pitch is about 300 mm. The upper edge of the junction bar is attached to a pipe or other roof element, its lower edge descends onto the roof in the form of an apron.

Firms engaged in the manufacture of adjoining slats, in addition to standard ones, can produce profiles of additional elements for individual orders, the required sizes and colors, original shapes, in accordance with design sketches.

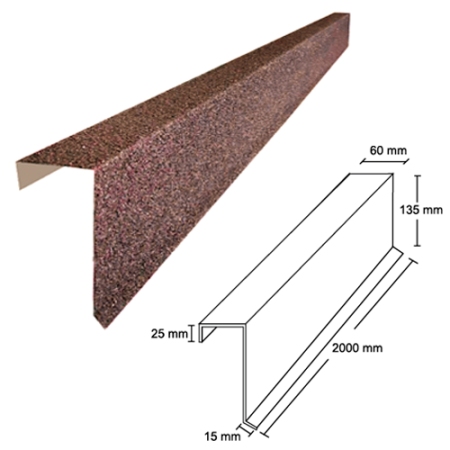

Roof junction bar lower - in what cases will it be required to use it

![]()

With its help, docking of individual sections of the roofing is performed:

- for water drainage in the corners of the junction with the pediment,

- for sealing the joints of the roof with chimneys, other functional and decorative elements of the roof rising above the roof.

The lower junction bar is also used when decorating the walls of the house with siding. The junction bar is used for metal tiles, soft roofing and corrugated board. When performing roofing work, both the upper and lower strips are usually used, only the installation of the upper one is carried out after laying the upper layer of the roofing system, the lower one is brought under the roof layer with one edge.

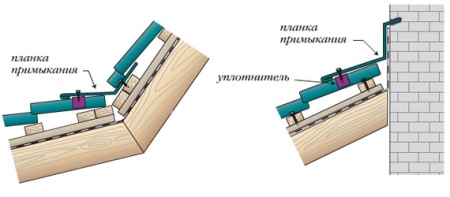

How to properly equip the breaks of the roof and the junction of metal tiles to the walls

One of the conditions for the correct arrangement of a broken roof with a covered metal tile is the maximum approximation of the boards of the crate to each other. The metal tile sheet that will cover the fracture should be pulled out so that it silently covers the fracture. In this case, a cornice strip can serve as an abutment for a metal tile; a layer of universal sealant should be laid between it and the tile sheet. If the fracture of the tile is in the opposite direction, then the mating of the planes is made out with a plank adjoining the wall, laying it on the lower slope with the rolled side. The maximum approximation of the boards of the crate in the places of fractures is also necessary. It will be necessary to install a layer of universal sealant, it is manufactured by manufacturers of roofing materials.

In a similar way, the place of junction with the walls is drawn up, while the waterproofing is removed, then it is lifted onto the wall to a height of about 5 cm, depending on the type of junction, side or end, a profile or universal seal is installed.

Adjoining strip for shingles

For its production, steel with a thickness of 0.4 to 0.5 mm, galvanized or polyester-coated, is used. The development of the junction bar for flexible tiles is 78 mm, the length is two meters. Its installation will be necessary in areas where the roofing material adjoins walls or chimneys.

This site is located in a zone of special risk and it is best to plan the creation of enhanced protection from precipitation on it from the very beginning. The installation of the roof in these places is carried out with the installation of an abutment strip, which helps to create an abutment of the roof corners to the wall and serves as additional waterproofing.

You can learn more about the rules for performing work on the video: