Topic: Introduction (1). Structural materials production complex

Due to a large number of factors, mechanical engineering is developed in all regions of Russia, however, to a greater extent in the Western macroregion. The Western macroregion accounts for 95% of output.

Largest specific gravity mechanical engineering is in the industry of the Volga-Vyatka (39%), Volga (36%), Central (29%) and North-Western (25%) economic regions. At the same time, the central and Volga economic regions together provide more than 40% of output. In the Eastern macroregion, mechanical engineering is concentrated mainly in large cities.

The geography of mechanical engineering enterprises is presented in a “cramming” book.

Complex of construction materials

In the conditions of scientific and technological progress, intersectoral complexes interact and complement each other, forming large systems, an example of which is a complex that processes natural resources into construction materials and chemical substances.

The bulk of the 70 types of mineral raw materials mined in Russia (not counting fuel resources), as well as wood, are used in the production of structural materials

Construction materials - natural and artificial materials intended for the manufacture finished products or structures

Construction materials are divided into:

traditional (cast iron, steel, clay, sand, wood, natural rubber, natural fibers, etc.);

new (plastics, polymers, metal-ceramics, fiberglass, metal-plastic, glass concrete, etc.).

Composition of the complex of construction materials:

|

Complex construction materials | ||||||||||||||||||||||||

|

Metallurgical complex |

Production building materials |

Chemical-forest complex | ||||||||||||||||||||||

|

Rolled products production | ||||||||||||||||||||||||

|

Household and perfumery |

Polymer processing |

forest chemistry |

Pulp and paper |

|||||||||||||||||||||

|

hydrolysis | ||||||||||||||||||||||||

|

Smelting production | ||||||||||||||||||||||||

|

Fertilizer production |

Polymer production |

Production |

||||||||||||||||||||||

|

refining | ||||||||||||||||||||||||

|

Off-Domain Production | ||||||||||||||||||||||||

|

Chernova |

Production of other basic chemical products |

Organic synthesis |

Sawmilling and woodworking |

|||||||||||||||||||||

|

Blast furnace production | ||||||||||||||||||||||||

|

MINING INDUSTRY | ||||||||||||||||||||||||

This complex combines industries producing structural materials, i.e. materials intended for the manufacture of finished products or structures: ferrous and non-ferrous metallurgy, chemical and forestry industries, production of building materials. This unification is due, firstly, to the participation of these industries in the production of structures intended for the manufacture of finished products or structures, and secondly, many types of products of the complex are interchangeable (for example, metal and building materials are currently being actively replaced by plastics and polymers).

Mining industry lies at the basis of not only this complex, problems of rational use are closely related to it natural resources and the formation of state environmental policy. The geography of development of this industry depends on natural resources. The mining industry in Russia has an imperfect structure: it is extremely hypertrophied and accounts for 22.5% of production, although in developed countries it is no more than 9%. The reason for this is not only the wealth and diversity of natural resources in our country, but also the technological backwardness of industry, which does not make it possible to effectively use the extracted resources. The Russian mining industry has a number of negative features:

large disturbances of the lithosphere due to extensive processing of rocks;

losses during the extraction of huge amounts of raw materials;

Progressive mining methods are poorly implemented, which affects the cost of the metals produced;

poor use of secondary resources;

There is no slowdown in the rate of development of the mining industry, which is typical for developed countries.

Large combinations of resources that are of national importance and cover large areas are called resource bases countries. In Russia it is:

Ural-Povolzhskaya,

Central,

South Siberian,

North-Eastern,

Structural materials are materials on the basis of which parts for machines are made, engineering structures and designs. During operation, they will be repeatedly subjected to mechanical stress. Such parts are characterized by a wide variety of not only shapes, but also operational ones. They are used in various industries, they are used to make industrial ovens, parts for automobiles, they are used in the aviation sector. The manufacturer's task is to produce a structural part that is ready to operate at different temperatures, in different environments and with fairly intense loads. The main difference between the products and other structural additions is their readiness to take on maximum loads for a long time.

Types, types, classifications

Due to the fact that metals are practically the most reliable and durable components, structural materials are made to a greater extent from them. Therefore, CMs are classified and recognized by the material from which they were made. Steel is often the preferred metal because of its strength, reliability and ease of processing.

