What boards for roof rafters. How to make a roof sheathing from a board for the roof of a private house

A roof for a house made of timber can be installed of any type: gable, four-slope, mansard, multi-gable, etc. Most often they make a double-sided one. It's easier and more economical.

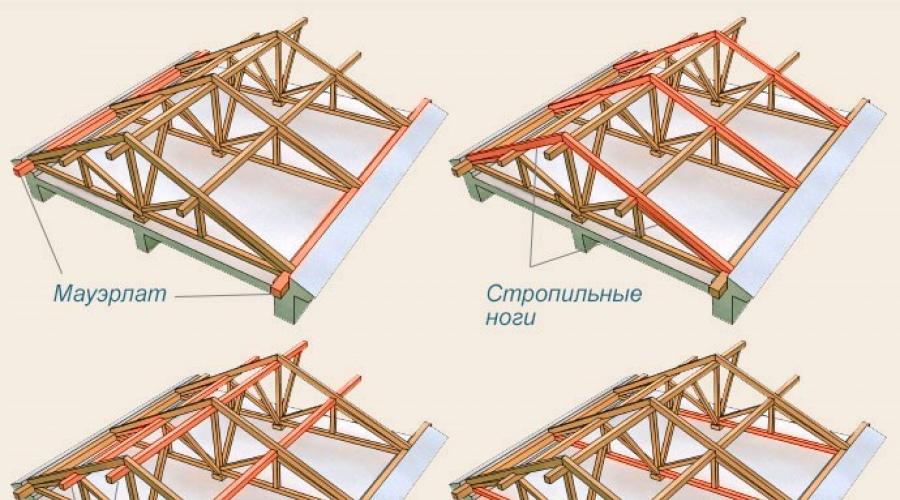

roof elements

Rafters for the roofs of houses of this type are made of bars measuring 100 × 50, 150 × 50 or 200 × 50 millimeters.

The exit of the rafters outside the wall must be at least thirty centimeters, so that subsequently the water flowing from the roof does not fall on the walls, leading to their destruction.

The crate can be made from a 25 mm board, and the counter-lattice from a 40 × 50 mm beam.

The roof must contain in its design skates, crossbars, sills, vertical posts, struts, puffs, a chimney, as well as a drainage system.

The roof of a house made of Mauerlat timber is not needed, the main thing is to install a stretch to reduce pressure on the walls. Mauerlat will be the top bar.

Roof ridge

A ridge is a horizontal roof element, which is formed at the junction of its two slopes.

A ridge is a horizontal roof element, which is formed at the junction of its two slopes.

Sometimes a beam is called a ridge, which is fixed on vertical posts resting on floor beams or puffs. The rafters, in turn, rest on this beam.

There is another version of the ridge - when at the top point the rafters are sewn up with boards, forming a ridge element.

Roof ridge

Someone shares the concept of a roof ridge and a roof, someone does not. A roof ridge is a coating that closes the gap at the top point, which is formed after laying the roofing material. The material of the ridge element is the same as that of the roof. This element can be of any shape.

Someone shares the concept of a roof ridge and a roof, someone does not. A roof ridge is a coating that closes the gap at the top point, which is formed after laying the roofing material. The material of the ridge element is the same as that of the roof. This element can be of any shape.

The ridge is mounted at the last stage of the roof construction and in such a way that there is a gap in the under-roof space for ventilation. At the same time, ventilation material is laid, for example, mineral wool. It is needed to protect the space under the roof from the penetration of birds and insects, as well as the ingress of precipitation.

crossbars

The crossbar is necessary to give the structure rigidity. It is installed between the rafter legs, preventing their convergence and divergence.

The distance from the ridge to the crossbar should be about one and a half meters. If you install it too high or low, the roof will fall apart.

Struts

Struts (rafter legs) are called spacers that are attached between the rafters and the supporting elements of the roof.

Struts (rafter legs) are called spacers that are attached between the rafters and the supporting elements of the roof.

You can install struts and crossbars at the same time. This design will be stable even with wide spans.

puff

Tightening is necessary in order to reduce the load of the roof on the load-bearing walls, and also to prevent the rafter legs from moving apart.

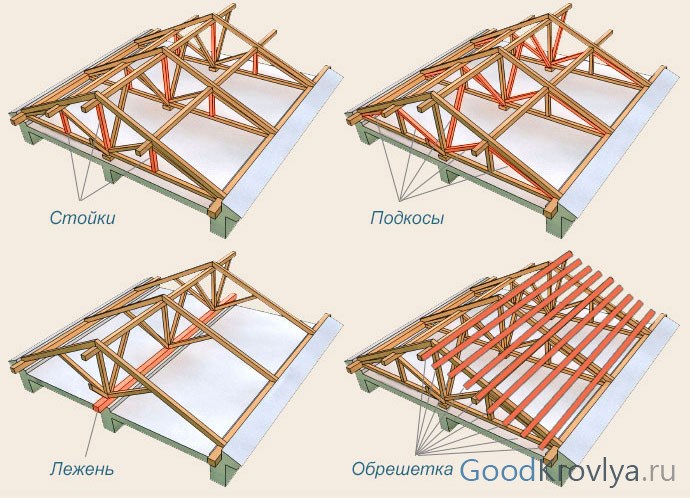

Racks

For racks, a beam with a section of 10 × 10 or 15 × 15 centimeters is used. They are necessary in order to transfer the load from the roof to the building frame, preventing the destruction of the roof.

Sill

Sill- this is a horizontal beam on which vertical roof racks are installed. It evenly distributes the load from them. For lying use a bar of the same section as for racks.

Roof for a house made of timber: the choice of insulation

Much more heat escapes through the roof than through the floor or walls - 30-45%. Therefore, when constructing the roof of a house from a bar, care must be taken to choose a reliable insulation. Now there is no shortage of such materials in the construction market.

Much more heat escapes through the roof than through the floor or walls - 30-45%. Therefore, when constructing the roof of a house from a bar, care must be taken to choose a reliable insulation. Now there is no shortage of such materials in the construction market.

Today, slabs of mineral wool, polystyrene foam, polyurethane foam are popular. Insulators from Izover, Ursa, etc. are also widespread.

When installing insulation, it is necessary to arrange vapor and waterproofing.

Roofing material for the roof of a house from a bar

You can cover the roof of a house from a bar with almost any roofing material, from slate to metal tiles.

At construction sites today are used:

- Ondulin

- Soft roof

- metal tile

- Onduvilla

- Flexible roof tiles

- natural tile

- Decking

The cost per square meter of material is quite affordable.

Roof care

Every roof needs repair over time. To prevent this process from taking you by surprise, the masters advise checking the roof for damage annually.

As soon as the snow has melted, we arm ourselves with a ladder and actively explore the surface. If deficiencies are identified, they must be urgently eliminated. If you neglect the regular inspection of the roof, then in the future it will be more difficult to restore damaged areas.

Most often, two defects occur - deflection and leakage. The deflection can be eliminated by mounting additional crossbars and struts. The leak is eliminated by replacing part of the roofing material.

Mistakes made when installing the roof

Here are a few mistakes that you should try to avoid in the process of work and not only:

Incorrect installation of roofing material

It is necessary to strictly observe the installation technology in order to avoid the occurrence of cracks and other flaws. As a result of improper laying of the material, atmospheric precipitation enters the roof, which leads to damage to electrical wiring and building material. If you do not do the installation of the roof yourself, then contact a trusted company, do not save.

Non-compliance of load-bearing elements with loads

Bearing structural elements must withstand both permanent and temporary loads, as well as endure local climatic conditions. Therefore, it is necessary to carefully carry out calculations: do not take from the ceiling the cross section of rafters, lathing bars and counter-lattices, as well as the step of their installation, use a sufficient number of supporting elements to give the roof the necessary strength.

Insulation errors

When insulating the roof, it is necessary to use a heater of sufficient thickness, do not leave voids and cracks through which cold air enters the room. It is forbidden to compress the insulation, trying to push it into the space between the rafters. On both sides, it must be protected with vapor barrier films or diffusion membranes.

Lack of ventilation

The lack of ventilation is the reason why microorganisms under the roof begin to flourish. They will quickly lead to its destruction. Ventilation ducts must be left to prevent consequences.

Do not make such mistakes and approach your work responsibly!

A beautiful, durable house is the dream of many who are lucky enough to acquire their own suburban area. Spectacular, and most importantly, reliable, the roof decorates any building, protects it from all sorts of weather troubles, in a word, its value cannot be overestimated. How to make the roof exactly the way we want - beautiful, strong, durable? The correct installation of the roof truss system is the first step to creating a high-quality roof that meets all the requirements and requests.

Over the entire long history of construction, mankind has come up with many varieties of truss systems, each of which has its own distinctive features. Those of them that turned out to be the most reliable and durable have survived to this day and are used by modern professional builders.

Here are their main types:

- lean-to;

- gable gable, semi-hip;

- tent;

- four-slope hip and half-hip;

- multi-forceps;

- attic hip and semi-hip;

- conical, pyramidal tongs;

- hip broken line.

