Soft roofing and its installation. Types and how to lay

Which roofing coverings were the most popular just recently?

This is the well-known slate, galvanized steel and. To carry out roofing work, a whole working team was required, since all the necessary activities took a significant amount of effort and time.

The emergence of modern new generation materials has made it possible to significantly simplify these procedures.

Advantages of a soft roof

Soft roofing is superior to many other materials in its technical and performance qualities. It is one of the most popular various configurations.

Soft roofing is superior to many other materials in its technical and performance qualities. It is one of the most popular various configurations.

What properties does this material have?

- Light weight ensures a reduction in the load on the building as a whole and on the roof structure in particular.

- Excellent sound insulation properties They make even the sounds of hail or rain inaudible for the inhabitants of the building.

- Tightness guarantees excellent protection of the house foundation, walls and roof space from winds and moisture.

- Wonderful appearance. This coating looks elegant and quite status-worthy, in no way inferior in appearance to natural tiles.

- Significant periods of use. Such coverage lasts for about thirty years on average. Naturally, it needs ongoing repairs and preventive maintenance.

- Simplicity and ease of installation, as well as subsequent maintenance. Even one person can handle the job, requiring only a few days to complete the work.

What is this wonderful soft roof?

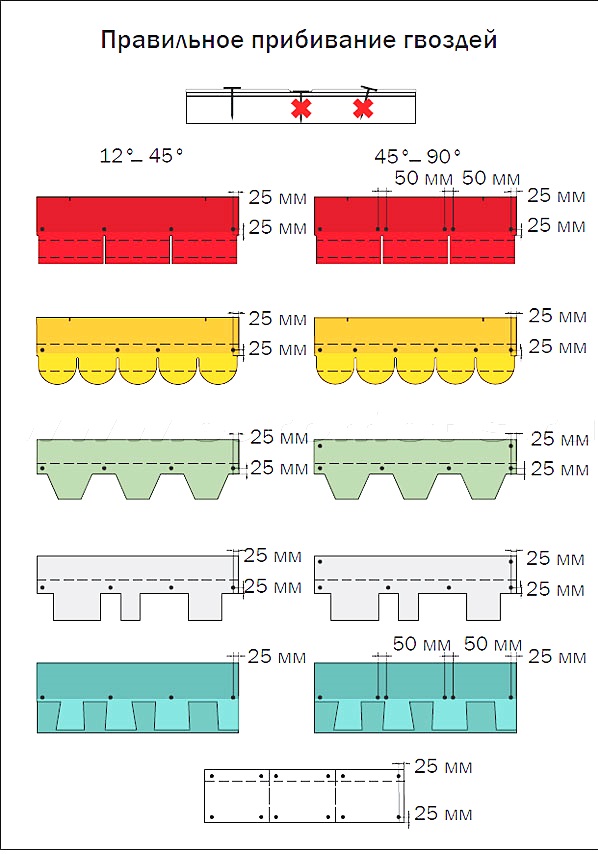

It is important to consider that it is recommended to install soft roofing on pitched roofs with a slope angle of more than eleven degrees. The maximum size of the angle of inclination can be any; its value is not limited.

DIY roofing

As noted above, one person can handle the installation of soft tiles.

![]() What materials and tools will he need?

What materials and tools will he need?

- Directly roofing material.

- Trowel and mastic for gluing.

- High-quality sealant for treating areas of coating adjacent to walls and pipes, as well as for finishing connecting seams.

- Sharp knife.

- Roofing nails and hammer.

- Pencil and plumb line.

- Trims for neat finishing of ends and cornices.

- Gloves.

Preparing to lay a soft roof

What is the main difference between soft tiles and other roofing materials?

What is the main difference between soft tiles and other roofing materials?

- The fact is that this type of roofing must be laid on a solid solid base.

Let’s say it is successfully mounted on timber, and the gaps between the individual beams do not in any way degrade the quality of the coating. - But it does not have a fixed rigid structure, like metal or like.

It has to be mounted on special boards (oriented strand boards), on a tongue-and-groove or edged board, or thick moisture-resistant plywood. - If boards are preferred as a base for soft tiles, then it is better to buy them in the winter and use them in the summer. This is what experts advise.

It will benefit from “resting” in the stack for a certain time, during which time it will acquire the required level of humidity. Ideally, it should be 20 percent. It is better to choose boards about 10 cm wide; it is more convenient to use material of approximately the same size.

If the developers plan to equip a warm attic, then the “pie” of the roof is not enough with just a hard base and soft tiles. You will also need the necessary layers, arranged in the following order from the inside of the structure to the outside:

- A special waterproofing membrane laid on top of the rafters;

- A layer of basalt or mineral wool as a layer of thermal insulation;

- Vapor barrier layer;

- Lathing required for installing the base of a bitumen roof.

Features of a soft roof device

Before you begin laying and strengthening the roofing material, you need to carry out a number of mandatory measures to strengthen individual areas.

Installation of under-roof carpet

This is a kind of non-woven fabric impregnated with a bitumen mixture and treated with a special coating. It is located on valleys, roof ends and eaves. It is usually purchased in the same color as the main roofing material.

This is a kind of non-woven fabric impregnated with a bitumen mixture and treated with a special coating. It is located on valleys, roof ends and eaves. It is usually purchased in the same color as the main roofing material.

- The canvas is carefully glued with an overlap of 15 cm horizontally and 10 cm vertically, in the direction from bottom to top.

- All joints of the product are well coated with mastic. The ridges should have 25 cm of under-roofing carpet, and 50 cm on the sides of the valley.

- Cornice overhangs and ends are finished with it to a width of 40 cm.

