The nuances and subtleties of laying porcelain stoneware

Porcelain stoneware itself is a durable material even during operation, especially when used as a floor covering, significant loads arising from the operation of the floor do not cause damage to it. However, it is possible to fully use all the possibilities of this material only if it is properly installed.

Therefore, the correct laying of porcelain stoneware is an extremely important and responsible stage of work, which largely determines its further successful operation.

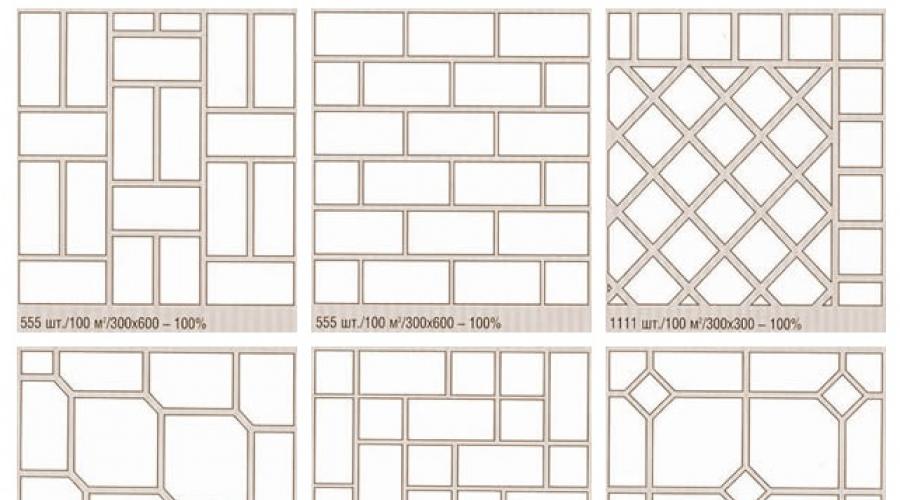

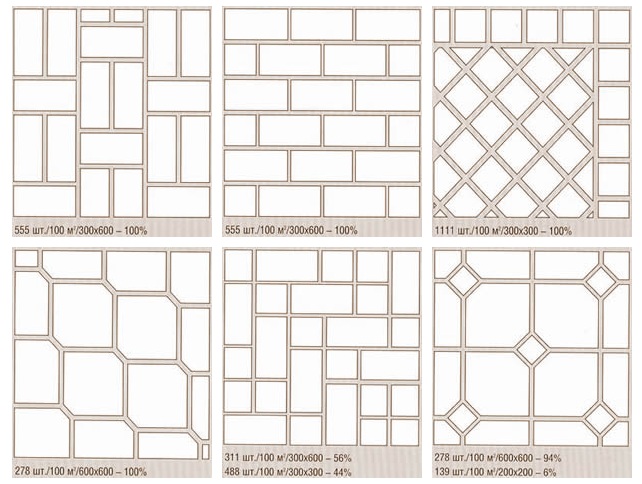

As usual, any work begins with a project. In this case, it is necessary to decide on the scheme for laying porcelain stoneware. The required number of tiles and its dimensions will depend on this. The fact is that tiles can be laid in various ways, creating a real mosaic on the floor, and porcelain stoneware of different colors can be used in it. Below are drawings showing some possible examples of porcelain stoneware installation, as well as the required number of tiles and their dimensions.

Porcelain stoneware tile options

Of course, the examples given do not cover all possible options for installing porcelain stoneware, everything here will be determined by your imagination. You can do it simply and lay porcelain stoneware on the floor in rows. But this is a personal choice for everyone.

The most important thing here is different. It is necessary to determine the method of installation - whether porcelain stoneware will be laid without joints, or whether the usual method of laying with joints will be used. It depends on this choice which porcelain stoneware you need to buy - rectified or ordinary.

In addition, it is necessary to estimate the required number of tiles per 1 m2 and determine the required amount of porcelain stoneware, and then increase it by (10-15)%. This is due to the fact that when porcelain stoneware is being laid, additional unaccounted for consumption, defective tiles, as well as trimming, fitting tiles in place are possible.

It is also important to determine the laying technique - the thickness of the adhesive, the width and direction of the joints (straight, zigzag, etc.) between the tiles or choose that the laying of porcelain stoneware will occur without joints, as well as determine the required amount of work to prepare the surface. The result of such a study should be a set of tasks, as a result of which the desired surface of porcelain stoneware is obtained.