The materials are based on alloys made of steel, cast iron and iron. This type has good strength, parts and elements are used more often than others. Alloys with magnetic and non-magnetic forms are also used. Colored and non-colored combinations of metals are used. This is often aluminum, but in some parts it is possible to use alloys based on it. Alloys are used when a part needs to be deformed and transformed repeatedly. Among the non-ferrous ones, copper (bronze) and titanium are also used.

Non-metallic materials began to be used much later than the previous group. Advances in technology have helped create more cheap alternative. At the same time, non-metals are also strong and reliable. Non-metallic structural materials are made from wood, ceramics, glass and different types rubber.

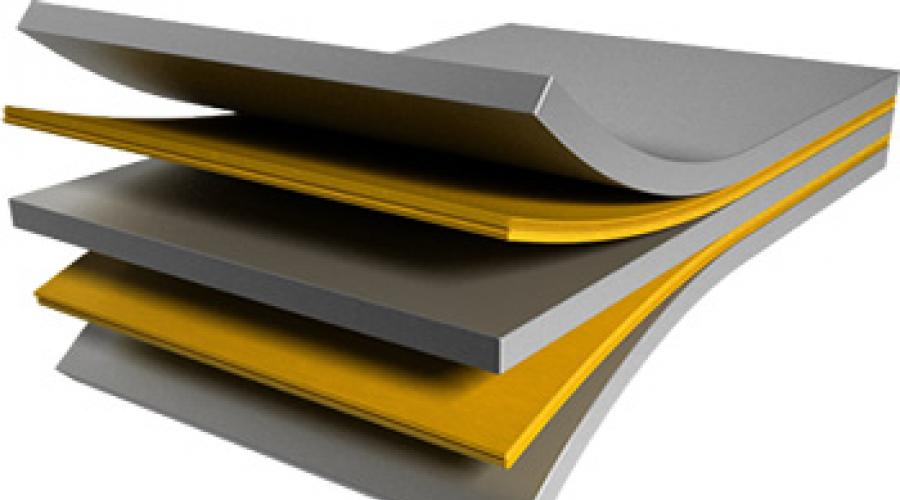

- Composite materials

Composite materials consist of elements that differ greatly in properties. They allow you to create structures with predetermined characteristics. Materials are used to improve efficiency. The name of the composition is determined by the matrix material. Such materials all have a basis. Composites that have a metal matrix are metallic, ceramic are ceramic, and so on. They are created artificially, the material that is obtained at the output has new complex properties. Composite materials can include both metallic and non-metallic components.

Composite materials consist of elements that differ greatly in properties. They allow you to create structures with predetermined characteristics. Materials are used to improve efficiency. The name of the composition is determined by the matrix material. Such materials all have a basis. Composites that have a metal matrix are metallic, ceramic are ceramic, and so on. They are created artificially, the material that is obtained at the output has new complex properties. Composite materials can include both metallic and non-metallic components.

There is another classification that allows you to recognize exactly what material is needed to complete the selected task - this is a breakdown into types according to technical criteria.

- Materials with increased strength;

- Materials with distinctive technological capabilities;

- Durable materials (elements whose operation is not affected by mechanical irritants);

- Elastic structural materials;

- Loose materials;

- Materials resistant to natural influences;

- Materials with high strength.

Areas of application

The use of structural materials occurs in any area related to construction and production. The electrical power, construction and engineering industries have the widest range of use. This is where the collection of structures is the first part to create a large project.

| Groups | Materials | Scope of application | Fur. properties |

| Metal construction materials | Bronze | For the production of shaped castings, bushings, bearings, gears and gears. | High compressive strength and frictional loads, does not oxidize. |

| Tool steel | For the production of measuring instruments, cutting parts and measuring templates. | Durable, heavy, does not oxidize, waterproof. | |

| Titanium | Critical parts in the field of aviation, rocketry and medicine. | Lightweight, waterproof, conductive. | |

| Non-metallic structural materials | Rubber | Sealing elements of any designs, voltage insulators, sealing, flexible parts in the automotive industry, medicine, rocket science. | Low density with high elasticity. Resistance to chemical and thermal influences. |

| Plastics | Widely used for making products National economy, automotive, food, aviation, construction industries. | Low density and good strength. Low temperature melting. Chemical resistance. | |

| Asbestos | Production of pipes, house coverings, fire-resistant fabrics and sealants. | Low impact strength. Resistance to natural influences and chemicals. | |