- Secure the carpet with large roofing nails at a distance of 20 cm from one another.

- It is necessary to install steel eaves strips on the eaves overhangs, on top of the roofing carpet.

- Special pediment strips are mounted and secured at the ends of the roof.

Soft roof in winter. Prerequisites for installation

Regardless of whether the roofing is installed with your own hands or by specialists, the working surface must always be clean and dry. This is an indispensable condition!

What else is important when laying a roof in winter?

- It is advisable that all necessary work be carried out exclusively in relatively warm weather. Temperatures should not fall below 5 degrees Celsius.

- In cases where there is an urgent need to carry out work in winter, you should use special hot air heating pad. In addition, the roofing material stored for work must be kept in a room with a positive temperature (close to room temperature) for several hours.

- A freshly laid bitumen roof needs warmth.

Why does she need it? The fact is that on the inside, each shingle (a sheet of three or four separate tile petals) is equipped with a self-adhesive bitumen lining. And although it (shingles) is nailed to the base of the roof structure, its individual components are glued together under the influence of solar heat.

They are also firmly soldered to the roofing base.

In cold weather this is impossible, so the reliability and tightness of the roofing will noticeably suffer. - During the laying process bitumen roofing must be used from several different packages at the same time.

This is required so that there is a uniform alternation of shades of materials. Standard packages may vary slightly in color. Knowing this and specially combining material from different packs, you can get an original design. In addition, if repairs are required in the future, it will be easier to select pieces of a suitable color.

Ventilation for soft roofs

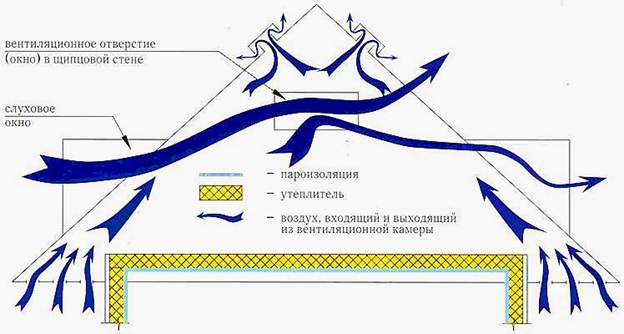

The installation of a soft roof is a multi-stage process, including several stages. One of the first is to equip a reliable ventilation system. Experts are well aware that poorly ventilated (or unventilated) roofing often causes rapid damage to rafters.

Condensation accumulating on the roof, rot and mold, icicles and ice - all these unfavorable factors contribute to the fairly rapid destruction of the rafters.

How to avoid this?

Special vents and ventilation outlets under the eaves, as well as a pre-designed gap between the tiles themselves and the base of the roof, provide excellent air circulation to the under-roof space. They also do an excellent job of removing water vapor.

Do-it-yourself mastic for soft roofing

This polymer bitumen material is necessary for laying the outer layer of soft tiles. With its help, an elastic, uniform coating is formed that can withstand mechanical and temperature deformations of the base. According to the technology, when laying a soft roof, hot and cold mastics will be required to fix the rolled material on the roof.

Traditionally, cold compounds are used for the internal parts of the coating, while hot ones are used to coat the outer layers. Bitumen and roofing felt are cold types of mastics, roofing felt and tar are hot types. The composition of the substance used, in addition to bitumen, must include a dust-type filler or made of fiber. Ash, lime or gypsum are often used as dust materials.

The highest quality mastics contain polymers. You can buy a ready-made composition, but if you wish, it is quite acceptable to make it yourself. There is nothing complicated about this.

Cold mastic:

- For this you will need bitumen and filler for it.

- You need to take two containers, in one of which you need to place two portions of bitumen, in the other a couple of portions of diesel fuel and one filler.

- At the same time, both dishes need to be heated to a temperature of 180 degrees.

- When the water finally evaporates from the container with bitumen, the contents of both are mixed.

As a result of such actions, a cold product is obtained.

To make hot mastic:

- Filler is carefully added to bitumen heated to 200 degrees in small portions. The process must take place at a temperature of at least 160 degrees, this should be closely monitored.

- After uniform mixing, the product is ready. You can also check its quality yourself.

- The composition heated to 60 degrees is applied to a slope having an angle of 45 degrees.

If the mixture is good, it will not drain from the inclined surface. After hardening, the product will remain smooth, without defects or cracks.

Soft roofing technology

During the work process, you should follow simple rules. It is best to place individual roofing sheets in different rows so that the joints are aligned. In other words, this is called taking a running start. This type of flooring significantly improves the moisture-proofing qualities of the coating.

Each new layer should lie on the previous one with a good overlap of at least 8-10 centimeters. In those places where the coating comes into contact with pipes and other communications, as well as with the edges of the roof, the material is cut to shape. The edges of the roof are securely glued using mastic.

It is not at all difficult to lay a roofing carpet around antennas, chimneys and other communications if you measure and calculate everything in advance and apply the necessary markings. The so-called pass-through elements necessary for this should be ready. The joints between the pipes and the roof itself are reinforced with the special under-roofing substrate mentioned earlier, and then covered with the same mastic.

The tiles are already laid on it, then the passage elements. It’s a good idea to treat the joints with sealant. When the soft roofing covering is installed up to the roof slope, special elements called ridge elements will be required. With their help, the tops of the slopes are covered, they are secured with mastic and secured with nails.

From all that has been said, we can draw a conclusion. Modern soft roofing is a wear-resistant and easy-to-work material that has a very affordable cost.

Subject to strict adherence to flooring technology, as well as the purchase of high-quality materials, you can be sure that the resulting roof will not only be attractive, but also functional and reliable protection for your home.