Technical regulations requirements for the safety of gas supply systems. Technical regulations on the safety of gas distribution and gas consumption networks

HISTORY OF THE ISSUE December 2005 - OJSC Giproniigaz (co-executor - Scientific and Technical Center "Industrial Safety"), under the State contract with the Ministry of Industry and Energy of Russia, on the basis of the Government program for the development of technical regulations (1421-r of the year), developed a draft Federal Law - special technical regulations"About safety production processes and gas supply systems." During public discussions, more than 500 proposals and comments were received from 22 organizations, about 70% of which were accepted. In particular, new proposals and comments from Rostekhnadzor, the Ministry of Regional Development of the Russian Federation, the Ministry of Emergency Situations of the Russian Federation, OJSC Gazprom, OJSC Gazpromregiongaz, OJSC Promgaz were taken into account. On November 29, 2006, the Expert Commission of the Ministry of Industry and Energy recommended submitting the draft technical regulations approved by it to the State Duma Federal Assembly RF for consideration and adoption in the prescribed manner. In amendments were made to the federal law “On technical regulation”, administrative reform and the Government program for the development of technical regulations was adjusted, according to which it was decided to adopt technical regulations in the form of a Decree of the Government of the Russian Federation. In June 2008, as a result of many years of requests from OJSC Giproniigaz, the old name of the draft technical regulations was changed to the new name “On the safety of gas distribution and gas consumption networks.”

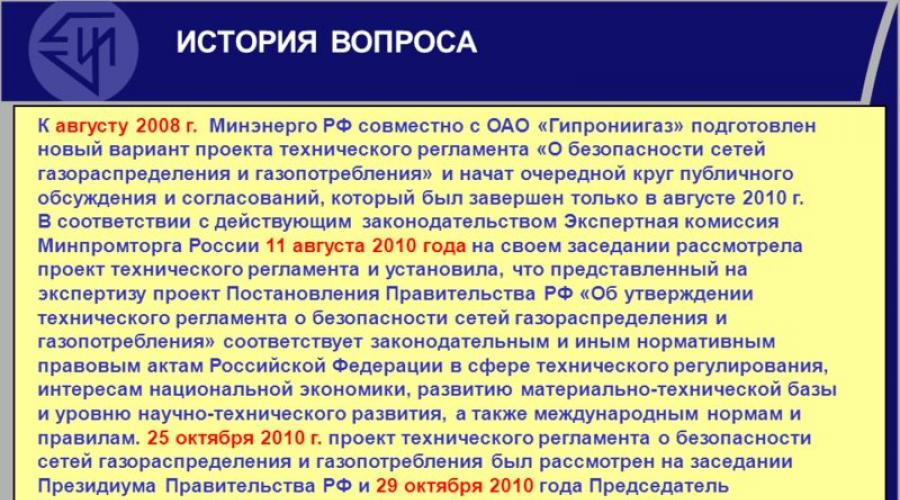

HISTORY OF THE ISSUE By August 2008, the Ministry of Energy of the Russian Federation, together with OJSC Giproniigaz, prepared new option draft technical regulations “On the safety of gas distribution and gas consumption networks” and began the next round of public discussion and approvals, which was completed only in August 2010. In accordance with the current legislation, the Expert Commission of the Ministry of Industry and Trade of Russia on August 11, 2010 at its meeting reviewed the draft technical regulations and found that the draft Resolution of the Government of the Russian Federation “On approval of technical regulations on the safety of gas distribution and gas consumption networks” submitted for examination complies with legislative and other regulatory standards legal acts of the Russian Federation in the field of technical regulation, the interests of the national economy, the development of the material and technical base and the level of scientific and technical development, as well as international norms and rules. On October 25, 2010, the draft technical regulation on the safety of gas distribution and gas consumption networks was considered at a meeting of the Presidium of the Government of the Russian Federation and on October 29, 2010, the Chairman of the Government of the Russian Federation V.V. Putin signed Resolution 870 “On approval of the technical regulation on the safety of gas distribution and gas consumption networks.” In just 5 years of work on the draft technical regulations, about 700 proposals and comments were officially received, of which approximately 75% were accepted by the developers. Over the years, more than 70 versions (editions) of technical regulations have been prepared.

Federal Law 184-FZ “On Technical Regulation” Federal Law 116-FZ “On industrial safety hazardous production facilities" Federal Law 384-FZ "Technical Regulations on the Safety of Buildings and Structures" Technical Regulations on the Safety of Gas Distribution and Gas Consumption Networks (approved by Decree of the Government of the Russian Federation of October 29, 2010 870) Legislative framework of the technical regulations

About the ideology of the draft technical regulation YES The technical regulation is a state regulatory legal act: - having as its goals - ensuring the protection of society from potentially dangerous business that may pose a threat to the life, health, property of the population; threat to the environment; the danger of misleading purchasers of products and services; as well as ensuring energy efficiency; – establishing the minimum necessary administrative barriers for a potentially dangerous business, determined taking into account the degree of risk of harm to third parties as a result of the business carrying out its activities. NO Technical regulations are not corporate regulatory and technical a document justifying, and often lobbying for, specific design and design solutions, materials, technical and technological devices.

On the need to take into account international experience when developing regulations 184-FZ “On Technical Regulation”, Article 7, paragraph 8: “International standards should be used in whole or in part as the basis for the development of draft technical regulations, except in cases where international standards or their sections were would be ineffective or unsuitable for achieving the goals established by Article 6 of this Federal Law, including due to climate and geographical features Russian Federation, technical and (or) technological features.”

Positive and negative experience (65 years) of mass gasification according to domestic regulatory documents based on excessive (mostly prohibitive) regulation of requirements for design, construction and operation, including a planned preventive maintenance system; - Gas distribution and gas consumption networks that have been built and are in operation are significant in scale and age: for example, more than km of gas pipelines (only about 25% are polyethylene) and near gas control points; - The impossibility of a one-time revolutionary change in the requirements for gas distribution and gas consumption networks in isolation from the requirements for other engineering infrastructure facilities in Russia; - Formed under conditions of excessive regulation qualification level and the mentality of engineering and technical personnel; - Not good high quality natural gas supplied to the Russian market. UNCONDITIONAL ORIENTATION TO BEST INTERNATIONAL EXPERIENCE WHILE ENSUREING A PLANNED AND EVOLUTIONARY CONVERGENCE OF DOMESTIC AND FOREIGN REGULATORY REQUIREMENTS. On accounting for technological and technical features Russian Federation

Structure of the technical regulations The technical regulations consist of four sections and two appendices: I. General provisions II. Rules for identifying objects of technical regulation III. Requirements for gas distribution and gas consumption networks IV. Compliance assessment Appendix 1 Classification of external and internal gas pipelines by pressure in gas distribution and gas consumption networks Appendix 2 Maximum values of natural gas pressure in gas consumption networks The technical regulations apply to networks gas distribution and gas consumption, as well as related processes of design (including engineering surveys), construction, reconstruction, installation, overhaul, operation, conservation and liquidation. The technical regulations do not apply to gas consumption networks of residential buildings.

