How to run a chimney through a metal roof?

January 21, 2017

How to run a chimney through a metal roof?

When installing a stove in a house, the question invariably arises, how to get it out. The solution to this issue depends on the following components:

- pipe shape;

- placements;

- roof structures (insulated, non-insulated);

- roof shapes;

- roof coverings.

Now we will consider the order of arrangement on. It is best to produce a pipe exit in the area of \u200b\u200bthe roof ridge. In this case, the pipe will pass through the roof in a warm zone, which will significantly reduce the risk of condensation in the chimney. The second important fact is the absence of snow pockets. This greatly affects the possibility of roof leaks.

However, the question immediately arises of what to do with the truss system. If at the stage of construction of your house a ridge with a gap is structurally provided, then the task of passing the chimney will be greatly simplified. If not, then it is best to make a passage on the slope of the roof near the ridge.

Having decided on the place of the pipe outlet, we proceed directly to the work. We draw the place of penetration. At the same time, we immediately determine that the hole for penetration itself should be 7-10 cm larger than the pipe itself. This is necessary for arranging thermal insulation and avoiding fire on the roof. In the place where the pipe exits in the metal tile, using a jigsaw, metal shears or a grinder, we make a hole of the required shape.

In the absence of these tools, a hole in the metal tile can be made using a drill, or a hammer and a chisel in the following way:

- we make as many holes as possible around the perimeter of the marking;

- squeeze out a piece of metal;

- clean the edges with a file.

When the hole is ready, we proceed to further work. Given that the roof consists of various, including combustible materials, such as wooden lathing, rafters, insulation, steam and waterproofing film, it is imperative to comply with fire safety measures. The materials used to design the penetration must be non-combustible and provide maximum protection of the elements in contact with the pipe from heating. The maximum temperature in the contact zone should not exceed 40-50 degrees.

Arrangement of a round chimney

When arranging a round chimney, we use a factory pass-through element (sleeve). It is installed from the bottom of the roof and fastened from the side of the attic (mansard), taken in a size larger than the pipe itself. For example, for a pipe with a diameter of 160 mm, a passage element is taken (it is also a sleeve or roof penetration) with a diameter of 230 mm. A pipe is installed in the passage element.

The voids between the sleeve and the pipe are filled with basalt wool. This will ensure fire safety. The sleeve will not heat up from the pipe. In the future, a master flash is put on the pipe (it is also called a cap). The master flash is a metallized sheet with a top elastic silicone joint with dimensions marked on it. The size must be selected and cut smaller than the size of the pipe.

Next, the master flash is lubricated with liquid soap and put on the pipe. The base of the master flash and the metal tile at the attachment point are lubricated with silicone and tightly crimped. In the future, the base of the master flash with a step of 30-35 cm is attached to the metal tile with roofing screws.

Due to its elastic shape, the master flash adheres tightly to all elements of the roof covering and ensures complete watertightness. The master flash must be selected in accordance with the shape of the roof. It is different for a straight or pitched roof.

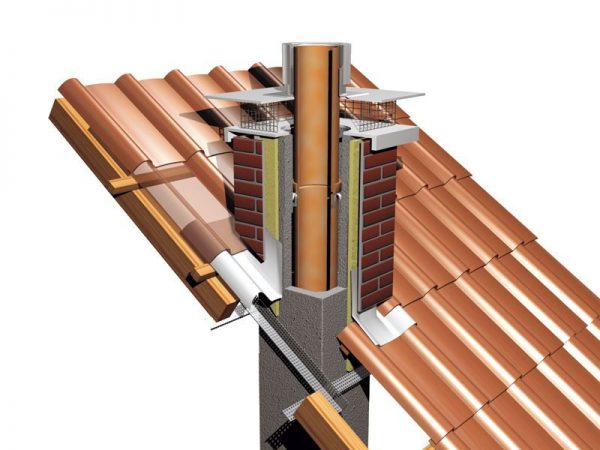

Arrangement of a square (rectangular) chimney

In general, the work on arranging a square (rectangular) chimney is in many ways similar to the above method for arranging a chimney for a round pipe, although there are a number of differences. Initially, after cutting the hole for the chimney, work is carried out to ensure fire safety. In the cut hole, the edges along the entire depth of the roof are laid with basalt wool and foil.

In the future, the installation of an internal apron is carried out before the installation of the coating, and subsequently, the installation of an external decorative and protective element. After that, to ensure tightness, a tie is installed near the lower edge of the pipe between the roof and the apron. Its narrow edge passes into the valley or into the gutter. Next, the chimney is bypassed with a metal tile.