A beautiful roof is not easy at all!

As you can see, the designers have to their credit a lot of opportunities for the construction of not only a reliable, but also a spectacular roof, which will become a real decoration of the house, reflecting the individuality of the owners. In addition, sometimes the architect's imagination is not limited to this set, and the designer creates combined roofs, matching one or another of their varieties in one design. This gives the house a special chic and immediately distinguishes it from others.

Calculation of roof structures is one of the most difficult tasks that have to be solved during the construction of a house at the design stage. It is necessary to take into account not only constant loads that will affect the roof - this is the weight of the structure itself, roofing and insulation materials, but also variables - snow masses, strong winds, the weight of people climbing the roof for repairs, etc.

This is interesting: The most popular in private construction are gable and four-slope varieties of roofs. Sheds are usually used for the construction of outbuildings, baths, sheds, etc. The multi-gable roof shape is also often used recently. It allows you to most rationally use the attic space to create attic rooms. Such roofs are often created as a result of conjugation of conventional types of roof structures.

![]()

Modern builders have a wide choice of roofing structures

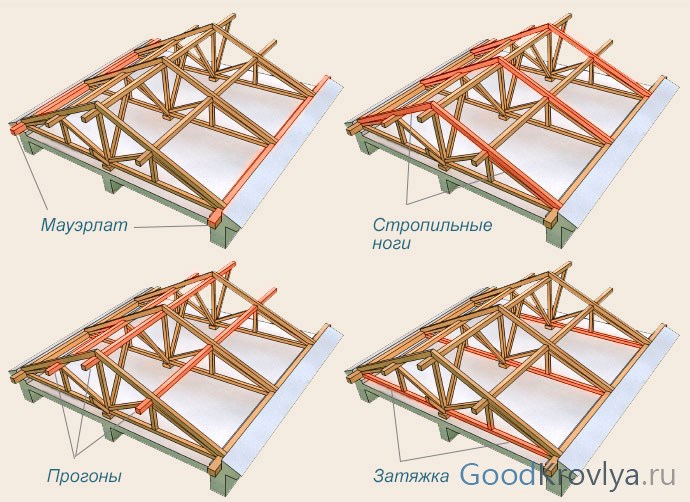

The main elements of the roof truss system

The roof of any type is based on a structure consisting of the same typical elements. Consider them, taking the most common, gable roof.

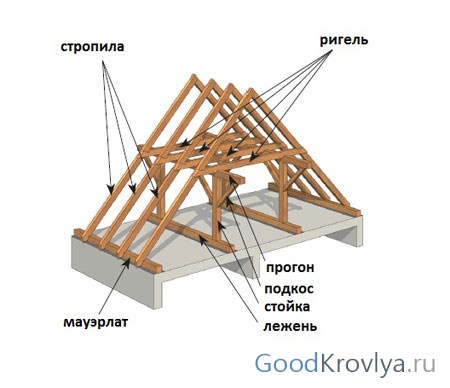

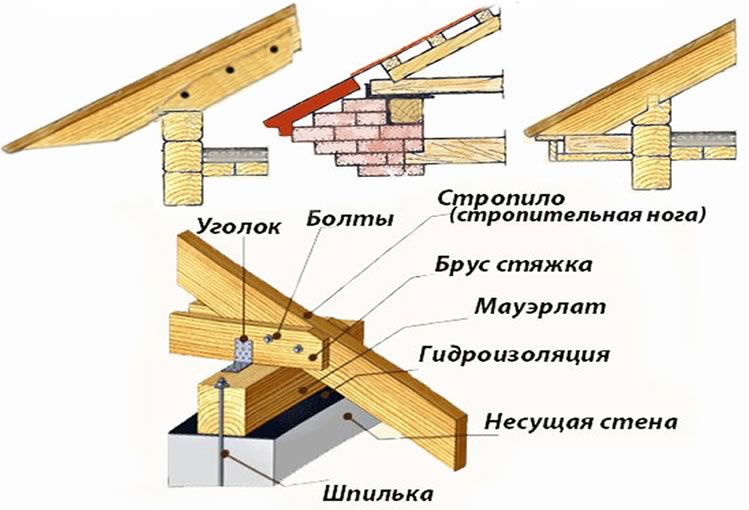

Mauerlat - the foundation of the roofing system. This is a beam located on the outer walls of the house, on which all other structural elements rely, primarily the rafters. For its device, the most durable and massive material is selected.

