Additional elements for soft roofing

Any pitched roof made of flexible tiles must be framed by means of metal strips: adjoining, cornice and end. Every self-respecting manufacturer of modern roofing materials produces components with a "company" name, but the purpose of such elements is the same. Additional elements can be both standard and individual. The use of roofing strips is advisable on roofs with a pitched slope of at least thirty degrees.

purpose

Cornice strips or drips mounted on the roofing cornice, covering the frontal board of wood and the supporting part of the truss system. They serve to protect the closed elements from moisture and redirect water flows to the gutters.

End or gable strips mounted on roof gables and serve to protect the end parts of the roof from wind and snow, and also divert water flows from the cornice filing.

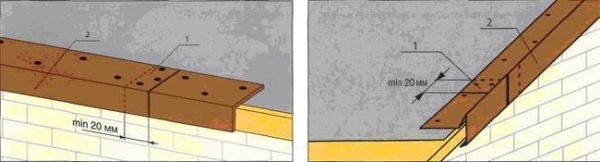

Installing a drip (left) and wind strip (right) for a soft roof

Planks or linings of abutment mounted at the junction of the roof and vertical surfaces. They protect against the accumulation of dust and debris at the junction points, and also contribute to the unimpeded draining of water.

In addition, additional elements of the plank type can be attributed ridge fan or aerator, the main function of which is the device of a ventilated type ridge when installing roofs from a flexible tile covering. Individual additional elements for a roof made of flexible tiles can be represented by plinth strips made according to the customer's dimensions.

Elements of flexible tiles

Additional elements and components used in the process of arranging roofing from flexible tiles include: metal strips, metal or plastic snow retainers, ridge aerator, ventilation systems. Individual metal roofing elements can be represented by weathervanes, chimneys, caps, ebbs, parapets and plinths.

End (wind) bar

A wind or end strip for flexible tiling is installed on the underlayment carpet in the direction from the ridge towards the cornice overhang. Above the bar is made.

![]()

The plank prevents precipitation from blowing under the tiling and contributes to additional waterproofing of the joints of the roofing and the roofing end. Represented by galvanized metal with a polymer coating to match the roof. The standard dimensions are 10 x 2.5 x 13 x 1.5 cm with a length of two meters.

Cornice strip (drip)

It is installed before the installation of the roofing on the eaves, along the crate of the lower edge of the roof. Represented by galvanized metal with a polymer coating, the thickness of which is 0.45 mm. The standard dimensions are 10 x 6.5 cm with a fold of 1 cm and a length of two meters.

Wall connection

It is mounted in conditions of direct or reverse roofing breaks, at the junction points of the roofing and walls or chimneys. At the break point, one part of the plank is located under the upper roofing sheet, and the other is located on top of the lower roofing sheet. Promotes reliable sealing of joints. The upper and lower junction bars are different. The standard dimensions are 2 x 4.5 x 1.5 x 1 cm with a length of two meters.

Material calculation

The standard length of roofing additional elements in the form of strips produced by various manufacturers is two meters. To correctly calculate the required number of all the strips needed during the installation process, you must perform the following calculations:

- depending on the category of the additional element, it is required to add up all the lengths of those sides of the roof slopes, where their installation is necessary in accordance with technological standards;

- the resulting amount of lengths must be divided in accordance with an overlap of ten centimeters by 1.9;

- to calculate the amount of material for arranging the lower valley, it is necessary to divide the result obtained by 1.7 with an overlap of thirty centimeters.

The standard rule should be followed and any result obtained should be rounded up.

For fixing all additional elements, it is necessary to use only hardware recommended by the manufacturer. The fastening of the ridge bar is carried out by means of special ridge screws, maintaining a standard step. When fixing additional elements, special ones are used, the optimal size of which is 30 x 10 x 2.5 mm.

Summing up

Cornice and end strips are attached to the base by means of special galvanized nails or stainless, with a countersunk head type, self-tapping screws with a distance of 12-15 centimeters in two rows and in a checkerboard pattern. When installing cornice strips, an overlap of 3-5 centimeters is performed.

In order for the frontal plank to have a high-quality adjoining to the cornice plank, it is necessary to cut the plank of the gable overhang with metal scissors after installation. The final fixing is carried out only after fitting and trimming.

The use of individual additional elements allows you to give the building a distinctive style. For standard additional elements, it is advisable to use the rule of matching the color of the planks to match the main roofing.