Production of steps for porcelain stoneware stairs in the house

Porcelain stoneware is a combined material, which includes sand, clay, mineral dyes and quartz. This material entered the construction market quite recently, in comparison with the entrance doors, the installation of which is described in, but has already gained its application and popularity.

Porcelain stoneware is used to finish stairs.

He deserved popularity, like, not in vain, his use for facing stairs made it possible to achieve amazing success.

A staircase finished with porcelain stoneware not only acquires a charming look and gives the room a saturation of the interior, but also lasts much longer, like the corrugated board, which we wrote about earlier.

This material is obtained by grinding and mixing natural materials.. After mixing, the resulting suspension is subjected to pressure and finally annealed. This principle of preparing porcelain stoneware contributes to its use for facing stairs.

The material has the following series features in application:

wear resistance, which cannot be achieved with . It has almost maximum resistance to mechanical and physical effects on the material. According to the wear resistance measurement scale, porcelain stoneware has an indicator of 8 units. To understand what this figure means, we note the following:

- Diamond has almost maximum hardness, and takes 10 units on the scale.

- Topaz has 8 units according to the hardness scale.

- Quartz - a material that is part of porcelain stoneware, has 8 units of hardness and is an order of magnitude lower in strength.

Resistance to temperature changes, as in . Due to the uniform structure during cooking and pressure forming, this material has a high density. High density eliminates the destruction of the material from the temperature difference. Withstands drops from -50 to +50 degrees.  Porcelain stoneware staircase in the photo

Porcelain stoneware staircase in the photo

Water absorption resistance. The homogeneity of porcelain stoneware does not allow moisture to penetrate into its composition, which leads to resistance to moisture. This makes it possible to use porcelain stoneware not only in dry rooms, but also in wet ones.

Chemical resistance, like corrugated board, read about the cladding of balconies here. Stability is due to the manufacturing system and processing at a temperature of 1300 degrees. Together, the maximum resistance of the material to chemically active media is obtained.

You should know that due to such properties and features, porcelain stoneware is increasingly used in the construction industry. Facing stairs is possible not only indoors, but also outside the houses.

Additional features of porcelain stoneware also include the following indicators:

- It is a non-combustible material. In addition, it has dielectric properties, i.e. does not conduct electricity.

- Due to the use of only natural materials for the preparation of porcelain stoneware, it is highly hygienic and unpretentious in care.

- After decades, it is able to not change its structure and color, unlike from our material. It is not afraid of the influence of sunlight and ultraviolet radiation, which causes it not to burn out.

- Environmentally friendly and safe. The use of natural clay determines the environmental friendliness of the material.

All these features make it possible to widely use porcelain stoneware in the construction industry.

Advantages and disadvantages for stairs

As for the comparison of disadvantages and advantages, it is natural that there are much more advantages of using porcelain stoneware:

- A wide variety of colors, textures, tones and imitations.

- Waterproof.

- Resistance to influence of chemical reagents.

- Resistance to temperature changes.

- Do not collapse under the influence of mechanical loads.

- Care of porcelain stoneware is not required.

As for the disadvantages, they can be reduced to a minimum. The cold surface of porcelain stoneware is really a big problem. The placement of this material on the outside of the house or building has a neutral effect.

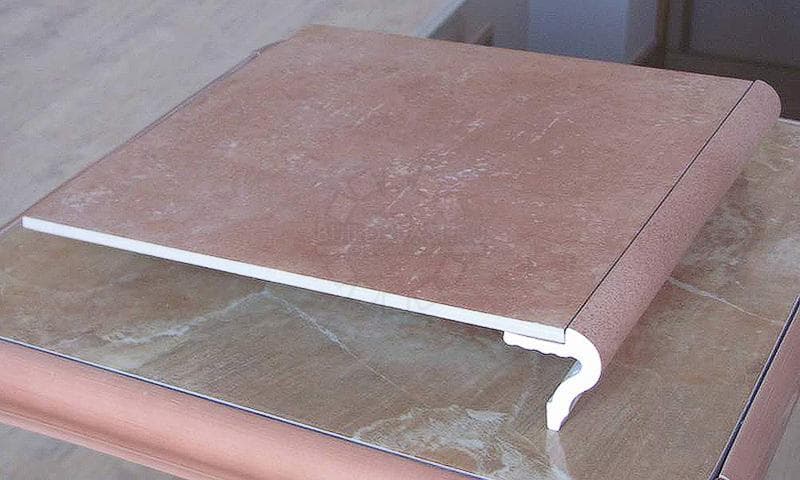

Indeed, often outside people walk in shoes and the cold from the stairs is practically not noticeable. As for this problem, if the staircase in the house leading to the second floor is lined with porcelain stoneware. Anyone who has encountered the installation of porcelain stoneware knows how cold it really is. But not everything is so sad.  Step size 1200x300

Step size 1200x300

The following reasons are proposed for solving such a problem if the stairs in the room are made of this material:

- When climbing stairs, use shoes. These can be indoor shoes, warm socks or regular outdoor shoes. This is the easiest way to solve the problem.

- Lay a carpet over the steps along the entire length, depending on. This will change the interior of your stairs not for the better, but there will be no problem with a cold floor.