The rafter leg is the main bearing part of the truss system, which determines the slope of the roof slopes. Made from durable timber. Two rafter legs connected at an angle at the top form a rafter pair, the angle of their connection determines the silhouette of the future roof.

Run - a bar that runs across the rafters from the underside and connects them into a single system. The ridge run is located directly at the junction of the rafter legs, the side ones are placed in the middle of their height.

A spacer (tightening) connects the opposite Mauerlat bars to increase structural rigidity and transfer part of the load.

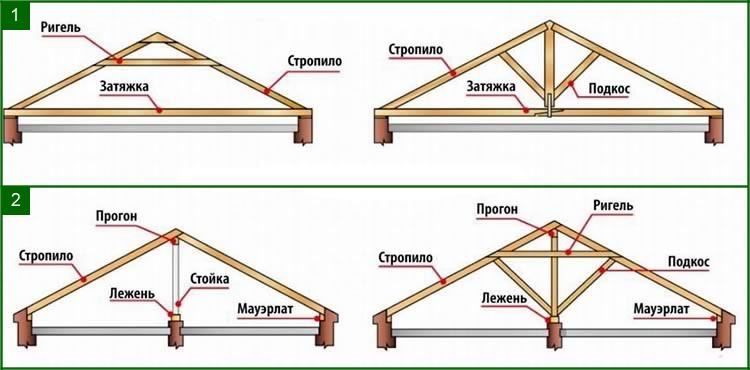

The truss system includes a significant number of elements

Rack - vertical beam, in a gable roof it is located directly under the ridge and rests on a spacer, thereby transferring a share of the load to it. It can be located in pairs under the middle part of the rafter leg.

Strut - a beam that runs obliquely from the base of the rafter rack to the middle of the rafter leg. Increases the rigidity of the structure, reduces the load on the rack. It is located in the same plane with a rafter pair (longitudinal strut).

Lying - a beam parallel to the ridge, laid on an internal load-bearing wall (if such is provided for by the design). Racks and struts are attached to it.

Lathing - boards or beams located across the rafters from the outside and used for laying roofing.

Important: All wooden elements of the truss structure must be carefully treated with antiseptic and flame retardant substances, which will guarantee effective protection of wood from insect pests and fire.

The design of the gable roof truss system

Rafters can rest on the Mauerlat in two ways; depending on this, the systems of hanging and layered rafters differ.

Hanging rafters rest only on the Mauerlat bars and are connected at the top at the required angle. This design creates a large bursting horizontal force, to compensate for which horizontal bars - screeds are used. A triangular truss truss is formed, which, in the case of a large horizontal span, is reinforced with additional elements.

Laminated rafters have an additional support - lying. They are also connected at the top at a given angle, and the vertical posts do not rest on ties, but on a bar that lies parallel to the Mauerlat inside the truss system.

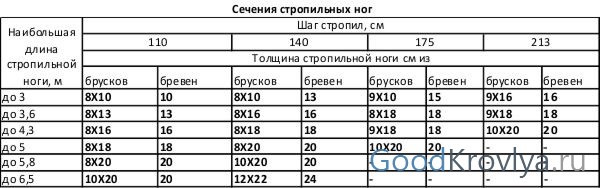

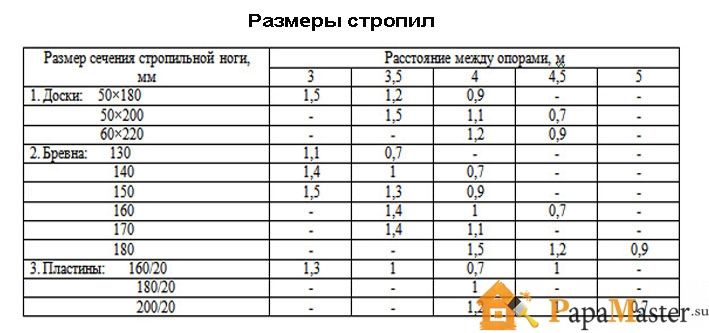

Roof rafter dimensions

Naturally, the exact dimensions of all elements of the roof structure depend on many factors, the main of which are the projection dimensions of the house and the angle of the roof. But, certain rules for selecting the optimal section of the beam still exist.

With a rafter length of up to 3 meters, the distance between the rafters should be 120 or 180 cm. The optimal beam section is 8x10 or 9x10 cm.

With a rafter length of 3-4 m, they are installed at a distance of 100, 140 or 180 cm from each other. The cross section of the beam is 8x16, 8x18 or 9x18 cm.

