Do-it-yourself warm baseboard system. Reliable heating system - warm water baseboard: price, reviews and installation recommendations. Video about installing a baseboard heating system

Winter is coming to an end, but the issue of choosing a heating system is still relevant for FORUMHOUSE users. Despite wide choose devices, there is one system, interest in which is constantly growing. Its name is “warm baseboard”.

System Features

Thermal plinth is a heating device installed instead of a regular plinth.

Being essentially a microconvector, a warm baseboard can act both as the main heating system and as an additional one.

Thanks to small sizes– the height of the industrially produced warm skirting board is 15-20 cm, and the width is 3 cm; the thermal skirting board fits well into any interior.

chicken-A:

– Thermal plinth is similar to a standard plinth mounted at the bottom of the wall. Thermal plinth is made of metal and, most often, heated by liquid coolant supplied from the boiler (this type is called “warm water plinth”; there is also “warm electric plinth”).

Read in the diary of a member of our portal what is special about the second type, and whether someone who cares about the composition of the air in their home should even think about doing it.

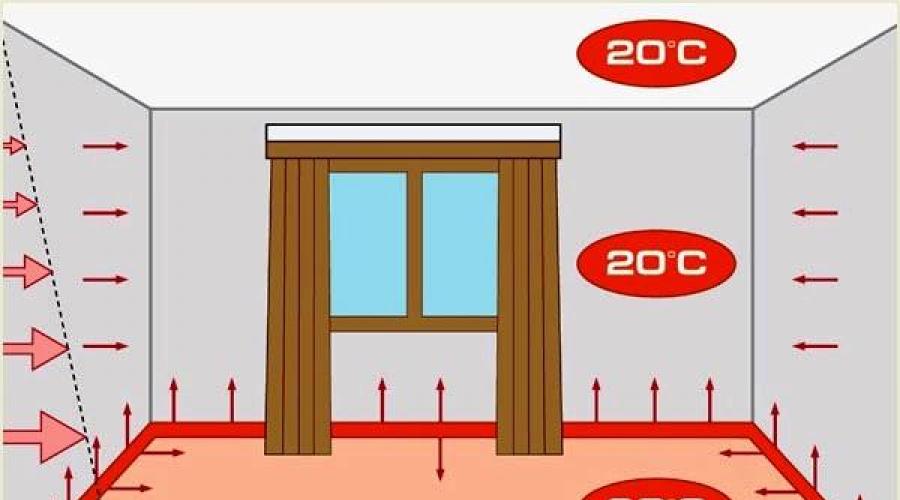

Unlike conventional window sill radiators, heating with warm baseboards occurs not due to convection currents, which first heat the air, but due to radiant energy, which has a beneficial effect on humans.

Data are often given that the radial component of heat transfer from a thermoplinth is 80%, and the convection component is 20%.

Let's take a room with an area of 16 sq.m. Indoors, along three walls 4 meters long, thermal baseboards installed. The panel height is 14 cm. Thus, total area The radiating surface of the plinth will be 1.68 sq.m.

With a panel width of 3 cm, the ascending convection heat flow, under the influence of the Coanda effect, seems to be “pressed” against the wall. Therefore, it does not mix with the rest of the air mass in the room, but heats the overlying inner surface walls.

Thus, the walls under which a warm baseboard is installed, at a height of up to 1.5 meters, heat up several degrees higher room temperature, which creates a feeling of thermal comfort for people in the room.

°C °C .

As a result of the experiment, it was found that for a person to be comfortable, the air temperature in the room should be approximately 16°C , provided that the wall temperature is about 22°C .

The system is simple to design and operate. The supply of water or other coolant to the warm baseboard registers is carried out through a conventional collector using circulation pump from any heating boiler.

We list the main advantages of heating with thermoplinths:

- uniform heating of the entire room without the formation of “cold corners”;

- creating a thermal curtain near the window, which is especially important in winter with a large glazing area;

- comfortable thermal mode allows you to save energy resources, because due to the predominance of the radiant component, it is not necessary to heat the air strongly, as with convection heating;

- The absence of protruding components and parts allows the system to fit into almost any interior.

Warm baseboard: buy or make

You can easily buy a warm water baseboard, both in Moscow and in any region. But the main and, perhaps, the most significant drawback, which a warm water baseboard has - the price for it is too high. Yes, and on a warm baseboard electric price also not very humane. In this article we consider the water option:

On average, the price per linear meter of a warm baseboard panel with all necessary fastenings is above 2500 rubles.

If you add to this price necessary components that you will have to buy - eyeliner, manifold, mixing unit and other elements, the cost of thermal baseboard doubles.

That's why chicken-A I decided to make the thermal baseboard myself.

The requirements necessary for this are the low cost and ease of manufacturing baseboard heating at home.

chicken-A:

– Having brainstormed, I decided to abandon the fins and make a panel from a copper plate, soldering a tube to it.

Technical characteristics of a homemade panel:

- panel height – 140 mm;

- internal diameter of the tube – 10 mm;

- outside diameter tubes – 12 mm.

The tubes were made of unannealed copper in sticks 6 m long.

Of particular interest is the user's approach to the manufacture of warm baseboards. For this chicken-A I cut a strip of ordinary roofing copper into 4 strips with a grinder.

The tubes are soldered to the panel with soft plumbing solder containing 3% copper using gas burner and flux. In order to avoid warping of the metal at the soldering site, the main flame of the burner must be directed towards the tube.

For connecting tubes and panels into a trunk chicken-A I used pieces of oil and petrol resistant pressure hose. And I secured the rubber pipes placed on the ends of the copper tubes with screw clamps.

chicken-A:

– At the time of manufacture, this system (including the manifold and connections) cost me less than 500 rubles. in terms of 1 meter of panel. Now, as of January 2015, this amount, due to inflation, is approximately 800-900 rubles.

Installation of warm baseboard

To prevent excess heat loss in the places where the panels were attached to the wall, the forum member attached a strip of isolon with a reflective aluminized layer. On top of it, he screwed plastic plumbing clips to the wall.

This will allow the panels to be easily removed if repairs are necessary.

For each heated room, its own circuit is drawn from the collector. Its total length, including the liner, should not exceed 15-16 meters. The temperature of the coolant is regulated using a thermostatic mixture from the boiler circuit through a three-way valve with a servomotor.

For each heated room, its own circuit is drawn from the collector. Its total length, including the liner, should not exceed 15-16 meters. The temperature of the coolant is regulated using a thermostatic mixture from the boiler circuit through a three-way valve with a servomotor.

Propylene glycol is used as a coolant. Thermal valves with thermostatic heads are installed at the entrance to each room.

chicken-A:

– It took approximately 55 liters of coolant to fill the system. It took 10 liters to fill the room circuits (total heated area 100 sq. m) and the collector. 35 liters were spent on the TT boiler, electric boiler and mains.

To improve the heat transfer of panels, chicken-A I wanted to paint them first, but abandoned this idea, deciding that natural copper color looks great in the interior of rooms.

Summing up

Homemade thermoplinths have been successfully operating as the main heating system in a forum member’s home for 7 years. Over the entire period, the system did not lose power and did not require any repairs.

chicken-A:

– My house is well insulated. Depending on the weather, the coolant temperature is set in the range from 50°C to 70°C. Only at the very cold winter I raised the coolant temperature to 80°C.

Feels like chicken-A, The thermal effect from working skirting boards is very soft and pleasant. The air does not dry out. And thanks to radiant energy, the air temperature in the house can be kept at 20-21°C.

Also, as an improvement to the system, chicken-A proposes to increase the height of the panel from 14 to 19 cm. In his opinion, this fully compensates for the lack of complex self-made tube fins.

Read on FORUMHOUSE about how to make and install it yourself, learn everything about and get acquainted with the basic principles.

Watch in our video how to heat a large house in the absence of gas, how to build an air heating system based on a heat pump.

In our market, a new product in solving heating problems has become new system, which provides heating - a warm baseboard, although in Europe it has been known for two decades and is considered quite effective there. A metal baseboard is installed around the perimeter of the room, and a heating element is located inside it. Heating here is carried out by thermal radiation. This system can complement heating with radiators or even be the only source of heat in a private house or apartment.

- The principle of operation of a warm baseboard

- Warm baseboard design

- Classification of warm baseboard systems

- Water warm baseboard

- Electric warm baseboard

- Advantages and disadvantages of warm baseboards

- Advantages

- Flaws

- Installation of warm baseboard

- Preparation

- Installation process using the example of a warm baseboard water system

- Nuances of installing electrical panels

- Option No. 1 – made of roofing copper

- Option No. 2 – made of aluminum profiles

The principle of operation of a warm baseboard

The warm baseboard has simplest principle actions: electricity or coolant heats the tubes and their fins, and they radiate heat, heating the outer aluminum body of the plinth.

The body, uniformly heated along the entire length, creates a peculiar thermal curtain. The air slowly rising along the walls heats them, giving them its heat. A screen is created near the walls and windows, preventing heat from escaping from the room, and the heated walls gently radiate heat into the room, heating it. As a result, the heat from warm baseboards is distributed more evenly around the perimeter of the room, and, therefore, the height of the room is also heated more evenly.

Video about the principle of operation of a warm baseboard:

Warm baseboard design

Externally, this device is a metal box with dimensions of 30x140 mm. Such a box is mounted directly on the wall, replacing the classic wooden or plastic skirting board. On the upper side there is a gap in the box through which heated air flows along the wall, rushing upward. Aluminum panels heat up to 40-70 degrees, while a comfortable temperature is established in the room.

From conventional radiators located at some distance from the floor, this design It differs favorably in that the heat-emitting baseboard is capable of heating the lowest level of the room.

Inside the box there are special brackets on which a heating element is mounted, consisting of a pair of copper tubes with brass plates attached. Copper tubes have an internal diameter of only 11 mm with a wall thickness of 1 millimeter. The heating modules are connected to each other with crimp nuts or by copper soldering, and special copper or polyethylene rotary tubes are used in the corners.

The coolant, which is most often ordinary water, enters the circuit through supply pipes from the distribution manifold. It is advisable to equip the distribution manifold with shut-off and drain taps, flow meters and automatic air traps. In addition, it is useful to add a water pressure gauge and thermometer to the warm baseboard, with which you could monitor the entire system and make it easier to manage its parameters.

Classification of warm baseboard systems

Like a heated floor system, heated baseboards can be:

- water;

- electric.

Water warm baseboard

Despite the name, not only water, but also heavy alcohols can circulate through the tubes of this circuit. On linear meter baseboard, 0.34 liters of coolant are required to fill the tube, whose working temperature can fluctuate between 50-85 degrees. Temperature control is carried out automatically or manual mode through the collector. The water baseboard perfectly adapts to both centralized and autonomous heating systems, and can even serve as the main source of heat in the room, and not just as an additional one.

The length of each circuit of a warm water baseboard cannot be longer than 13-15 m, therefore, if the perimeter of the room exceeds this value, then it is necessary to install several consecutive autonomous circuits in it.

