Do-it-yourself induction heating at home, water heating system. Indirect heating boiler: device, operating principle and connection diagrams Water heating system

Read also

Hot water in an apartment or house has always been an integral part of comfort, without which modern man can't imagine his life. There are often cases when hot water is turned off in apartments, but in the private sector the owner himself must take care of its availability. Water heating devices can help in this matter. The design of a boiler for heating water can be very different, but the main thing distinctive feature it from flow-through heaters – the presence of a storage tank in which There is a constant supply of heated, ready-to-use water.

Boiler device for heating water - photo

Modern storage water heaters can be direct or indirect. Direct heating boilers can use electricity or natural gas. In systems indirect heating heat exchange occurs from the home heating system or from other sources of thermal energy (for example, solar water heaters).

Let's consider various schemes devices of modern boilers.

In such systems, thermal energy is transferred directly to water heated for further domestic use. They can be electric or gas.

The layout, location, placement of inlet and outlet pipes, control and automation systems may vary significantly from manufacturer to manufacturer, however circuit diagram- united. The figure shows its general simplified view:

Direct heating electric boiler - diagram

- The entire structure is assembled in metal case(1), having one or another external decorative design. There is a water tank (2) inside, and the space between it and the outer casing is filled with thermal insulation material (3), most often polyurethane foam.

- Innings cold water carried out through the intake pipe (4), on which it is placed check valve And safety valve, triggered when the pressure inside the boiler exceeds. The supply pipe (10) is usually equipped with a mesh sprayer to avoid the formation of turbulent water flows.

- An alternating current is supplied through the power cord (5) to the heating element - heating element (9). The device is necessarily equipped with a temperature control system and a thermostat, which allows you to set the required level of water heating and produce automatic shutdown supplying power when the required temperature is reached.

- The pipe (6) is connected to the hot water supply system - through it, heated water is supplied through a tube (8) from the top of the boiler to the points of consumption. The required pressure is maintained by a constantly open cold water supply - it replenishes the tank as it flows, and it always remains full.

- The air valve (7) serves to bleed air when the boiler is initially filled with water - it prevents the formation of an air cushion.

To prevent galvanic corrosion from occurring in the water tank, an anode made of magnesium is placed in it. Its electrical potential is less than that of the tank body or the surface of the heating element, so destructive corrosion processes will affect it. Periodically, as corrosion and overgrowth occurs, the anode is replaced with a new one.

This scheme is simple and is the most widespread among domestic boilers. Such devices are usually inexpensive, which makes them popular among consumers. Main disadvantage– The heating element operates directly in heated running water, which leads to its fairly rapid overgrowing with mineral deposits dissolved in it.

Direct heating gas boiler

The gas boiler is quite simple in its operating principle and has the following general layout:

- A water tank is located in a metal case (most often made of stainless steel), which has reliable thermal insulation.

- Through the pipe (1) in bottom part cold water is supplied to the container. At the top of the tank there is a welded pipe for collecting heated water with its subsequent distribution to points of consumption.

- The gas burner is located under the bottom of the container (4); it is protected from water by a semicircular panel that acts as a heat exchanger.

- The second heat exchanger is a pipe for removing combustion products - it passes through a container of water. Gases are removed through a conventional chimney or a coaxial type system (depending on the boiler model - open or closed camera combustion).

- The magnesium anode (5) serves to collect scale; it must be changed regularly as it becomes overgrown.

- The boiler must be equipped with a system automatic control– a thermostat (3), to monitor the temperature level, a valve to shut off the gas supply when the set water heating level is reached, a piezo ignition device – to automatic start gas burners when the liquid cools as it is consumed.

A gas boiler has high performance and is much more economical than an electric one. However, he also has significant shortcomings– it requires a mandatory chimney, and its installation is associated with the process of coordinating the project with the regulatory technical supervision authorities. In addition, such direct heating boilers are much more expensive than electric ones.

Indirect heating boilers

The main fundamental difference is that it is heated for domestic needs ( so-called, sanitary) water does not have direct contact with electrical or gas devices heating Broadcast the heat is coming by connecting to the home heating system (or other sources of hot boiler water).

Such a boiler is most often installed in conjunction with a single-circuit heating boiler. This type of boiler can have a volume measured in tens or hundreds of liters, and which one to choose will depend on the number of household members. Models are being produced floor-standing version, or which are attached to the wall horizontally or vertically on special brackets.

According to the organization of heat exchange, they can have completely different layouts:

Boiler with spiral heat exchanger

This boiler is designed as follows:

Indirect heating boiler with a heat exchanger - coil (sectional photo)

- A voluminous tank for sanitary water is placed inside the thermally insulated body. A heat exchanger (2) shaped like a coil is installed in its cavity.

- Through pipes 3 and 4, the coolant circulates - hot process water, obtained from a single-circuit boiler. Heat is transferred to sanitary water, which enters the lower part of the tank through the inlet pipe (1).

- Heated sanitary water is discharged from the upper part of the tank through the pipe (5).

The coil in some models is located closer to the bottom of the tank, where cold water falls, and in others it is evenly distributed throughout the tank, which allows you to quickly heat the entire volume of liquid.

Boilers are produced, the design of which includes two heat exchanger tubes. The coolant heated by the boiler passes through one circuit, and through the second - from other possible heat sources, for example, from solar water heaters.

Tank-in-tank scheme

Another version of the indirect heating boiler does not have coils with coolant inside, but is designed slightly differently. It consists of two containers that are installed one inside the other. Naturally, the tank, which is located inside, has a smaller volume - it is an accumulator of heated sanitary water.

Indirect heating according to the “tank in tank” principle

The diagram clearly shows internal structure this model.

- Through pipe 1, cold sanitary water is supplied to the internal tank.

- Connections 2 and 4 are connected to the heating system - boiler hot water circulates through them.

- The internal tank (3) is made of stainless steel.

- Through pipe 5, heated water is taken for domestic consumption.

Positive qualities of indirect heating boilers:

- Good performance of the device if the heat exchanger has sufficient area and the boiler is connected to a high-power boiler.

- Saving energy and eliminating the load on the power grid.

- The coolant does not come into contact with sanitary water. Specially prepared water, which contains a minimum of salts, passes through the heat exchanger.

- Possibility to switch the boiler to different energy sources, e.g. winter time it can be powered by a heating boiler, and in the summer - by a solar battery.

However, there are also disadvantages:

- When water is heated in the boiler, the temperature in the heating system decreases.

- This is quite expensive equipment compared to a direct heating boiler.

- The whole complex takes up quite a lot of space, i.e. It is better to allocate a separate room for it, which is not always possible.

You can learn more about the design of a boiler for heating indirect water by watching the video attached to the article:

Video - overview of the capabilities of an indirect heating boiler

Combined action boilers

A good option are boilers that combine both principles. They are connected to the heating circuit, but their design also implies the presence of their own heating element. For example, here is a diagram of the SMART heating boiler from ACV:

- A steel outer tank (8) made of sheet hoist with reliable polyurethane foam thermal insulation (3) is installed in an impact-resistant polypropylene casing (10). It serves to circulate water from the heating system supplied from the boiler through the pipes (11).

- Inside it there is a tank for sanitary water made of stainless steel (9). It provides for the inlet of water from the hot water supply (14) and its discharge to the points of consumption through a tube (2).

- In the upper part there is a cover (7) with a manual air vent (1) - for the initial filling of the system.

- Inside the external tank there is a heating element with a power of 2 to 6 kW (5) - it will turn on at the command of the automatic controller if the thermostat (4) detects insufficient heating through the external heat exchange system. In the summer, when the heating system is turned off, the heating element will be the main source of thermal energy.

- The control panel is equipped with the necessary adjustment devices - the heating temperature of sanitary water, a timer for turning on the heating element (for example, for its use at a preferential night rate).

This boiler design is the most universal and combines positive traits all the systems mentioned above. Perhaps the only drawback of such a water heater is its rather high price.

When choosing a water heater, consider the pros and cons of each option by looking at the characteristics of each. It is also important to pay attention to the size of the selected device and think about the space it should occupy.

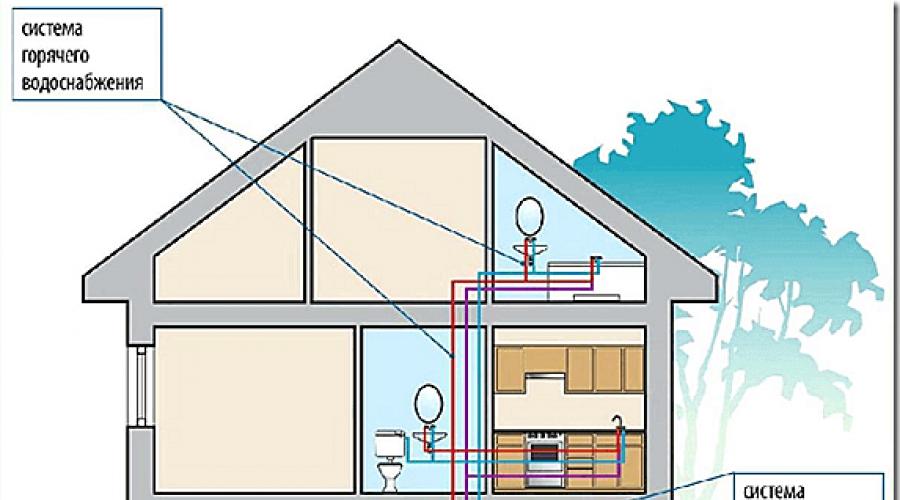

Two DHW schemes for a country private house - which one to choose?

What needs to be done to ensure that hot water flows immediately after opening the tap?

Depending on the method of heating water hot water supply systems (DHW) for private country house divided into:

- DHW with instantaneous water heater.

- DHW with storage water heater (boiler).

Scheme of hot water supply with instantaneous water heater

As instantaneous water heater can be used:

- DHW gas water heater;

- DHW heating circuit of a double-circuit heating boiler;

- electric instantaneous water heater.

- plate heat exchanger connected to the heating circuit.

Instantaneous water heater begins to heat the water at the moment the water is drawn when the tap is opened hot water.

All energy spent on heating passes from the heater to the water almost instantly, in a very short time of water movement through the heater. In order to obtain water at the required temperature in a short period of time, the design of an instantaneous water heater provides for limiting the speed of water flow. The water temperature at the outlet of the flow-through heater very much depends on the water flow — the size of the stream of hot water flowing from the tap.

To properly supply hot water to only one shower head, the power of the instantaneous water heater must be at least 10 kW. You can fill a bathroom in a reasonable time using a heater with a power of more than 18 kW. And if, when filling the bathtub or running the shower, you also open the hot water tap in the kitchen, then For comfortable use of hot water, you will need a flow heater power of at least 28 kW.

To heat an economy class home, a lower power boiler is usually sufficient. That's why, power double-circuit boiler choose based on the need for hot water.

A DHW circuit with an instantaneous water heater cannot provide comfortable and economical use of hot water in the house for the following reasons:

- With low hot water consumption The instantaneous water heater does not turn on at all and does not heat the water. To obtain water at the required temperature, it is often necessary to spend more water than is necessary.

- Each time the water tap is opened, the instantaneous water heater starts again. Constantly turning on and off, which reduces the resource of its work. Each time, hot water appears with a delay, only after the heating mode has stabilized. Frequent restart of the heater reduces efficiency and increases energy consumption. Some of the water goes down the drain uselessly.

- It is impossible to recirculate water in the distribution pipes throughout the house. Hot water from the tap appears with some delay. The waiting time increases as the length of the pipes from the water heater to the water collection point increases. Some of the water at the very beginning has to be drained uselessly into the sewer. Moreover, this is water that has already been heated, but has managed to cool down in the pipes.

- Scale deposits accumulate quickly on a small surface inside the heating chamber of an instantaneous water heater. Hard water will require frequent descaling.

The temperature and pressure of water in the pipes very much depend on the amount of water flow. For this reason When you open another tap, the water temperature and pressure in the hot water system changes greatly. It is very uncomfortable to use water even in two places at the same time.

Ultimately, the use of an instantaneous water heater in a hot water supply system leads to an unreasonable increase in water consumption and volume of sewage waste, to an increase in energy consumption for heating, as well as to insufficiently comfortable use of hot water in the house.

A hot water supply system with an instantaneous water heater is used, despite its disadvantages, due to relatively low cost and small size equipment.

The system works better if Install a separate individual instantaneous water heater near each water collection point.

In this case, it is convenient to install electric flow heaters. However, such heaters, when drawing water simultaneously in several places, can consume significant power from the electrical network (up to 20 - 30 kW). Typically, the electrical network of a private home is not designed for this, and the cost of electricity is high.

How to choose an instantaneous water heater

The main parameter for choosing an instantaneous water heater is the amount of water flow that it can heat.

- from the tap of a sink or washbasin 4.2 l/min (0,07 l/sec);

- from the bath or shower tap 9 l/min (0,15 l/sec).

For example.

Three points of disassembly are connected to one instantaneous water heater - a sink in the kitchen, a washbasin and a bathtub (shower). To fill only the bathtub, you must select a heater that is capable of delivering at least 9 l/min. water with a temperature of 55 o C. Such a water heater will also provide the use of hot water simultaneously from two taps - in the sink and washbasin.

It will be comfortable to use hot water in the shower and washbasin at the same time if the heater capacity is no less than 9 l/min+4,2 l/min=13,2 l/min.

Manufacturers in technical specifications usually indicate maximum performance instantaneous water heater, based on water heating to a certain temperature difference, dT, for example 25 o C, 35 o C or 45 o C. This means that if the water temperature in the water supply is +10 o C, then at maximum performance water will flow from the tap with a temperature of +35 o C, 45 o C or +55 o C.

Be careful. Some sellers in advertising indicate the maximum performance of the device, but “forget” to write for what temperature difference it is defined. You can buy a gas water heater with a capacity of 10 l/min., but it turns out that at such a flow rate it will heat the water by only 25 o C., i.e. up to 35 o C. Using hot water with such a column may not be very comfortable.

Suitable for our example geyser or a double-circuit boiler with a maximum output of at least 13.2 l/min at d T=45 o C. The power of the gas appliance with these hot water parameters will be about 32 kW.

When choosing an instantaneous water heater, pay attention to one more parameter - minimum productivity, consumption l/min, at which the heating is turned on.

If the water flow in the pipe is less than the value specified in the technical characteristics of the device, the water heater will not turn on. For this reason, often you have to use more water than necessary. Try to choose a device with the lowest possible minimum performance, for example, no more than 1.1 l/min.

Electric instantaneous water heaters intended for domestic use have a maximum heater power of about 5.5 - 6.5 kW. At maximum performance 3.1 - 3.7 l/min heat water at d T=25 o C. One such water heater is installed to serve one water point - a shower, washbasin or sink.

DHW circuit with storage heater (boiler) and water circulation

A storage water heater (boiler) is a heat-insulated metal tank of a fairly large volume.

Most often, two heaters are built into the lower part of the water heater tank at once - an electric heating element and a tubular heat exchanger connected to heating boiler(). The water in the tank is heated by the boiler most of the time.

The electric heater is turned on as needed when the boiler is stopped. This boiler is often called indirect heating boiler.

Hot water in an indirect heating boiler is consumed from the top of the tank. In its place, cold water from the water supply immediately enters the lower part of the tank, is heated by a heat exchanger and rises upward.

In the European Union, hot water systems in new houses are required to be equipped with a solar heater - a collector. To connect solar collector another heat exchanger is installed in the lower part of the indirect heating boiler.

DHW circuit with layer-by-layer heating boiler

Last time The DHW system with a stratified heating boiler is gaining popularity, the water in which is heated by a flow-through water heater. This boiler does not have a heat exchanger, which reduces its cost.

Hot water is drawn from the top of the tank. In its place, cold water from the water supply immediately flows into the lower part of the tank. The pump drives water from the tank through a flow-through heater and supplies it directly to the top of the tank. Thereby, The consumer gets hot water very quickly— you don’t need to wait until almost the entire volume of water warms up, as happens in an indirect heating boiler.

Rapid heating of the top layer of water, allows you to install a smaller boiler in the house, as well as reduce the power of the flow-through heater, without sacrificing comfort.

The Galmet SG (S) Fusion 100 L layer-by-layer heating boiler is connected to the DHW circuit of a double-circuit boiler or to a gas water heater. The boiler has a built-in three-speed circulation pump. Boiler height 90 cm, diameter 60 cm.

The Galmet SG (S) Fusion 100 L layer-by-layer heating boiler is connected to the DHW circuit of a double-circuit boiler or to a gas water heater. The boiler has a built-in three-speed circulation pump. Boiler height 90 cm, diameter 60 cm. Manufacturers produce double-circuit boilers with built-in or remote layer-by-layer heating boiler. As a result,the cost and dimensions of the DHW system equipment are somewhat smaller,than with an indirect heating boiler.

The water in the boiler is heated in advance, regardless of whether it is spent or not. The hot water reserve in the tank allows you to use hot water in the house for several hours.

Thanks to this, heating the water in the tank can be done quite long time, gradually accumulating thermal energy in hot water. Hence another name for the boiler - cumulative water heater

Long duration of water heating allows use a relatively low power heater.

Storage gas water heater - boiler

Storage boilers, the water in which is heated by a gas burner, are less popular in domestic hot water systems. Installation of heating and hot water systems in the house with two gas appliances - a gas boiler and a gas boiler, it turns out noticeably more expensive.

Cumulative gas water heater- boiler

Cumulative gas water heater- boiler It can be advantageous to install gas boilers in apartments with central heating or in private houses with heating solid fuel boiler and heating water in the hot water supply system with liquefied gas.

Gas water heaters, like boilers, are produced with open camera combustion and closed, with forced removal of flue gases and with natural draft in the chimney.

Savings are available for sale gas boilers, which do not require connection to the chimney. (Household gas stoves They also work without a chimney.) The power of the gas burners of such devices is small.

Gas boilers with a capacity of up to 100 liters are designed for wall mounting. Large volume water heaters are installed on the floor.

Water heaters are used different ways gas ignition— with a duty wick, electronic on batteries or hydrodynamic ignition.