With a length of 4-6 m, the distance between the rafters of the truss system is set to 100 or 140 cm, the beam is taken with a section of 8x20 or 9x20 cm. The beam is laid with the narrow side up.

How roof truss nodes are made

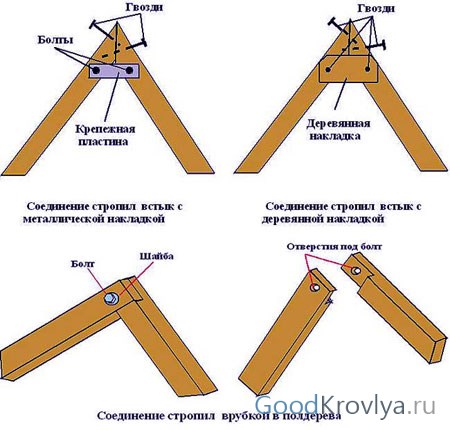

The reliability of truss structures depends not only on the correctly selected section of the beam, but also on the quality of its connections, or truss units. The joints of the elements of roof structures are made according to certain rules, which must be strictly observed.

The main nodes of truss structures:

- ridge knot;

- rafter support unit on Mauerlat;

- junction of the rafter and the upper puff (located in the middle part of the rafter);

- connection of the strut, rack and beam;

- connection of the strut, rack and rafters.

Triangular truss structures "truss pair - puff" are called trusses. For their manufacture, various methods of connecting wooden elements are used, while various types of fasteners are used. Traditional methods of manufacturing trusses involve complex pairing of wooden elements using various types of felling, while metal fasteners are used to a minimum. The use of modern metal fasteners greatly facilitates the process of assembling roof structures, simplifies the requirements for the qualifications of builders. True, in this case, it is necessary to pay close attention to the anti-corrosion treatment of the metal parts of the system.

Truss wooden trusses are usually assembled on the ground, and then rise to the top. This allows for a more precise fit of parts, facilitates work and increases its safety.

The task of the builder is to ensure maximum rigidity and strength of the structure, while giving it the opportunity to "breathe", i.e. move under the influence of wood shrinkage, increase and decrease in humidity, temperature, etc. Naturally, such movement is so small that it is not noticeable to the eye, but allows the structure to maintain its shape and dimensions without damaging the roofing. However, you should not drive in extra nails and screw in bolts - this will weaken the wood and may cause it to crack.

After choosing a constructive solution - hanging or layered rafters - a plan of rafters is drawn up, on which all nodes of the system are indicated. Accordingly, in a particular design, they can be performed in different ways, in addition, it depends on the size and type of roof - single-pitched, double-pitched, hip, etc.

To create a ridge knot, the rafter pair is connected half a tree with nails or bolts, after which the knot is reinforced with bolted metal strips. Between these slats, the central post (if it is present in the project) is cut and rigidly fixed.

To connect the rafters with the Mauerlat, a cut is made in them according to its shape, after which the knot is carefully strengthened with the help of metal corners, building brackets, nails and bolts.

The connection of the rafters with the upper puff is made half a tree using nails or bolts.

The joints of the struts, racks and rafters are made by cutting, reinforced with special construction brackets.

The fastening of the lathing bars to the rafters is carried out with the help of a counter-lattice. These are bars that are placed under the crate on the rafters. Their use allows you to create an air gap between the vapor barrier, which will be laid between the rafters and the counter-lattice, and the roofing carpet.

A rafter system of this complexity is a job for professionals!

The construction of a truss system is a complex work that includes several stages: design selection, calculation and design, material selection, construction itself. Mistakes and carelessness made at any of these stages can adversely affect the final result. The professionalism and experience of engineers and roofers is the best guarantee against such an unpleasant finale of building a country house. Therefore, before deciding on the independent construction of the roof of your "nest", carefully weigh your strengths and capabilities.

Think about it: is it worth risking, if not the health of loved ones, then a lot of money that will be spent on materials? Any work only benefits when it is performed by professionals, so it is much more profitable and safer to entrust the work to the builders.

Making the roof of the house is an important and responsible task. The integrity of the structure and the peace of the residents will directly depend on the quality of the upper structure. Before starting work, it is necessary to choose the right boards for rafters and other roof details, perform their high-quality pre-treatment and correctly connect them, preparing them for the roofing material.

Roof types

Currently, about ten different types of roofs are used for residential buildings and outbuildings. Some of them are more familiar to us, others are very rare. The main designs are.

Pitched roofs made using direct truss systems:

- lean-to;

- gable;

- four-slope - hip and half-hip (with a ridge) and tent (without a ridge);

- multi-forceps:

- conical.

