Flushing the heating system based on what document. Rules for flushing the heating system of an apartment building. What is flushing and pressure testing of a heating system?

In any home, this is one of the main components of comfortable living in it when cold weather sets in. Even a system installed in compliance with all rules and regulations will not be able to operate effectively without periodic inspection and preventive maintenance. If you do this from time to time once every two or three years, or even less often, then blockages and breakdowns will inevitably occur.

It's no secret that water circulating through pipes and heating radiators good quality is not different. Some impurities in the form of silt, sand, and small particles of rust inevitably settle on the inner surface of heating devices. Flushing the heating system plays perhaps the main role in preventative work.

When to start flushing

To the question of when heating systems in a new house are flushed, the answer will be unequivocal - immediately after installation, first with cold and then with heated water. Cold washing is needed to remove small particles of construction debris, all taps and valves are opened to the maximum, the circuits are washed until the water becomes clear.

This procedure will not take much time - no more than one or two hours.

Hot water removes dirt from oil based and removes some of the rust.

Preventative flushing of the system

After a scheduled heating shutdown, it is not recommended to drain water from the system. Firstly, all deposits on the inner surface of pipes and radiators will dry out and harden; no amount of flushing will help. Secondly, in places installation connections After drying and subsequent filling with water, leaks may occur.

You need to start cleaning the system immediately before its planned launch. Stagnant and rusty water is discharged into the sewer system. If there is more than one floor in the house, then to speed up the draining process you need to open air valves on the top radiators. To create effective pressure, it is necessary to flush all circuits using special equipment, most often compressors are used for this.

There are two ways to prevent the system. The first of them involves flushing only due to high pressure water and is called pneumohydraulic.

But due to the fact that scale and corrosion build-ups form due to poor water quality, when flushing heating systems, the second method is more in demand - chemical,

Typically, bleach or other chemical additives are added to the water.

Each circuit should be flushed separately, and the direction of movement of the flushing liquid must necessarily coincide with the path of water circulation when the heating system is operating. Flushing is also done first with cold and then with heated water until the liquid goes down the drain clean and free of foreign particles.

After the washing is completed, filling the system begins with the boiler; it is advisable to add special chemical compounds (inhibitors) to the liquid composition that slow down the process of metal corrosion. The water level in the filled system should not exceed the control mark in the safety tank.

Flushing heating radiators

In some cases, when heating systems are flushed, one of the stages is pre-cleaning, this is more true for cast iron heating devices or those made of steel without anti-corrosion coating.

To do this, the batteries are disconnected from common system and washed separately.

You can add caustic soda or special chemical additives to the water to remove scale. Through certain time, usually no more than two hours, the radiators are pumped from one end to the other, periodically tapping the sections with a mallet or rubber mallet. There is no need to pour the cleaning solution down the drain; it will be useful for washing other batteries.

Sometimes a special cleaning composition is used for these purposes. car radiators, in this case the liquid is drained after 15–20 minutes.

As a result of flushing the heating system, circulation is significantly facilitated, heat transfer from heating batteries increases, and the pump is subject to less load. All this leads to energy savings and reduces the amount of fuel used for heating.

Therefore, flushing must be carried out annually before the onset of cold weather.

Using water that has been previously purified and filtered from unwanted impurities for the heating system will allow you to resort to this procedure much less frequently.

- Relatively recently, monthly fees for using certain services in Russian Federation was so small that we had to note a very interesting trend - citizens practically did not pay attention...

- Although ordinary people believe that they have no need to know exactly what heating scheme is used apartment building, situations in life can really be different. Eg,...

Flushing the heating system of an apartment building

How often is a procedure such as flushing the heating system of an apartment building performed, and why is there a need for flushing? Let's try to answer these questions in this article.

When does it become necessary to flush the heating system in residential buildings?

The answer to the question of when heating systems are flushed lies on the surface when a significant decrease in the efficiency of its operation is detected. And the latter decreases significantly over time due to the fact that in them (especially when it comes to heating systems apartment buildings) processes such as siltation occur continuously.

First of all, this occurs in areas of heating systems through which the coolant moves at minimal speeds: heating radiators, connections to them and bottling.