In the devices with a duty wick A small flame is constantly burning, which is first ignited manually. A certain amount of gas burns uselessly in this torch.

Electronic ignition works from the mains or battery, accumulator.

Hydrodynamic ignition it is launched by the rotation of a turbine, which is driven by the flow of water when the tap is opened.

How to choose the volume of a storage water heater - boiler

The larger the volume of the storage water heater, the higher the comfort of using hot water in the house. But on the other hand, the larger the boiler, the more expensive it is, the higher the costs for its repair and Maintenance, those more space he borrows.

The size of the boiler is selected based on the following considerations.

Increased comfort will be provided by a boiler, the volume of which is selected at the rate of 30 - 60 liters per user of water.

A high level of comfort will be provided by a water heater with a volume of 60-100 liters per person living in the house.

Almost all the water must be used to fill the bathtub. from a boiler with a volume of 80 - 100 liters.

How to choose boiler power for a DHW boiler

When choosing a boiler, you need to pay attention to the power of the heating element that is installed in it. For example, to heat 100 liters of water to a temperature of 55 o C within 15 minutes a heater must be installed in the boiler (heat exchanger for the boiler, built-in gas-burner or heating element) with a power of about 20 kW.

IN real conditions During operation, the temperature of the water in the boiler is equal to the temperature of the water in the water supply only when the heating is first turned on. In the future, the boiler almost always contains water that has already been heated to a certain temperature. To heat water to the required temperature in an acceptable time, use heating devices less power.

But it’s still better to check how long it will take to heat the water in the boiler. This can be done using the formula:

t = m cw (t2 – t1)/Q, wherein:

t– water heating time, seconds ( With);

m– mass of water in the boiler, kg (mass of water in kilograms equals the volume of the boiler in liters);

cw– specific heat capacity of water equal to 4.2 kJ/(kg K);

t2– the temperature to which the water should be heated;

t1– initial water temperature in the boiler;

Q– boiler power, kW.

Example:

Time for heating water with a boiler with a power of 15 kW in a 200-liter boiler from a temperature of 10 °C(we assume that the water entering the boiler has this temperature) up to 50 °C will be:

200 x 4.2 x (50 – 10)/15 = 2240 With, that is, about 37 minutes.

DHW scheme with water recirculation in the system

The use of a storage water heater in a domestic hot water system allows for the recirculation of hot water in pipelines. All hot water collection points are connected to a ring pipeline through which hot water constantly circulates.

The length of the pipe section from each point of hot water consumption to the ring pipeline should not be more than 2 meters.

Hot recirculation pump DHW water has small dimensions and low power

Hot recirculation pump DHW water has small dimensions and low power Water recirculation in the DHW system is ensured by a circulation pump. The pump power is small, several tens of watts.

Pumps for DHW, unlike heating pumps, must have a maximum operating pressure at least 10 bar. Heating pumps are often designed to maximum pressure no more than 6 bar. Another difference is that the DHW pump must have a hygienic certificate allowing use in drinking water supply systems.

The water in hot water supply systems is constantly renewed and the oxygen content in it remains quite high. Hot water is highly corrosive. In addition, hot water must correspond sanitary requirements To drinking water. Therefore, for making DHW pumps use corrosion-resistant non-ferrous metals or stainless steel. For these reasons, circulation pumps for hot water supply are noticeably more expensive than similar pumps for heating systems.

In some designs DHW pipelines It is possible to create natural water recirculation, without a pump.

As a result of water circulation in the DHW system hot water is constantly supplied to the sampling points.

In a DHW system with a storage heater and water recirculation, the water supply mode is more stable:

- Hot water is always present at the sampling points.

- Water can be collected simultaneously in several places. The temperature and pressure of water change slightly when the flow rate changes.

- You can take any, no matter how small, amount of hot water from the tap.

The recirculation circuit not only improves the comfort of water supply at remote points in the house, but also provides possibility to connect underfloor heating circuits to it V separate rooms. For example, in a bathroom, a water-heated floor will be comfortable all year round.

A DHW system with water recirculation constantly consumes energy for the operation of the circulation pump, as well as to compensate for heat losses in the boiler itself and in the pipes with circulating water. To reduce energy consumption, it is recommended to install a circulation pump with a built-in programmable timer that turns off water circulation during hours when it is not needed. The boiler and hot water pipes are insulated.

Disadvantages of a hot water supply system with a double-circuit gas boiler or water heater

Clocking of a double-circuit boiler in heating mode

As you know, a double-circuit gas boiler can provide a house with hot water and be a source of heat in the heating system. Hot water is prepared in a flow-through heat exchanger of the boiler. Read about the general disadvantages of a DHW system with a flow-through heater at the beginning of this article. But gas apparatus with a flow-through heater, there is another problem - the difficulty of choosing the maximum power of a double-circuit boiler or water heating gas water heater.

Most often it turns out that required power boiler for preparing hot water, significantly more power needed to heat all rooms in the house.

As already mentioned in the article above, to obtain hot water at the required temperature and its maximum flow rate, double-circuit gas boilers and hot water geysers have a fairly large maximum power, about 24 kW . or more. Boilers and heaters are equipped with automatic equipment, which can, by modulating the burner flame, reduce their power to a minimum, equal to approximately 30% of the maximum. The minimum power of a double-circuit gas boiler or water heater is usually about 8 kW. or more. This is the minimum boiler power, both in DHW and heating modes.

Gas burner of a double-circuit boiler or water heater due to design features cannot work stably with power less than the minimum (less than 8 kW.). At the same time, to work with the heating system of a private house or autonomous heating of an apartment, the boiler in heating mode very often must produce a power of less than 8 kW.

For example, power 8 kW. enough to provide heat to the premises of a house or apartment with an area of 80 - 110 m 2, and on the coldest five-day period heating season. In warmer periods, the productivity and power of the boiler should be significantly less.

Due to the fact that the boiler cannot operate below the minimum power, problems arise with adaptation (coordination) of a double-circuit boiler and heating system.

In small facilities with low heat consumption for heating, the boiler produces more heat than the heating system can accept. As a result of inconsistency between the parameters of the boiler and the system, the double-circuit boiler begins to operate in pulse mode, "beat"- as people say.