Electric warm baseboard

The warm electric baseboard is heated using heating elements with a power of 200 W per linear meter of module length. In this case, the operating temperature does not exceed 60 degrees. All heating elements included in the system are connected to each other in parallel. Their operation can be regulated through a wall-mounted electronic or electromechanical thermostat that has a built-in ambient temperature sensor.

The heaters are laid in the lower copper tube, and in the upper there is a special cable with a heat-resistant sheath. The voltage from this cable is transmitted to the electric heaters located underneath it, which are sections ranging from 0.7 to 2.5 m in length.

Advantages and disadvantages of warm baseboards

Advantages

- When using a warm baseboard, almost all restrictions on the placement of furniture in the room are removed; only placing it close to the walls can lead to its overheating and drying out.

- A warm baseboard helps create a comfortable microclimate in the room, and slow rising air currents along the walls do not raise much dust. The volume of the room will be heated more evenly: it is not too hot near the ceiling, and not too cold near the floor.

- Constant heating of the walls will completely rid them of mold and dampness, and if such heating is used in rooms with large area glazing, then condensation does not form on the windows.

- Due to the small cross-section of the tubes, a large volume of coolant is not required, which reduces the cost of preheating it. The coolant circulates more intensively, due to which the heat loss of the system can be reduced by 5%. This also leads to a decrease in the thermal inertia of the system, which responds more quickly to any adjustment to the operating mode. In the electric version of a warm baseboard, it is possible to save energy.

- Due to the fact that the device does not heat up too much, it is possible to save energy costs. Thanks to the possibility of separate adjustment for each room, the desired temperature can be maintained in any of them.

- Skirting boards are very easy to install because they consist of ready-made modules, which only remains to be connected to the heating system or power supply.

- Moderate heating of baseboard boxes makes them safe for curtains, furniture and other objects located close to the walls.

- After installation, the skirting boards remain almost invisible; they can be organically integrated into any interior style, since aluminum protective panels can have different colors.

Flaws

- High cost of the structure itself.

- High energy costs.

- This system needs constant functioning.

- Because of low power The warm baseboard system is unable to quickly warm up the room; it will warm up the walls for a long time until they begin to give off heat.

A logical question is what is better: a warm floor or a warm baseboard, because a warm baseboard system is in many ways similar to its related warm floor system, but at the same time requires much less effort and costs during its installation.

In addition, heated floors (primarily water) cannot be installed in every room, since it requires preparation concrete screed. There are no such restrictions for the plinth; all it needs is flat wall. At the same time, the modular design of the system makes it mobile, so if necessary, it can be dismantled and assembled in another room.

Installation of warm baseboard

Preparation

- climate of the area;

- glazing area;

- quality of thermal insulation of the room.

For a temperate climate, the average power consumption is 100 W/m2. If the home is well insulated, then you can install a cheaper and less powerful system in it.

To connect adjacent modules of the device, it is advisable to use copper soldering - this method is considered the most reliable, since it allows you to withstand high pressure and thanks to this the system can be connected to centralized heating. If copper soldering is not possible, then threaded fittings are used. Water from the boiler is supplied through reliable pipes from polymers.

Installation process using the example of a warm baseboard water system

Typically, a warm baseboard is connected through a distribution comb or manifold.

For the system to function effectively, it is necessary that the length of each heating element does not exceed 13 meters, and then the next element, connected separately to the comb, will work.

- Lead the pipes coming from the distribution manifold to the installation site of the panels.

- Before installing, mark the panel installation lines, keeping in mind that the distance from the box to the floor should be approximately a centimeter.

- Place the back panel on the marked line and mark the mounting holes, which can then be drilled with a hammer drill.

- Secure the panel with self-tapping screws and plastic dowels or glue. The back side of the box has stops that provide the required distance of the device from the wall, which is 15 mm.

- Stick between the baseboard body and the wall thermal insulation tape, carefully trim the edge of the tape.

- Drill 2 holes in the supporting brackets for self-tapping screws and countersink them.

- Insert the prepared brackets into the slot of the top bar in increments of 50 cm.

- For corner connecting elements, prepare and install the upper parts of the corners.

- Install the plank with brackets in the prepared place on the wall. Attach the brackets with self-tapping screws, recessing their caps.

- The lower parts of the brackets were broken and removed - they were needed only to maintain strict parallelism in the installation of the upper bar relative to the bottom.

- Insert a fluoroplastic gasket into each bracket.

- Prepare the heating module for installation, cutting off excess sections if necessary. To attach the module, you need to remove 2-3 slats from the edge. Place connecting nuts, rubber gaskets of fittings and crimping cones on the tubes.

- Connect the heating module, tighten the nuts, and make the final crimp.

- If necessary, make linear and/or angular joining of heating modules.

- The fully assembled system must be connected to the collector and hot coolant must be run there.

- Apply heat reflective tape to inner part closing strip and attach the latter to the brackets in a mesh: first slide the top of the strip onto the hooks of the brackets, then click bottom part with effort.

- You can always choose a decorative closing profile:

A warm baseboard with all connecting elements is quite expensive, but at the same time it is very effective, and provides new opportunities when designing an interior.

Video about installing warm baseboards:

Nuances of installing electrical panels

- Due to high consumption electrical power, you can use no more than 17 modules together so as not to overload the network.

- The electrical cable powering the device can be placed outside or inside the wall, covering it with a box.

- The device is connected to the power supply through a thermostat, which is conveniently mounted on the wall one and a half meters from the floor, and must be left freely accessible. As a rule, the thermostat is installed next to the outlets.

