Overview of prices and characteristics of wind strips for corrugated board

In the total mass of roofing metal, additional elements make up about 3%. At the same time, their installation is the finishing operation of the installation of the roof, giving it a finished look and ensuring the functional readiness of the entire structure to perform the tasks assigned to it.

Proper installation of additional elements connects all the elements of the roofing pie into a single whole, due to which the upper structure of the building acquires the ability to reliably protect the house from external factors. The price for each element separately depends on the complexity of its design, but their acquisition is inevitable due to the importance of the functions performed.

Types and purpose of additional elements

An important factor in the correct selection of these details is the color scheme of the structure as a whole, therefore, when purchasing them, this property is one of the decisive ones. As a rule, additional elements come complete with a roof, made of a material of the same color.

All finishing work is carried out by installing closing parts that give the roofing pie solidity. For corrugated roofing, they are:

The material for these parts is a galvanized sheet with a thickness of about 0.5 - 0.7 mm. To improve the performance and anti-corrosion properties of the material, the surface is additionally covered with several layers of special dyes or polymer films. The price is presented to the consumer for each type separately, and not for a set. Therefore, there are no problems in the form of buying parts that are unnecessary for the roof structure.

Purpose and installation location of the wind bar

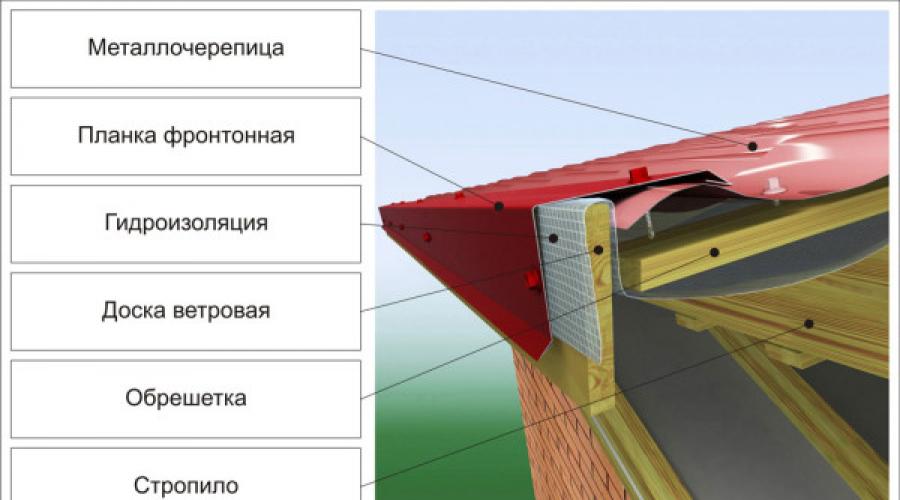

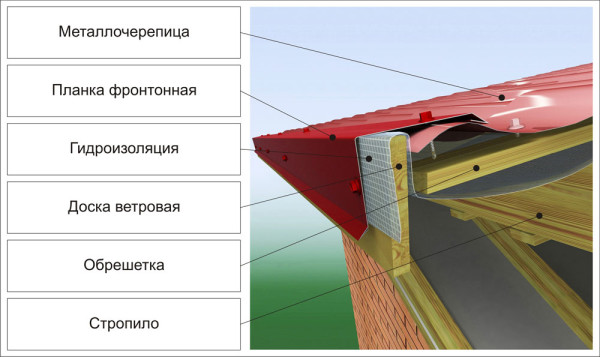

The wind strip for corrugated board is designed to protect the side ends of the roof from wind influences, while closing the gap between the roofing material and the end board of the formed roofing cake.

The design and dimensions of the part depend on the size of the selected profiled sheet, as well as the device for the roof overhang. It should be taken into account that the overlapping element captures at least two protrusions of the corrugated board along the length.

The corner is fastened to the roof lathing on a horizontal surface and to the end board that closes the roofing pie. This creates a monolithic roof. When installing wind strips, it is desirable to use additional seals at the joints of parts.

It is best to fix the wind bar with self-tapping screws of the appropriate size with the obligatory use of rubber gaskets or polyurethane washers under the fastener heads. The screws are preferably selected with hexagonal bolt heads. To preserve the aesthetics of the roof, they are also selected according to the color of the protective coating. The distance between the screws must be at least 400 mm. The overlap between the individual corners is at least 100 mm, while fixing through two metals is mandatory.

The standard length of the wind bar is 2000 mm. The size and shape of the shelves depends on the type of corrugated board chosen.

Installation is carried out from the bottom up along the edge of the roof slope with an overlap. The installation order is the penultimate operation before installing the ridge trims.

If it is necessary to cut a part, the ends of the cut must be painted over with a paint of a suitable color. If a gap occurs at the junction with other parts, it must be closed by bending the mating parts or an additional part of the desired shape. When purchasing roofing material, it is advisable to take care of several small pieces of corrugated board material from trimmings in production waste.

Purpose of the wind bar:

- protection of the under-roof space from water and wind at the junction of the roofing material to the end board, as well as from nesting birds and the penetration of small animals such as martens;

- additional reinforcement of corrugated board along the edges of the roof, which is especially important in areas with strong winds;

- fixing soffits, if any, are provided for in the roof structure;

- decorative design of the end elements of the roof sections, edging of the gables.

Cost indicators for wind bars

The price of these products depends on several factors, including dimensions and designs.

Comparative table of the cost of wind bars

| Image | Manufacturer | Price | Notes |

| Decking MD Moscow |

Price 55 r / m.pg = | For standard sizes 40×60 mm with drip | |

| Software "Etalon" Moscow |

The price from a type of a covering, r/piece - galvanization-340; Polyester premium-336; |

||

| TD "ADS-Metal" | Price 292 r / piece | Catalog color | |

| "Metallic and Co" | 192 r / piece | Catalog color | |

| Promintech company | 312 r/pc | ||

| DMD Industries Moscow | Produced in lengths of 2 - 3 - 4 meters | ||

|

Siberian Roof House Novosibirsk | From 380 r / piece | Depending on the coating, colors according to the catalog |

| Group of plants "Metalkomplekt", Kirov | From 390 r / piece | Length 2500 mm, depending on the coating in the catalog |

Considering the data in the table, we can conclude that the price of the main indicators on which the price of a product depends is the characteristics of the coating and the metal content of the parts.

Regional cost differences are insignificant and depend on logistics and market needs.

Conclusion

Modern trends in the construction of suburban housing tend to create reliable sealed roofs using various insulating materials. In this regard, it became necessary to use counter-grids that create reliable and efficient blows. And the use of insulating materials, especially fibrous ones, places high demands on the tightness of the upper structure of the roofing pie. If moisture gets into it, manifestations of rotting and molding of heaters, the development of various fungal infections in the wood of the rafter system and the crate are possible.

The tightness of the roofing cake is ensured by a system of additional elements, the correct installation of which ensures this requirement.

No matter how high the price of these parts may seem, they must be purchased in optimal quality and the right quantity. Otherwise, such "savings" may result in the cost of a complete alteration of the roof.

A warm roof, even if it is installed in a non-residential attic, provides energy savings of about 15 - 25%, which will gradually justify the costs incurred for its installation.

We hope that the information provided will be useful. And in the next short video - a brief instruction for mounting the wind bar.