Working in “clocking” mode significantly reduces the service life of boiler parts and significantly reduces efficiency.

Clocking a gas boiler or water heater in DHW mode

Heating diagram tap water double-circuit gas boiler or hot water column, depending on the temperature ( T o C) and flow rate ( Q l/min) hot water. The thick line shows the boundaries of the Working Area. Gray zone, pos. 1 - clock zone boiler or column (switching between ON/OFF).

Heating diagram tap water double-circuit gas boiler or hot water column, depending on the temperature ( T o C) and flow rate ( Q l/min) hot water. The thick line shows the boundaries of the Working Area. Gray zone, pos. 1 - clock zone boiler or column (switching between ON/OFF). For normal heating of water by a boiler or column, on the diagram the point of intersection of the temperature and hot water flow lines (operating point) must always be inside working area, the boundaries of which are shown in the diagram with a thick line. If the hot water consumption mode is selected so that the operating point will be in the gray zone, pos. 1 on the diagram, then the boiler and column will clock. In this zone, with a small water flow, the power of the boiler or dispenser turns out to be excessive, the boiler, dispenser turns off due to overheating, and then turns on again. Either hot or cold water comes out of the tap.

Low efficiency of double-circuit gas boilers and water heaters

Double-circuit gas boilers when working with maximum power have an efficiency of more than 93%, and less than 80% when operating at minimum power. Imagine how the efficiency will further decrease if such a boiler has to operate in pulse mode, with the gas burner constantly re-igniting.

Please note that a double-circuit boiler operates at minimum power most of the time throughout the year. At least 1/4 of the spent gas will literally fly uselessly down the pipe. Add to this the cost of replacing prematurely worn-out boiler parts. This will be the price to pay for installing cheap heating and hot water equipment in your home.

What do you want - choose

If the power of a double-circuit gas boiler is more than 20 kW., selected based on maximum heating required flow hot water, then the boiler cannot provide economical and comfortable operation in mode low power heating and when heating water with low flow rates. The same can be said about the operation of a hot water column.

Most often, there is no need to prepare large flows of hot water in the house. For many people, it is much more important to ensure comfortable and economical use of hot water with low consumption.

For such thrifty owners many manufacturers produce double-circuit gas boilers and water heaters with a maximum power of about 12 kW. and the minimum is less than 4 kW. Such boilers and heaters will provide more economical and comfortable heating and the use of hot water in quantities sufficient for taking a shower or washing dishes.

Before purchasing a double-circuit boiler or water heater, owners need to decide, which mode of hot water consumption is more profitable and comfortable - with a large water flow or with a small one. Based on this decision, choose the power of the boiler or dispenser. If you want both, you will have to choose a hot water system with a boiler.

For shower lovers, for preparing hot water and heating houses and apartments with a heated area of up to 140 m 2, with one bathroom power 12 kW. They the best way meet the needs of heating and hot water systems of small private houses and apartments.

For those who love to take a bath, as well as for houses and apartments large sizes, with an area of more than 140 m 2, I highly recommend using a single-circuit boiler.

Many manufacturers heating equipment They produce special kits, a boiler plus a built-in or remote boiler, just for such cases. Such a set of equipment will be more expensive, but will provide an increased service life of the equipment, gas savings and more comfortable use of hot water.

DHW circuit with sewerage heat recuperator

IN Western Europe and popular in the world various ways saving energy when operating a private home.

Hot water from the house flows down the drain after use and takes away with it a significant part of the thermal energy that was spent on heating it.

Scheme for the recovery of thermal energy from sewerage wastewater into the hot water supply system

Scheme for the recovery of thermal energy from sewerage wastewater into the hot water supply system To reduce energy losses in the house, a scheme is used to recover (return) heat from sewage into the domestic hot water system of a private house.

Cold water passes through a heat exchanger before entering the DHW boiler. The wastewater from sanitary equipment is sent to the heat exchanger.

In the heat exchanger, two streams, cold water from the water supply and hot water from the wastewater, meet but do not mix. Some of the heat from hot water is transferred to cold water. The hot water boiler receives already heated water.

In the diagram shown in the figure, only those sanitary fixtures that operate with hot water flow are sent to the heat exchanger. This recovery scheme is advantageous to use with any method of heating water - both with a boiler and with a flow-through heater.

To recover heat from the drains of sanitary fixtures, which first accumulate hot water and then release it into the sewer system (bathtub, swimming pool, washing machine, etc.) dishwasher), apply more complex circuit with water circulation between the boiler and the heat exchanger while these devices are emptying.

For houses and apartments with permanent residence, I highly recommend using DHW system with layer-by-layer heating boiler and double-circuit boiler, or with indirect heating boiler and a single-circuit boiler. The boiler volume is at least 100 liters. The system will provide good comfort use of hot water, economical consumption of gas and water, as well as a smaller volume of waste into the sewer. The only disadvantage of such a system is that it is more high price equipment.

With a limited construction budget in small suburban areas country houses For seasonal residence You can install a hot water system with a flow-through heater.

It is advisable to use a DHW circuit with a flow-through heater in houses with a kitchen and one bathroom, where the heating source and hot water collection points are located compactly, at a short distance from each other. It is recommended to connect no more than three water taps to one instantaneous water heater.

The cost of such a system is relatively low, and the disadvantages of operation in this case are less pronounced. A double-circuit gas boiler or gas water heater takes up little space. Almost everything necessary equipment mounted in the device body. For installing a boiler with a capacity of up to 30 kW or a gas water heater does not require a separate room.

For preparing hot water and heating houses and apartments with a heated area of up to 140 m 2, with one shower in the bathroom, I recommend installing double-circuit gas boilers with maximum power 12 kW.

In a DHW system with a gas water heater or a double-circuit boiler the stability of the water supply mode will increase significantly if the circuit install a buffer tank between the heater and water collection points- a conventional storage electric water heater. It is especially recommended to install such a buffer storage electric water heater near distribution points remote from the gas appliance.