- Calibrate the device before putting it into operation.

When making a warm baseboard with your own hands, you need to consider two possible options its manufacture:

Option No. 1 – made of roofing copper

In the first case, the structure consists of unannealed copper tubes with a diameter of 12-20 mm and roofing copper sheets 0.4 mm thick. Such systems are assembled in the following order:

- Copper roofing plates must be cut into strips 15 cm wide.

- Then bend the edges of the resulting strips at right angles to the base so that the width of the bent part is approximately 7-8 mm. At the same time, the length of the strip itself should not be more than 3 m, otherwise it will simply be inconvenient to work with such workpieces.

- Then solder the copper tubes to inside housing, first bending the ends of the tubes slightly to the side to make it easier to install the adapters.

- The coolant can be supplied using standard hoses having an internal diameter of 12 mm and secured with ordinary pipe clamps.

- After this, homemade skirting boards must be secured to the wall using mounting clips, which must be selected in accordance with the diameter of the tubes.

Option No. 2 – made of aluminum profiles

In another option, the design uses standard aluminum profiles, the same as those used when installing plasterboard structures. In this case, the assembly order is as follows:

- First, you need to make several small holes at the top and bottom of the workpiece through which the profile will be attached to the wall.

- After this, place copper tubes inside it and secure them with aluminum wire.

- Then the profile along with the tubes must be secured to the wall so that one of the tubes is higher than the other.

- To collect all the fragments into unified system, the easiest way is to use standard connectors, for example, fittings. The front panels in such boxes can be the same profiles, which simply need to be painted in a color that harmonizes with the color of the walls of the room.

Would you like to install a warm baseboard system in your home or apartment? Or do you already heat your house this way? Tell us about your plans or accomplishments in the comments.

Inconspicuous, effective, comfortable heating. A very attractive combination of characteristics. For many people, warm floors immediately come to mind. And rightly so. But this is not the only heating method that meets these characteristics. There is also a warm baseboard. The system is easier to install, and most of it is available for maintenance at any time. So a heating baseboard should also be considered as an option for invisible heating.

Warm baseboard system: what is it?

Heating baseboards or baseboard heating is not new in the heating field. The idea was proposed at the beginning of the last century, but due to the complexity of implementation and high price, it was almost forgotten. With the development of technology, the complexity has become lower, but the price remains high. This is what mainly holds back potential users.

The main difference of this system is the non-standard shape of the heating devices and their unusual location. The heaters are long and low, located around the perimeter of the room at floor level. Heating appliances are covered with a long decorative strip that looks very similar to a plinth. When installed, they replace a regular baseboard. That is why such a system is often called “warm baseboard”. This system is very good at panoramic glazing- it may not be higher than the frames, so it is completely invisible. She is no worse in ordinary rooms- she’s not visible at all.

Types of warm baseboards

There are two types of warm baseboards: electric and water. Electric warm baseboards are distinguished by the fact that each heating device is independent and can work separately. They can be installed in case of insufficient power of the main heating - as an additional one in case of cold weather. Installation is simple, and it works effectively, is invisible, and does not dry out the air too much.

There is a water-heated baseboard. This is one of the subtypes of water heating, that is, all heating devices are connected into one system. It can be either the main type (only baseboard heaters) or an additional type of heating (together with or radiators).

Heating baseboard device

In any case, a warm baseboard looks like this: these are two copper tubes, which are located at a distance of 7-15 cm from one another. To increase heat transfer, the tubes are vertical plates made of aluminum, brass (they cost a little less, but the heat transfer is a little lower) or copper (more expensive and “warmer” option). The finned pipes are covered on top with decorative covers made of extruded aluminum. Aluminum was not chosen by chance - it transfers heat well. So the heated lid itself radiates heat.

There are holes at the top and bottom of the lid for air movement. The cold is sucked in through the lower ones, and the heated one comes out through the upper ones. So it turns out that heating comes from three sources:

This triple heat source ensures that the room heats up quickly, and the placement of heating elements around the perimeter contributes to uniform heating of the air throughout the entire volume.

Advantages and disadvantages of baseboard heating

What is the difference between heating using warm baseboards? Warm air flows from the heating element upward along the wall, heating the wall. As it moves upward, the air gradually cools down, then falls down, but not along the wall, but in the center of the room.

As a result, it turns out that the most warm air located downstairs along the perimeter of the room. The warmest object - besides heaters - is the walls. Also, warmer air is located near the floor. As it rises, it cools down and at head level it is a little colder. The difference is small, 1-2 degrees, but this temperature distribution is better for human well-being.

Uniform distribution of heat over the entire area and volume is one of the most important advantages

Heating using a warm baseboard is inertial. It is impossible to unequivocally classify this property as an advantage or disadvantage. There are both positive and negative aspects. Minus: until the walls warm up, the room is cool. Because this system is only good for houses permanent residence and is completely unsuitable for a summer cottage. Positive point The fact is that when they heat up, the walls work as a large stabilizer - they maintain the temperature at the same level, releasing the accumulated heat if necessary. Such a large heat accumulator will help to last for some time even if the heating is turned off.

The advantages of heating systems with heating baseboards include their efficiency. After the walls heat up, the boiler consumes a minimum of fuel - only to maintain the temperature. And such modes are usually more economical. But this applies to any inertial heating system, so this cannot be considered a special advantage of a warm baseboard.

The warm baseboard assembly is a little closer

Baseboard heating has and undeniable advantages. First, this is one of the few systems that provides uniform heating. Even the corners are always warm. Secondly, this is the most inconspicuous system that easily fits into any interior. With all this, heating devices are easily accessible, the system can be repaired at any time.