It should be remembered that these processes occur most intensively in radiators made of cast iron, since they have large intra-sectional volumes. This is explained elementary physics. With fixed diameters of the connections and risers, the speed of water movement is inversely proportional to the internal volume of the heating device. And the lower the speed, the more deposits.

Basic methods for flushing the heating system of a residential building

The method for flushing the heating system of an apartment building may be different, but, in any case, flushing, confirmed by the relevant Act, is designed to restore the efficiency of your system.

The method for flushing the heating system of an apartment building may be different, but, in any case, flushing, confirmed by the relevant Act, is designed to restore the efficiency of your system.

The rules and procedure for flushing the heating system of an apartment building depend on the time period that has passed since the day overhaul heating systems (HC), materials from which pipelines are made, etc.

The sediment in the CO is formed due to scale formed during the installation of the system during welding work, sand and other solid suspensions entering the main line from the heating main. The fact is that the thermal power plant takes in water around the clock and heats large volumes; it is technically impossible to filter them with proper purity.

If the CO line is made of steel pipes that have not undergone special anti-corrosion treatment, then flushing the heating system of a residential building is required due to another problem - mineral deposits. Mg and Ca salts settle on the inside of the pipes and the internal diameter, due to this, constantly decreases. This problem can be solved simply; instead of pipes made of ordinary steel, galvanized pipes or pipes with internal polymer coating.

The presence of solid suspensions in the coolant becomes the reason leading to complete blocking of movement through the entire radiator. Water moves only through a number of outer sections. Things can get to the point where the circuit completely overlaps and falls out of the CO (when the internal hole is completely silted up).

Chemical flushing of the heating system

Flushing heating in an apartment building using this method is considered the most effective and efficient and is chosen in cases where:

Flushing heating in an apartment building using this method is considered the most effective and efficient and is chosen in cases where:

- Work is being carried out to restore CO in an old apartment building that has been in operation for several decades without replacing the pipelines. Flushing of intra-house heating systems, in this situation, is carried out only after calculating the economic feasibility of the operation. Often it is completely absent, since the pipeline is so destroyed that after cleaning, dozens of leakage points appear.

- Work is being carried out to remove deposits formed in it from the system. But only in cases where the owner of the specified object refuses to completely change it to a modern one. In this case, the overwhelming majority of precipitation is concentrated in the boiler heat exchanger, and the sludge lies evenly over the entire surface (mainly in the lower parts).

Flushing the heating system of an apartment building, in these cases, consists of pouring a special solution (reagent) into the flushed circuit instead of the water present there. As a rule, the reagent is an alkaline solution (sodium hydroxide, NaOH) or phosphoric acids ( general formula P2O5 nh3O).

Equipment for flushing the heating system of an apartment building, specially used for the specified purposes, in in this case is a pump that performs bubbling and circulation in the flushed circuit. The process continues continuously for at least two hours. Then the reagent is drained and the CO is pressurized, after successful completion of which it is put into operation again.

The technique for flushing the heating system of an apartment building strictly prohibits pouring waste solutions into the sewer. But, if there is no other disposal option, then this is possible provided that you have a neutralizing solution.

Hydropneumatic cleaning of the system

Flushing heating in an apartment building using the specified method is most often used by all housing and communal services since the times of the USSR, because demonstrated her high efficiency at a relatively low cost of work.

In different organizations it is called differently: pneumopulse flushing of the home heating system, hydrodynamic flushing method, etc. But this does not change the essence of the technology.

