Photo printing on tiles: an easy way to create a panel with your own design

Decor is used to diversify the cladding, add bright accents, and make the design more fun. But it’s even better if this decor is made specifically for your interior. Photo printing on tiles allows you to draw any drawing or photo, or break it into several parts, and then cover the entire wall with it. From this article you will learn which method of photo printing is better and how much such beauty will cost.

Quick navigation through the article

Printing methods

Printing on tiles can be done in four ways:

- With firing,

- Decal,

- Sublimation,

- UV printing.

Each of these technologies has its pros and cons, but the first 2 methods are the best; they remain usable for up to 50 years. Other methods of drawing do not allow achieving proper resistance to mechanical and chemical influences.

Based on this table, it is easy to understand that the highest quality method is with firing. But this technology increases production time and the cost of the material.

Firing printing technology

Firing in a kiln

- You choose a collection of tiles without a pattern. Availability of texture depends on the selected collection. Companies that do photo printing on ceramic tiles offer ready-made options, and some even work only with their proven collections.

- You choose any picture you like with good quality and resolution. Printing is done directly from the file. You can apply the design to one tile or split it.

- A design is applied to the surface of the tile using ceramic ink. Some companies allow you to do several trials to find the best color.

- For protection, the surface is coated with powder glaze and the tile is sent to a muffle furnace for firing at a temperature of +900 degrees. The glaze can be glossy or matte, regardless of the selected collection, according to your desire.

After firing, the surface is in no way inferior to the factory applied glaze. In addition to wall decor, patterned floor tiles or even porcelain tiles can also be made.

Sublimation printing technology

Technology principle:

- The image is printed on special paper using sublimation ink.

- The paper is applied to the tile and pressed in a heat press for 3-12 minutes at a temperature of 180-250 degrees. Due to this, the paint is converted into gas and penetrates deeply into the glaze layer.

- To obtain a high-quality result, the color of the workpiece must be white or close to it.

Digital decal

The decal method has been used for a very long time; in simple words, it is applying a design using carbon paper.

- The picture is printed using a digital printer on gummed paper. Ceramic ink is used.

- The drawing on paper is coated with ceramic varnish and dried.

- The sheet is soaked in water and the design is transferred to the tile. After removing air bubbles, the tiles are dried for 8-12 hours at a certain temperature (depending on the toner).

- To fix the pattern, the tiles are fired in a muffle furnace for several hours at a temperature of 750-900 degrees.

UV printing

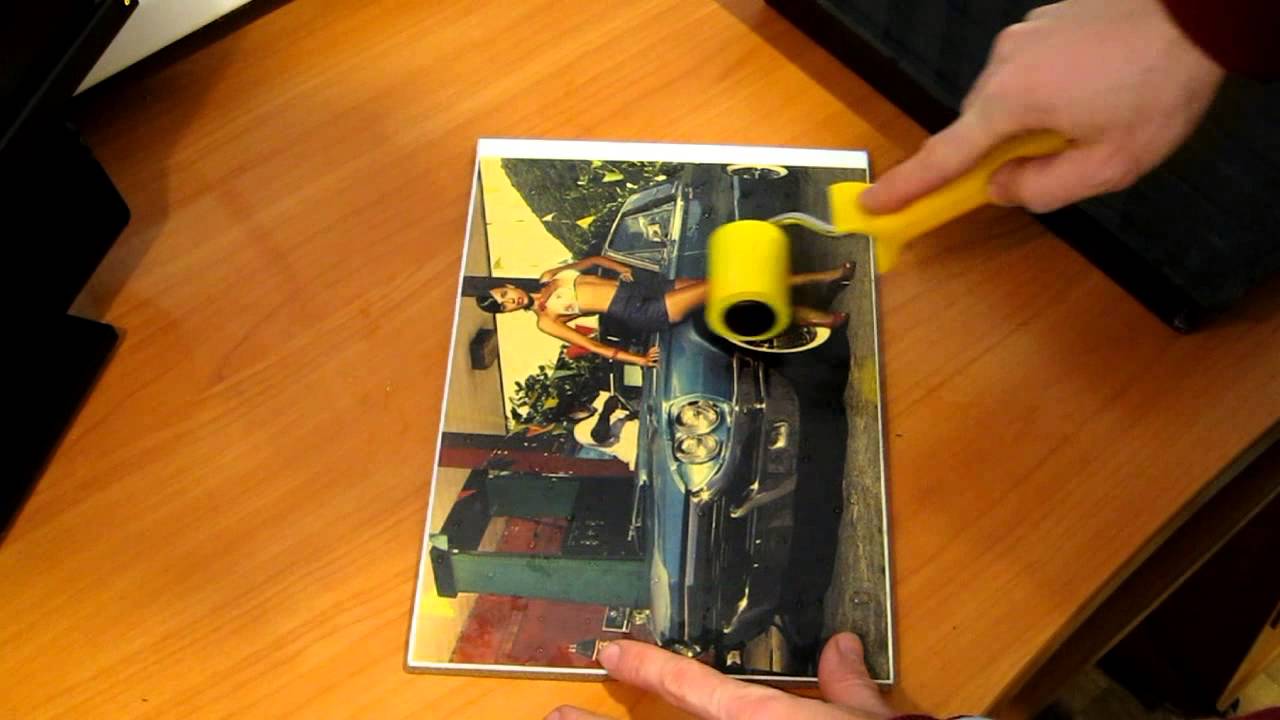

UV printer

- The workpiece is placed in the machine and a design is applied using UV ink. The ink hardens instantly when exposed to UV lamps. There are restrictions on the size of the workpieces.

- To obtain a brighter and more saturated color, the printer can increase the number of passes by 50%, and also use white ink as an underlayer, but this increases the cost.

- To protect the thin paint and add shine, it is sometimes coated with varnish, but even with this it will only last 6-12 months.

The video shows an example of printing with regular ink on an inkjet printer with a varnish coating:

How much does printing cost?

- Firing printing will cost 9-13 thousand rubles per square meter, depending on the order volume. This price includes the material (white tiles), printing and firing.

- Porcelain tiles with a pattern made using a similar technology will cost approximately 10% more expensive.

- The sublimation method of application costs from 1400 to 2900 rubles per square meter depending on volumes. Plus, you will need to buy or pay extra for blanks from 60 to 210 rubles per piece (depending on the size). If you place a piece order, 1 element will cost from 170 to 450 rubles(depending on size - from 10x10 to 30x30 cm).

- UV printing costs from 1000 to 3900 rubles, depending on the number of layers and passes of the printer.

Conclusion

If relief is not important to you, sublimation printing on tiles will be more profitable. In terms of characteristics, it is not inferior to firing printing, but costs less. The cost of 1 element made using this technology can be compared with the purchase of ready-made decor.

But this is far from the only way to apply a photograph to the floor and walls. On the floor, you can replace the tiles with a polymer self-leveling floor with a 3D pattern, and protect the apron with a glass panel with photo printing.