It has a warm baseboard and an obvious drawback - high price. This is due to the fact that copper and aluminum are used to increase heat transfer, and they cost a lot.

Types of heating baseboards

The baseboard heating system can be of two types: with electric and water heaters. At the installation stage more complex system with warm water baseboards (requires a collector or radial connection), but during operation it is more economical. An electric warm baseboard can be installed quickly - you just need to fasten the heaters to the wall, and immediately after installation it is ready for use. But heating costs, like any electric heating, are high.

One of the most inconspicuous heating systems is a warm (heating) baseboard

Heating device with warm water baseboard

The water baseboard heating system differs only non-standard form heating devices. The key components do not differ from the standard ones: you need a hot water boiler, a collector unit and a pipe system with which the warm baseboard is connected.

There is also a combined warm baseboard - with an electric heating element and pipes for coolant

Note: optimal mode system operation - low temperature. On the supply side it is 40-50°C, on the return side it is about 5°C lower. Therefore, you need to select a boiler or build a system based on this. If the boiler is gas, optimal choice- condensation. When installing any other, the system requires a heat accumulator and/or a mixing unit to reduce and stabilize the temperature.

Connection method

There are also features in choosing the connection method. Serial connection All baseboard heaters in the room are ineffective: by the time the coolant reaches the last ones in the heater branch, it will cool down greatly and they will remain cold almost all the time.

For water heating baseboard it is used beam system: devices are connected one by one or in pairs. To do this, a collector unit is built into the system, to which the pipes that go to the heating devices are connected. The disadvantage of such a system is high consumption pipes After all, each device (or small group) has two pipes - supply and return. The pipe flow rate is much higher, but the heat distribution is more uniform and the system itself is more reliable. Why is it more reliable? If pipes or radiators in one group are damaged, all others work normally.

Installation features

When installing water baseboard heating, the pipes are usually hidden in the floor. It will not be possible to lay them along the walls, since the space is occupied by heating devices. That is, installation of warm water baseboards is possible only at the renovation stage - the floors will have to be raised.

It is recommended to lay special polymer pipes in the screed - they are not subject to corrosion and have low heat transfer, that is, heat loss during transportation of the coolant will be small. But since these systems have limited availability for repairs, you need to buy a quality product famous manufacturers, and this is not cheap.

Electric warm baseboard

An electric heated baseboard differs in appearance from a water baseboard only in the presence of terminals for connecting power. Otherwise the view is the same. These are two tubes with perpendicularly fixed aluminum/brass/copper plates. In the lower tube there is a heating element - heating element, in the upper tube there are wires for connection.

Installing and connecting an electric heated baseboard is much easier. You just need to secure it, stretch the wires and connect them to the terminals. To maintain the set temperature, a thermostat is built into the system, which turns the heaters on and off. The use of thermostats is desirable, as it optimizes operation and saves electricity.

Installation is really simple, but you need to connect the electric warm baseboard to a dedicated line with a correctly selected circuit breaker rating and copper single-core wires the corresponding section. So in this case, repairs are required - it is customary to lay the wiring in the wall, and for this you need to do it, that is, break the walls.

Installation of a warm water baseboard system

Installation of an electric warm baseboard is very simple: we fix it on the wall. That's it, the system is ready for operation. All that remains is to plug it into the sockets. The main thing is that it is calculated correctly and stands. This is the main problem when using an electric warm baseboard. The water one is much more difficult to install. Everything must be collected into a single system, and this is not easy.

Calculation of baseboard heating

A complete thermotechnical calculation of heating is a long and complex matter. The size and geometry of the room, the material of the walls, floor, and ceiling are taken into account, and the degree of insulation of all structural elements, including windows and doors, is taken into account. In general, the calculation is not at all easy. Therefore, most often they take the average figure, which is derived as a result of the analysis of many calculations.

It is believed that to heat one square meter of room area with average insulation, 100 W of thermal energy is needed. That is, to calculate the power of a warm baseboard, you need to multiply the area of the room by 100. Get the required figure. This is exactly how much (or better, about 20-25% more) should be given in total by all the elements of the warm baseboard.

For example, the area of the room is 18 square meters. To heat it you will need 1800 W. Next, we look at how much heat is generated by one meter of heating. A water heating baseboard can work in different modes, depending on the mode, releases different amounts of heat. The table above shows data for one of the systems. For example, let's take the heat transfer of one meter of warm baseboard from this table (other manufacturers may have significant differences).

For example, the system will operate with a supply temperature of 50°C. Then one linear meter produces 132 W of heat. To heat this room you will need 1800/132 = 13.6 m of warm baseboard. When ordering, it is better to add a margin of 20-25%. This reserve is necessary so that the system does not work at the limit all the time. This time. And also in case of abnormal cold weather. That's two. So, we take 17 meters with a reserve.

Once again, please note: these are average data for some average house. Moreover, even the height of the ceilings is not taken into account here. Again, it is taken as average - 2.5 meters. If your insulation is better, you will need less heat; if it is worse than “average”, you will need more. In general, this method provides only approximate calculations.

How to act

The first thing to do is to draw a plan on which to indicate the length of each heating device, length connecting tubes. After all, the length of a warm baseboard is not always equal to the perimeter of the room. In this case, the sections of heating devices are connected to each other by copper or polymer pipes. It is undesirable to use steel ones, since they chemically interact with copper (it gradually collapses).

