What doborny elements for roofing from a metal tile consist of and how to mount them correctly?

A variety of roof coverings gives today's consumer ample opportunities for choice.

But for those who want to purchase high-quality and at the same time aesthetically attractive material, it is worth taking a closer look at, which fully complies with the specified parameters.

And here some may have a question: what is this material?

A metal tile is one of the types of profiled sheets, made of thin-sheet galvanized steel and equipped with colored polymer coating that performs a protective function.

The material is produced on high-tech equipment, which allows using the profiling method to imitate rows of natural tiles on steel sheets. To perform a high-quality installation of a metal roof, additional elements are used that are installed in certain places. The types, characteristics and installation of these structural components will be discussed further.

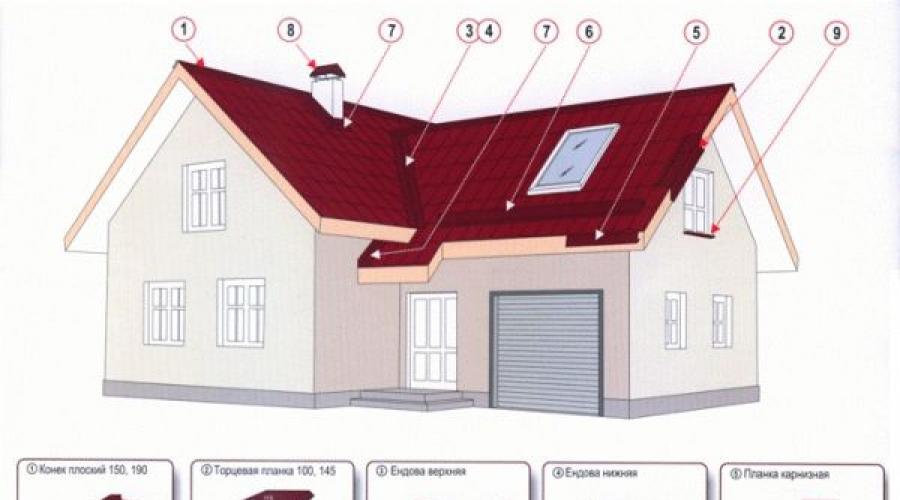

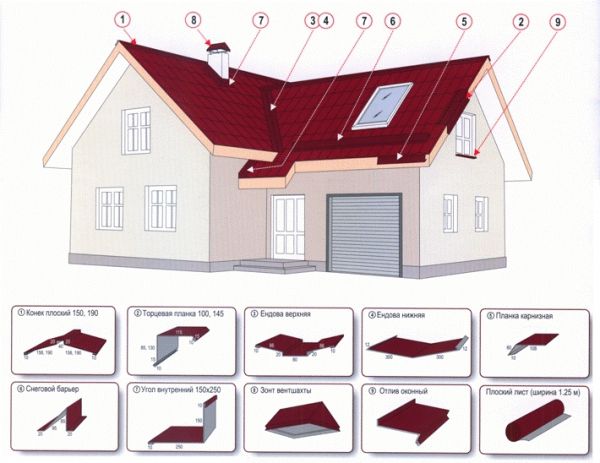

The following additional parts are included in the device of a metal tile roof:

- end plate(aka wind) - is installed to protect the pediment from wind loads. Ensures the safety of fasteners (they will not loosen during operation) and protects the structure from moisture penetration.

- Lower valley plank- used to divert water from the joints between the slopes. Prevents the penetration of moisture into the under-roof space.

- Upper valley overlay- closes the edges of the metal tile at the inner joints of the slopes.

- - installed at the top of the roof and at its outer joints. It protects the under-roof space from dirt and moisture getting into it, and also additionally keeps the coating sheets from being torn off by the wind.

- eaves plank- protects the frontal board from sedimentary moisture.

- dropper- installed to remove moisture (condensate) from the waterproofing.

- junction bar- used to seal the coating in places where it adheres to roof elements (for example, a wall or a pipe).