Pitched roofs with curved rafters:

- semicircular;

- hemispherical.

Almost all types of roofs are based on special parts that provide the roof with the necessary strength and give it the desired shape. It's about rafters.

Requirements for the quality of rafters

For the manufacture of rafters, edged boards of various sections are used. The most common parts with a section of 50x150 or 50x200. A bar of square or rectangular section is not used, since it cannot provide the necessary strength to the structure or will significantly make it heavier. Do-it-yourself rafters are always installed on edge. In this direction, the parts are stronger and not subject to bending.

Installation of the truss system of the outbuilding

For work it is better to choose softwood boards. This is due to several of their features:

- the presence of resin prevents the formation of rot in the material;

- such parts have a relatively low weight, unlike, for example, boards of the same section made of birch;

- coniferous material is more affordable, and it is much easier to find it at sawmills.

In addition, be sure to pay attention to such elements in the wood as knots. The presence of rotten drop-down elements, which can lead to a decrease in the strength of the rafter leg in the future, is not allowed.

Preparing rafter system parts for installation

Before proceeding with the installation of the roof truss system with our own hands, we recommend that you carefully treat the surface of all wood parts used in the work.

Pre-inspect the purchased lumber, select the highest quality. Boards with falling knots can be used in pieces, for example, when lengthening or for making racks (headstocks), struts, crossbars and other roofing details. After selecting a sufficient amount of lumber, it is treated with special protective compounds that prevent rotting and burning.

You can apply flame retardants and antiseptics with your own hands in the following ways:

- immersion;

- brush or paint roller;

- spraying.

Each method is good for one purpose or another. After one layer of impregnation has dried, it is recommended to re-treat. It is advisable not to mix formulations for different purposes in the same container.

Choosing the best truss system

Having selected high-quality boards 50x150, and having completed their processing with our own hands, we proceed to the installation of the truss system. Before starting work on the perimeter of walls made of bricks or blocks, it is necessary to lay a mauerlat - a beam that will serve as a support for the lower parts of the rafter legs.

It is fastened with threaded studs recessed into the wall or steel wire laid in the seam of the masonry. In buildings made of timber or logs, the role of the Mauerlat is played by the upper crowns of the log house.

Depending on the size of the span between the walls of the house, we choose the option of installing rafters. There are systems with hanging rafters or layered, based on an intermediate load-bearing wall.

Roof options: 1) With hanging rafters. 2) With layered rafters

The first type of construction has a horizontal transverse beam - puff. In the second, this element is missing. For support, the ridge beam rests in several places on the intermediate wall of the house. This is not very convenient in the case of manufacturing an exploited under-roof space - an attic, but it is optimal for large flights between walls.

Determine the number of roof trusses

To determine the amount of lumber needed for the manufacture of rafters, for example, 50x150 boards, it is necessary to calculate the required number of truss trusses - pairs of rafters connected at the required angle. On average, the span between them is 0.9-1.2 meters or slightly less. The determining criterion is the roofing material intended for use.

So, for ondulin, the manufacturer recommends a rafter installation step of 0.6-0.9 meters, for metal tiles - one of the most common materials in recent years - 0.65-0.95 meters. Of great importance when choosing the inter-rafter distance is the slope angle of the slopes, which depends on the snow and wind load in each particular area.

Having determined the step size, we divide the length of the walls by this indicator and add one, taking into account the installation of gable trusses. We get the number of rafter pairs. Multiplying this number by two, we determine the required number of rafters. We calculate the length of the boards according to the Pythagorean theorem, knowing the same slope angle of the slope and the span of the walls.

We mount the truss system - we collect trusses

Having decided on the number and size of the rafters, you can begin to assemble the roof truss system with your own hands. As a rule, they try to install pre-assembled farms. You can make them both on the attic floor of the house, and on the ground and raise them ready-made.

In any case, a few templates will greatly facilitate the work.

The first of them is a rafter of the required length with ends sawn at the required angle. If necessary, the edges can be cut not in a straight line, but with ledges that facilitate the installation of parts. For example, if the rafters rest on a beam, fastening can be done with steel angles, perforated steel tape, or nails. In all cases, a figured cut will increase the quality of the installation.

The second template is a sheet of plywood with stops nailed at the required angle, into which the upper ends of the rafters are inserted and connected by crossbars - transverse boards with a section of 50x150, providing the necessary rigidity of the rafter pairs. If free space allows, you can use one self-assembled farm as a template.