Examples of identification requirements 1. Gas distribution and gas consumption networks for the purpose of applying these technical regulations are identified by the following essential characteristics, considered exclusively in the aggregate: by purpose; by the composition of the objects included in it; according to natural gas pressure defined in Appendices 1 and 2 of the technical regulations. 2. An object is identified as a gas distribution network if it transports natural gas: through the territories of populated areas with a pressure not exceeding 1.2 MPa; exclusively for (k) production sites of gas turbine and combined cycle gas plants with pressure above 1.2 MPa; between settlements with pressure above 0.005 MPa. 3. An object is identified as a gas consumption network if it transports natural gas: to gas-using equipment of gasified buildings and gas-using equipment located outside buildings, with a pressure not exceeding 1.2 MPa; to gas turbine and combined cycle gas plants with a pressure not higher than 2.5 MPa.

Examples of design requirements 1. Design must be carried out taking into account the assessment of the risks of accidents, fire risks, related emergencies and other adverse effects on people, property, physical and legal entities and the environment during operation, conservation and liquidation of gas distribution and gas consumption networks. 2.Selection of technical and technological devices, material and design of pipes and connecting parts, protective coatings, type and method of laying gas pipelines should be carried out taking into account the pressure and temperature of natural gas required by operating conditions, hydrogeological data, natural conditions, and man-made influences. 3. Calculations of gas pipelines for strength and stability must be carried out taking into account the magnitude and direction of the loads acting on the gas pipelines, as well as the time of their action. 4.Design bypass lines in gas control points and gas control installations with shut-off valves installed on them (for manual regulation of gas pressure) is not allowed.

Examples of construction requirements 1. At the stage of construction, reconstruction, installation and major repairs, compliance must be ensured with: technical solutions provided for in the design documentation; requirements operational documentation manufacturers of gas-using equipment, technical and technological devices, pipes, materials and connecting parts; construction and installation technologies in accordance with the work project or technological maps. 2. The technology for laying gas pipelines must ensure: the safety of the surface of the gas pipeline pipe, insulating coatings and connections; position of the gas pipeline indicated in project documentation. 3.Energy efficiency constructed, reconstructed, installed and repaired gas distribution and gas consumption networks must be ensured due to their tightness (no gas leaks). 4. During construction, reconstruction, installation and major repairs, welding technologies and welding equipment must be used to ensure tightness and strength welded joints.

Examples of operating requirements 1. When operating external gas pipelines, the operating organization must ensure monitoring of ground conditions (detection of heaving, subsidence and other phenomena that may affect the safety of operation), construction work carried out in the area where gas distribution networks are laid, in order to prevent them damage. 2.During operation underground gas pipelines The operating organization must ensure monitoring and elimination of: natural gas leaks; damage to insulation and gas pipeline pipes, structures on them; malfunctions in the operation of the equipment electrochemical protection And pipeline fittings. 3. The duration of operation of gas pipelines, technical and technological devices is established during design, based on the condition of ensuring the safety of technically regulated objects in the event of predicted changes in their characteristics and the guarantees of the manufacturer of technical and technological devices. Deadlines further exploitation objects of technical regulation of this technical regulation should be established based on the results of technical diagnostics. 4. When operating gas distribution and gas consumption networks, the possibility of unauthorized changes must be excluded.

Examples of requirements for conformity assessment 1. When designing (including engineering surveys) gas distribution and gas consumption networks in the form of examination of design documentation and engineering surveys in accordance with the legislation on urban planning activities. 2. Upon completion of construction, installation and reconstruction of gas distribution and gas consumption networks - acceptance of gas distribution and gas consumption networks. 3. During construction, reconstruction, major repairs, operation, conservation and liquidation of gas distribution and gas consumption networks - state control (supervision). 4. State control (supervision) over compliance with the requirements of technical regulations is carried out federal body executive power exercising control (supervision) functions in the field of industrial safety, and the federal executive body authorized to carry out state construction supervision, within their competence and in the manner established Federal law“On the protection of the rights of legal entities and individual entrepreneurs when exercising state control (supervision).”

Some technical conclusions according to the requirements of the developed technical regulations It does not prohibit (with appropriate engineering justification): - The choice of any material of pipes and connecting parts, type and method of installation (including hidden installation of internal gas pipelines); - Laying of polymer gas pipelines of any pressure, which are subject to the requirements of the document; - Laying inter-settlement gas pipelines with pressure above 1.2 MPa; - Underground placement of gas control points (without requiring the location of hydraulic fracturing above ground level); - Application on any gas pipelines locking devices to ensure safety (not excluding gas-stop valves); - Device for exiting a gas pipeline from the ground without a case. Prohibits: - Design of bypass lines with manual reduction of gas pressure in gas control points and installations.

Requires the adoption of additional technical solutions to ensure safety (much fewer requirements are established than in the current normative and technical documentation) when: - Gas pipelines cross natural and artificial barriers; - Laying gas pipelines in special soil conditions and in mined areas; - Laying gas pipelines in places with an increased risk of damage. Does not regulate: - The timing and scope of work during the operation of gas pipelines, technical and technological devices, establishing only a list of mandatory procedures for monitoring actual technical condition objects of technical regulation; - Timing and frequency of technical diagnostics of gas pipelines, technical and technological devices. Some technical conclusions on the requirements of the developed technical regulations

Technical regulations on the safety of gas distribution and gas consumption networks (approved by Decree of the Government of the Russian Federation of October 29, 2010 870, as amended by Decree of the Government of the Russian Federation of June 23, 2011 497). Order of the Government of the Russian Federation dated June 10, 2011 “On approval of the list of documents in the field of standardization containing rules and methods of research (testing) and measurements, including sampling rules necessary for the application and implementation of technical regulations on the safety of gas distribution and gas consumption networks and carrying out conformity assessment. Order of the Federal Agency for Technical Regulation and Metrology dated October 3, 2011 on approval of the list of documents in the field of standardization, as a result of which, on a voluntary basis, compliance with the requirements of technical regulations on the safety of gas distribution and gas consumption networks is ensured. On the entry into force of technical regulations

In accordance with clause 2 of the Government of the Russian Federation of October 29, 2010 No. 870, the functions of state control (supervision) over compliance with most of the requirements established by the technical regulations on the safety of gas distribution and gas consumption networks are carried out by the Federal Service for Environmental, Technological and Nuclear Supervision. The text of the technical regulation itself (clause 100) also defines bodies of state control (supervision) over compliance with the requirements of the technical regulation (federal executive body performing control (supervision) functions in the field of industrial safety and federal executive body authorized to implementation of state construction supervision), and the volume of requirements controlled by them (clause 101). On the state control (supervision) body

The requirements of the PB “Safety Rules for Gas Distribution and Gas Consumption Systems” are valid only to the extent that they do not contradict the requirements of the Technical Regulations on the safety of gas distribution and gas consumption networks (approved by Decree of the Government of the Russian Federation of October 29, 2010 No. 870) On the interpretation of contradictions in the requirements of various legislative and regulatory requirements - legal acts Requirements of the joint venture "SNiP" Gas distribution systems. Updated version" (put into effect by the Ministry of Regional Development of the Russian Federation on May 20, 2011) are valid to the extent that they do not contradict the requirements of the Technical Regulations on the safety of gas distribution and gas consumption networks (approved by Decree of the Government of the Russian Federation of October 29, 2010 870) The requirements of the Technical Regulations themselves on safety of gas distribution and gas consumption networks (approved by Decree of the Government of the Russian Federation of October 29, 2010 No. 870) are valid and binding to the extent that they do not contradict the requirements of federal laws, in particular the Urban Planning Code of the Russian Federation