| Ceramics | Manufacturing of tableware, toilet and bathroom products. Making models and souvenirs. Selected species used for making knives and cutting tools. | High density, brittleness, corrosion resistance. Low elasticity. Abrasion resistance. | |

| Production of body armor, reinforcing layer car tires, protective layer of cables, equipment for astronauts, motorcyclists, firefighters. | High strength, flexibility and low density. Resistance to chemical and mechanical influence. | ||

| Composite materials | Plywood | Furniture production, interior decoration, prefabricated panel structures in construction | Low density with high strength. Ease of processing |

| Concrete | Construction of a wide variety of houses and structures. | High compressive strength. High density. | |

| Fiberglass | Manufacturing of boat and boat hulls. Car body kit and dielectric parts. Pool casings and decorative products. | High strength and low density. Low ductility. |

Lesson objectives: give an idea of the complex for the production of structural materials, as part of the intersectoral complexes of the national economy; show its role and significance in life and economic activity person.

Lesson Objectives:

Development creativity, initiative and independence of students in lessons to generalize acquired knowledge.

Development cognitive interest, elements of research, project activities in the classroom and during the joint preparation of generalization lessons.

Improving practical skills in working with textbooks, Internet resources, and multimedia.

The use of new forms and methods of teaching to increase students’ motivation, develop their creativity, initiative, and involve them in an active cognitive process.

Teaching methods:

– Explanatory and illustrative;

– reproductive;

– partially search.

Lesson type: integrated lesson for learning new material.

During the classes

1. Organizing time. Greeting students, identifying absentees, psychological attitude towards work.

2. Checking homework. Students are given differentiated task cards.

3. Updating knowledge.

The teacher asks questions to the class.

– What complexes of the national economy do you know?

– is there a connection between them?

– The mechanical engineering complex produces machinery and equipment; what are the main raw materials for obtaining mechanical engineering products?

– correct: metal, plastic, plastic, glass, etc., and what complex produces these products? Right. This is a complex for the production of structural materials.

4. Explanation new topic. Write down the date and topic of the lesson.

Explanation of lesson objectives.

"Production of construction materials and chemicals"

Industries involved in the production of construction materials and chemicals belong to the secondary sector of the economy and are the most important basic sectors of modern industry.

Note: Industry is an association of enterprises that extract or produce specific or homogeneous products using similar technologies.

Construction materials - natural or artificially created materials used for further use in the manufacture of structural parts of machines and structures.

These industries include: metallurgical, chemical, and forestry industries.

Work in groups.

Assignment: using Internet resources, text in the textbook, study independently and express your topic in the form of a drawing diagram. Time for the task is given 7-8 minutes.

Topics: metallurgy, chemical industry, forestry industry.

Reports on drawings are heard.

Mastering a new topic: (students must find answers to questions)

General test on the topic “Complex for the production of structural materials”

1. The main products of ferrous metallurgy are:

A) cast iron;

B) cast iron and steel;

B) cast iron, steel and rolled products.+

2. A group of metallurgical plants using common sources of raw materials and fuel are called:

A) fuel base;

B) raw material base;

B) metallurgical base.+

3. Production gravitates towards places of cheap energy and fuel:

A) non-ferrous metallurgy;+

B) ferrous metallurgy.

4. Among the branches of the chemical industry, production is focused on raw materials:

A) potash fertilizers;+

B) sulfuric acid;

B) plastics.

5. Production is more energy and water intensive:

A) plastics chemical fibers;+

B) sulfuric acid and fertilizers.

6. Among the branches of the chemical industry, production is consumer-oriented:

A) potash fertilizers;

B) sulfuric acid.+

7. Iron ore is the raw material of a metallurgical enterprise:

A) full cycle; +

B) pigment metallurgy

8. Bauxites and nephelines are raw materials for obtaining:

A) copper;

B) aluminum;+

B) zinc.

9. Where are the exploitable forest areas of Russia located:

A) northern regions;+

B) the south of Western and Eastern Siberia.

10. The forestry complex includes:

A) timber harvesting;

B) mechanical processing;

B) chemical processing;

D) all of the above.+

11. Production forests take up from all forest resources:

A) 8%;

B) 70%;+

B) 22%.