Installing farms

Do-it-yourself farms are lifted up. Installation is convenient to start with the extreme pairs, called gables. They are installed vertically, controlling the position along a plumb line or a board nailed to the wall of the house, and fix the position with the help of additional slopes. The lower ends of the truss rest on the mauerlat beam or on the log crowns. They are nailed to them with nails No. 100.

Methods for attaching the rafter leg to the Mauerlat

Having fixed the extreme farm, the rest are fixed, observing the span between them. To control this value, you can first cut spacers from a 50x150 board with your own hands and do not measure the distance for each pair. The corners of the roof trusses after their installation are additionally connected with a ridge beam or board. In addition, the crate will help fix the rafters.

If you are going to do roofing in the near future, then you should know everything about rafters - how to choose them and what to look for. These supporting structures are needed then to protect the house from gusts of wind, rain, and if they are chosen incorrectly, they simply will not cope with their main function.

First of all, you need to choose the right type depending on the slope of your roof. They are inclined and hanging. Inclined structures usually have 2-3 supports; for buildings with small spans, a single-slope type of construction is used. For public and residential buildings, where there are columns, load-bearing walls inside or partitions, supports are more suitable.

Usually, wooden rafters are installed on the roof, but sometimes it is advisable to use a metal structure.

How to choose the right rafter size?

So that the support does not deform over time and is able to withstand gusts of wind, snow load and the weight of the crate, it is extremely important to choose the right section for it.

Paying attention to the support, look at the quality of the wood, because today it is quite difficult to find high-quality wood. The most "running" dimensions are boards, the section of which is in the range from 5x15 to 7x17 cm. Usually, boards of this section are installed at a distance of at least 90 cm and a maximum of 150 cm from each other.

To strengthen the rafter leg, you can use two boards connected together by bosses (in increments of no more than 50 cm).

The cross section of the support must be selected, knowing the length, step and load. By increasing any one of these values, the section of the leg should increase.

To prevent the rafter legs from moving apart, you need to use a puff, which also acts as an additional support. However, when choosing a puff, it is worth considering the factor that its cross section should not be as large as the cross section of the rafter itself. If the dimensions of the rafter are 5x17 cm, then the puff should be 5x16 cm, with the size of the support 5x16 cm, the puff should be 5x15 cm.

When installing supports on large spans, you need to use struts that are able to transfer to withstand the load. The cross section of these struts is selected according to the same type as the cross section of the puffs.

When laying the roofs of private houses, a hanging system is often used. In such a system, the fulcrum of the foot is either the wall of the house itself. This design is quite flexible and light, but you need to be aware that it cannot be used on large spans, as it will not be able to withstand loads.

It will be much easier for you to calculate the required size of the rafters, knowing the angle of the roof. An angle of 30-35 degrees is considered the most optimal, with an increase in the angle of inclination, the total area and height of the roof increase, thereby “raising the cost” of the entire structure.

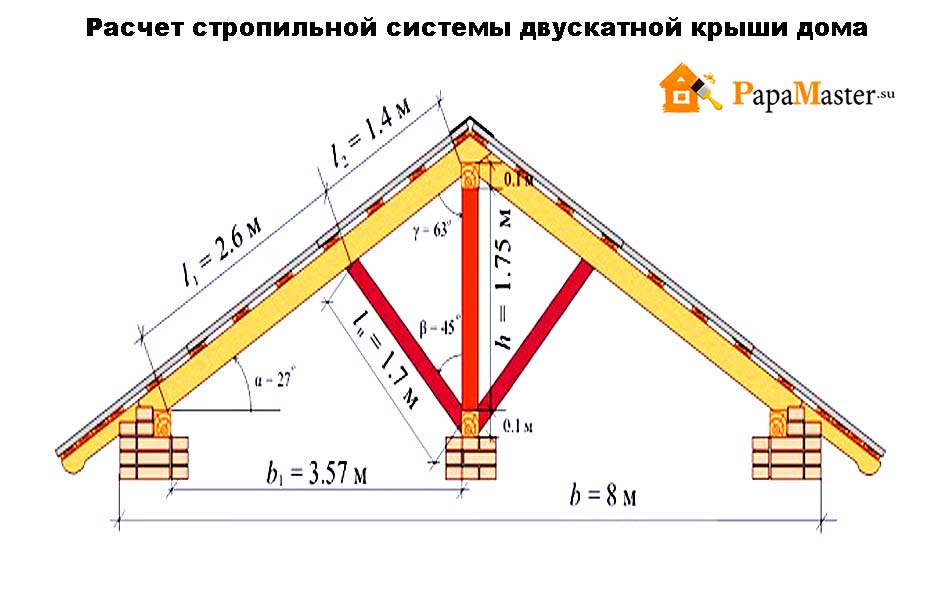

calculation of the truss system of a gable roof for a house

calculation of the truss system of a gable roof for a house

beam load calculation table

beam load calculation table

How is the price of rafters calculated?