Preparation for installation occurs long before its actual start. At the very beginning of the repair, even before leveling the floor, pipes are stretched from the boiler or collector unit to the connection point for the warm baseboard. The pipes are laid, tested for integrity, and filled with screed under pressure ( operating pressure in a private house 2-3 atm, in a multi-story house you need to find out at the housing office). Then everything is carried out renovation work and only after finishing walls and floors, the installation of warm baseboards begins. Here's the order:

Actually, installing warm baseboards is not too complicated. But the tightness of the connections is important and special attention must be paid to this.

Everyone knows the common heating methods: underfloor heating and installing radiators. However, there is another unusual option- warm water baseboard. This option cannot yet be called very widespread, but nevertheless it is worth taking into account, because it combines the advantages of two types of heating at once: both and underfloor heating. Warm baseboards are now used to heat both administrative and office buildings, and residential buildings and apartments.

- Plintusnoe

- In general, a water baseboard consists of the following elements:

- Advantages of baseboard heating

- Manufacturers of water skirting boards

- Water or electric baseboard?

- Installing a water baseboard

Baseboard heating

Despite the fact that in our country what a warm baseboard is became known not so long ago, in Europe premises have been heated using this method for several decades. This technology is very simple, but at the same time quite convenient. The basis is metal (most often copper) pipes, which are also the heating element. The pipes are installed in the same place where the baseboard usually runs, that is, along the perimeter of the room. Then they are closed metal box from plates with a corrugated surface. Due to this design, the box acts as a heat exchanger, thereby increasing the efficiency of the structure.

In general, a water baseboard consists of the following elements:

- front panel with holes, due to which it is ensured air flow (standard size: width - 3-4 cm, height - 15-20 cm);

- rear panel - facilitates installation of the structure and protects the wall from constant impact high temperature;

- , performing the heating function ( standard dimensions- 1 m x 0.4 m x 1.6 m);

- rotating side plugs;

- a heat exchange module consisting of two tubes through which water circulates.

Currently, there is a variety of warm baseboards (electric.) They differ from warm water baseboards only in the type of heating element.

Due to the fact that the baseboard is installed around the perimeter of the entire room, the heat gradually rises, and then the entire room is evenly heated. As a result, this technology does not cause temperature changes.

Since the heating element is hidden under the front panel, it is not noticeable, which distinguishes it from massive ones. As you can see in the photo, the warm plinth looks very neat; it can be additionally designed so that it better matches general style rooms.

The system is effective, but at the same time quite simple to install. Having minimal skills, you can carry out installation without involving professionals.

Advantages of baseboard heating

It is not difficult to explain the popularity of water baseboards in the USA and Europe if you familiarize yourself with all the advantages of such a heating system. The advantages of the system are:

- Saving usable area in the apartment. The plinth does not take up much space, which can be invaluable for the inhabitants of small rooms.

- Install a water-heated baseboard doing it yourself is not particularly difficult - it allows you to save money, since there is no need to pay for the work of the craftsmen.

- Good room heating.

- High efficiency rate.

- Efficiency.

- If there is a need for repairs, access to the internal components is extremely simple: you need to remove the front panel.

- The appearance of the skirting board can be easily changed according to style requirements.

- Skirting boards are available in different color options.

- Pairs well with a variety of floor coverings.

- The plinth consists of separate modules, each of which can be easily replaced or upgraded if necessary.

- If you install a thermostat, then the heating will be maintained at the same level.

- Aesthetic appearance, you won’t have to look for ways to hide batteries.

- Heating takes place from different sides, and not from one.

- Compactness.

Heating using a water baseboard - best option, if you need quality heating system, compact and efficient, but at the same time easy to install.

Of no small importance is the fact that a warm baseboard is one of the few heating methods that is ideal for “non-standard” rooms (with high ceiling, arched entrance, big amount window openings). Even in such rooms, the air warms up quickly and evenly.

Water warm baseboard can be used as independent system heating, or can be combined with a more traditional one. For example, radiators or heated floors are often installed in residential premises, and water skirting boards are installed on loggias, closed verandas, in closets, utility rooms and other rooms that are not used so often. A warm baseboard prevents the appearance of fungi and mold, as not only the air in the room heats up, but also the walls. At the same time, the air does not become excessively “dry”, the temperature is maintained at the optimal level.

This allows you to avoid possible restrictions when planning heating in apartment buildings.

Manufacturers of water skirting boards

There are now a lot of manufacturers of warm baseboards, but when purchasing you should always choose only products from the most famous and reputable companies. Since water-based warm baseboards are not yet a common heating method, manufacturers’ brands may not be well-known. However, you need to know the most famous ones so as not to make a mistake in your choice:

- Mr. Tektrum (Russia);

- Thermia (Ukraine);

- Best Board (Austria).

The Best Board company produces lines of electric and water-heated skirting boards, and the latter received greatest distribution. The company's products are distinguished by their quality and practicality. Such skirting boards are very quickly assembled and disassembled, take up minimal space, and are very convenient to use. Front panels are available in different styles and colors. The cost of the structures is considerable - one section (usually 1 m long) costs at least $100.

Slightly inferior to Best Board in popularity domestic manufacturer Mr. Tektrum. This manufacturer focuses on budget buyers, so the prices for warm water skirting boards from Mr. Tektrum is significantly lower than its European counterparts. The cost of the design was reduced through the use of cheaper materials and components. What is especially pleasing is that if this has an effect on the quality of the structure, it is insignificant.

Tektrum water skirting boards are produced in Vinnitsa and in the same way as Mr. Tektrum are aimed at average buyers. Skirting boards are of good quality and work well both in houses and apartments, but one section costs 5 times less than from an Austrian manufacturer.

Water or electric baseboard?

Currently, skirting boards are only available with water or electric, which makes choosing a design easier. The main criterion can only be the characteristics and conditions of the room.

So, it is not always possible to install a warm water baseboard. The design of such heating requires a heating boiler, which will “bring” the water to the desired temperature and send it into the pipes. In this case, the temperature of the heating circuit should always be approximately the same level.

For this reason, electricity may seem more profitable option. It is already in the house and does not require the installation of additional structural components. Skirting boards with an electric heating element raise the temperature in the room faster than water ones. Electric skirting boards easier to install - just swipe heating cable from the mains (voltage - 220 W), secure and cover with the front panel. All that remains is to connect it to the distribution unit, and the warm baseboard will start working. But in any case, installation requires skills in working with electricity.

But at the same time, electricity tariffs are rising almost every year, and in the end heating will cost much more. Moreover, in use water heating safer than electricity and easier to regulate temperature regime premises.

Installing a water baseboard

In order to install a warm baseboard with your own hands, you need to prepare the following tools:

- adjustable wrenches;

- plastic scissors;

- pliers;

- hammer;

- hammer drill or drill;

- wire cutters

Before installing a warm baseboard, you need to measure the distance from the section to the collector connection. Use scissors to cut the plastic pipe the right size with a small margin. Place it so that the pipe outlet is 6 cm above the floor level, there should be at least 15 cm left to the corner. The pipe should be laid in the floor or in the wall, whichever is more convenient.

Glue the baseboard installations around the perimeter of the room using glue or self-adhesive tape. Installation of profiles must be started from the corner. Cut the profile and install it in any way in a convenient way: on silicone, double-sided tape or screw to the wall (floor).

Then you need to install the holders. To do this, you need to drill a hole 15 cm from the edge of the profile, and for the remaining clips - every 40 cm.

Then convectors are installed. Cut the plastic pipe to the required length, trying to ensure that it fits well with the section and that no kinks appear. On copper pipes put on the bushing, nuts and rubber gasket. Install the support sleeve into the plastic pipe, twist and tighten wrench the right size.

Place the radiator against the wall. If brass fins remain, remove them with wire cutters. Using an adapter, connect to the next section. Fit the skirting board bodies so that there are no gaps, but you need to deviate 1 mm from the corners so that you can then install decorative elements. Place the radiator against the wall again and remove excess elements.

The structure is installed and assembled in exactly the same way on other sections. You need to collect, moving from one corner to another. For a section located in the corner of the room, you need to use special corner plastic pipes. Last section needs to be looped. This can be done using a special corrugated stainless steel sleeve.

On final stage decorative elements are installed - plugs, corner connections. The system must be connected to the collector and the water supply must be turned on. Next, you need to observe whether water is leaking somewhere. This usually happens at junctions. If this does not solve the problem, you need to turn off the water for a while and disassemble the structure. Possibly damaged sealing rubber, it needs to be replaced.

2018-03-03Everyone knows the common heating methods: underfloor heating and installing radiators. However, there is another unusual option - a warm water baseboard. This option cannot yet be called very widespread, but nevertheless it is worth taking into account, because it combines the advantages of two types of heating at once: radiators and heated floors. Warm baseboards are now used to heat administrative and office buildings, residential buildings and apartments.

Despite the fact that in our country what a warm baseboard is became known not so long ago, in Europe premises have been heated using this method for several decades. This technology is very simple, but at the same time quite convenient. The basis is metal (most often copper) pipes, which are also the heating element. The pipes are installed in the same place where the baseboard usually runs, that is, along the perimeter of the room. Then they are covered with a metal box made of plates with a corrugated surface. Due to this design, the box acts as a heat exchanger, thereby increasing the efficiency of the structure.

In general, a water baseboard consists of the following elements:

- front panel with holes that ensure air flow (standard size: width - 3-4 cm, height - 15-20 cm);

- rear panel - facilitates installation of the structure and protects the wall from constant exposure to high temperatures;

- heating radiator that performs the heating function (standard dimensions - 1 m x 0.4 m x 1.6 m);

- rotating side plugs;

- a heat exchange module consisting of two tubes through which water circulates.

Currently, there is a variety of warm baseboards (electric.) They differ from warm water baseboards only in the type of heating element.

Due to the fact that the baseboard is installed around the perimeter of the entire room, the heat gradually rises, and then the entire room is evenly heated. As a result, this technology does not cause temperature changes.

Since the heating element is hidden under the front panel, it is not noticeable, which distinguishes it from massive radiators. As you can see in the photo, the warm baseboard looks very neat; it can be additionally decorated so that it better matches the overall style of the room.

The system is effective, but at the same time quite simple to install. Having minimal skills, you can carry out installation without involving professionals.

Advantages of baseboard heating

It is not difficult to explain the popularity of water baseboards in the USA and Europe if you familiarize yourself with all the advantages of such a heating system. The advantages of the system are:

- Saving usable space in the apartment. The plinth does not take up much space, which can be invaluable for the inhabitants of small rooms.

- Install a water-heated baseboard doing it yourself is not particularly difficult - it allows you to save money, since there is no need to pay for the work of the craftsmen.

- Good room heating.

- High efficiency rate.

- Efficiency.

- If there is a need for repairs, access to the internal components is extremely simple: you need to remove the front panel.

- The appearance of the skirting board can be easily changed according to style requirements.

- Skirting boards are available in different colors.

- Pairs well with a variety of floor coverings.