- - protect the drainage system from the collapse of snow from the roof.

Additional elements for the roof

Now a little more about each of these elements.

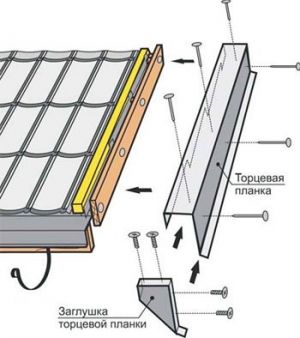

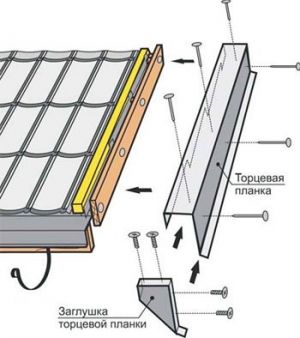

End (wind) bar

Wind strip for metal roofing ( she is the end plate for metal tiles) is made of 0.55 mm thick galvanized steel and is equipped with a polymer or  composite coating. The bar is presented in the form of a corner with curved edges, and can also be equipped with ribs located on a plane, due to which the product acquires additional rigidity. The standard length of the part is 200 cm.

composite coating. The bar is presented in the form of a corner with curved edges, and can also be equipped with ribs located on a plane, due to which the product acquires additional rigidity. The standard length of the part is 200 cm.

Since this roofing element protects the structure from moisture and wind, it is also called a wind bar.

Mounting the end plate of the metal tile is performed as follows:

- Measure the length of the ends of the slopes, based on which the required number of whole parts is prepared. If necessary, the last element is cut to the desired size.

- Installation is carried out from the bottom of the slope to the top. Parts are stacked with an overlap of at least 5 cm.

- The plank is applied so that it is located above the lathing layer at the height of the tile wave.

- The part is fixed with self-tapping screws screwing on both sides. The step between the fasteners should be 0.3-0.5 m.

Eaves strip for metal tiles

For the manufacture of this product, the same metal and the same technology are used as in the production of metal tiles. A layer of polymeric material (plastisol or polyester) is applied to galvanized steel with a thickness of 0.5 mm. The standard plank length is 0.5-0.6 m, width 20 cm. Detail done in the shape of a corner.

Before proceeding with fixing the cornice strip, front panel should be installed, which is fastened with galvanized nails to the rafter legs. The front board should be as flat as possible. which greatly simplifies the installation work.

Mounting cornice plank of metal tile:

- The cornice is hemmed with a tongue-and-groove board or corrugated board.

- A support beam is attached to the wall of the building, which will serve as an auxiliary support for filing the overhang of the eaves.

- Holders for gutters are attached to the crate.

- After that, a cornice bar is installed, which is placed over brackets. It is attached with screws to the crate. The distance between fasteners must be not less than 0.3-0.35 m.

cornice strip for metal tiles: photo

Cornice strips must be installed with an overlap no more than 10 cm.

dropper

Dropper for metal tiles - this is essentially the same cornice plank, only it is located in a different place, unlike the previous version.

Dropper for metal tiles - this is essentially the same cornice plank, only it is located in a different place, unlike the previous version.

The purpose of the drip is to protect against the penetration of moisture flowing down the sheets of metal (see photo above).

The dropper is installed along the edge of the roof slope and is attached to the rafter legs in front of and, respectively, to the counter-lattice and.

To fix the parts, self-tapping screws are used, screwing them in increments of 30-35 cm.

endova

Valley strips (grooves), as well as metal tiles, are made of galvanized sheet steel coated with a layer of polymer material. For high-quality arrangement, especially with non-continuous roofing, it is better to purchase products with a thickness of at least 0.7 mm. The width of the part depends on the length of the plank and the width of the lining and can range from 30 to 60 cm.

NOTE!