Read more:

Read more: In a scheme with a buffer tank, hot water from a gas water heater or double-circuit boiler first enters the tank of an electric boiler - water heater. Thus, the tank always contains a supply of hot water. An electric heater in the tank only compensates for heat loss and maintains required temperature hot water during periods when there is no water supply. An electric water heater with a small capacity tank is enough - even 30 liters, and using hot water will become much more comfortable.

DHW system with instantaneous water heater and built-in boiler or remote layer-by-layer heating boiler will be somewhat more expensive. But here you will not need to spend expensive electricity to maintain the water temperature, and the comfort of using water will be the same as with an indirect heating boiler.

In houses with an extensive DHW networkimplement a scheme with a storage water heater (boiler) and water recirculation. Only such a scheme will provide the necessary comfort and economical operation of the hot water system. True, the initial costs of its creation are the highest.

It is recommended to buy boilers that are sold complete with a boiler. In this case, the parameters of the boiler and boiler have already been correctly selected by the manufacturer, and most additional equipment built into the boiler body.

If the heating in the house is provided by a solid fuel boiler, then it is beneficial to install, to which to connect a hot water supply system with water circulation.

Otherwise, to heat water in the house, connected to a solid fuel boilerindirect heating boiler, additionally equipped with an electric heater.

It is beneficial to use an electric hot water boiler in a house with a solid fuel boiler

It is beneficial to use an electric hot water boiler in a house with a solid fuel boiler Often, only electricity is used to heat water in a house with a solid fuel boiler. For hot water supply in the house, near water points, a storage tank is installed electric boiler- water heater. There is no hot water circulation system in this option. It is more profitable to install your own separate storage heater near remote water collection points. In this case, electricity is spent more economically on heating water.

When heating water above 54 o C Hardness salts are released from the water. To reduce scale formation If possible, heat the water to a temperature lower than specified.

Instantaneous water heaters are especially sensitive to scale formation. If hard water, contains more than 140 mg CaCO 3 in 1 liter, then the use of instantaneous water heaters, including those with stratified heating boilers, for heating water is not recommended. Even small scale deposits clog the channels in flow heater, which leads to the cessation of water flow through it.

It is recommended to supply water to the instantaneous water heater through an anti-scale filter, which reduces water hardness. The filter has a replaceable cartridge that will have to be changed regularly.

To heat hard water, it is better to choose a hot water storage system with an indirect heating boiler. Salt deposits on the heating element of the boiler do not impede the flow of water, but only reduce the performance of the boiler. The boiler is easier to clean from scale.

It should be remembered that prolonged heating of water to a temperature less than 60 o C can lead to the appearance of storage tank(boiler) with hot water contains Legionella bacteria harmful to human health. Recommended periodically perform thermal disinfection of the hot water system, increasing the water temperature to 70 o C for some time.

More articles on this topic:

The modern and most economical device for heating water is an induction water heater. Unlike analogues, it is completely environmentally friendly, does not dry out or burn out air, and meets modern safety requirements. It can be used both as an instantaneous water heater and as a boiler for heating a room. The device is usually bought in a store, but we offer an alternative - making it yourself. In the latter case, the device may not have such an attractive appearance, but will cost much less.

Pros and cons of induction water heating devices

The device has quite simple design and does not require special documents permitting use and installation. The induction water heater has high degree efficiency and optimum user reliability. When using it as a heating boiler, you don’t even need to install a pump, since water flows through the pipes due to convection (when heated, the liquid practically turns into steam).

The device also has a number of advantages, which sets it apart from other types of water heaters. So, an induction heater:

In induction heaters, water becomes hot due to the pipe through which it flows, and the latter is heated due to the induction current created by the coil.

- much cheaper than its analogues, such a device can be assembled independently without any problems;

- completely silent (although the coil vibrates during operation, this vibration is not noticeable to humans);

- during operation it vibrates, thanks to which dirt and scale do not stick to its walls, and therefore does not require cleaning;

- has a heat generator that can be easily made sealed due to the operating principle: the coolant is located inside the heating element and the energy is transferred to the heater through electromagnetic field, no contacts needed; so won't be needed sealing rubber bands, seals and other elements that can quickly deteriorate or leak;

- there is simply nothing to break in the heat generator, since the water is heated by an ordinary pipe, which is unable to deteriorate or burn out, unlike a heating element;

Don’t forget that servicing an induction heater will be much cheaper than a boiler or gas boiler. The device has a minimum of parts that almost never fail.

Despite the huge number of advantages, an induction water heater also has a number of disadvantages:

- the first and most painful for owners is the electricity bill; the device cannot be called economical, so you will have to shell out a fair amount of money to use it;

- second, the device gets very hot and heats not only itself, but also the surrounding space, so it is better not to touch the body of the heat generator during its operation;

- third, the device has extremely high efficiency and heat transfer, so when using it be sure to install a temperature sensor, otherwise the system may explode.

DIY induction water heater: diagram

The device is a transformer with two windings: primary and secondary. The first circuit converts electrical energy into eddy currents, thereby creating a directed induction field, which provides induction heating. In the secondary circuit, the converted energy is transferred to the coolant (in our case, it is water).

It is important to consider the type of material from which the winding is made. So, in household models most often used copper wire. This material is well suited for heating water in boilers.

In addition to the transformer, the device contains a generator and a pump (optional).

Diagram of a simple induction water heater. As you can see, the device has a fairly simple design and a small number of elements.

Heat generator components and parts

The device includes:

- generator alternating current, which increases the frequency of the current;

- the inductor, which transforms electricity into magnetic energy, is a coil of copper wire;

- heating element, most often its role is played by a metal pipe.

Thanks to this design, energy transfer is carried out practically without losses. Efficiency reaches 98%.

Principle of operation

An induction water heater consists of a generator, a coil and a core, the latter is heated by electromagnetic energy

The device converts electrical energy into electromagnetic energy. The latter, in turn, acts on the core (pipe), which heats up and transfers thermal energy to the water. All these energies are converted by an inductor consisting of a coil and a core. The generator is used to increase the frequency of the current, since with a standard frequency of 50 Hz it is difficult to achieve high heating.

In factory models, the current frequency reaches 1 kHz.