- Use of underfloor heating for steps. This is an expensive way to solve the problem, but it is the most valid one. When installing the stairs, you must immediately lay the heating elements in the steps.

With the help of additional materials or items, one more drawback can be eliminated:

- In order not to be injured in the house on the porcelain stoneware stairs, you must use shoes, rugs on the steps, or do not walk barefoot on the wet floor.

- If the problem arises with an external staircase, then special carpets or sand must be used here. In case of icing on the surface of porcelain stoneware, it will melt like a skating rink.

- Anti-slip notches are applied to some types of porcelain stoneware steps. It does not provide complete safety, but reduces the risk of falling.

- The use of matte surfaces of porcelain stoneware.

Types of steps and their features

Installation of porcelain stoneware steps, as well as, produced in two ways:

- Whole.

- Suture.

Accordingly, upon completion of installation in one of these ways, the steps of the stairs will have the same views. Let's take a closer look at each type of steps.

The whole view is based on porcelain stoneware sheets measuring 1200x300 mm. This leads to the receipt of an integral type of steps as a result. The sheet size for integral installation of steps is more expensive than for the suture method. If the porcelain stoneware staircase has a certain pattern, then installation in one piece is ideal.

Steps are made of porcelain stoneware with a thickness of 12 mm. Seam types start from 10 mm. There is a variety of rolling of the leading edges. In particular: semi-circular, round or in relief.

Steps made of porcelain stoneware

Steps made of porcelain stoneware

Porcelain stoneware for stairs in the house consists of the following parts:

- riser- the vertical base of the stairs.

- Assault- horizontal base plate.

- plinth- the corner of the steps.

- Cornice. In a solid slab, it is part of a monolith.

Features of porcelain stoneware steps

The features of the steps include methods of manufacture and installation.

Prefabricated steps

Prefabricated steps are produced, both from modular tiles and from solid slabs. The sizes of prefabricated slabs are often varied: 450x450, 300x300, 300x600. They are also made to order, only it will cost more than usual.

Prefabricated steps have two installation methods: seamless and suture. Seamless is carried out by the maximum joint of the plates. The installation of the suture method is characterized by the formation of a decorative type of seam.

solid steps

They have increased strength compared to prefabricated ones. The whole view of the step is indistinguishable from a monolithic slab.

It is possible to stick strips of metal or plastic. There is an anti-slip notch on some types. Increases the reliability and safety of the use of steps.

Shapes and colors

As for the shapes and colors of porcelain stoneware, it has no equal here. It has limitless color options. The surface of the steps can be either glossy or rough or matte. A matte base is more often used to cover floors and stairs. A variety of color palette makes porcelain stoneware an undisputed leader in sales and expands the range of applications every day.

Regarding the forms of porcelain stoneware, there are two main types of stairs: spiral and mid-flight. In mid-flight stairs, straight porcelain stoneware slabs are used to cover the steps. In screw, plates with certain angles are used. This is a more complex way to cover steps with porcelain stoneware. These types of porcelain stoneware for degrees are made to order. Installation of prefabricated steps for spiral types of stairs is possible.

According to the standard, a step is taken to be 15 cm high. It is for this height that manufacturers produce step details.

A wide range of colors for porcelain stoneware steps allows you to furnish your home the way you want. The interior of porcelain stoneware stairs will not only emphasize its inimitability, but will also delight for many years.

Laying

Initially, you need to decide on the type of laying steps. After that, purchase the necessary materials for facing the steps of the stairs. Facing the steps of stairs can be performed on any surface: metal, brick or concrete.

So, if you decide to carry out the installation of a solid type of steps, then you need to prepare the surface to perfect condition. To do this, it is necessary to align each step and clean it, as they say, to a shine.

In the typesetting version, you need to devote more effort to laying. After all, joining the plates is not an easy task, and it is also necessary to align them. You also need to prepare the surface. After the preparation and availability of the material, you can start laying porcelain stoneware.

Installation is carried out in stages:

Glue must be diluted strictly according to the instructions. Poorly diluted glue can lead to loose adhesion of the plate to the base.

Features of laying prefabricated steps:

- To get perfect joints, the tiles must be flush with the steps or wider than them.

- The protruding part of the step must be cut off immediately. After gluing, cutting is prohibited.

- The last stage is characterized by laying skirting boards. Plinths are both right-handed and left-handed.

Finishing the steps with porcelain stoneware is finished. As you can see, there is nothing complicated. But this is an internal type of porcelain stoneware laying.

For laying outside there are some features which are very important and must be considered:

- Use a rubber profile for the corners of steps. This will save and protect the steps from icing.

- Leave the channel on the side of the outer tiles of the steps. The water will flow down the channel, and will not accumulate and destroy the surface.

The use of porcelain stoneware will give your room structure, elegance and a certain charm.

An interesting staircase in a porcelain stoneware house with wrought iron railings

An interesting staircase in a porcelain stoneware house with wrought iron railings

The individuality of the interior is the main task that designers set themselves, and porcelain stoneware is an excellent solution to this task. Consider some of the design solutions for porcelain stoneware stairs, which are presented below in the photo.

The decorative highlighting of the steps with the color of cave stones saturates the room and gives it a certain antique image.