12. The bulk of forest resources are located:

A) in the Western part of the country;

B) in the Eastern part of the country.+

13. The complex for the production of structural materials includes the following industries:

A) ferrous metallurgy;

B) chemical industry;

B) non-ferrous industry;

D) forestry industry;

D) all answers are correct.+

(Self-monitoring this key)

Key to the test:

1. B

8. B

12 – 13 b – “5”

2. B

9. A

9 – 11 b – “4”

3. A

10. G

6 – 10 b – “3”

4. A

11. B

0 – 5 b – “2”

5 A

12. B

6. B

13. D

7. A

Reflection. Continue the sentence...

today I found out...

it was interesting…

it was difficult…

I completed tasks...

I realized that...

Now I can…

I felt that...

I purchased...

I learned…

I managed …

I was able...

I will try…

I was surprised...

gave me a lesson for life...

I wanted…

Homework: Label on contour map construction materials industry.

Giving and commenting on ratings.

Some intersectoral complexes interact and complement each other so much that they can be combined into even larger systems. A similar system is formed by complexes producing construction materials and chemicals. Their joint consideration is necessary for a number of reasons. Firstly, they are all involved in the production of materials called structural materials. Structural are materials intended for the manufacture of finished products or structures. In table 11.2 provides a classification of structural materials depending on their origin.

In addition, many of their products are interchangeable, for example, metal and building materials are increasingly being replaced by plastics and polymers. All the complexes under consideration are based on extractive industries, the development of which is closely related to the problems of rational use of natural resources and the formation of environmental policy.

Table 11.2 Classification of structural materials

|

Origin of materials |

|||

|

Metal |

Non-metallic |

Compositional |

|

|

Traditional |

Cast iron, steel, copper, alloys based on copper and iron Special alloys using rare metals |

Glass, brick, wood, cement Plastics, polymers, wood plastics |

Metal ceramics, fiberglass |

Metallurgical complex . Almost 90% of all metals used in modern production, - ferrous metals, that is, iron and alloys. However, there are much more non-ferrous metals (more than 70 types) and they have very valuable properties. Metallurgy covers the entire process of metal production: mining and preparation of ores, fuels, metal production, production auxiliary materials(refractories, oxygen, etc.). Therefore, in metallurgy, the integration of several production facilities of various industries into one enterprise is widely developed. In ferrous metallurgy, combination based on the sequence of ore - cast iron - steel - rolled products predominates, and in

non-ferrous is used in a complex manner, when several metals are obtained from polymetallic ores. Metallurgy is characterized by high material consumption: 1 ton of steel consumes up to 7 tons of raw materials and fuel. The location of metallurgical plants is greatly influenced by:

1) the characteristics of the raw materials (ore) used;

2) the type of energy used for the metal;

3) geography of raw materials and energy sources. Businesses related to final stage metallurgy - metal processing, most often located in areas of finished products.

Russian metallurgical bases are concentrated in 3 regions: Ural metallurgical base (older and therefore currently lacking its own iron ores, the central link is Magnitogorsk) uses ore from Kazakhstan, the Kola Peninsula and the Kursk Magnetic Anomaly (KMA), coking coal from Kuzbass and Karaganda; The central metallurgical base (Central and North-Western region, central link - Cherepovets, Lipetsk, Oskol) uses ores from the KMA and the Kola-Karelian region, coking coal from the Pechora basin, Kuzbass and Donetsk basin; South Siberian (Novokuznetsk), based on the deposits of the Angara region and Mountain Shoria, coal from the Kuznetsk basin.

The dynamics of production of the main types of ferrous metallurgy products in the Russian Federation is presented in Figure 12.2

Fig. 12.2 Dynamics of production of the main types of ferrous metallurgy products in the Russian Federation

One of the most important industrial complexes for the Russian economy is non-ferrous metallurgy (20% of world production of aluminum, 40% of nickel, most of platinum group metals and copper), which is an export-oriented industry - 70% of non-ferrous metals produced in the country are exported. A feature of non-ferrous metallurgy is the large dispersion of sources of raw materials, the low content of useful components, the need for enrichment and unique technologies processing. Therefore, non-ferrous metallurgy enterprises are located in the areas of deposits, with the exception of aluminum industry enterprises, which gravitate towards sources of cheap electricity. The location of raw material bases is as follows: aluminum ores: Northern and Southern Urals, Leningrad region, Kola Peninsula, south Western Siberia, Krasnoyarsk region; copper: Ural, Krasnoyar

region, Transbaikal, North Caucasus; tin: Eastern Siberia And Far East; nickel: Norilsk, Kola Peninsula; zinc and lead: south of Western Siberia, Far East, Transbaikalia.