Clause 4 of Article Federal Law: “This Federal Law does not regulate relations related to the development, adoption and implementation of...requirements for carrying out activities in the field of industrial safety...except for cases of development, adoption, application and implementation of such requirements for products or for products and related with product requirements for the processes of design (including research), production, construction, installation, commissioning, operation, storage, transportation, sales and disposal. Amendments to 184-FZ (as amended by 255-FZ of the city) and 116-FZ (as amended by 243-FZ of the city) Clause 1 of the article of the Federal Law: “Types of activities in the field of industrial safety include design, construction, operation, reconstruction, major repairs, technical re-equipment, conservation and liquidation of a hazardous production facility; manufacturing, installation, adjustment, maintenance and repair technical devices, used at a hazardous production facility; conducting industrial safety examinations; training and retraining of workers at hazardous production facilities in non-educational institutions"

Paragraphs 1 and 3 of the Federal Law article: “1.Legal regulation in the field of industrial safety is carried out by this Federal Law, other federal laws..., as well as federal norms and rules in the field of industrial safety.... 3. Federal norms and rules in the field of industrial safety establish mandatory requirements to: implementation of activities in the field of industrial safety, including requirements for employees of hazardous production facilities; Safety of technological processes at hazardous production facilities, including mandatory requirements for the procedure in the event of an accident or incident at a hazardous production facility. Federal norms and rules in the field of industrial safety are developed and approved in the manner established by the Government of the Russian Federation" Amendments to 184-FZ (as amended by 255-FZ of the year) and 116-FZ (as amended by 248-FZ of the year) Clause 1 of the article Federal Law: “Technical regulations, taking into account the degree of risk of harm, establish the minimum necessary requirements to ensure: ... explosion safety; mechanical safety; fire safety; product safety (technical devices used at a hazardous production facility);... other types of safety for the purposes corresponding to paragraph 1 of Article 6 of this Federal Law"

ABOUT current state regulatory framework(design and construction) SNiP “Gas distribution systems” JV “General provisions for the design and construction of gas distribution systems made of metal and polyethylene pipes"; JV “Design and construction of gas pipelines from metal pipes"; JV “Design and construction of gas pipelines from polyethylene pipes and reconstruction of worn-out gas pipelines” Currently being updated on the instructions of the Ministry of Regional Development of Russia within the framework of the activities of TC 465 “Construction” of Rosstandart JV “SNiP “Gas distribution systems”. Updated edition" (put into effect by the Ministry of Regional Development of the Russian Federation on May 20, 2011) A set of GOST R is being developed, including requirements for the design, construction and operation of polyethylene and steel gas pipelines: "Gas distribution systems. Part 0. General requirements. Part 1. Polyethylene gas pipelines. Part 2. Steel gas pipelines" within the framework of the activities of TC 23 "Engineering and technology of oil and gas production and processing" of Rosstandart. The same TC 23 developed the approved and put into effect GOST R “Gas distribution systems. Terms and Definitions"

On the current state of the regulatory framework (operation) PB "Safety rules for gas distribution and gas consumption systems" Rules for the protection of gas distribution networks PB is being processed into the Rostechnadzor joint venture "Ensuring compliance with safety requirements for gas distribution and gas consumption networks" Now the first edition of the joint venture has been transferred to Rostechnadzor for organizing public discussion. The RD is also being processed into a Rostechnadzor joint venture project. The protection rules are being processed into a draft Decree of the Government of the Russian Federation, which will be introduced by Rostechnadzor. All work is carried out on behalf of Rostechnadzor and the initiative of OJSC Gazprom Gazoraspredeleniye and NP SRO Gas Distribution System. Design”, which finances development. As part of the activities of PC 4 “Gas distribution and gas consumption” of TC 23, a set of NS projects on the technical operation of gas distribution and gas consumption networks was developed, which successfully passed all stages of public discussion in TC 23 and was submitted to Rosstandart for approval. RD "Instructions for diagnosing the technical condition of underground steel gas pipelines" Set OST (052.053)-2003 " Technical operation gas distribution systems", approved. Ministry of Energy of the Russian Federation

1. Official written explanations from Rostechnadzor (possibly together with the Ministry of Justice of the Russian Federation) on the issue of the status of industrial safety regulations in transition period until the adoption of the relevant Code of Rules. 2. Rostechnadzor’s appeal to the Government of the Russian Federation or to specific federal executive authorities (Ministry of Regional Development of the Russian Federation, Ministry of Emergency Situations of the Russian Federation, Ministry of Energy of the Russian Federation, Rosstandart) on the need to bring those under their jurisdiction regulatory documents in accordance with the requirements of TR PP RF 870, as well as the need to issue orders to cancel the validity of old documents when approving new documents or updated editions. Measures requiring urgent adoption in connection with the entry into force of TR PP RF 870

Technical regulations on the safety of gas distribution and gas consumption networks (approved by Decree of the Government of the Russian Federation of October 29, 2010 870) Possible variant structure of the regulatory framework for gas distribution and gas consumption Codes of rules of Rostekhnadzor (on issues within its competence in accordance with the requirements of 116-FZ and RF PP 870) Codes of rules of the Ministry of Regional Development of the Russian Federation (on issues of design and construction in accordance with the requirements of 384-FZ and RF PP 870) Codes of rules of the Ministry of Emergency Situations RF (on issues within its competence, in accordance with the requirements of 123-FZ, 384-FZ and RF PP 870) National standards on issues traditionally within the competence of Rosstandart: - terminology; - materials; - technical devices; - methods of testing, research, measurements, sampling; - risk management; - non-destructive testing, etc. Regulatory legal acts of other federal executive authorities (Ministry of Economic Development of the Russian Federation, FST, etc.)

GOVERNMENT OF THE RUSSIAN FEDERATION

RESOLUTION

On approval of technical regulations on network security

Document with changes made:

Decree of the Government of the Russian Federation of June 23, 2011 N 497 (Collection of Legislation of the Russian Federation, N 26, 27.06;

(Official Internet portal of legal information www.pravo.gov.ru, 01/24/2017, N 0001201701240013).2011);

Decree of the Government of the Russian Federation of December 14, 2018 N 1560 (Official Internet portal of legal information www.pravo.gov.ru, 12/19/2018, N 0001201812190040).

____________________________________________________________________

____________________________________________________________________

The document takes into account:

by the decision of the Supreme Court of the Russian Federation dated April 13, 2016 N AKPI15-1534 (left unchanged by the Determination of the Appeal Board of the Supreme Court of the Russian Federation dated August 9, 2016 N APL16-344).

____________________________________________________________________

In accordance with the Government of the Russian Federation

decides:

1. Approve the attached technical regulations on the safety of gas distribution and gas consumption networks.

The specified technical regulation comes into force after 12 months from the date of official publication of this resolution.

2. Establish that state control (supervision) over compliance with the requirements established by the technical regulations approved by this resolution during operation (including maintenance and Maintenance), reconstruction, overhaul, installation, conservation and liquidation of gas distribution and gas consumption networks, is carried out by the Federal Service for Environmental, Technological and Nuclear Supervision within the limits established by the Government of the Russian Federation of the maximum number of employees of its central apparatus and territorial bodies and budgetary allocations provided for by this federal body executive power in the federal budget for leadership and management in the field of established functions.

3. The Ministry of Energy of the Russian Federation, within 6 months, develop jointly with interested federal executive authorities and submit to the Government of the Russian Federation a draft list of documents in the field of standardization containing rules and methods of research (testing) and measurements, including rules for sampling, necessary for the application and implementation of technical regulations on the safety of gas distribution and gas consumption networks and the implementation of conformity assessment.