Elements with a width of 30 cm are recommended for use when the length of the valley is no more than 4 m or for arranging simple slopes. The optimal value of the overlap of the metal tile over the plank is 25 cm. This is with regard to the lower valley. The size of the top part is not particularly important, since it is used only as a decorative element.

Mounting end strips includes the following steps:

- Before proceeding with the installation of elements, you need to make sure that the waterproofing material is intact.

- In the valley, a continuous crate of boards is mounted, on top of which waterproofing is laid.

- Attach brackets for the drainage system.

- Install the eaves.

- The groove sheets are mounted from the bottom to the top, fastening them with roofing screws. All parts are laid with an overlap of 20-30 cm. The protruding edges of the planks are cut off, after which the cut points are treated with a special paint composition.

Endova on a metal tile

Sheets of metal tiles are laid on slopes adjacent to the valley.

Joints of sheets, if necessary, close upper valley linings. They are laid with an overlap of at least 10 cm.

CAREFULLY!

You can not screw the screws closer, than 25 cm from the axis of the valley.

Snow guards

These elements are several species:

- tubular;

- lattice;

- snow retainers from logs;

- corner;

- rope tows.

Now in order about each.

Tubular

This view is a construction of brackets with  pipes inserted into them. The height of this barrier is 15 cm. The brackets themselves look like vertical plates provided with holes for pipes. Tubular snow retainers are attached to the roof slope with metal screws. They are screwed into holes located on a horizontal shelf, which is at the bottom of the bracket.

pipes inserted into them. The height of this barrier is 15 cm. The brackets themselves look like vertical plates provided with holes for pipes. Tubular snow retainers are attached to the roof slope with metal screws. They are screwed into holes located on a horizontal shelf, which is at the bottom of the bracket.

lattice

Lattice structures consist of brackets with vertical gratings attached to them. Products are made of galvanized steel and are available in various colors, which allows them to be matched to the color of the roofing. The height of the gratings can be different - from 50-70 mm to 150-200 mm. Such barriers are usually mounted on long, steep slopes to ensure that snow layers do not fall.

log cabins

The design consists of logs attached to special hooks that are fixed to the crate or. Today, barriers with wooden logs are practically not used. They were replaced by products from pipes of large diameter. Such structures effectively retain snow and are able to withstand significant loads.

Corner structures

Products are made in the form of corners made of sheet steel and represent the most budget option. Are established for detention of small volumes of snow. They are fastened with the help of shelves located at the bottom of the barrier, and self-tapping screws that are screwed into the upper wave of the sheet. The height of the structure is 40-60 mm. As a rule, such snow retainers are mounted on roofs whose slope does not exceed 30 degrees.

yokes

These elements, made in the form of hooks, by themselves are not capable of holding the snow mass in any significant volumes. Therefore, it is most appropriate use as auxiliary elements when installing tubular and lattice barriers.

The rest of the roofing units are made of metal tiles

Along with the above elements of the roof, an equally important role in its arrangement is played by such additional elements of metal tiles as skates, covering the outer joints between the slopes, as well as adjoining strips, which cover the joints of the roofing with a wall or .

Skates are the following types:

- semicircular - most often installed on roofs with two or four slopes, at the points of their joining;

- rectangular - suitable for almost all types of roofs;

- narrow decorative - used more as a decoration than in the role of protection;

- Y and T-shaped - serve as an addition to rectangular skates and are used to connect them to each other.

Ridge for metal tiles

The junction bar for metal tiles is made of thin steel and has the shape of corners. The horizontal part of the part is attached to the roof, the vertical part - to the wall of the building or to the pipe(depending on the place of application), thereby closing the joint between the roofing material and the building element adjacent to it.

Useful video

Installation of additional elements:

Conclusion

The tightness of the roof depends on the correct installation of additional metal roofing elements, during installation of which all overlaps must be observed and self-tapping screws must be screwed in at the recommended distance. In the absence of work skills, it is best to contact specialists in order to avoid damage to the material and leakage of the roof.