Chemical-forest complex consists of two large and complex branches of the chemical and forestry industries. The leading one among them is undoubtedly the chemical industry. Therefore, the connections between these industries are almost one-way. Industries included in the chemical industry are: mining chemistry, basic chemistry, chemistry of organic synthesis, polymer chemistry, processing of polymer materials.

Features of the chemical industry:

1) creation of new materials that are superior in many qualities natural products. The use of such materials saves labor and raw materials: for the production of nylon, for example, labor costs are 20 times lower than for the production of natural silk;

2) great opportunities combinations. Chemical Technology allows you to use raw materials comprehensively and obtain different products from the same types. Combination leads to the creation of chemical plants. When the chemical industry is combined with other industries, special industries arise - coke chemistry, petrochemistry, forest chemistry, shale chemistry;

3) an extensive raw material base: minerals, water, air, industrial waste, but the main raw materials are products of oil refining, coking, etc. All this makes it possible to build chemical industry enterprises everywhere, but taking into account the high water and energy intensity of its production.

In Russia, the leading branch of the chemical complex is the production of synthetic resins and plastics, chemical fibers, and synthetic rubber.

The production of synthetic resins, plastics and synthetic rubber is located mainly in areas rich in oil and gas - the Volga region, the Ural region, West Siberia, and the North Caucasus.

The production of chemical fibers is concentrated in regions with a developed textile industry - Central, Northwestern and Volga.

The timber industry is a traditional sector of the Russian economy. Logging is mainly carried out in densely forested areas - Northern region, Ural, Siberia and Far East.

For the production of lumber leading place occupy the East Siberian, Northern, Ural, West Siberian, Volga-Vyatka and Far Eastern regions of the country. Furniture industry in Russia it is developed almost everywhere. The pulp and paper industry is most developed in logging areas.

Many problems have accumulated in the chemical forestry complex: replacement of equipment, further development of the most modern industries, for example, the chemistry of organic synthesis and polymers; more rational use forest resources; improving product quality.

Classification of construction materials, problems of proportionality of the industries producing them.

Metallurgy, its composition and structure, place in the economy, connection with other industries. Contemporary issues Russian metallurgy and their geographical consequences. Russia's place in the world in terms of reserves of metal ores and production of metallurgical products.

Ferrous and non-ferrous metallurgy. Traditional and new metal production technologies. Types of metallurgical enterprises and location factors. Features of the geography of metallurgy of ferrous, light and heavy non-ferrous metals. Metallurgical bases, the largest metallurgical centers. Export of metals and its role in the country's economy.

Chemical industry. Composition and importance in the economy, connection with other industries. The role of chemicalization of the economy. The main factors for locating chemical industry enterprises. Grouping of chemical industry branches, features of their geography. Main chemical bases, largest chemical complexes. Problems of industry development. Chemical industry\and security environment.

Timber industry. Composition and importance in the economy, connection with other industries. Russia's place in the world in the production of forest products. Grouping of forest industry branches, features of their geography. The main forest bases, the largest wood processing complexes. Forestry industry and environmental protection. Production of building materials, structures and parts.

Practical work : 1. Compilation of characteristics of one of the metallurgical bases on maps and statistical materials; 2. Determination from maps of the main factors for the location of metallurgical enterprises for the production of copper and aluminum; 3. Compilation of characteristics of one of the bases of the chemical industry using maps and statistical materials.

Topic 6. Agro-industrial complex (AIC)

Agriculture. Differences between agriculture and other economic sectors. Land is the main wealth of Russia. Agricultural land, its structure. The role of land reclamation in development Agriculture countries. The concept of agro-industrial complex(APK). The main problems of the development of the Russian agro-industrial complex.

Agriculture. The leading role of grain farming. Geography of cultivation of the most important grain and industrial crops, potatoes. Gardening and viticulture.

Animal husbandry. The leading role of cattle breeding. Geography of the main livestock sectors.

Forestry. The role of forests in people's lives. Russian forests are an important part of it national wealth. The role of forests in the Russian economy. Geography of industrial forests.

Hunting. Fur harvesting is a traditional industry Russian economy. Geography of fur trade. Raising fur animals.

Fisheries. The dominant role of marine fishing. Specifics of the main fishing basins. The leading role of the Far Eastern basin. Geography of fish processing. Insufficient development of pond and lake fish farming.