After clarity has come with the required number of tiles, you can proceed to the choice of the material itself. In the event that the laying of porcelain stoneware on the floor will be carried out in the bathroom, hallway, kitchen or toilet, it is better to use tiles with a rough surface. On such a tile, there is less chance of slipping and getting injured.

First of all, you need to pay special attention to two things - the caliber and tone of the tile. Under the caliber is understood the discrepancy between the geometric dimensions of the tile. So, for example, a 300x300 tile could actually be 298x298 and 302x302 (rounded values). This is due to differences in the properties of materials (clay) obtained from different deposits.

Typically, the manufacturer selects tiles of the same size and completes them together, so that there are tiles in one pack, for example, 298x298. This is the caliber.

And if laying porcelain stoneware on the floor of similar sizes is still somehow possible (compensation for the size of the tile occurs due to the thickness of the seam), then with large discrepancies, the installation of tiles of different calibers is simply impossible. And often there is a situation when tiles of the required caliber are not available, because the factory does not specifically produce such sizes, they are obtained during the selection from the finished product.

Therefore, when choosing a tile for laying porcelain stoneware on the floor, it is imperative to choose a tile of the same caliber and take it with a margin, because. re-finding the same may be simply impossible.

Another, no less important, feature when choosing tiles for laying porcelain stoneware is the selection of tiles by tone (shades of color). This, like the caliber, is due to differences in the properties of the original components. As a result, the color of tiles from different batches will vary, and this must be taken into account when choosing a tile.

Manufacturers, when picking a batch of products, select by tone, but laying porcelain stoneware to achieve the desired surface quality (no color spots) should be done with tiles of the same tone. The selection of tiles of the same tone is carried out when buying it.

Quality work requires quality tools. Porcelain stoneware tiles are no exception. This will require:

- container for diluting glue;

- drill with a nozzle for preparing glue;

- tape measure (ruler) to perform the necessary measurements;

- level to check the horizontalness of the laid tiles;

- Master OK;

- putty knife.

First of all, you need to apply glue. Considering the task of how to lay porcelain stoneware on the floor, you need to remember that porcelain stoneware does not absorb moisture. Therefore, when working, special glue is used. The use of cement mixtures is impractical, because. they do not provide a strong fastening of the tiles. To ensure the required strength of the joint, adhesive manufacturers add special additives to its composition that increase adhesion to the surface of porcelain stoneware.

To make the laying of porcelain stoneware tiles even and beautiful, special crosses are used during installation to create permanent gaps between individual tiles, which are removed after installation is completed.

When the tile is fixed, the formed seams are filled with a special grout.

If you look at the arrangement of porcelain stoneware floors, then there is nothing complicated about them. A layer of glue is applied to a concrete surface (or any other - drywall, plaster, boards), on top of which porcelain stoneware is laid. However, to ensure a high-quality and durable coating, the surface must be prepared.

In this case, the determining factor will not be how to put porcelain stoneware on the floor, but where to put it. If the floor surface is uneven, then it must first be leveled, for which it is necessary to remove the protruding sections of the surface, seal the seams, cracks, depressions and depressions. Contaminants present on the ground must be removed.

After the floor has been prepared in accordance with the recommendations described, it must be primed. It is necessary to use a primer intended for the floor material.

Although this does not directly apply to surface preparation, before laying porcelain stoneware on the floor, it is necessary to assess the environment. It is not recommended to carry out tiling work at temperatures below 5 ° C, especially if the work will be carried out outside the building. Also, work should not be carried out if the heating is turned on, especially underfloor heating.

After the completion of the preparatory work, you can begin to lay porcelain stoneware, how to lay it was decided at the stage of project development. Yes exactly. This is achieved, in particular, by the fact that the laying starts from the middle of the room and is carried out symmetrically relative to it. The line of symmetry is best marked with twine. This is done so that the whole tile is located in the center of the room, and the cut one is located at the edges.

First, a solution is applied to the surface, to a small area.

Before laying porcelain stoneware, the adhesive is leveled with a smooth trowel, it must be held at an angle of approximately 45° to the base. The resulting smooth surface is then processed with a notched trowel, as shown in the photo.

You can lay tiles as shown in the photo below. If the tile is covered with a protective layer, which is applied by the manufacturer to preserve the porcelain stoneware during transportation, it must be removed using cleaning solutions.

After laying, the tile must be slightly moved away from the adjacent one, while the gap between the tiles must remain free of glue, unless, of course, seamless porcelain stoneware installation is used.

A constant clearance over the entire surface is ensured by the use of crosses. The gap must be at least 3 mm.

The laid tile is checked by the level for correct laying and, if necessary, leveled.

After the entire tile is laid, it is necessary to withstand the lined surface for three to four days until the glue hardens.

When the adhesive layer has gained strength, proceed to the grouting. The color of the grout is selected depending on the width of the joint and the color of the tile. Usually, experts recommend using gray grout as less easily soiled. For grouting, a rubber spatula is used to apply the grout and remove its residues.

Grouting on porcelain stoneware

Before applying the grout, make sure that the joints do not contain adhesive residues. The grout is diluted with water to the required consistency and applied over the lined surface. When the grooves are filled, its excess is removed with a spatula with a sponge.

The finished surface is wiped with a sponge dipped in a cleaning solution, trying not to wash the grout out of the joints. After two weeks, the surface can be washed with the usual detergents. Additional information on how porcelain stoneware is laid -

On the wooden floor

Porcelain tiles can be laid not only on a concrete floor. Using special techniques and technologies, it is possible to lay porcelain stoneware on a wooden floor.

To do this, the coating is initially removed, and the logs are set strictly horizontally. They are impregnated with antiseptic compounds. Expanded clay is poured between the lags to the upper level, and then, with the help of self-tapping screws, a “rough” board is attached with a gap of five to ten millimeters.

Waterproofing is laid on top of the “rough” floor. Then you can create the base itself, on which the tiles will be laid in the future.

Further, two different options are possible. A metal mesh is located on top of the subfloor and is fastened with self-tapping screws. Then beacons are set up, along which a cement screed is poured, forming a horizontal plane. You can also use self-leveling compounds. When the screed hardens, you can mount porcelain tiles.

In another option, the so-called dry screed is used. In this case, sheets of moisture-resistant drywall, gypsum fiber sheets or cement-bonded particle board are laid on the waterproofing. Sheets are arranged in several layers and are attached to the floor with self-tapping screws. After that, the surface is primed in several layers.

Porcelain stoneware can be placed on a surface prepared in this way. When choosing glue, you need to pay special attention to whether it is suitable for working with drywall.

On plywood

It is quite possible to lay porcelain stoneware on plywood. With this option, plywood should be located on the logs with a small step. The thickness of the plywood layer must be sufficient, at least 30 mm. Plywood must be firmly attached to the joists, ensuring a snug fit over the entire surface. The resulting surface is polished, debris is removed, and the seams are sealed.

After that, the plywood is primed twice, and when the second layer of primer dries, the installation of tiles can begin. In this case, it is necessary to use polyurethane adhesive, used when laying parquet.

As already noted, despite the excellent characteristics of porcelain stoneware, the quality of the resulting coating will largely depend on its installation. Experienced tilers know all the subtleties and nuances of the process, and they will ensure high quality work. The cost of laying porcelain stoneware on the floor will depend on the amount of work.

It is common practice to provide discounts when the volume of work increases. If porcelain stoneware is being laid, the price for large volumes (in square meters of surface) will be per square meter. meter less.

Of course, this is a matter of personal choice, to do the styling on your own or use the services of masters. Moreover, it is sometimes quite difficult to find qualified craftsmen who are able to perform complex work with high quality. And, nevertheless, given the durability of the porcelain stoneware coating, the cost of purchasing materials, the cost of laying porcelain stoneware may not be prohibitive in comparison with them.

At the same time, trusting the masters of laying porcelain stoneware, the price of whose services, among other things, depends on their qualifications and available recommendations, it is necessary to present the total scope of work and the stages of its implementation. This will allow you to control the process and get the desired result.

Laying tiles, despite its outward simplicity, is associated with many nuances and subtleties of the process. Nevertheless, it is precisely this that allows you to fully reveal the possibilities of porcelain stoneware and get a coating that is unique in its technical capabilities, creating a vivid and unforgettable impression with its beauty and originality.