Chairman of the Government

Russian Federation

V.Putin

Technical regulations on the safety of gas distribution and gas consumption networks

APPROVED

Government resolution

Russian Federation

dated October 29, 2010 N 870

Lists of national standards and other documents,

ensuring compliance

of these Technical Regulations

I. General provisions

1. In accordance with the Federal Law “On Technical Regulation”, this technical regulation is adopted to protect the life and (or) health of citizens, property of individuals and (or) legal entities, state and (or) municipal property, environmental protection, life and ( or) animal and plant health, preventing misleading practices, and ensuring energy efficiency.

2. This technical regulation applies to the gas distribution network and gas consumption network, as well as to the associated processes of design (including engineering surveys), construction, reconstruction, installation, operation (including maintenance, routine repairs), overhaul, conservation and liquidation .

3. Requirements for the gas distribution network and gas consumption network established by this technical regulation, with the exception of the requirements established by sections I, II, VI-VIII, paragraphs 14 and 15 of section III, as well as paragraph 18 of section IV of this technical regulation, up to reconstruction or capital repairs of a facility that is part of the gas distribution network or gas consumption network do not apply:

a) to the gas distribution network and gas consumption network put into operation before the entry into force of these technical regulations;

b) to the gas distribution network and gas consumption network, the construction, reconstruction and overhaul of which is carried out in accordance with the design documentation approved or sent for state examination before the entry into force of these technical regulations;

c) to the gas distribution network and gas consumption network, an application for a construction permit for which was submitted before the entry into force of these technical regulations.

4. The requirements of these technical regulations do not apply to the gas consumption network of residential buildings.

5. This technical regulation does not apply to objects that are not identified as the object of technical regulation of this technical regulation.

6. Requirements for the components of the gas distribution network and gas consumption network may be established by other technical regulations. In this case, these requirements cannot contradict the requirements of this technical regulation.

7. The basic concepts used in these technical regulations mean the following:

“building explosion resistance” - ensuring the prevention of damage to the load-bearing building structures of the building and injury to people dangerous factors explosion due to the release of pressure (explosion energy) into the atmosphere as a result of the opening of openings in the building envelope, covered with safety anti-explosion devices (glazing, special windows or easily removable structures);

“gas pipeline” is a structure consisting of interconnected pipes intended for transporting natural gas;

"internal gas pipeline" - a gas pipeline laid from the outer edge external structure the building being gasified to the connection point for gas-using equipment located inside the building;

“external gas pipeline” - an underground or above-ground gas pipeline of a gas distribution network or gas consumption network, laid outside buildings, to the outer edge of the outer structure of a building;

“underground gas pipeline” - an external gas pipeline laid in the ground below the ground level, as well as along the ground surface in an embankment (embankment);

“overground gas pipeline” - an external gas pipeline laid above the surface of the earth, as well as along the surface of the earth without embankment (embankment);

“purge gas pipeline” - a gas pipeline designed to displace gas or air (according to operating conditions) from gas pipelines and technical devices;

“discharge gas pipeline” - a gas pipeline designed to remove natural gas from safety relief valves;

“easily removable structures” - building envelopes that, in the event of an explosion inside the building, provide the release of explosion energy, protecting others from destruction building construction building;

“special conditions” - the presence of a threat of occurrence (development) of dangerous natural and man-made (under the influence of human activity) phenomena and events, and (or) soils specific in composition and condition;

“disconnection device” is a technical device intended for periodic shutdowns of individual sections of a gas pipeline and gas-using equipment in compliance with tightness conditions;

“gas metering point” is a technological device designed to account for natural gas consumption in gas distribution and gas consumption networks;

"gas distribution network" - a unified production and technological complex, including external gas pipelines, structures, technical and technological devices located on external gas pipelines, and intended for transporting natural gas from a shut-off device installed at the outlet of the gas distribution station to the shut-off device, located on the border of the gas distribution network and the gas consumption network (including the gas consumption network of residential buildings);

"gas consumption network" - a single production and technological complex, including external and internal gas pipelines, structures, technical and technological devices, gas-using equipment, located on one production site and intended for transporting natural gas from a shutdown device located on the border of the gas distribution network and gas consumption networks, to the disconnecting device in front of the gas-using equipment;

"technical device" - component gas distribution networks and gas consumption networks (pipeline fittings, compensators (lens, bellows), condensate collectors, water seals, electrical insulating connections, pressure regulators, filters, gas metering units, electrochemical corrosion protection equipment, burners, telemechanics and automatic control equipment technological processes natural gas transportation, instrumentation, safety automation equipment and settings for gas combustion parameters) and other components of the gas distribution network and gas consumption network;

“technological device” - a set of technical devices connected by gas pipelines, ensuring the receipt of specified parameters of the gas distribution network and gas consumption network, determined by the design documentation and operating conditions, including gas control points, block gas control points, cabinet gas control points, gas control units and gas metering points ;

"transportable block building" - a building made of prefabricated metal structures and having devices for transportation, in which technological equipment is mounted;

“natural gas transportation” - the movement of natural gas through gas pipelines of the gas distribution network and gas consumption network;

“transit laying of a gas pipeline” - laying of a gas pipeline along the structures of a non-gasified building or premises;

“operation of the gas distribution network and gas consumption network” - use of the gas distribution network and gas consumption network for the purpose specified in the design documentation;

"operating organization" - a legal entity operating the gas distribution network and gas consumption network and (or) providing services for them maintenance and repairs legally.

II. Rules for identifying objects of technical regulation

8. Application of this technical regulation is possible only after identification of the object of technical regulation.

9. For the purpose of applying these technical regulations, gas distribution and gas consumption networks are identified by the following essential characteristics, considered exclusively in the aggregate:

a) appointment;

b) the composition of facilities included in the gas distribution and gas consumption networks;

c) natural gas pressure defined in paragraph 11 of these technical regulations, as well as in Appendices No. 1 and 2.

10. An object of technical regulation can be identified as a gas distribution network if it transports natural gas:

a) in the territories of populated areas - with a pressure not exceeding 1.2 megapascals;

b) in the territories of populated areas exclusively to production sites where gas turbine and combined cycle gas plants are located, and in the territories of the specified production sites - with a pressure exceeding 1.2 megapascals;

c) between populated areas - with pressure exceeding 0.005 megapascal.

11. An object of technical regulation can be identified as a gas consumption network if it transports natural gas:

a) to gas-using equipment of gasified buildings and gas-using equipment located outside buildings - with a pressure not exceeding 1.2 megapascals;

b) to gas turbine and combined cycle plants - with a pressure not exceeding 2.5 megapascals.

12. Materials for identifying objects of technical regulation include:

a) design documentation;

b) conclusion of an examination of design documentation for the construction, reconstruction and overhaul of gas distribution and gas consumption networks;

Decree of the Government of the Russian Federation of January 20, 2017 N 42.

c) conclusion of an industrial safety examination of project documentation for the conservation and liquidation of gas distribution and gas consumption networks;

d) construction permit;

e) information on gas distribution and gas consumption networks contained in the Unified state register real estate;

(Subparagraph as amended, put into effect on December 27, 2018, by Decree of the Government of the Russian Federation of December 14, 2018 N 1560.

f) executive documentation;

g) act of acceptance of gas distribution and gas consumption networks by the acceptance committee;

h) permission to commission.