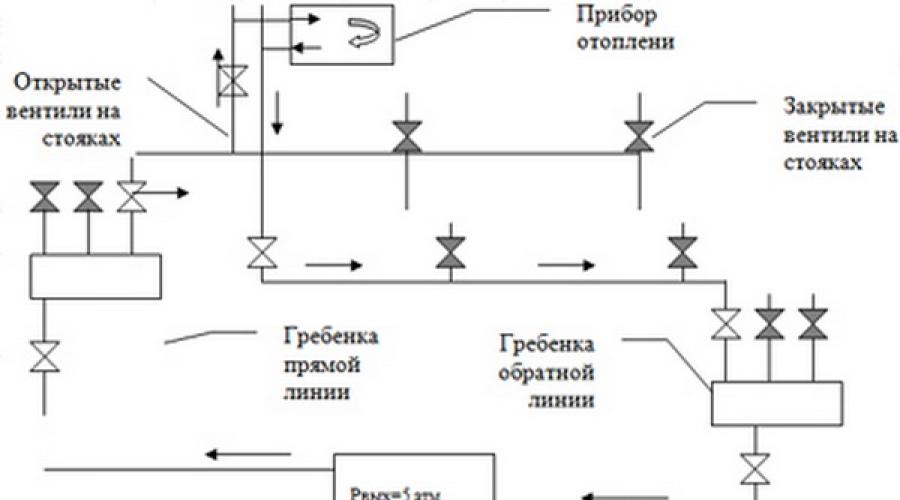

The above work is performed very simply. Circuit heating system is closed for discharge into the sewer at the first stage from the supply line to the return line, and at the second stage - vice versa. The passing water, in these cases, is “adjusted” by a compressor (pneumatic pump), which supplies air under pressure into the main line.

The resulting pulp is driven along the contour of the entire CO. At the same time, it partially breaks up the scale and loosens the silt deposits and takes it all with it into the sewer.

The step-by-step sequence of work such as flushing in-house heating systems looks like this:

- The valve on the return supply line is closed (common house);

- After it, there is a metering valve in the system, to which the compressor is connected;

- A discharge on the common house return line opens;

- We raise the pressure in a special container of the connected compressor to 6 kgf/sq. cm, then open the valve;

The instructions for flushing the heating system of a residential building provide for the sequential closing of a group of risers, selected in such a way that no more than ten of them are opened at a time. With this approach, washing is as efficient and effective as possible.

The time during which flushing should be performed is easily determined by the state of the discharged liquid. It has reached a transparent state, we move on to the next group of risers.

After complete flushing of all risers, the heating system is reconnected so that the discharge is directed in the opposite direction.

- The valve to which the compressor was connected shuts off the discharge;

- then the supply line to the house is closed with a valve and the house return is opened;

- The supply opens the reset;

- The compressor is docked to the valve on the return, after which this valve opens;

- The risers are being flushed. Only in reverse order.

The frequency of flushing the heating system can be significantly reduced if a recurring problem is solved, when it is enough to flush not the entire system, but only one heating device (radiator).

For this procedure, you can purchase a special flushing tap. But it is better to use a self-made structure for this, consisting of a ball valve and a radiator plug.

It should be installed in the system with the coolant discharged from the riser. Then, when the CO starts working, the specified device can be successfully used to remove any contaminants (slag, silt, etc.). Moreover, not only from the radiator, but also from the supply pipes to it.

In addition to the previously mentioned tap, you will need a hose equipped with a fitting. Moreover, the latter must have a thread that matches the one on the tap we installed for flushing.

Heating schemes for a private house, the pipe routing of which is carried out according to one of the above options, requires the contractor to carry out high-quality preliminary calculations.

Today, there are several most popular methods for insulating chimneys. residential buildings.

Brick chimneys absolutely need additional insulation. High-quality insulation of a brick chimney means significantly extending its service life.

The most optimal solution when performing the above work is a one-time replacement of the heating riser with polypropylene on all floors at once (the entire span).

https://vse-otoplenie.ru

legkoe-delo.ru

Flushing and pressure testing of the heating system in an apartment building

The heating system, like any other structure, has a certain service life. The duration of its operation is influenced by many factors: the magnitude of the water pressure and pressure drops, the degree of water hardness and the specified temperature regime, the presence of preventive measures and non-standard radiator material.

Extend "life" heating system within the capabilities of both the apartment owner and the business organization.

Flushing the heating system: what is it?

Any pipes - water supply, sewer, heating - eventually become a victim of scale. This process is inevitable, since even the most pure water contains a certain amount of salts. And since the liquid is constantly heated and cooled, some of it is deposited on the walls of the pipe. At the same time, its internal surface becomes uneven, which, in turn, provokes the process of sediment deposition due to the relief surface.

The appearance of scale significantly accelerates the wear of pipes and batteries, and, even worse, reduces heat transfer. Experts say that a layer of sediment 1 mm thick can reduce the level of heat transfer by 15%.

- You can reduce the speed of the process by installing a filter on the pipeline. And quite often, such a device is mounted on water pipes. The use of a filter in this case is completely justified. But heating, especially in an apartment building, is not profitable from an economic point of view.