Typically, the price of rafters is indicated per meter, depending on the size of the rafter itself and on its length.

With a support length of 4-4.5 meters and its dimensions ranging from 50x100 mm to 50x200 mm, the price per square meter ranges from 7.65 UAH. up to 15.30 UAH. ($1.20 to $1.70).

With a support length of 6 meters and its size of 50x100 mm, the price of one square meter is 8 UAH ($1.21), with a size of 50x120 mm - 9.60 UAH ($1.05), with a size of 50x150 mm - 12 UAH. ($ 1.25), size 50x200 mm costs 16 UAH. ($1.70).

These prices for rafters are approximate and may fluctuate depending on the size of the support and the dollar exchange rate. However, when calculating the approximate cost of the roof, these prices can be taken into account.

Choosing rafters for the future, you should not put only their cost as the main factor of choice. The most important thing is the quality of the board, it depends on it how much the future structure will perform its main functions and how long it will last. If you choose poor quality wood, you will have to redo the roof over time, as low-quality wood can crumble or crack. Therefore, no matter how limited the budget you have allocated for the purchase of rafters, you should not rush to the cheapest supports if you do not want to redo the roof several times.

Despite the apparent simplicity, the construction of a truss system is a very complex process that requires certain mathematical calculations. Here it is important to choose the correct dimensions of the board for the rafters. On the one hand, this will ensure the reliability of the structure, on the other hand, it will allow more rational use of wood and avoid unnecessary financial costs.

Board and timber are the two main materials that are used for the truss system. A bar is the best option, but since its cost is an order of magnitude higher than the cost of a board, in order to save money, a number of additional elements of the truss system are made from a cheaper board.

Calculation of parameters

Accurate calculation of the main parameters of the board for rafters is very important. The strength of the structure directly depends on them - if boards of insufficient section are used, the structure may collapse under the weight of roofing material or snow. A board that is too thick is also not recommended - such material is more expensive, and it also creates an additional load on the foundation and walls.

Thickness

For the manufacture of rafters, boards with a thickness of 40-60 mm are usually used. Boards with a cross section of 40 mm are used only for outbuildings: garages, sheds, and so on. For roofs of houses, a board with a thickness of 50 mm or more is used.

cross section

The cross section has the following formula: S=b*h. In this case, b is the width of the board, and h is its thickness. The cross section of the board should be proportional to its length.

Table for selection of section in relation to length

In the event that the rafter is built up by rallying two boards together, then the rallying area must be at least 500 mm. In this case, it is recommended to install it as high as possible to the ridge.

Dependence of the cross section on the installation step

The installation step of the rafters is a very important condition, which affects the cross section of the board. The greater the distance between the rafters, the thicker the board is required and, conversely, with a sufficiently frequent step, boards of less thickness can be used.

Table of ratio of rafter pitch to section

| Section, mm | Rafter spacing, m, with distance between supports, m | |||

| 3 | 3.5 | 4 | 4.5 | |

| 40x180 | 1.4 | 1.0 | - | - |

| 50x180 | 1.5 | 1.2 | 0.9 | - |

| 50x200 | - | 1.5 | 1.1 | 0.7 |

| 50x220 | - | - | 1.2 | 0.9 |

How to calculate the exact parameters of the board

All the characteristics provided above are average data, which can only be roughly guided, but in no case can you fully rely on, especially when creating a truss system for the roof of a residential building. A complete and most accurate calculation is carried out using complex mathematical formulas or in specialized computer programs, which take into account a number of additional factors. These factors include wind and snow load, wood material, rafter angle, roofing material, and many others. Only taking them into account, it is possible to obtain a complete calculation of the strength and calculation of the probability of deformation of the roofing system.

In addition to calculating the cross section and thickness of the board, you should be careful when choosing the material itself. First of all, the board must have a moisture index not exceeding 18% - otherwise it will lead over time, the geometry of the entire structure will be disturbed, additional stresses will arise.

Also, the board should not have defects. It is allowed to have small non-through cracks and knots (no more than three knots with a diameter of up to d = 30 mm per linear meter), fraying of the ends of the board, etc. Such material either generally needs to be rejected, or used as a last resort for those elements that are not related to the main and load-bearing ones.