Eaves strip for metal tiles

Such material as high-quality roofing metal tiles has been holding one of the first places in the modern range of universal roofing materials throughout Russia for quite a long time.

One of the most important elements of this roofing are these types of wooden planks:

- Wind, which is also used when working with modern metal tiles;

- Cornice is in demand;

- Special bar for wall and pipe connection;

- Konkovaya.

Installation of a roof covering with simultaneous installation of a covering, such an element as an adjoining strip, as an end strip for a metal tile, just like a cornice and a ridge one, plays a very important role. It is directly responsible for the most reliable and long-term operation of the entire roofing part of the structure.

Modern cornice strips, which are intended for roofing material, as well as wind structures, are made from high-quality materials. They are similar in their properties and structure to the coating used, the installation of which is used in the construction of the roof.

The main feature and structural detail of these structures is galvanized steel. Its thickness must be approximately 0.5 mm. There is also a high-quality rust-resistant coating. There are several main functions that these strips for roofing metal produce, they are expressed in such important factors:

- The cornice strip is designed to effectively protect such a structure as a frontal board, which is characterized as a high-quality cornice. This is necessary to protect and prevent the process of water penetration during heavy precipitation. Thus, this element effectively protects against the ingress of water into the space present under the roof.

- The end, according to the features of its production, is a bit like sheets of metal, therefore it is attached to the ends of the roof slope. The design serves to effectively protect the crate from moisture, and also most effectively levels the load from strong winds.

Important! It is high-quality protection from the wind that characterizes this element as a wind bar. Many modern specialists, for whom its installation is a common service, that is what they call it.

- An element such as a ridge strip can, if necessary, take on a variety of forms, therefore it serves to protect the common space under the roof with high quality. This will protect against the penetration of a large amount of precipitation at the place where the convergence of the slopes is present.

- A special junction bar is a universal element that has not only a protective function, but also a decorative one.

Such information will help to make the choice of the bar as reasonably as possible. This will be exactly the element that best suits a particular structure.

The process of fastening the strap should be carried out according to the following small instructions. Installation work consists of several main stages:

- First of all, a special frontal board is installed. It is attached to the end parts of the truss system by using special nails, preferably galvanized. As an alternative, a special cornice junction board can be used, it has a strong fastening located in recessed grooves in the rafters.

- The next step will be the installation of the filing, which is carried out using a special, high-quality tongue-and-groove board. It is also acceptable to use high-quality corrugated board.

- A strong support beam is attached to the wall surface of the house, which will play the role of a special high-quality support for the subsequent installation of the hemming part of the overhang located on the eaves.

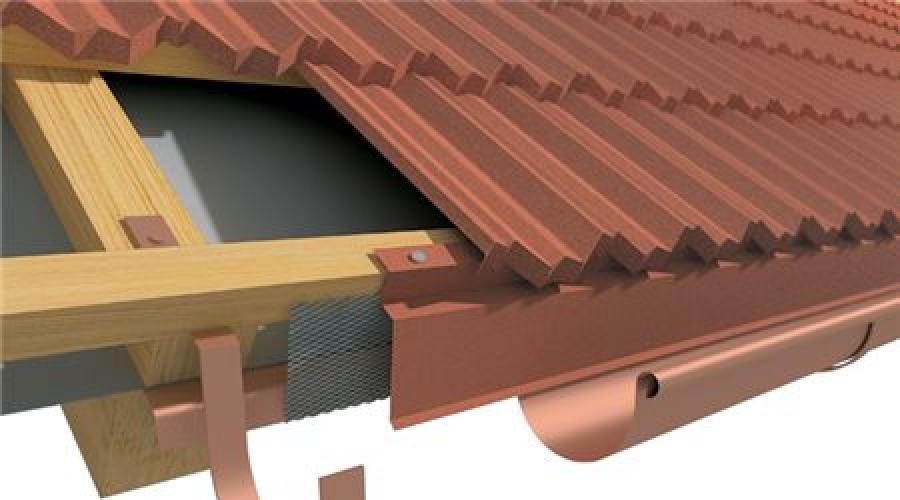

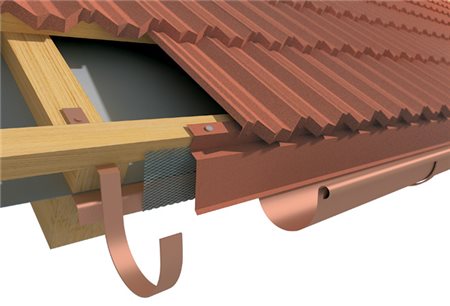

- Before mounting the junction bar, you will need to install special durable brackets designed for the water drainage system. They usually have a quality mount.

- Only after that, you can begin the installation of the cornice strip itself. It is usually fastened in front of the roofing deck, as well as roofing sheets.

Installation is made on top of a special mount. For installation, self-tapping screws are used, which are screwed into the cornice board. It is worth observing the step located between the screws used, which is usually about 30 cm.

Important! In the process of building up the mounted cornice strip, a small overlap is required. Its dimensions should be less than 100 mm.

The installation and all installation work of the end strip is usually started immediately after the installation of the roofing material made from the sheets of the used metal tile has been completed. Its high-quality fastening is carried out as follows:

- The wind bar for metal tiles is mounted strictly at the height of the wave located in the vicinity of the roof sheet. When carrying out such work, it is necessary to take into account the factor that the corner of the end part of the roof to be equipped must be blocked in a special way;

- A special bar of the end plan is fixed on the top or on the sides. A similar process is carried out using special screws. Such high-quality fasteners as self-tapping screws are usually mounted on top of the wave crest of the metal tile element;

- In the process of building up such a structure as a wind bar, it is imperative to make a special protective overlap, reaching 100 mm;

- Without exception, all abutment joints located between this element and the high-quality coating itself must be carefully sealed.

It is worth noting that the plank of the end plan, in addition to its main protective functions, plays a serious role in the design of the roof. Therefore, this structural element must be fixed in such a way as to effectively cover the wave crest.

Otherwise, there will be a chance that water will get under the metal tile. To avoid this circumstance, it is necessary to flang the roofing material, its upper edge of the junction, strictly up.

Following the above instructions will allow you to install the strips quickly and efficiently. Also, following the basic recommendations is able to provide significant time savings.