DIY instantaneous induction water heater

Before you begin installation, you need to stock up necessary details. So, the best option there will be a high-frequency welding inverter, a smoothly varying current range. Such a device will cost the least. A more expensive option would be a three-phase transformer, which is the AC power source for the water heater inductor. In this case, you should use a coil of 50-90 turns, and use copper wire with a diameter of 3 millimeters or more.

As a core, you can use either a metal or polymer pipe together with wire (used as a heating element). In the latter case, the thickness of the walls should not be less than 3 mm in order to easily withstand high temperatures.

To assemble the water heater you will need: wire cutters, screwdrivers, a soldering iron and welding machine if a metal pipe is used.

Installation of an induction water heater

Wrap the pipe with copper wire, making about 90 turns.

There are many options for assembling the device. We suggest trying to assemble the device according to the following scheme:

- Prepare workplace, materials and tools.

- Record a small section polymer pipe(Do not forget that minimum thickness walls should be 3 mm).

- Trim the ends of the core to leave 10 cm of wire left for taps.

- On lower branch mount the corner. In the future, the return from the heating should be connected here (if the heater is used as a boiler).

- Place the chopped wire tightly around the pipe. It is necessary to make at least 90 turns.

- Install a tee on the top pipe through which hot water will flow out.

- Mount protective circuit devices. It can be made from either polymer or metal.

- Connect copper wire to the water heater terminals, then fill the core with water.

- Check the functionality of the inductor.

Recommendations. It is better to install ball valves on all terminals for convenience and ease of dismantling the water heater in the event of a breakdown. But it is not necessary to fill the pipe with metal pieces, since this does not give the desired effect. Do not forget to leave a window in the housing for access to the control panel of the welding machine.

Induction water heaters for heating

Heating circuit, where an induction boiler serves as a coolant heater.

Such a device has proven itself not only as an instantaneous water heater, but also as a heating boiler. True, in this case the welding machine will no longer be suitable as a generator, you will have to use a transformer with two windings. The latter transforms eddy currents arising on the primary winding into an electromagnetic field that is created on the secondary circuit.

In a heating system, the coolant can be not only water, but also oil or antifreeze. That is, any liquid capable of conducting electric current.

An induction water heater boiler must be equipped with two pipes for hot and cold water. Cold water will flow from the bottom; it must be mounted on the inlet section of the line, and on top it is necessary to place a pipe that will supply hot water to the heating system. As a result, water circulates naturally under the influence of convection without a pump.

What you need to know about security

Don't forget that we are dealing with the source increased danger– an electric heating device, therefore, when assembling and using it, you must follow some rules:

Be sure to use a separate electric line to connect an induction boiler, and also equip it with a safety group.

- If water circulates naturally in the boiler, be sure to equip it with a temperature sensor so that if it overheats, the device turns off automatically.

- Do not connect a homemade water heater to an outlet; it is better to draw a separate line for this with a larger cable cross-section.

- All open areas Wires must be insulated to protect people from electric shock or burns.

- Never turn on the inductor if the pipe is not filled with water.. Otherwise, the pipe will melt and the device will short out or it may even catch fire.

- The device must be mounted at a height of 80 cm from the floor, but so that about 30 cm remains from the ceiling. Also, you should not install it in a residential area, since the electromagnetic field has a bad effect on people’s health.

- Don't forget to ground the inductor.

- Be sure to connect the device through an automatic circuit breaker so that in the event of an accident, the latter will cut off the power from the water heater.

- A safety valve must be installed in the pipeline system, which will automatically reduce the pressure in the system.

Conclusion

An induction water heater has a high efficiency, can act as a boiler for a heating system, self-assembly and installation are also allowed, and its use is not regulated in any way by the law of the Russian Federation. But still, before using it, it is worth weighing the pros and cons. Despite its high efficiency, the device consumes a large number of energy, is considered unsafe (especially homemade) and has a bad effect on human health. Therefore, we recommend installing the inductor in a private house or country house.

Today induction heating creates quite strong competition for gas and electric boilers. And in the heating equipment market, induction boilers are positioned as one of the most economical options. If such boilers began to appear in industry in the distant 80s, then already in the 90s they began to be used for domestic purposes.

Basic operating principles

Operating principle of an induction boiler

Already from the name of induction heating you can understand that the operation of such boilers is based on the principle electromagnetic induction. And to understand exactly how the system works, it is enough to pass a large current through a coil of thick wire. An electromagnetic field will definitely appear around this device, and quite a strong one. And if you put any ferromagnet in it - that is, that metal that is attracted, then it will heat up - and quite quickly.

So, simplest example induction heating, that is, the heat source, is a coil that is wound on a dielectric pipe.

A steel core must be placed inside. The coil, which is connected to a source of electricity, will heat the metal rod. Now all that remains is to connect the device to the main line where the coolant circulates, and such primitive induction heating with your own hands will begin to work.

To briefly describe the principle of operation, it will require only a few judgments. Electric Energy creates an electromagnetic field. The metal core heats up when exposed to electromagnetic waves. Excess heat from the rod goes to the coolant, heating it.

The coolant in such systems can be not only ordinary water, but also ethylene glycol and oil. Due to the fact that the liquid is heated intensely, convection currents are obtained. The hot coolant rises, and its power is already enough for a small circuit to work. If the line is long, then it is necessary to install a circulation pump.

Heating system with induction boiler

Debunking myths

Sometimes in stores selling equipment for induction heating at home, you can hear simply unrealistic characteristics assigned to it. And, unfortunately, such properties are not always true. There are several basic points that you should know the truth about:

- Novelty of the principle. Many argue that this innovative technologies, which are built on the principles of physics. In reality, the situation is like this: the phenomenon of electromagnetic induction was discovered by Michael Faraday back in 1831. And since the twentieth century, the induction heating system has been widely used in industry to melt steel. As we see, this is not new technology, but just a well-known principle that has found application in modern times for everyday purposes.