- The plinth consists of separate modules, each of which can be easily replaced or upgraded if necessary.

- If you install a thermostat, then the heating will be maintained at the same level.

- Aesthetic appearance, no need to look for ways to hide batteries.

- Heating occurs from different sides, and not from one.

- Compactness.

Heating using a water baseboard is the best option if you need a high-quality heating system that is compact and efficient, but at the same time easy to install.

Of no small importance is the fact that a warm baseboard is one of the few heating methods that is ideal for “non-standard” rooms (with a high ceiling, an arched entrance, a large number of window openings). Even in such rooms, the air warms up quickly and evenly.

A warm water baseboard can be used as an independent heating system, or can be combined with a more traditional one. For example, radiators or heated floors are often installed in residential premises, and water skirting boards are installed in loggias, closed verandas, storage rooms, utility rooms and other rooms that are not used so often. A warm baseboard prevents the appearance of fungi and mold, as not only the air in the room heats up, but also the walls. At the same time, the air does not become excessively “dry”, the temperature is maintained at the optimal level.

This allows you to avoid possible restrictions when planning heating in apartment buildings.

The water baseboard is a low-temperature heat source, and therefore can be used in the same system with a heated floor, without separating the circuits

Manufacturers of water skirting boards

There are now a lot of manufacturers of warm baseboards, but when purchasing you should always choose only products from the most famous and reputable companies. Since water-based warm baseboards are not yet a common heating method, manufacturers’ brands may not be well-known. However, you need to know the most famous ones so as not to make a mistake in your choice:

- Mr. Tektrum (Russia);

- Thermia (Ukraine);

- Best Board (Austria).

The Best Board company produces lines of electric and water-heated baseboards, with the latter being the most widespread. The company's products are distinguished by their quality and practicality. Such skirting boards are very quickly assembled and disassembled, take up minimal space, and are very convenient to use. Front panels are available in different styles and colors. The cost of the structures is considerable - one section (usually 1 m long) costs at least $100.

The domestic manufacturer Mr. is slightly inferior to Best Board in popularity. Tektrum. This manufacturer focuses on budget buyers, so the prices for warm water skirting boards from Mr. Tektrum is significantly lower than its European counterparts. The cost of the design was reduced through the use of cheaper materials and components. What is especially pleasing is that if this has an effect on the quality of the structure, it is insignificant.

Tektrum water skirting boards are produced in Vinnitsa and in the same way as Mr. Tektrum are aimed at average buyers. Skirting boards are of good quality and work well both in houses and apartments, but one section costs 5 times less than from an Austrian manufacturer.

Water or electric baseboard?

Currently, skirting boards are only available with water or electric, which makes choosing a design easier. The main criterion can only be the characteristics and conditions of the room.

So, it is not always possible to install a warm water baseboard. The design of such heating requires a heating boiler, which will “bring” the water to the desired temperature and send it into the pipes. In this case, the temperature of the heating circuit should always be approximately the same level.

For this reason, electricity may seem like a better option. It is already in the house and does not require the installation of additional structural components. Skirting boards with an electric heating element raise the temperature in the room faster than water ones. Electric baseboards are easier to install - just run the heating cable from the mains (voltage - 220 W), secure it and cover it with the front panel. All that remains is to connect it to the distribution unit, and the warm baseboard will start working. But in any case, installation requires skills in working with electricity.

To ensure sufficient convection between the floor and the baseboard radiator, a wide gap is usually left

But at the same time, electricity tariffs are rising almost every year, and in the end heating will cost much more. In addition, water heating is safer to use than electricity and more convenient in terms of regulating the temperature of the room.

Installing a water baseboard

In order to install a warm baseboard with your own hands, you need to prepare the following tools:

- adjustable wrenches;

- plastic scissors;

- pliers;

- hammer;

- hammer drill or drill;

- wire cutters

Before installing a warm baseboard, you need to measure the distance from the section to the collector connection. Using scissors, cut the plastic pipe to the desired size with a small margin. Place it so that the pipe outlet is 6 cm above the floor level, there should be at least 15 cm left to the corner. The pipe should be laid in the floor or in the wall, whichever is more convenient.

Glue the baseboard installations around the perimeter of the room using glue or self-adhesive tape. Installation of profiles must be started from the corner. Cut the profile and install it in any convenient way: with silicone, double-sided tape or screw it to the wall (floor).

Then you need to install the holders. To do this, you need to drill a hole 15 cm from the edge of the profile, and for the remaining clips - every 40 cm.

Then convectors are installed. Cut the plastic pipe to the required length, trying to ensure that it fits well with the section and that no kinks appear. Place a sleeve, nuts and a rubber gasket on the copper pipes. Install the support sleeve into the plastic pipe, twist it and tighten it with an adjustable wrench of the required size.

Place the radiator against the wall. If brass fins remain, remove them with wire cutters. Using an adapter, connect to the next section. Adjust the baseboard bodies so that there are no gaps, but you need to deviate 1 mm from the corners so that you can then install decorative elements. Place the radiator against the wall again and remove excess elements.

The structure is installed and assembled in exactly the same way on other sections. You need to collect, moving from one corner to another. For the section located in the corner of the room, you need to use special corner plastic pipes. The last section needs to be looped. This can be done using a special corrugated stainless steel sleeve.

At the final stage, decorative elements are installed - plugs, corner joints. The system must be connected to the collector and the water supply must be turned on. Next, you need to observe whether water is leaking somewhere. This usually happens at junctions. If this does not solve the problem, you need to turn off the water for a while and disassemble the structure. The sealing rubber may be damaged and needs to be replaced.

I like