13. The use of other materials as identification materials is not permitted.

III. General requirements for gas distribution and gas consumption networks

14. Gas distribution and gas consumption networks must ensure the safety and energy efficiency of transporting natural gas with pressure and flow parameters determined by the design documentation and operating conditions.

15. Design, construction, reconstruction, installation, operation, conservation and liquidation of gas distribution and gas consumption networks must be carried out taking into account the features associated with the terrain, geological structure soil, hydrogeological regime, seismic conditions and the presence of underground mining.

16. Locations of discharge and purge gas pipelines should be determined based on the conditions of maximum dispersion harmful substances, while the concentration of harmful substances in the atmosphere should not exceed the maximum permissible maximum single concentrations of harmful substances in the atmospheric air.

17. To detect gas pipeline routes, the following must be marked:

a) for underground gas pipelines - using identification marks containing information about the diameter of the gas pipeline, the gas pressure in it, the depth of the gas pipeline, the material of the pipes, the distance to the gas pipeline, telephone numbers of the emergency rescue service of the organization operating this section of the gas pipeline, and other information. For polyethylene gas pipelines laid in an open way, additional provision must be made for laying warning tape. Instead of identification marks, it is possible to lay an insulated aluminum or copper wire together with a polyethylene gas pipeline;

b) for underwater gas pipelines laid through navigable and (or) rafting rivers - with the help of identification signs containing information about the prohibition of lowering anchors, chains, lots and other similar technical devices in the specified area.

IV. Requirements for gas distribution and gas consumption networks at the design stage

18. The design documentation for the gas distribution network must indicate the boundaries security zones gas distribution networks.

19. Design documentation for gas distribution and gas consumption networks must comply with the requirements of the legislation on urban planning activities.

20. Design should be carried out taking into account an assessment of the risks of accidents, fire risks, related emergencies and other adverse impacts on people, property of individuals and legal entities and the environment during the operation and liquidation of gas distribution and gas consumption networks.

21. The selection of technical and technological devices, material and design of pipes and connecting parts, protective coatings, type and method of laying gas pipelines must be carried out taking into account the pressure and temperature parameters of natural gas required by operating conditions, hydrogeological data, natural conditions and man-made influences.

22. When designing gas pipelines, the following calculations must be performed:

a) for strength and stability, the purpose of which is to exclude the possibility of destruction and unacceptable deformations of gas pipelines, which can lead to emergency situations;

b) on throughput, the purpose of which is efficient use energy of natural gas during its transportation by determining optimal ratio pressure drop across the gas pipeline section and the diameter of the gas pipeline.

23. Calculations of gas pipelines for strength and stability must be carried out taking into account the magnitude and direction of the loads acting on the gas pipelines, as well as the time of their action.

24. The thickness of the walls of pipes and connecting parts of gas pipelines must be determined by calculation taking into account the pressure of natural gas, external influences and reliability factors adopted based on the conditions of laying the gas pipeline and ensuring safety, as well as taking into account the material of the pipes.

25. When designing gas distribution and gas consumption networks, methods and means of corrosion protection of steel underground and above-ground gas pipelines, as well as steel inserts of polyethylene gas pipelines, must be provided to ensure the safety and energy efficiency of gas distribution and gas consumption networks.

26. When designing external gas pipelines, the following requirements must be met:

a) the type and method of laying gas pipelines, horizontal and vertical distances from gas pipelines to adjacent buildings, structures, natural and artificial barriers must be selected taking into account the pressure in the gas pipeline, building density, level of responsibility of buildings and structures in such a way as to ensure the safety of natural gas transportation and functioning of related facilities;

b) the depth of laying underground gas pipelines should be taken into account climatic and hydrogeological conditions, as well as depending on external influences on gas pipelines;

c) the depth of the underwater crossing of the gas pipeline into the bottom of the crossed water barriers must be at least 0.5 meters, and at crossings through navigable and floating rivers - 1 meter below the bottom profile predicted for the life of the gas pipeline, provided for by the design documentation. When carrying out work using directional drilling, the depth must be at least 2 meters below the bottom profile predicted for the life of the gas pipeline, provided for in the design documentation;

d) the height of laying the above-water passage of the gas pipeline through non-navigable water barriers should be taken based on the calculation of eliminating the possibility of damage to the gas pipeline when the water level rises, the presence of ice drifts and korcheskhod;

e) in the event that underground gas pipelines cross water barriers, measures must be taken to prevent erosion of trenches and protect soil along the gas pipeline route from destruction, including, among other things, placing stones or installing reinforced concrete covering, laying fixed soil or lattice coverings, sowing grass and shrubs;

f) in the case of crossing above-ground gas pipelines high voltage lines power transmission lines with a voltage exceeding 1 kilovolt, protective devices must be provided to prevent electrical wires from falling onto the gas pipeline when they break, as well as protective devices from falling power line supports.

27. When designing external gas pipelines, provisions must be made protective coatings or devices that are resistant to external influences and ensure the safety of the gas pipeline in places:

a) entering and exiting the earth;

b) intersections with underground communication collectors, tunnels and channels for various purposes, the design of which does not exclude the ingress of natural gas from the gas pipeline;

c) passage through the walls of gas wells;

d) passage under roads, railways and tram tracks;

e) passage through building structures;

f) the presence of underground detachable connections type "polyethylene - steel";

g) intersections of polyethylene gas pipelines with oil pipelines and heating mains.

28. Design of external gas pipelines of all pressure categories provided for in Appendix No. 1 to these technical regulations is not allowed:

a) along the walls, above and below rooms of categories A and B for explosion fire danger, with the exception of buildings of gas control points and gas metering points;

b) on pedestrian and automobile bridges built from flammable materials of group G1-G4, as well as on railway bridges.

29. Design of external gas pipelines is not allowed high pressure exceeding 0.6 megapascals on pedestrian and road bridges built from non-combustible materials.

30. It is not allowed to design the transit laying of external gas pipelines of all categories provided for in Appendix No. 1 to these technical regulations in the territories of warehouses of flammable and combustible materials of group G1-G4, as well as along the walls and above the roofs of industrial buildings made of combustible materials of group G1- G4, public buildings and structures.

The exception is the transit laying of a gas pipeline belonging to the categories of medium pressure and low pressure, the nominal diameter of which does not exceed 100 millimeters, along the walls of one residential building of fire resistance degrees I-III and structural fire hazard class C0 and at a distance from the roof of at least 0.2 meters (paragraph as amended.

31. The number, location and type of shut-off pipeline valves on external gas pipelines must ensure the possibility of disconnecting technical and technological devices and individual sections of gas pipelines to ensure the localization and elimination of accidents, carrying out repair and emergency restoration work, as well as for the liquidation and conservation of the gas distribution network.

32. When designing external gas pipelines planned for construction in water-saturated soils and at crossings over water barriers, measures must be taken (use of loads, thickening the wall of the gas pipeline pipe, etc.) to ensure the ability of the gas pipeline to maintain the position specified in the construction and operation process project documentation.

33. In landslide and erosion-prone areas, the underground gas pipeline should be designed 0.5 meters lower:

a) landslide sliding plane (for landslide areas);

b) boundaries of predicted erosion (for areas subject to erosion).

34. When designing external gas pipelines planned for construction in territories exposed to the influence of underground mining, as well as in seismic areas, technical solutions must be provided to reduce the magnitude of deformations and stresses in the gas pipeline (installation of compensators, overhead laying and other technical solutions to ensure the safety of the gas pipeline).

35. When designing technological devices, the following requirements must be met:

a) the structures of buildings of gas control points, block gas control points and gas metering points must ensure the explosion resistance of these buildings;

b) the building structures of the gas control point building must provide this building with I and II degrees of fire resistance and a class of structural fire hazard C0 (subclause as amended by Decree of the Government of the Russian Federation of June 23, 2011 N 497;

c) the buildings of the block gas control point and the gas metering point must be made of structures that provide these buildings with III-V degrees of fire resistance and a class of structural fire hazard C0;

d) the cabinet of the gas control unit must be made of non-combustible materials;

e) equipping technological devices with lightning protection, grounding and ventilation;

f) installation of purge gas pipelines after the first shut-off device and in sections of the gas pipeline with technical devices that are turned off for maintenance and repair;

g) equipping safety relief valves with discharge gas pipelines.

36. To ensure the explosion resistance of the room for placing the reduction lines of the gas control point and the technological room of the gas metering point, the said rooms must be provided with easily resettable structures, the area of which must be at least 0.05 square meters. meters per 1 cubic. meter of free volume of the room.

37. The room for placing reduction lines of the gas control point must be separated from other rooms by a fire wall without openings of the 2nd type or fire partition 1st type.

38. Gas control points can be located separately or attached to gasified industrial buildings, boiler room and public buildings I and II degrees of fire resistance and structural fire hazard class C0 with industrial premises of categories G and D or be built into 1-story gasified industrial buildings and boiler rooms (except for premises located in basements and ground floors) I and II degrees of fire resistance class of structural fire hazard C0 with premises of categories G and D, and also placed on the surfaces of gasified industrial buildings of I and II degrees of fire resistance and class of structural fire hazard C0 with non-combustible insulation or outside buildings in open fenced areas under a canopy on territories industrial enterprises(clause as amended by Decree of the Government of the Russian Federation dated June 23, 2011 N 497.

39. Block gas control points must be located separately.

40. Gas control units in cabinets may be placed:

a) on separate supports;

b) on the external walls of buildings for which they are intended for gasification, with the exception of cabinet gas control points with an inlet pressure exceeding 0.6 megapascal.

41. Gas control installations are permitted to be placed in rooms in which gas-using equipment is installed, or in adjacent rooms connected to them by open openings.

42. The pressure of natural gas at the inlet to the gas control unit should not exceed 0.6 megapascal.

43. It is not allowed to design the placement of gas control units in premises of categories A and B due to explosion and fire hazard.

44. In gas control points of all types and gas control installations, it is not allowed to design bypass gas pipelines with shut-off valves intended for transporting natural gas, bypassing the main gas pipeline at the site of its repair and for returning the gas flow to the network at the end of the section.

45. When designing internal gas pipelines, it is necessary to take into account that the pressure of natural gas in internal gas pipelines must correspond to the parameters established by the manufacturer of gas-using equipment, but should not exceed the values provided by Appendix No. 2.

46. Designing the laying of internal gas pipelines is not allowed:

b) in explosive areas of premises;

c) in basements, ground floors and technical floors located below the 1st floor of the building and intended to accommodate engineering equipment and laying of engineering support systems (except for cases when the laying is determined by production technology);

d) in warehouses categories A, B and B1-B3;

e) in the premises of substations and distribution devices;

f) through ventilation chambers, shafts and channels;

g) through elevator shafts and staircases, waste disposal rooms and chimneys;

h) through rooms in which the gas pipeline may be exposed to substances that cause corrosion of the material of the gas pipeline pipes;

i) in places where gas pipelines may be washed by hot combustion products or come into contact with heated or molten metal.

47. The design of internal gas pipelines proposed for construction in basements, ground floors and technical floors located below the 1st floor of the building and intended for the placement of engineering equipment and the installation of engineering support systems is allowed if the installation is determined by the production technology, approved in the prescribed manner, and at the same time:

a) the safety automatics must stop the gas supply when the power supply is interrupted, the ventilation of the room is disrupted, the gas pressure changes to values beyond the limits established in the design documentation, as well as when the air pressure in front of the mixing burners decreases;

b) the specified premises must be equipped with a gas control system with automatic shutdown of the gas supply and must be open from above.

48. When designing internal gas pipelines along the walls of premises, gas pipelines are not allowed to cross ventilation grilles, window and door openings, with the exception of frames and mullions of non-opening windows and window openings filled with glass blocks.

49. The number, location and type of shut-off pipeline valves on internal gas pipelines must ensure the ability to:

a) disconnecting sections of the gas consumption network for repairs of gas-using equipment and technical devices or localizing accidents with minimal periods of interruption in gas supply;

b) disconnecting gas-using equipment for its repair or replacement;

c) disconnecting a section of the gas pipeline for dismantling and subsequent installation of technical devices if they need to be repaired or verified.

50. When installing several units of gas-using equipment, it must be possible to turn off each unit of equipment.

51. When designing internal gas pipelines, the installation of purge gas pipelines should be provided:

a) in the sections of the gas pipeline most remote from the entry point;

b) on a branch to gas-using equipment after the shut-off pipeline valves.

52. The purge gas pipeline must be equipped with a fitting with a tap for sampling after the shut-off device.

53. The premises of buildings and structures in which gas-using equipment is installed must be designed taking into account their equipment with gas control systems (for methane and carbon monoxide) with a signal output to the control panel.

54. On flue ducts from gas-using equipment located horizontally, installation of safety explosion valves with an area of at least 0.05 square meters must be provided. meters each, equipped with protective devices in case of activation.

55. Ventilation of premises in which installation of gas-using equipment is planned must comply with the requirements for the production located in them and provide an air exchange of at least three times per hour for boiler rooms with the constant presence of service personnel, as well as for boiler rooms built into buildings for other purposes.

V. Requirements for the gas distribution network and gas consumption network at the stage of construction, reconstruction, installation and overhaul

56. During construction, reconstruction, installation and major repairs, compliance must be ensured:

a) technical solutions provided for in the design documentation;

b) requirements of operational documentation of manufacturers of gas-using equipment, technical and technological devices, pipes, materials and connecting parts;

c) technologies for construction, installation, major repairs and reconstruction in accordance with the work project or technological maps.

57. If deviations from the requirements specified in paragraph 56 of these technical regulations, facts of the use of materials not provided for in the design documentation, and violations of the order and poor quality of work are revealed, construction and installation work must be suspended, and the detected defects must be eliminated.

58. During the construction, reconstruction, installation and overhaul of the gas distribution network and gas consumption network, welding technologies and welding equipment must be used to ensure the tightness and strength of welded joints.

59. It is prohibited to place welded joints of gas pipelines in walls, ceilings and other structures of buildings and structures.

60. Welded joints made during construction, reconstruction, installation or major repairs are subject to control by methods non-destructive testing.

Inspection of welded joints is carried out by a person certified in the prescribed manner for the right to conduct non-destructive testing of welded joints. Based on the results of quality control of welded joints, the person performing the control draws up a conclusion on the compliance of the welded joints with the established requirements.

61. Upon completion of construction, reconstruction, installation and major repairs, gas distribution networks and gas consumption networks must be tested for air tightness.

62. Tests of gas pipelines made of polyethylene pipes should be carried out no earlier than 24 hours after the completion of welding of the last joint.

63. Results commissioning works gas distribution and gas consumption networks, the construction, reconstruction, installation and overhaul of which have been completed, must comply with the design documentation.