Heating water in an induction boiler

- Economical. A common statement is that an induction heater for heating uses 20-30% less energy than other electric analogues. In reality, everything is like this: any heating device converts 100 percent of the energy it uses into heat - of course, if it does not do mechanical work. The efficiency may be lower. It all depends on how the heat is dissipated around the heating device. The time it takes for the coolant to heat up to the desired temperature directly depends on how efficient the heating element is. Therefore, lofty speeches about revolutionary economy are just tricks. After all, no one has canceled the law of conservation of energy. To get 1 kW of heat, you need to spend at least 1 kW of electricity. In addition, some of the heat will be wasted just like that. For example, the coil itself heats up, since the conductor resistance is not zero.

Economic effect of using an induction boiler

- Durability. Another common statement is that heating with an induction stove will work for you for at least 25 years, and that this is the most durable option heating with electricity. Mechanical wear of boilers of this type is impossible, since they have no moving elements. Copper winding is highly durable and, if used with proper cooling, will last a long time. In any case, the core will gradually deteriorate - since it can be affected by aggressive impurities, and constant heating and cooling will not impart strength. But we note that even this process is very long. The control circuit contains several transistors. They will determine the service life of all equipment without failure. Typically a 10 year warranty is provided. Although there are cases where the equipment worked for 30 years. The conclusion from all this is the following: induction heaters Heating water will work much longer than its analogues - heating elements.

- Irreplaceable properties. Many people say that induction boilers retain their original characteristics for decades due to the fact that scale does not appear here. First of all, let's say that the influence of scale is slightly exaggerated. The lime layer does not have high heat-insulating properties, and in closed system there won't be a lot of deposits. But the same cannot be said about the core - scale is a common occurrence here. So, heating using an induction cooker is really not subject to scale.

- Quiet operation. In fact, if you study the reviews, you can say that any electric boiler will not make noise when heating water, since there are no acoustic vibrations. Noise can only come from pumps. So the judgment is correct.

- Compactness. Induction equipment can be installed in any room. This statement is true: this device- This is a piece of pipe that does not require any special space.

Induction boiler

- Induction heating of water for heating is safe. If a coolant leak occurs, the electromagnetic field will not disappear automatically. The core will continue to heat up; if the power supply is not interrupted, the housing and mount will melt in a matter of seconds. That is why during installation it is necessary to provide for automatic shutdown of the induction boiler in such situations.

The boiler is used to heat water. In addition, it can serve as a reservoir in which there is a constant supply of hot water. Nowadays, when hot water is cut off in summer time- a variant of the norm, the device has become in demand and many are interested in how to choose a boiler for an apartment or house.

Types of heating devices

First, it is important to understand what the operating principle of the heating device is. This will allow you to make smart choices in the future. Heating elements - heating elements - are used to heat water. After cold water enters the water heater, the heating elements heat it to the set temperature. Two operating principles of heating elements are used:

- Wet. During operation there is contact with water.

- Dry. A sealed flask is used to protect against water.

In the first case, the problem is that scale appears over time. It must be removed from the boiler every year. The second option – dry – is more reliable, but the cost of such a boiler will be almost twice as expensive.

The boiler design includes a thermostat. Thanks to it, the device stops heating after the water reaches a certain temperature. After the water cools down, the device starts working again. Usually the required temperature regime is set by the owner of the apartment.

There are models that, using electronic control allow you to control the heating intensity, taking into account the time of day.

It is worth remembering that if you have a boiler, energy is often used uneconomically. To avoid this, some turn off the boiler for heating or switch it to the minimum heating mode.

Since the heating elements of boilers are different, there are two options for water heaters, differing in the way the heating elements are placed:

- Direct heating. In them, the heating element is located directly under the tank. This option is convenient because it does not depend on additional heat sources.

- Indirect heating. Heating is carried out using technical fluid. Typically this option is used by those who live in a private house. In addition, the device does not depend on any energy carriers, but can also heat water from electricity when the boiler is not working.

The first version of the boiler can be either electric or gas (there is a gas burner available).

If we talk about the installation method, heating devices can be:

- Vertical type.

- Horizontal.

- Wall-mounted.

- Floor.

The choice is also influenced by the material used to construct the water heaters. In a relationship anti-corrosion coating It is worth noting that an inexpensive, but most often used option is enamel. However, there is no guarantee that this coating will last long. If there are constant temperature changes, then cracks appear in the tank and rust appears. In this case, it is recommended not to heat the water above 60ºС. But this is not an option either, because such a temperature increases the growth of bacteria. There are options coated with silver ions, but these are expensive models.

The choice is also influenced by the material used to construct the water heaters. In a relationship anti-corrosion coating It is worth noting that an inexpensive, but most often used option is enamel. However, there is no guarantee that this coating will last long. If there are constant temperature changes, then cracks appear in the tank and rust appears. In this case, it is recommended not to heat the water above 60ºС. But this is not an option either, because such a temperature increases the growth of bacteria. There are options coated with silver ions, but these are expensive models.

There is an option to purchase a stainless steel boiler. This material is not so affected by corrosion and it lasts much longer - more than 10 years. But the price for such a model will be high.

A water boiler is often used cylindrical. It has the following advantages:

- Compactness.

- The water cools down slowly.

Another option is slims. Many of them have a thin and elongated shape. Their advantage: oversized and relatively large supply of hot water.

There are also rectangular water heaters. Since they fit tightly to the wall, as a result they fit best into any type of interior. For a home with limited space, this is a practical solution.

But if there is very little space, then a horizontal heater is offered. It is installed under washbasins, shelves and ceilings.

What to consider when choosing tank volume

For those who live alone, a small 40 liter boiler is suitable. The water in it heats up in 2 hours. If a family of two people purchases a water heater, then suitable option there will be an 80 or 100 liter water heater. It will take up to 5 hours to heat the water. For families with children practical option there will be a 120 liter boiler. Sometimes even that is not enough. It takes 7 hours to heat the water.

The given indicators are average and depend on the power of the heating element.

Additional functions

Depending on the price, the following functions may be available:

- Eco heating

- An indicator showing the remaining time until the next heating cycle.

- Protection of the heating element in the absence of water.

- Frost protection.

- Thermal insulation.

The more expensive the device, therefore, it will have more functions, and this provides some additional convenience when using it.

Price is not always the right indicator, since a branded model with a minimum number of functions can cost more than a multifunctional Chinese boiler.

Video

This video explains how to choose the right water heater, taking into account its design features and the needs of the family: