Calculation of nichrome wire for the heater. Application and calculation of an electric nichrome spiral How to calculate a nichrome spiral for a 220 volt heater

Read also

Some household heating appliances still use nichrome wire. It has high heat resistance characteristic of an alloy of nickel and chromium. This material has good ductility, high electrical resistivity and low temperature coefficient of resistance. Therefore, when calculating a nichrome wire for a heater, these parameters must be taken into account. Otherwise, the calculation results will be inaccurate and will not give the desired result.

Using an online calculator in calculations

Quick calculations can be done with an online calculator. With it, you can calculate and approximately set the desired length of the nichrome wire. As a rule, the brands that are most widely used in heating devices are considered - Kh20N80, Kh20N80-N, Kh15N60.

Mandatory initial data are required to perform calculations. First of all, this is the value of the heater power that is planned to be obtained, the diameter of the nichrome wire and the value of the mains supply voltage.

The calculations are carried out as follows. First of all, you need to install in accordance with the specified parameters, according to the formula: I = P / U. After that, the resistance for the entire heating element is calculated. Next, you need electrical resistivity for a specific brand of nichrome wire. This value will be needed in order to set the most optimal length of the heating element using another formula: l = SR/ρ. The correct choice of length will bring the resistance of the heater R to the desired value.

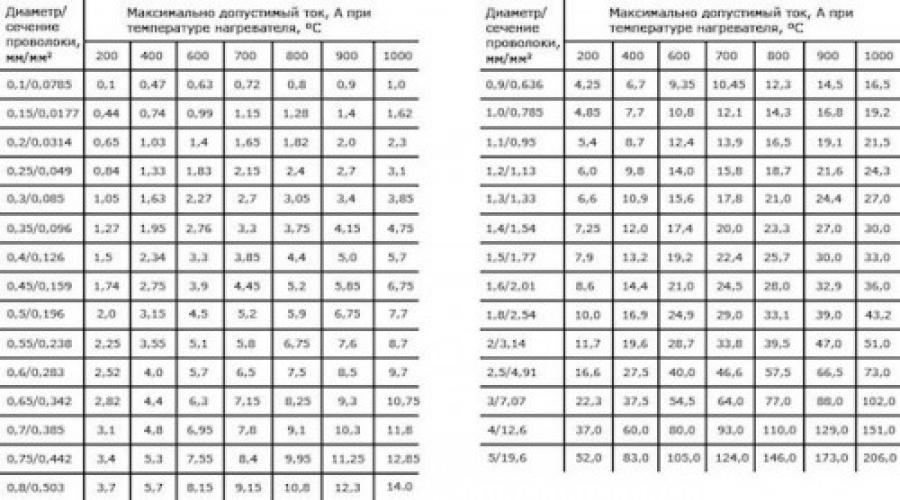

After performing the calculations, it is recommended to check the obtained data using the table and make sure that the calculated current corresponds to the permissible value. If the rated current exceeds the allowable limits, re-calculations should be performed by increasing the diameter of the nichrome wire or reducing the power of the heating element itself. It is necessary to take into account the factor that all the parameters given in the tables are calculated for heaters in a horizontal position and operating in an air environment.

If the nichrome spiral is planned to be used placed in a liquid, the value of the allowable current should be multiplied by a factor of 1.1-1.5. When the spiral is closed, on the contrary, it must be reduced by 1.2-1.5 times.

The winding of a nichrome spiral for further heating is carried out mainly by trial and error. After winding, voltage is applied to the heating element and the required number of turns is determined by how the wire heats up.

This process can take a long time. It is worth remembering that nichrome is able to lose its characteristics with a large number of kinks. The wire will quickly burn through in the deformation areas. Ultimately, it may turn out that good material turns into scrap.

For the correct calculation of the nichrome spiral, special tables are usually used, where the specific resistance of the nichrome wire \u003d (Ohm mm2 / m). But, these tables display data for a voltage of 220V. For the operation of the heating element in an industrial environment, you will have to carry out the calculation yourself, substituting the available data.

According to the tabular data, it is possible to accurately determine the length of the winding and the distance between the turns. Depending on the diameter of the wire and the diameter of the nichrome winding rod, it will not be difficult to recalculate the length of the spiral for operation at a different voltage. Here you need to use a simple mathematical proportion.

For example, if you need to calculate the length of the spiral for a voltage of 380 V using a wire with a diameter of Ø 0.6 mm, and a winding rod Ø 6 mm. In the table you can see that the length of the spiral at a voltage of 220 V should be 30 cm. Next, we calculate according to the following ratio:

220 V - 30 cm

380 V - X cm

Based on these data:

X= 380 30/220=52 cm

After the spiral is already wound, it should be connected to the energy carrier and make sure that the winding is correct. In this case, the wound wire is not cut off. For a spiral in a closed heater, the winding length should be 1/3 greater than the values \u200b\u200bgiven in the table.

Calculation of a heating element made of nichrome wire

The length of the wire is determined based on the indicators of the required power.As an example, we will carry out the following calculations based on the available indicators.

Very often, if you want to make or repair heater do-it-yourself electric furnaces, a person has many questions. For example, what diameter to take the wire, what should be its length, or what power can be obtained using a wire or tape with given parameters, etc. With the right approach to solving this issue, it is necessary to take into account quite a lot of parameters, for example, the strength of the current passing through heater, operating temperature, type of electrical network and others.This article provides reference data on the materials most common in the manufacture of heaters. electric ovens, as well as the methodology and examples of their calculation (calculation of heaters for electric furnaces).

Heaters. Materials for the manufacture of heaters

Directly heater- one of the most important elements of the furnace, it is he who performs heating, has the highest temperature and determines the performance of the heating installation as a whole. Therefore, heaters must meet a number of requirements, which are listed below.Requirements for heaters

Basic requirements for heaters (heater materials):- Heaters must have sufficient heat resistance (scaling resistance) and heat resistance. Heat resistance - mechanical strength at high temperatures. Heat resistance - resistance of metals and alloys to gas corrosion at high temperatures (the properties of heat resistance and heat resistance are described in more detail on the page).

- Heater in an electric furnace must be made of a material with high electrical resistivity. In simple terms, the higher the electrical resistance of the material, the more it heats up. Therefore, if you take a material with less resistance, then you need a heater of greater length and with a smaller cross-sectional area. Not always a sufficiently long heater can be placed in the furnace. It should also be taken into account that the larger the diameter of the wire from which the heater is made, the longer its service life . Examples of materials with high electrical resistance are chromium-nickel alloy, iron-chromium-aluminum alloy, which are precision alloys with high electrical resistance.

- A low temperature coefficient of resistance is an essential factor when choosing a material for a heater. This means that when the temperature changes, the electrical resistance of the material heater doesn't change much. If the temperature coefficient of electrical resistance is large, to turn on the furnace in a cold state, it is necessary to use transformers that initially give a reduced voltage.

- The physical properties of the heater materials must be constant. Some materials, such as carborundum, which is a non-metallic heater, can change their physical properties over time, in particular electrical resistance, which complicates their operating conditions. To stabilize the electrical resistance, transformers with a large number of steps and a voltage range are used.

- Metallic materials must have good technological properties, namely ductility and weldability, so that they can be made into wire, tape, and from the tape - heating elements of complex configuration. Also heaters can be made from non-metals. Non-metallic heaters are pressed or molded into a finished product.

Materials for the manufacture of heaters

The most suitable and most used in the production of heaters for electric furnaces are precision alloys with high electrical resistance. These include alloys based on chromium and nickel ( chromium-nickel), iron, chromium and aluminum ( iron-chromium-aluminum). The grades and properties of these alloys are discussed in “Precision alloys. Marks». Representatives of chromium-nickel alloys are grades Kh20N80, Kh20N80-N (950-1200 °С), Kh15N60, Kh15N60-N (900-1125 °С), iron-chromoaluminum alloys - grades Kh23Yu5T (950-1400 °С), Kh27Yu5T (950-1350 °С ), X23Yu5 (950-1200 °C), X15Yu5 (750-1000 °C). There are also iron-chromium-nickel alloys - Kh15N60Yu3, Kh27N70YuZ.The alloys listed above have good heat resistance and heat resistance properties, so they can work at high temperatures. good heat resistance provides a protective film of chromium oxide, which forms on the surface of the material. The melting temperature of the film is higher than the melting temperature of the alloy itself; it does not crack when heated and cooled.

Let us give a comparative description of nichrome and fechral.

Advantages of nichrome:

- good mechanical properties at both low and high temperatures;

- the alloy is creep-resistant;

- has good technological properties - ductility and weldability;

- well processed;

- does not age, non-magnetic.

- high cost of nickel - one of the main components of the alloy;

- lower operating temperatures compared to Fechral.

- cheaper alloy compared to nichrome, tk. does not contain ;

- has better heat resistance than nichrome, for example, Fechral X23Yu5T can operate at temperatures up to 1400 ° C (1400 ° C is the maximum operating temperature for a heater made of wire Ø 6.0 mm or more; Ø 3.0 - 1350 ° C; Ø 1.0 - 1225 °С; Ø 0.2 - 950 °С).

- brittle and fragile alloy, these negative properties are especially pronounced after the alloy has been at a temperature of more than 1000 ° C;

- because fechral has iron in its composition, then this alloy is magnetic and can rust in a humid atmosphere at normal temperatures;

- has low creep resistance;

- interacts with fireclay lining and iron oxides;

- Fechral heaters elongate significantly during operation.

Recently, alloys of the Kh15N60Yu3 and Kh27N70YuZ types have been developed; with the addition of 3% aluminum, which significantly improved the heat resistance of alloys, and the presence of nickel virtually eliminated the disadvantages of iron-chromium-aluminum alloys. Alloys Kh15N60YuZ, Kh27N60YUZ do not interact with chamotte and iron oxides, they are quite well processed, mechanically strong, not brittle. The maximum operating temperature of the X15N60YUZ alloy is 1200 °C.

In addition to the alloys listed above based on nickel, chromium, iron, aluminum, other materials are also used for the manufacture of heaters: refractory metals, as well as non-metals.

Among non-metals for the manufacture of heaters, carborundum, molybdenum disilicide, coal, and graphite are used. Carborundum and molybdenum disilicide heaters are used in high-temperature furnaces. In furnaces with a protective atmosphere, carbon and graphite heaters are used.

Among refractory materials, tantalum and niobium can be used as heaters. In high temperature vacuum and protective atmosphere furnaces, molybdenum heaters and tungsten. Molybdenum heaters can operate up to a temperature of 1700 °C in vacuum and up to 2200 °C in a protective atmosphere. This temperature difference is due to the evaporation of molybdenum at temperatures above 1700 °C in vacuum. Tungsten heaters can operate up to 3000 °C. In special cases, tantalum and niobium heaters are used.

Calculation of heaters of electric furnaces

Usually, the initial data for are the power that the heaters must provide, the maximum temperature required for the implementation of the corresponding technological process (tempering, hardening, sintering, etc.) and the size of the working space of the electric furnace. If the furnace power is not set, then it can be determined by the rule of thumb. During the calculation of heaters, it is required to obtain the diameter and length (for wire) or cross-sectional area and length (for tape), which are necessary for manufacture of heaters.It is also necessary to determine the material from which to make heaters(this item is not considered in the article). In this article, chromium-nickel precision alloy with high electrical resistance is considered as a material for heaters, which is one of the most popular in the manufacture of heating elements.

Determining the diameter and length of the heater (nichrome wire) for a given furnace power (simple calculation)

Perhaps the simplest option heater calculation of nichrome is the choice of diameter and length at a given power of the heater, the supply voltage of the network, as well as the temperature that the heater will have. Despite the simplicity of the calculation, it has one feature, which we will pay attention to below.An example of calculating the diameter and length of the heating element

Initial data:

Device power P

= 800 W; mains voltage U

= 220 V; heater temperature 800 °C. Nichrome wire X20H80 is used as a heating element.

1. First you need to determine the current strength that will pass through the heating element:

I=P/U

\u003d 800 / 220 \u003d 3.63 A.

2. Now you need to find the resistance of the heater:

R=U/I

= 220 / 3.63 = 61 ohms;

3. Based on the value obtained in paragraph 1 of the current passing through nichrome heater, you need to select the diameter of the wire. And this moment is important. If, for example, at a current strength of 6 A, a nichrome wire with a diameter of 0.4 mm is used, then it will burn out. Therefore, having calculated the current strength, it is necessary to select the appropriate value of the wire diameter from the table. In our case, for a current strength of 3.63 A and a heater temperature of 800 ° C, we select a nichrome wire with a diameter d = 0.35 mm and cross-sectional area S \u003d 0.096 mm 2.

General rule for choosing wire diameter can be formulated as follows: it is necessary to choose a wire whose permissible current strength is not less than the calculated current strength passing through the heater. In order to save the material of the heater, you should choose a wire with the nearest higher (than the calculated) allowable current.

Table 1

| Diameter, mm | Cross-sectional area of nichrome wire, mm 2 | Heating temperature of nichrome wire, °C | ||||||

|---|---|---|---|---|---|---|---|---|

| 200 | 400 | 600 | 700 | 800 | 900 | 1000 | ||

| Maximum allowable current, A | ||||||||

| 5 | 19,6 | 52 | 83 | 105 | 124 | 146 | 173 | 206 |

| 4 | 12,6 | 37,0 | 60,0 | 80,0 | 93,0 | 110,0 | 129,0 | 151,0 |

| 3 | 7,07 | 22,3 | 37,5 | 54,5 | 64,0 | 77,0 | 88,0 | 102,0 |

| 2,5 | 4,91 | 16,6 | 27,5 | 40,0 | 46,6 | 57,5 | 66,5 | 73,0 |

| 2 | 3,14 | 11,7 | 19,6 | 28,7 | 33,8 | 39,5 | 47,0 | 51,0 |

| 1,8 | 2,54 | 10,0 | 16,9 | 24,9 | 29,0 | 33,1 | 39,0 | 43,2 |

| 1,6 | 2,01 | 8,6 | 14,4 | 21,0 | 24,5 | 28,0 | 32,9 | 36,0 |

| 1,5 | 1,77 | 7,9 | 13,2 | 19,2 | 22,4 | 25,7 | 30,0 | 33,0 |

| 1,4 | 1,54 | 7,25 | 12,0 | 17,4 | 20,0 | 23,3 | 27,0 | 30,0 |

| 1,3 | 1,33 | 6,6 | 10,9 | 15,6 | 17,8 | 21,0 | 24,4 | 27,0 |

| 1,2 | 1,13 | 6,0 | 9,8 | 14,0 | 15,8 | 18,7 | 21,6 | 24,3 |

| 1,1 | 0,95 | 5,4 | 8,7 | 12,4 | 13,9 | 16,5 | 19,1 | 21,5 |

| 1,0 | 0,785 | 4,85 | 7,7 | 10,8 | 12,1 | 14,3 | 16,8 | 19,2 |

| 0,9 | 0,636 | 4,25 | 6,7 | 9,35 | 10,45 | 12,3 | 14,5 | 16,5 |

| 0,8 | 0,503 | 3,7 | 5,7 | 8,15 | 9,15 | 10,8 | 12,3 | 14,0 |

| 0,75 | 0,442 | 3,4 | 5,3 | 7,55 | 8,4 | 9,95 | 11,25 | 12,85 |

| 0,7 | 0,385 | 3,1 | 4,8 | 6,95 | 7,8 | 9,1 | 10,3 | 11,8 |

| 0,65 | 0,342 | 2,82 | 4,4 | 6,3 | 7,15 | 8,25 | 9,3 | 10,75 |

| 0,6 | 0,283 | 2,52 | 4 | 5,7 | 6,5 | 7,5 | 8,5 | 9,7 |

| 0,55 | 0,238 | 2,25 | 3,55 | 5,1 | 5,8 | 6,75 | 7,6 | 8,7 |

| 0,5 | 0,196 | 2 | 3,15 | 4,5 | 5,2 | 5,9 | 6,75 | 7,7 |

| 0,45 | 0,159 | 1,74 | 2,75 | 3,9 | 4,45 | 5,2 | 5,85 | 6,75 |

| 0,4 | 0,126 | 1,5 | 2,34 | 3,3 | 3,85 | 4,4 | 5,0 | 5,7 |

| 0,35 | 0,096 | 1,27 | 1,95 | 2,76 | 3,3 | 3,75 | 4,15 | 4,75 |

| 0,3 | 0,085 | 1,05 | 1,63 | 2,27 | 2,7 | 3,05 | 3,4 | 3,85 |

| 0,25 | 0,049 | 0,84 | 1,33 | 1,83 | 2,15 | 2,4 | 2,7 | 3,1 |

| 0,2 | 0,0314 | 0,65 | 1,03 | 1,4 | 1,65 | 1,82 | 2,0 | 2,3 |

| 0,15 | 0,0177 | 0,46 | 0,74 | 0,99 | 1,15 | 1,28 | 1,4 | 1,62 |

| 0,1 | 0,00785 | 0,1 | 0,47 | 0,63 | 0,72 | 0,8 | 0,9 | 1,0 |

Note :

- if the heaters are inside the heated liquid, then the load (permissible current) can be increased by 1.1 - 1.5 times;

- when the heaters are closed (for example, in chamber electric furnaces), it is necessary to reduce the load by 1.2 - 1.5 times (a smaller coefficient is taken for a thicker wire, a larger one for a thin one).

R = ρ l/S ,

where R - electrical resistance of the conductor (heater) [Ohm], ρ - electrical resistivity of the heater material [Ohm mm 2 / m], l - conductor (heater) length [mm], S - cross-sectional area of the conductor (heater) [mm 2 ].

Thus, we get the length of the heater:

l = R S / ρ

\u003d 61 0.096 / 1.11 \u003d 5.3 m.

In this example, nichrome wire Ø 0.35 mm is used as a heater. In accordance with "Wire from precision alloys with high electrical resistance. Specifications" the nominal value of the electrical resistivity of nichrome wire brand Kh20N80 is 1.1 Ohm mm 2 / m ( ρ \u003d 1.1 Ohm mm 2 / m), see table. 2.

The result of the calculations is the required length of the nichrome wire, which is 5.3 m, diameter - 0.35 mm.

table 2

Determining the diameter and length of the heater (nichrome wire) for a given furnace (detailed calculation)

The calculation presented in this paragraph is more complex than the one above. Here we will take into account the additional parameters of the heaters, we will try to figure out the options for connecting heaters to a three-phase current network. Calculation of the heater will be carried out on the example of an electric furnace. Let the initial data be the internal dimensions of the furnace.1. The first thing to do is to calculate the volume of the chamber inside the oven. In this case, let's take h = 490 mm, d = 350 mm and l = 350 mm (height, width and depth, respectively). Thus, we get the volume V = h d l \u003d 490 350 350 \u003d 60 10 6 mm 3 \u003d 60 l (a measure of volume).

2. Next, you need to determine the power that the furnace should give out. Power is measured in Watts (W) and is determined by rule of thumb: for an electric oven with a volume of 10 - 50 liters, the specific power is 100 W / l (Watts per liter of volume), with a volume of 100 - 500 liters - 50 - 70 W / l. Let us take the specific power of 100 W/l for the furnace under consideration. Thus, the power of the electric furnace heater should be P \u003d 100 60 \u003d 6000 W \u003d 6 kW.

It should be noted that with a power of 5-10 kW heaters are usually made in single phase. At high powers, for uniform loading of the network, the heaters are made three-phase.

3. Then you need to find the strength of the current passing through the heater I=P/U , where P - heater power, U - the voltage on the heater (between its ends), and the resistance of the heater R=U/I .

There may be two options for connecting to the electrical network:

- to a household single-phase current network - then U = 220 V;

- to the industrial network of three-phase current - U = 220 V (between neutral wire and phase) or U = 380 V (between any two phases).

I=P/U

\u003d 6000 / 220 \u003d 27.3 A - the current passing through the heater.

Then it is necessary to determine the resistance of the furnace heater.

R=U/I

\u003d 220 / 27.3 \u003d 8.06 ohms.

Figure 1 Wire heater in a single-phase current network

The desired values of the wire diameter and its length will be determined in paragraph 5 of this paragraph.

With this type of connection, the load is distributed evenly over three phases, i.e. 6 / 3 = 2 kW per phase. So we need 3 heaters. Next, you need to choose the method of connecting the heaters (load) directly. There can be 2 ways: “STAR” or “TRIANGLE”.

It is worth noting that in this article the formulas for calculating the current strength ( I ) and resistance ( R ) for a three-phase network are not written in the classical form. This is done in order not to complicate the presentation of the material on the calculation of heaters with electrical terms and definitions (for example, phase and linear voltages and currents and the relationship between them are not mentioned). The classical approach and formulas for calculating three-phase circuits can be found in the specialized literature. In this article, some mathematical transformations carried out on classical formulas are hidden from the reader, and this does not have any effect on the final result.

When connecting type “STAR” the heater is connected between phase and zero (see Fig. 2). Accordingly, the voltage at the ends of the heater will be U

= 220 V.

I=P/U

\u003d 2000 / 220 \u003d 9.10 A.

R=U/I

= 220 / 9.10 = 24.2 ohms.

Figure 2 Wire heater in a three-phase current network. Connection according to the "STAR" scheme

When connecting type “TRIANGLE” the heater is connected between two phases (see fig. 3). Accordingly, the voltage at the ends of the heater will be U

= 380 V.

The current passing through the heater is

I=P/U

\u003d 2000 / 380 \u003d 5.26 A.

Resistance of one heater -

R=U/I

\u003d 380 / 5.26 \u003d 72.2 ohms.

Figure 3 Wire heater in a three-phase current network. Connection according to the scheme "TRIANGLE"

4. After determining the resistance of the heater with an appropriate connection to the electrical network choose the diameter and length of the wire.

When determining the above parameters, it is necessary to analyze specific surface power of the heater, i.e. power dissipated per unit area. The surface power of the heater depends on the temperature of the heated material and on the design of the heaters.

Example

From the previous calculation points (see paragraph 3 of this paragraph), we know the resistance of the heater. For a 60 liter oven with a single-phase connection, it is R

= 8.06 ohms. As an example, take a diameter of 1 mm. Then, in order to obtain the required resistance, it is necessary l = R / p

\u003d 8.06 / 1.4 \u003d 5.7 m of nichrome wire, where ρ

- the nominal value of the electrical resistance of 1 m of the wire in [Ohm / m]. The mass of this piece of nichrome wire will be m = l μ

\u003d 5.7 0.007 \u003d 0.0399 kg \u003d 40 g, where μ

- weight of 1 m of wire. Now it is necessary to determine the surface area of a piece of wire 5.7 m long. S = l π d

\u003d 570 3.14 0.1 \u003d 179 cm 2, where l

– wire length [cm], d

– wire diameter [cm]. Thus, 6 kW should be allocated from an area of 179 cm 2. Solving a simple proportion, we get that power is released from 1 cm 2 β=P/S

\u003d 6000 / 179 \u003d 33.5 W, where β

- surface power of the heater.

The resulting surface power is too high. Heater will melt if it is heated to a temperature that would provide the obtained value of surface power. This temperature will be higher than the melting point of the heater material.

The example given is a demonstration of the incorrect choice of the wire diameter that will be used to make the heater. In paragraph 5 of this paragraph, an example will be given with the correct selection of the diameter.

For each material, depending on the required heating temperature, the permissible value of the surface power is determined. It can be determined using special tables or graphs. Tables are used in these calculations.

For high temperature furnaces(at a temperature of more than 700 - 800 ° C) the allowable surface power, W / m 2, is equal to β add \u003d β eff α , where β eff - surface power of heaters depending on the temperature of the heat-receiving medium [W / m 2 ], α is the radiation efficiency factor. β eff is selected according to table 3, α - according to table 4.

If a low temperature oven(temperature less than 200 - 300 ° C), then the allowable surface power can be considered equal to (4 - 6) · 10 4 W / m 2.

Table 3

| Heat-receiving surface temperature, °C | β eff, W/cm 2 at heater temperature, °С | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 | 1350 | ||

| 100 | 6,1 | 7,3 | 8,7 | 10,3 | 12,5 | 14,15 | 16,4 | 19,0 | 21,8 | 24,9 | 28,4 | 36,3 | |

| 200 | 5,9 | 7,15 | 8,55 | 10,15 | 12,0 | 14,0 | 16,25 | 18,85 | 21,65 | 24,75 | 28,2 | 36,1 | |

| 300 | 5,65 | 6,85 | 8,3 | 9,9 | 11,7 | 13,75 | 16,0 | 18,6 | 21,35 | 24,5 | 27,9 | 35,8 | |

| 400 | 5,2 | 6,45 | 7,85 | 9,45 | 11,25 | 13,3 | 15,55 | 18,1 | 20,9 | 24,0 | 27,45 | 35,4 | |

| 500 | 4,5 | 5,7 | 7,15 | 8,8 | 10,55 | 12,6 | 14,85 | 17,4 | 20,2 | 23,3 | 26,8 | 34,6 | |

| 600 | 3,5 | 4,7 | 6,1 | 7,7 | 9,5 | 11,5 | 13,8 | 16,4 | 19,3 | 22,3 | 25,7 | 33,7 | |

| 700 | 2 | 3,2 | 4,6 | 6,25 | 8,05 | 10,0 | 12,4 | 14,9 | 17,7 | 20,8 | 24,3 | 32,2 | |

| 800 | - | 1,25 | 2,65 | 4,2 | 6,05 | 8,1 | 10,4 | 12,9 | 15,7 | 18,8 | 22,3 | 30,2 | |

| 850 | - | - | 1,4 | 3,0 | 4,8 | 6,85 | 9,1 | 11,7 | 14,5 | 17,6 | 21,0 | 29,0 | |

| 900 | - | - | - | 1,55 | 3,4 | 5,45 | 7,75 | 10,3 | 13 | 16,2 | 19,6 | 27,6 | |

| 950 | - | - | - | - | 1,8 | 3,85 | 6,15 | 8,65 | 11,5 | 14,5 | 18,1 | 26,0 | |

| 1000 | - | - | - | - | - | 2,05 | 4,3 | 6,85 | 9,7 | 12,75 | 16,25 | 24,2 | |

| 1050 | - | - | - | - | - | - | 2,3 | 4,8 | 7,65 | 10,75 | 14,25 | 22,2 | |

| 1100 | - | - | - | - | - | - | - | 2,55 | 5,35 | 8,5 | 12,0 | 19,8 | |

| 1150 | - | - | - | - | - | - | - | - | 2,85 | 5,95 | 9,4 | 17,55 | |

| 1200 | - | - | - | - | - | - | - | - | - | 3,15 | 6,55 | 14,55 | |

| 1300 | - | - | - | - | - | - | - | - | - | - | - | 7,95 | |

Table 4

Wire spirals, half-closed in the grooves of the lining

Wire spirals on shelves in tubes

Wire zigzag (rod) heaters

Let us assume that the temperature of the heater is 1000 °C, and we want to heat the workpiece to a temperature of 700 °C. Then, according to table 3, we select β eff \u003d 8.05 W / cm 2, α = 0,2, β add \u003d β eff α \u003d 8.05 0.2 \u003d 1.61 W / cm 2 \u003d 1.61 10 4 W / m 2.

5. After determining the permissible surface power of the heater, it is necessary find its diameter(for wire heaters) or width and thickness(for tape heaters), as well as length.

The wire diameter can be determined using the following formula: d

- wire diameter, [m]; P

- heater power, [W]; U

- voltage at the ends of the heater, [V]; β add

- allowable surface power of the heater, [W/m 2 ]; ρt

- resistivity of the heater material at a given temperature, [Ohm m].

ρ t = ρ 20 k

, where ρ 20

- electrical resistivity of the heater material at 20 °C, [Ohm m] k

- correction factor for calculating the change in electrical resistance depending on temperature (by ).

The length of the wire can be determined by the following formula:

l

- wire length, [m].

We select the diameter and length of the wire from nichrome Х20Н80. The specific electrical resistance of the heater material is

ρ t = ρ 20 k

\u003d 1.13 10 -6 1.025 \u003d 1.15 10 -6 Ohm m.

Household single-phase current network

For a 60 liter stove connected to a household single-phase current network, it is known from the previous calculation steps that the power of the stove is P

\u003d 6000 W, voltage at the ends of the heater - U

= 220 V, permissible surface heater power β add

\u003d 1.6 10 4 W / m 2. Then we get

The resulting size must be rounded up to the nearest larger standard. Standard sizes for nichrome and fechral wire can be found in. Appendix 2, Table 8. In this case, the nearest larger standard size is Ø 2.8 mm. Heater diameter d = 2.8 mm.

Heater length l = 43 m.

It is also sometimes required to determine the mass of the required amount of wire.

m = l μ

, where m

- mass of a piece of wire, [kg]; l

- wire length, [m]; μ

- specific gravity (mass of 1 meter of wire), [kg/m].

In our case, the mass of the heater m = l μ \u003d 43 0.052 \u003d 2.3 kg.

This calculation gives the minimum wire diameter at which it can be used as a heater under given conditions.. From the point of view of material savings, such a calculation is optimal. In this case, wire of a larger diameter can also be used, but then its quantity will increase.

Examination

Calculation results can be checked in the following way. A wire diameter of 2.8 mm was obtained. Then the length we need is

l = R / (ρ k)

\u003d 8.06 / (0.179 1.025) \u003d 43 m, where l

- wire length, [m]; R

- heater resistance, [Ohm]; ρ

- nominal value of electrical resistance of 1 m of wire, [Ohm/m]; k

- correction factor for calculating the change in electrical resistance depending on temperature.

This value is the same as the value obtained from another calculation.

Now it is necessary to check whether the surface power of the heater we have chosen will not exceed the allowable surface power, which was found in step 4. β=P/S \u003d 6000 / (3.14 4300 0.28) \u003d 1.59 W / cm 2. Received value β \u003d 1.59 W / cm 2 does not exceed β add \u003d 1.6 W / cm 2.

Results

Thus, the heater will require 43 meters of X20H80 nichrome wire with a diameter of 2.8 mm, which is 2.3 kg.

Industrial three-phase current network

You can also find the diameter and length of the wire required for the manufacture of furnace heaters connected to a three-phase current network.

As described in point 3, each of the three heaters has 2 kW of power. Find the diameter, length and mass of one heater.

STAR connection(see fig. 2)

In this case, the nearest larger standard size is Ø 1.4 mm. Heater diameter d = 1.4 mm.

Length of one heater l

= 30 m.

Weight of one heater m = l μ

\u003d 30 0.013 \u003d 0.39 kg.

Examination

A wire diameter of 1.4 mm was obtained. Then the length we need is

l = R / (ρ k)

\u003d 24.2 / (0.714 1.025) \u003d 33 m.

β=P/S \u003d 2000 / (3.14 3000 0.14) \u003d 1.52 W / cm 2, it does not exceed the permissible.

Results

For three heaters connected according to the “STAR” scheme, you will need

l

\u003d 3 30 \u003d 90 m of wire, which is

m

\u003d 3 0.39 \u003d 1.2 kg.

Connection type “TRIANGLE”(see fig. 3)

In this case, the nearest larger standard size is Ø 0.95 mm. Heater diameter d = 0.95 mm.

Length of one heater l

= 43 m.

Weight of one heater m = l μ

\u003d 43 0.006 \u003d 0.258 kg.

Examination

A wire diameter of 0.95 mm was obtained. Then the length we need is

l = R / (ρ k)

\u003d 72.2 / (1.55 1.025) \u003d 45 m.

This value almost coincides with the value obtained as a result of another calculation.

Surface power will be β=P/S \u003d 2000 / (3.14 4300 0.095) \u003d 1.56 W / cm 2, it does not exceed the permissible.

Results

For three heaters connected according to the “TRIANGLE” scheme, you will need

l

\u003d 3 43 \u003d 129 m of wire, which is

m

\u003d 3 0.258 \u003d 0.8 kg.

If we compare the 2 options discussed above for connecting heaters to a three-phase current network, we can see that “STAR” requires a larger diameter wire than “TRIANGLE” (1.4 mm vs. 0.95 mm) in order to achieve a given furnace power of 6 kW. Wherein the required length of the nichrome wire when connected according to the “STAR” scheme is less than the length of the wire when connecting the “TRIANGLE” type(90 m vs. 129 m), and the required mass, on the contrary, is more (1.2 kg vs. 0.8 kg).

Spiral calculation

During operation, the main task is to place the heater of the estimated length in the limited space of the furnace. Nichrome and fechral wire are wound in the form of spirals or bent in the form of zigzags, the tape is bent in the form of zigzags, which allows you to fit more material (along the length) into the working chamber. The most common option is the spiral.The ratio between the pitch of the spiral and its diameter and the diameter of the wire is chosen in such a way as to facilitate the placement of the heaters in the furnace, ensure their sufficient rigidity, to the maximum extent possible exclude local overheating of the turns of the spiral itself and at the same time not hinder the heat transfer from them to the products.

The larger the diameter of the spiral and the smaller its pitch, the easier it is to place heaters in the furnace, but with an increase in diameter, the strength of the spiral decreases, and the tendency of its turns to lie on top of each other increases. On the other hand, with an increase in the frequency of winding, the shielding effect of the part of its turns facing the products on the rest increases and, consequently, the use of its surface deteriorates, and local overheating may also occur.

Practice has established well-defined, recommended ratios between the wire diameter ( d ), step ( t ) and the diameter of the spiral ( D ) for wire Ø 3 to 7 mm. These ratios are as follows: t ≥ 2d and D = (7÷10) d for nichrome and D = (4÷6) d - for less durable iron-chromium-aluminum alloys, such as fechral, etc. For thinner wires, the ratio D and d , as well as t usually take more.

Conclusion

The article discussed various aspects related to calculation of electric furnace heaters- materials, calculation examples with the necessary reference data, references to standards, illustrations.In the examples, methods for calculating only wire heaters. In addition to wire from precision alloys, tape can also be used for the manufacture of heaters.

The calculation of heaters is not limited to the choice of their sizes. Also it is necessary to determine the material from which the heater should be made, the type of heater (wire or tape), the type of location of the heaters and other features. If the heater is made in the form of a spiral, then it is necessary to determine the number of turns and the pitch between them.

We hope that the article was useful to you. We allow its free distribution provided that the link to our website http://www.site is maintained.

If you find any inaccuracies, please let us know by e-mail [email protected] website or using the Orfus system by selecting the misspelled text and pressing Ctrl+Enter.

Bibliography

- Dyakov V.I. "Typical calculations for electrical equipment".

- Zhukov L.L., Plemyannikova I.M., Mironova M.N., Barkaya D.S., Shumkov Yu.V. "Alloys for heaters".

- Sokunov B.A., Grobova L.S. "Electrothermal installations (electric resistance furnaces)".

- Feldman I.A., Gutman M.B., Rubin G.K., Shadrich N.I. "Calculation and design of heaters for electric resistance furnaces".

- http://www.horss.ru/h6.php?p=45

- http://www.electromonter.info/advice/nichrom.html

There are several types of tandoor heating. Today, the electric method is becoming more widespread, since it does not require the purchase of fuel, does not emit combustion products, and facilitates the use of the stove.

Collapse

The device is heated by heating the spirals and subsequent uniform heat transfer. The article discusses in detail the features of the tandoor spiral. This information will help you choose and install the heating element on the stove correctly.

What is a tandoor spiral?

The spiral is an important element of the tandoor, without it the device will not work. Warms up fairly quickly. Allows you to maintain the required temperature for a long time, which is especially important if you have to cook on the stove all day.

What does a spiral look like?

The heating element is made of wire with high resistivity to electric current. The length of the wire is large enough, therefore, for convenience, it is twisted in turns. Spirals can be in the form of cylinders or flat coils, equipped with contact leads. The heaters are attached to the furnace on ceramic or metal bases with special heat-resistant inserts or insulators.

Appointment of the spiral

The main function of the tandoor coil is to heat up and then evenly distribute the heat. To do this, the element must have the following qualities:

- Heat resistance (do not collapse at high temperatures in tandoors).

- High resistance to current (the heating rate, the resulting temperature, and the service life of the element depend on this).

- Constancy of properties (does not change depending on environmental conditions, duration of operation).

Kinds

The most practical materials for heating parts are nichrome and fechral compounds. Let's briefly consider their features.

Nichrome

Nichrome coils are made from Cr+Ni. This alloy allows you to achieve heating of the device up to 1200 degrees. Differs in kripoustoychivost, resistance to oxidation. Minus - a lower temperature regime in comparison with fechral alloys.

The price of nichrome products is democratic. For example, brand Х20Н80(20% chromium, 80% nickel) suitable for a standard voltage of 220 volts will cost 150-170 rubles. per metre.

Fechral

Fechral is a combination chromium, iron, aluminum and titanium. The material has good resistance to current. It has increased heat resistance: the maximum melting point for spirals made of this material reaches 1500 degrees.

Fechral spiral

Types

When choosing a heating device, it is important to pay attention not only to the material, but also to the type of product: a tandoor coil for 220 or 380 volts has some differences.

220 V is the standard voltage for home electrical networks (that is, for connecting to ordinary sockets in apartments and country cottages). It can also be used in small restaurants with low productivity. According to safety rules, spirals with a power of 3.5-7 kilowatts are connected to 220 volts.

A powerful tandoor is not connected to a standard consumer electrical network. This will cause the heater to burn out and short out. Requires connection to an industrial three-phase 380 volt power supply. The power of each spiral in the tandoor in this case rises to 12 kilowatts. Special requirements for wires used in heating elements: they must have a cross section of at least 4 mm.

How to choose the right spiral?

The dimensions of the wire used to create heaters are determined by the power of the tandoor, the voltage in the mains and the heat that the stove should give out. First, you need to determine the current strength using the formula: I = P:U

- P is the technical power of the furnace.

- U - voltage in the mains.

For example, for a stove of 800 watts and a mains voltage of 220 volts, the magnitude of the electric current will be 3.6 amperes. After that, according to the specified parameters (temperature and electric current strength), suitable wire dimensions are searched in a special table.

The length of the wire for the spiral is calculated by the formula l=RхS:ρ. For example, with a resistance of 61 ohms, a cross section of 0.2 square meters. mm and a resistance of 1.1 requires a spiral made of wire 5.3 meters long.

Installation work

Specialists for the installation of heating elements in the furnace take about 2300-3000 rubles. If you want to save money and install a spiral in the tandoor yourself, then here are some important tips:

- It is not necessary to place the heating element vertically. Hot wire is soft and can bend due to gravity. It is better to lay it horizontally.

- It is not recommended to install the heater close to the heat-insulating brick - the risk of overheating increases. A small “air cushion” is made between the walls of the furnace and the wire

- When installing, it is necessary to stretch the spiral so that all the turns are at a small distance from each other (experts advise the distance between the rings is 1.5-2 times greater than the diameter of the wire).

Alternative option: a heating element (a tubular electric heater with a wire spiral inside) is installed at the bottom of the tandoor. This is a convenient and safe option. But as practice shows, warming up from the heating element will slower than in the case of an open helix.

The photographs below show several types of spiral installation:

Spiral installation example

Another way

TEN instead of a spiral

Conclusion

The correct and safe operation of the tandoor depends on such an important element as the spiral. When buying a finished oven or making a device with your own hands, it is important to choose the right material, type, size of heaters. If there is no confidence in your abilities and knowledge, it is better to entrust the choice and installation of foam spirals to specialists.

←Previous article Next article →On this page, we will consider background information on the materials used for the manufacture of electric heaters, as well as provide examples of the calculation of nichrome heaters for electric furnaces.

Materials for heaters

The heaters are the most important element of the furnace and they must meet many requirements.

- Heat resistance and heat resistance. Wire heaters must have good heat resistance (resistance of a metal or alloy at high temperature to gas corrosion) as well as heat resistance.

- Low temperature coefficient of resistance. This factor is important when choosing a material. A low coefficient says that even when the material is heated, its electrical resistance changes very little. For example, if this temperature coefficient is large, then in order to turn on the furnace in a cold state, it is necessary to use undervoltage transformers at the initial moment.

- High electrical resistivity. This characteristic must have a heater in an electric furnace. The higher the resistance value, the more the material can heat up, and the shorter the length is needed. The larger the diameter of the heating wire, the longer its service life. Materials with very high electrical resistance are nickel-chromium precision alloys and, and.

- Good technological properties. The materials must have good ductility, weldability, as they are used to make: wires, tapes, complex-shaped heating elements.

- permanent physical properties. Neither should change at high temperatures, for long periods of time.

Nichrome and Fechral, which have a high electrical resistance, are best suited for the production of electric heaters for electric furnaces. For more information about grades and their properties, see GOST 10994-74.

Nichrome grades suitable for the manufacture of heaters:

Fechral grades suitable for the manufacture of heaters: .

Also, iron-chromium-nickel alloys: Kh27N70YuZ, Kh15N60Yu3.

All these alloys have the characteristics described above. For example, high heat resistance is ensured by the film formed on the chromium oxide surface.

Compare Nichrome and Fechral

Advantages of nichrome:

- Excellent mechanical properties at all temperatures;

- creep resistance;

- Plastic and well processed;

- Has excellent weldability;

- does not age;

- non-magnetic.

Advantages of fechral:

- has a lower price than nichrome, since it does not contain expensive nickel;

- Fechral Kh23Yu5T has better heat resistance than nichrome. Fechral wire 6 mm thick can operate at 1400 °C.

Disadvantages of nichrome:

- More expensive than Fechral, since the main component of Nickel has a high cost;

- The operating temperature is lower than that of Fechral.

Fechral Disadvantages:

- the alloy is more brittle, especially at temperatures of about 1000 ° C and more;

- Low creep resistance;

- the alloy is magnetic, as it contains iron. Fechral also rusts in a humid environment.

- Interacts with iron oxides and fireclay lining;

- Fechral heaters lengthen during operation.

There are also alloys Kh27N70YUZ and Kh15N60Yu3 which contain 3% aluminum. This element improves the heat resistance of alloys. These alloys do not act with iron oxides, and with fireclay. They are not brittle, durable and well processed. The maximum operating temperature is 1200 °C.

Heaters are also made from refractory metals or non-metals (coal, molybdenum disilicide, graphite, carborundum). Molybdenum disilicide and carborundum are used for heaters in high-temperature furnaces. Graphite and carbon heaters are used in furnaces with a protective atmosphere.

Refractory metals that are often used are tantalum, molybdenum, niobium, tungsten. In furnaces with a protective atmosphere, as well as high-temperature vacuum furnaces, tungsten and molybdenum are used. Molybdenum heaters are used in vacuum up to 1700°C and in a protective atmosphere at temperatures up to 2200°C. This feature is that molybdenum begins to evaporate at a temperature of 1700 ° C (vacuum). Tungsten heaters are able to work at that. up to 3000 °С. Very rarely, niobium and tantalum are used for the production of heaters.

Calculation of heaters for electric furnaces

When calculating heaters for electric furnaces, the following initial data are taken into account:

- the volume of the working space of the furnace;

- heater power;

- maximum temperature (required for the implementation of the technological process: hardening, tempering, sintering).

Important: In the absence of data on the power of the furnace, then it is calculated according to the rule of thumb. You need to know: the length and diameter of the wire, or the length and cross-sectional area of \u200b\u200bthe tape, heater.

We will consider one of the most popular alloys for the production of heaters - nichrome X20H80.

Simple calculation of the length and diameter of the heater wire for a specific furnace power. With one small feature.

Example. Nichrome wire Х20Н80.

Initial data:

- Device power P = 1.5 kW = 1500 W.

- The maximum temperature to which the heater will be heated is 900 °C.

- Voltage U = 220 V.

- The current strength is defined as follows:

- The heater resistance is defined as follows:

- The current strength plays a key moment when choosing the diameter of the wire of a nichrome heater. According to the table below, we select the required diameter. In our example, Current strength = 6.8181 A, and heater temperature = 900 ° C, then the wire diameter will be equal to - d = 0.55 mm, and, accordingly, the cross section - S = 0.238 mm2.

We got such values because the wire is chosen such that it has an allowable current strength. Which in turn is less than the calculated current strength. That is, we choose a nichrome wire with the nearest higher value of the allowable current strength.

Note:

Provided that the nichrome heater is located inside the heating liquid, then the allowable current strength is increased by 10-50%.

If the heater is in a closed position, then the allowable current is reduced by 20% for thick wire, and 50% for thin wire.

- Determination of wire length.

R - electrical resistance, Ohm,

p is the specific electrical resistance of the material, Ohm mm2/m,

l – heater length, m,

S is the cross-sectional area, mm2.

Based on the formula above, we get that the length of the heater is calculated as follows:

In the example, the wire diameter d = 0.55 mm was used.

The nominal value of the electrical resistivity of the X20H80 wire is taken from Table 2, in accordance with GOST 12766.1-90, and has a value of ρ = 1.1 Ohm mm2/m.

The result of the calculations showed that under the conditions:

device power P = 1.5 kW = 1500 W;

heater temperature 900 °C;

nichrome wire is required with a valley: 6.91 m, and a diameter of 0.55 mm.

table 2

Detailed calculation of the length, as well as the diameter of the nichrome wire for the heaters of a particular furnace.

Here is a complex calculation that takes into account: additional parameters of heaters, various options for connecting them to a three-phase network.

The calculation is carried out according to the internal volume of the furnace.

- The volume of the chamber is calculated by the well-known formula:

For example, let's take:

- height h = 490 mm,

- chamber width d = 350 mm,

- chamber depth l = 350 mm.

The volume will be:

- The furnace power is calculated according to the rule of thumb: electric furnaces with a volume of 10 to 50 liters have a specific power of about 100 W / l, furnaces with a volume of 100 - 500 liters - respectively, a power of 50 to 70 W / l ..

In our example, the specific power of the furnace will be - 100 W / l.

Based on this, the power of the nichrome heater should be:

Important!

Heaters with a power of 5-10 kW are made single-phase. With a power above 10 kW, the heaters are made three-phase.

- The strength of the current that passes through the heater is calculated by:

P is the power of the nichrome heater,

U is the voltage.

The resistance of the heater is calculated by the formula:

If the heater is connected to one phase, then U \u003d 220 V, if to three-phase, then U \u003d 220 V will be between zero and any other phase, or U \u003d 380 V will be between two phases.

Single-phase current (domestic network)

is the current on the heater wire.

is the resistance of the furnace heater.

With a three-phase connection, the load goes to three phases evenly, that is, divide 6 by 3 and you get 2 kW for each phase. It follows from this that we need 3 heaters of 2 kW each.

There are two ways to connect three heaters at once. "TRIANGLE" and "STAR".

Connection "STAR" means the connection of each heater between zero and its phase (Fig. 2). In this case, the voltage U = 220 V.

Current strength:

Resistance:

Rice. 1 Connection "STAR" in a three-phase network

The “TRIANGLE” connection implies the location of the heater between two phases (Fig. 3). It follows from this that the voltage U = 380 V.

Current strength:

Resistance:

Rice. 2 Connection "TRIANGLE" in a three-phase network

- Having determined the resistance of the nichrome heater, you need to calculate its diameter and length.

It is also necessary to analyze the specific surface power of the wire (the power that is released from 1 cm2 of surface area). This power depends on the design of the heater itself, and the temperature of the heated material.

With a single-phase connection, for 60 l. furnace resistance: R = 8.06 ohms.

We take the wire X20H80 with a diameter of d \u003d 1 mm.

To get our resistance, we need to calculate the length:

ρ is the nominal value of the electrical resistance of a wire 1 meter long according to GOST 12766.1-90, (Ohm / m).

The desired piece of nichrome wire will have a mass:

μ is the mass of 1 meter of nichrome wire.

The surface area of the wire length l=5.7 meters, is calculated by the formula:

l is the length in centimeters.

d is the diameter in centimeters.

According to the calculations, we obtained that the surface area of the wire - 179 cm2 emits 6 kW. Thus, 1 cm2 of wire area releases power:

β is the surface power of the heating wire.

In this example, we got too much surface power of the wire, because of which the heater will simply melt when it is heated to such a temperature that is needed to obtain surface power. This temperature will definitely be higher than the melting point of nichrome. This calculation example shows the incorrect choice of the diameter of the heating wire for the manufacture of the heater.

Each material has its own permissible value of surface power depending on temperature. The value is taken from the tables.

High-temperature furnaces (700 - 800 °C) have an allowable surface power, (W / m2), which is calculated by the formula:

βeff - surface power depending on the temperature of the heat-receiving medium, (W / m2).

α is the radiation efficiency coefficient.

Tab. 4

Low-temperature furnace (200 - 300 °C), has a permissible surface power (4 - 6) × 104 W / m2.

Let's assume that the temperature of our heater is 1000 °C, and we need to heat the conditional workpiece to 700 °C. Then from Table. 3 is taken

βeff = 8.05 W/cm2,

and calculate:

- Next, you need to calculate the diameter of the wire heater or the thickness and width of the tape heater, and of course the length of the heater.

The diameter is determined by the formula:

d is the diameter, m;

U is the voltage at the ends of the heater, V;

P is power, W;

βad — permissible surface power, W/m2.

ρt is the resistivity of the material at a certain temperature, Ohm m;

ρ20 is the specific electrical resistance of the material at a temperature of 20 °C, Ohm m.

k - Correction factor that is used to calculate the change in electrical resistance as a function of temperature.

The length of the nichrome wire is determined as follows:

l - length, m.

Electrical resistivity Х20Н80 –

Single-phase current (domestic network)

Looking at the previous calculations, it became clear that for a 60 liter oven connected to a single-phase network:

U = 220 V, P = 6000 W, permissible surface power βadd = 1.6 × 104 W/m2. Substituting these numbers into the formula, we get the thickness of the wire.

This thickness is rounded up to the closest standard size, which is in plate 8 according to GOST 12766.1-90.

Appendix 2, Tab. eight.

In our example, the wire diameter from the formula is rounded up to d= 2.8 mm.

The heater will have this length

For our example, a wire with a length of l = 43 m is required.

Sometimes you also need to find out the mass of all the wire you need.

There is a formula for this:

m is the mass of the piece of wire we need, kg;

l - length, m.

μ is the specific gravity (1 m of wire), kg/m;

The calculation showed that our nichrome wire will have a mass m = 43 × 0.052 = 2.3 kg.

Our calculation example allows us to determine the minimum wire diameter required for the heater under certain conditions. This method is the most economical and optimal. Of course, you can use a wire with a large diameter, but its number will certainly increase then.

Examination

The calculation of nichrome wire can be checked.

We got the wire diameter d = 2.8 mm. The length is calculated like this:

l is length, m;

ρ is the nominal value of the electrical resistance of a wire 1 m long, Ohm/m.

R is resistance, Ohm;

k is the correction factor for electrical resistance as a function of temperature;

The calculation showed that the obtained wire length coincides with the length obtained in another calculation.

To check the surface power, and compare with the allowable power. In accordance with paragraph 4.

and does not exceed the allowable βadd= 1.6 W/cm2.

Outcome

In our example, we need 43 meters of X20H80 nichrome wire with a diameter of d = 2.8 mm. Wire weight - 2.3 kg.

Three-phase current (commercial network)

We find the length and diameter of the wire, which is necessary for the production of heaters.

Connection to a three-phase current according to the "STAR" type.

We have 3 heaters, each of which needs a power of 2 kW.

We find the length, diameter and mass of only one heater.

The nearest standard larger size d = 1.4 mm.

Length, l = 30 meters.

Heater weight

Checking

With a diameter of nichrome wire d = 1.4 mm, we calculate the length

The length is almost the same as the calculation above.

The surface power of the wire is

Count total

We have three identical heaters connected according to the “STAR” type, and for them you need:

l \u003d 30 × 3 \u003d 90 meters of wire weighing m \u003d 0.39 × 3 \u003d 1.2 kg.

Connection to a three-phase current according to the "TRIANGLE" type. (Fig. 3)

Comparing our obtained value, the nearest large standard size, d = 0.95 mm.

One heater will have a length, l = 43 meters.

Heater weight

Calculation check

With a wire diameter d = 0.95 mm, we calculate the wire length:

The values along the wire length practically coincide in both calculations.

Surface power will be:

and does not exceed the limit.

Summarize

Connecting three heaters according to the “TRIANGLE” scheme, you need:

l \u003d 43 × 3 \u003d 129 meters of wire, weighing

m \u003d 0.258 × 3 \u003d 0.8 kg.

Summing up for both types of connection "STAR" and "DELTA" to three phases, we get interesting data.

For the "STAR" you need a wire with a diameter of d \u003d 1.4 mm, and for the "TRIANGLE" diameter d \u003d 0.95 mm,

The length of the wire for the "STAR" scheme will be 90 meters with a mass of 1.2 kg, and for the "TRIANGLE" scheme 129 meters with a mass of 0.8 kg, that is, 800 gr.

For the operation of nichrome wire, it is wound into a spiral. The diameter of the spiral is taken equal to:

for nickel-chromium alloys.

- for chrome-aluminum.

D is the diameter of the spiral, mm.

d is the wire diameter, mm.

To eliminate overheating, the spiral is stretched to such an extent that the distance between the turns is 1.5-2 times greater than the diameter of the nichrome wire itself.

We reviewed information about electric heaters, examples of the calculation of wire heaters for electric furnaces.

It is also worth remembering that in addition to wire, tape can also be used as heaters. In addition to choosing the wire size, it is worth considering the heater material, type, location.