64. The technology for laying gas pipelines must ensure:

a) safety of the surface of the gas pipeline pipe, its insulating coatings and connections;

b) the position of the gas pipeline specified in the design documentation.

65. During the construction, installation, major repairs and reconstruction of gas pipelines, measures must be taken to prevent clogging of the cavity of pipes, sections and strings of pipes.

66. Sections of gas pipelines laid inside protective devices through the building envelopes should not have butt, threaded and flanged connections, and sections of gas pipelines laid in channels with removable ceilings and in wall grooves should not have threaded and flanged connections.

67. The energy efficiency of constructed, repaired and reconstructed gas distribution and gas consumption networks must be ensured due to their tightness (no gas leaks).

VI. Requirements for gas distribution and gas consumption networks during the operation phase (including maintenance and routine repairs)

68. When operating external gas pipelines, the operating organization must ensure monitoring of ground conditions (detection of heaving, subsidence, landslides, collapse, soil erosion and other phenomena that may affect the safety of operation of external gas pipelines) and construction work carried out in the area where gas distribution networks are laid for preventing them from being damaged.

69. When operating underground gas pipelines, the operating organization must ensure monitoring and elimination of:

a) natural gas leaks;

b) damage to the insulation of gas pipelines and other damage to gas pipelines;

c) damage to structures, technical and technological devices of gas distribution and gas consumption networks;

d) malfunctions in the operation of electrochemical protection equipment and pipeline fittings.

70. When operating above-ground gas pipelines, the operating organization must ensure monitoring and elimination of:

a) natural gas leaks;

b) moving gas pipelines beyond the supports;

c) vibration, flattening and deflection of gas pipelines;

d) damage and bending of supports that violate the safety of the gas pipeline;

e) malfunctions in the operation of pipeline fittings;

f) damage insulating coating(color) and condition of the pipe metal;

g) damage to electrical insulating flange connections, means of protection against falling of electrical wires, fastenings of gas pipelines and marker signs in places where vehicles pass.

71. When operating technological devices, the operating organization must ensure monitoring and elimination of natural gas leaks, checking the operation of safety and relief valves, maintenance, routine repairs and adjustment.

72. Checking the operation of safety and relief valves, maintenance, routine repairs and adjustment of technological devices must be carried out in accordance with the manufacturers’ instructions.

73. Safety shut-off valves and safety relief valves must provide automatic and manual shutdown of the supply or discharge of natural gas into the atmosphere when the gas pressure changes to values beyond the limits established in the design documentation for safety shut-off valves and safety relief valves.

74. Malfunctions of gas pressure regulators, leading to a change in gas pressure to values beyond the limits established in the design documentation for gas pressure regulators, as well as to natural gas leaks, must be eliminated immediately when they are identified.

75. When the supply of natural gas is interrupted, pressure regulators should be put into operation only after identifying the reason for the operation of the safety shut-off valve and taking measures to eliminate the malfunction.

76. The duration of operation of gas pipelines, technical and technological devices is established during design based on the condition of ensuring the safety of technically regulated objects in the event of predicted changes in their characteristics and guarantees of the manufacturer of technical and technological devices.

To establish the possibility of operating gas pipelines, buildings and structures and technological devices of gas distribution and gas consumption networks after the deadlines specified in the design documentation, their technical diagnostics must be carried out.

The deadlines for further operation of objects of technical regulation of this technical regulation should be established based on the results of technical diagnostics.

77. It is not allowed to operate the gas consumption network if the gas-using equipment is faulty or with the technological protections, interlocks, alarms and instrumentation provided for by the project disabled.

78. When the safety automatic system is turned off or malfunctions, it should block the ability to supply natural gas to gas-using equipment manually.

79. When commissioning the gas consumption network and after completion repair work Gas pipelines connected to gas-using equipment must be purged with natural gas until all air is displaced. The end of the purge is determined by analyzing the oxygen content in the gas pipelines. When the oxygen content in gas-air mixture more than 1 percent of the volume, ignition of burners is not allowed.

80. When operating gas distribution and gas consumption networks, the possibility of unauthorized changes is excluded.

VII. Requirements for gas distribution and gas consumption networks at the conservation stage

81. The decision to mothball and re-mothball the gas distribution network and gas consumption network is made by the organization that owns the gas distribution network or gas consumption network with notification of this to the federal executive body exercising control (supervision) functions in the field of industrial safety.

82. Conservation of the gas distribution network and gas consumption network involves the implementation of measures to ensure their industrial and environmental safety, material safety and prevention of their destruction, as well as restoration of the functionality of gas distribution and gas consumption networks after re-preservation.

83. During the conservation period, corrosion protection must be provided for objects included in the gas distribution and gas consumption networks.

84. Conservation of the gas distribution network and gas consumption network is carried out on the basis of design documentation approved in the prescribed manner.

85. The design documentation for the conservation of the gas distribution network and gas consumption network must provide for measures to exclude the possibility of the formation of a maximum permissible explosive concentration of the gas-air mixture.

VIII. Requirements for gas distribution and gas consumption networks at the liquidation stage

86. The liquidation of gas distribution and gas consumption networks must be carried out in accordance with the design documentation for the liquidation of gas distribution or gas consumption networks, approved in the prescribed manner.

87. During the liquidation process, the following measures must be ensured:

a) prevention of environmental pollution;

b) recycling of production waste;

c) reclamation of disturbed lands;

d) prevention of damage to buildings and structures located in the zone of influence of the liquidated facility;

e) maintaining the level of anti-corrosion protection of other gas distribution networks (if the anti-corrosion protection system of the disposed gas distribution network participated in the formation of the anti-corrosion protection system of other gas distribution networks);

f) preventing the activation of dangerous geological processes (landslides, landslides and similar phenomena).

IX. Conformity assessment

88. Assessment of compliance of the gas distribution network and gas consumption network with the requirements of these technical regulations is carried out in the following forms:

a) when designing (including engineering surveys) gas distribution and gas consumption networks - examination of design documentation and engineering survey results in accordance with the legislation on urban planning activities;

(Subclause as amended, put into effect on February 1, 2017 by Decree of the Government of the Russian Federation dated January 20, 2017 N 42.

b) upon completion of construction or reconstruction of gas distribution and gas consumption networks - acceptance of gas distribution and gas consumption networks;

c) during construction, operation (including maintenance and current repairs), reconstruction, major repairs, installation, conservation and liquidation of gas distribution and gas consumption networks - state control (supervision).

89. The use of other forms of assessing the compliance of gas distribution and gas consumption networks with the requirements of technical regulations not provided for in paragraph 88 of these technical regulations is not permitted.

90. When conducting an examination of design documentation and engineering survey results, compliance with the requirements established by paragraphs 15-17 of Section III and Section IV of this technical regulation, as well as the requirements established by other technical regulations for the objects of technical regulation of this technical regulation, is verified.

Decree of the Government of the Russian Federation of January 20, 2017 N 42.

91. The conclusion of the examination of design documentation and the results of engineering surveys is included in the evidentiary materials when obtaining permission to build a gas distribution network and a gas consumption network.

(Clause as amended, put into effect on February 1, 2017 by Decree of the Government of the Russian Federation dated January 20, 2017 N 42.

92. Acceptance of the gas distribution network after construction or reconstruction is carried out upon completion of construction and installation work.

Acceptance of the gas consumption network after construction or reconstruction is carried out upon completion of construction and installation work, as well as commissioning work and comprehensive testing of gas-using equipment.

93. Acceptance of gas distribution and gas consumption networks is carried out by an acceptance committee created by the developer or investor (hereinafter referred to as the acceptance committee), which includes representatives of:

a) developer;

b) construction organization;

c) design organization;

d) operating organization;

e) the federal executive body exercising state control in the field of environmental protection (in cases provided for in Part 7 of Article 54 of the Town Planning Code of the Russian Federation);

f) the federal executive body authorized to carry out state construction supervision;

g) the federal executive body exercising control (supervision) functions in the field of industrial safety.

94. If necessary, representatives of other interested organizations may be included in the acceptance committee.

95. When accepting gas distribution and gas consumption networks carried out by the acceptance committee, Building company provides the following documents and materials:

a) design documentation (executive documentation);

b) a positive expert opinion on the design documentation;

(Subclause as amended, put into effect on February 1, 2017 by Decree of the Government of the Russian Federation dated January 20, 2017 N 42.

c) magazines:

supervision of construction by the organization that developed the project documentation (if there is an agreement for its implementation);

technical supervision by the operating organization;

control of construction work;

d) protocols:

conducting leak tests of gas distribution and gas consumption networks;

inspection of welded joints and protective coatings;

e) construction passports of gas pipelines, gas-using equipment and technological devices;

f) documents confirming the compliance of the technical devices, pipes, fittings, welding and insulating materials used;

g) technical and operational documentation of manufacturers of technical and technological devices (passports, operating and installation instructions);

h) acts on:

laying out and transferring the route;

acceptance of hidden work;

acceptance of special works;

acceptance of the internal cavity of the gas pipeline;

acceptance of insulating coating;

acceptance of electrochemical protection installations;

checking the condition of industrial smoke exhaust and ventilation systems;

on the results of commissioning and comprehensive testing of gas-using equipment;

i) a copy of the order appointing a person responsible for the safe operation of gas distribution and gas consumption networks;

j) regulations on the gas service or an agreement with an organization that has experience in carrying out maintenance and repair of the gas distribution network and gas consumption network;

k) plan for localization and liquidation of emergency situations.

96. In the process of accepting constructed or reconstructed gas distribution networks and gas consumption networks, the acceptance committee checks the compliance of the constructed or reconstructed facility with the requirements established by paragraphs 15-17 of Section III and Section V of these technical regulations, as well as the requirements established by other technical regulations for objects of technical regulation of this technical regulation.

97. During the work of the acceptance committee, the following are formed:

a) a document confirming the compliance of the parameters of the constructed or reconstructed gas distribution network or gas consumption network with the parameters provided for in the design documentation, signed by the person carrying out the construction (the person carrying out the construction, and the developer or customer - in the case of construction or reconstruction on the basis of a contract);

b) a diagram showing the location of the constructed or reconstructed gas distribution network or gas consumption network, the location of engineering support networks within the boundaries land plot and the planning organization of the land plot, signed by the person carrying out construction (the person carrying out construction, and the developer or customer - in the case of construction or reconstruction on the basis of a contract);

c) conclusion of the state construction supervision body in cases determined by the legislation on urban planning activities;

d) conclusion of state environmental control in cases determined by the legislation on urban planning activities.

98. Documentary evidence compliance of constructed or reconstructed gas distribution and gas consumption networks with the requirements established by these technical regulations and other technical regulations is an acceptance certificate, which is signed by all members of the acceptance committee.

99. The powers of the acceptance committee terminate from the moment the acceptance certificate is signed.

100. State control (supervision) over compliance with the requirements of these technical regulations is carried out by the federal executive body performing control (supervision) functions in the field of industrial safety, and the federal executive body authorized to carry out state construction supervision, within their competence and in the procedure established by the Federal Law "On the protection of the rights of legal entities and individual entrepreneurs in the exercise of state control (supervision) and municipal control".

101. In the process of state control (supervision), the compliance of the measures applied by the operating organization with the requirements established by paragraphs 14, 15 and 17 of Section III and Sections V-VIII of these technical regulations is established.

X. Liability for violation of the requirements of these technical regulations

102. Persons guilty of violating the requirements of these technical regulations are liable in accordance with the legislation of the Russian Federation.

Appendix No. 1. Classification of external and internal gas pipelines by pressure in gas distribution and gas consumption networks

Appendix No. 1

to technical regulations

about network security

gas distribution and gas consumption

High pressure gas pipelines of category 1a (over 1.2 MPa)

High pressure gas pipelines of category 1 (over 0.6 to 1.2 MPa inclusive)

High pressure gas pipelines of category 2 (over 0.3 to 0.6 MPa inclusive)

Medium pressure gas pipelines (over 0.005 to 0.3 MPa inclusive)

Low pressure gas pipelines (up to 0.005 MPa inclusive)

Appendix No. 2. Maximum values of natural gas pressure in gas consumption networks

Appendix No. 2

to technical regulations

about network security

gas distribution and gas consumption

Revision of the document taking into account

changes and additions

GOVERNMENT OF THE RUSSIAN FEDERATION

RESOLUTION

On approval of technical regulations on network security

Document with changes made:

Decree of the Government of the Russian Federation of June 23, 2011 N 497 (Collection of Legislation of the Russian Federation, N 26, 27.06;

(Official Internet portal of legal information www.pravo.gov.ru, 01/24/2017, N 0001201701240013).2011);

Decree of the Government of the Russian Federation of December 14, 2018 N 1560 (Official Internet portal of legal information www.pravo.gov.ru, 12/19/2018, N 0001201812190040).

____________________________________________________________________

____________________________________________________________________

The document takes into account:

by the decision of the Supreme Court of the Russian Federation dated April 13, 2016 N AKPI15-1534 (left unchanged by the Determination of the Appeal Board of the Supreme Court of the Russian Federation dated August 9, 2016 N APL16-344).

____________________________________________________________________

In accordance with the Government of the Russian Federation

decides:

1. Approve the attached technical regulations on the safety of gas distribution and gas consumption networks.

The specified technical regulation comes into force after 12 months from the date of official publication of this resolution.

2. Establish that state control (supervision) over compliance with the requirements established by the technical regulations approved by this resolution during operation (including maintenance and current repairs), reconstruction, major repairs, installation, conservation and liquidation of gas distribution and gas consumption networks is carried out by the Federal service for environmental, technological and nuclear supervision within the limits established by the Government of the Russian Federation of the maximum number of employees of its central apparatus and territorial bodies and budgetary allocations provided for this federal executive body in the federal budget for leadership and management in the field of established functions.

3. The Ministry of Energy of the Russian Federation, within 6 months, develop jointly with interested federal executive authorities and submit to the Government of the Russian Federation a draft list of documents in the field of standardization containing rules and methods of research (testing) and measurements, including rules for sampling, necessary for the application and implementation of technical regulations on the safety of gas distribution and gas consumption networks and the implementation of conformity assessment.

Chairman of the Government

Russian Federation

V.Putin

Technical regulations on the safety of gas distribution and gas consumption networks

APPROVED

Government resolution

Russian Federation

dated October 29, 2010 N 870

Lists of national standards and other documents,

ensuring compliance

of these Technical Regulations

I. General provisions

1. In accordance with the Federal Law “On Technical Regulation”, this technical regulation is adopted to protect the life and (or) health of citizens, property of individuals and (or) legal entities, state and (or) municipal property, environmental protection, life and ( or) animal and plant health, preventing misleading practices, and ensuring energy efficiency.