The problem is solved using the flushing procedure, that is, supplying an air-water mixture under pressure - no more than 6 kgf/sq. see. The mixture flushes risers and radiators, breaking up plaque and washing it out of the pipeline. The air is supplied by a compressor through a hose - the device provides air under pressure, a conventional tap water. The waste mixture is discharged through another hose into the sewer.

Flushing is carried out until the outlet water becomes completely clear.

The procedure is carried out once a year before starting heating season. Depending on the condition of the pipes in an apartment building, it can be carried out either less frequently - if the water is soft, then scale does not form as intensely - or more often. But last option implemented, as a rule, by the apartment owner.

Heating in a private residential building also needs periodic cleaning. The need for flushing is determined by the level of reduction in heating efficiency:

- heating of the premises takes a long time, while cooling follows in normal mode;

- with hot pipes, the radiator does not heat up well or remains cold;

- there is an increased need for energy, which is associated with increased costs;

- The operation of the system is accompanied by unusual whistling sounds.

If the above symptoms are observed, cleaning is necessary.

Flushing technology

The procedure cannot be carried out without the necessary equipment - an air compressor with sufficient power to support required pressure– no more than 0.6 MPa. The compressor supplies compressed air to risers pre-filled with water. The air-water mixture moves at high speed and removes scale.

The device, if the procedure is carried out on its own, can be rented - purchasing it for such a rare need is irrational. Shown in the photo air compressor.

Two methods are used

In the first case, a pipe with a check valve is cut into the supply pipe. If the residential building is small, then it is possible to use existing pipes.

- A drain pipe is attached to the return pipe.

- The compressor supplies compressed air, which is mixed with water. Check valve protects the device from water ingress.

- The mixture circulates through the system for some time - 10-15 minutes, and then, after turning off the compressor, it is discharged through the return line.

The second method is more often used in large apartment buildings. In this case, the air supply through the heating is carried out in parallel with the process of removing the waste liquid. The procedure ends after the outlet water is completely clarified.

The result of cleaning is more effective work heating, improved heat transfer, since the walls of heating devices are cleared of plaque, and, in fact, reduced costs.

Cleaning work does not require a license and can be carried out both by organizations and by the owners of private homes. However, it should be remembered that this procedure is calculated for each heating system individually, therefore, if you do not have the necessary experience, it is recommended to contact specialists.

Hydropneumatic testing: what is it?

As a rule, they are carried out after flushing the heating system. Their essence comes down to detecting leaks and damage or confirming the absence of such. In this case, the absence or presence of defects is documented. Pressure testing is carried out in several cases:

- without fail after the end of the heating season, regardless of whether the cleaning procedure was carried out or not;

- upon commissioning of the entire building or autonomous heating in the apartment;

- after repair of any part of the system;

- after liquidation emergency situations, pipeline replacement and so on.

Pressure testing is carried out after turning off the heating and removing the coolant - water or antifreeze. The equipment used to supply compressed air is a pneumatic or hydraulic pump. In this case, the pressure created by the pump noticeably exceeds the usual value. This way, leaks and damage that might not have been noticeable at low pressure will be immediately detected. Crimping does not affect the efficiency of undamaged elements in any way.

Before the procedure, if flushing has not been carried out, you should visually verify that there are no leaks on all elements: risers, pipelines, batteries, elevator unit, and so on.

- The heating is filled with water. If the building is small - 1-2 floors, then there is no need to increase the pressure. In an apartment building, the pressure is raised by a press to the value specified in the documentation. The pressure level depends on the material of the pipeline and radiators. So, when using cast iron batteries, the recommended pressure reaches 3–5 atm, and for a private cottage, increase the pressure above 2 atm. does not make sense, since the emergency release valve will operate.

- The pressure gauge readings are observed for half an hour. If the data does not change, then the system is considered sealed. If the readings change, the pressure is dropping, which is a sign of a leak.

- After identifying the location of the damage, the water is removed and the element is repaired. Then pressure testing is carried out a second time to ensure the quality of the repair.

- If the leak is no longer observed, representatives of the heating supply and heating network fill out the corresponding report.

Pressure testing is carried out by relevant organizations, usually employees utilities. The procedure can be carried out by any trained specialist - a certificate is required, using special equipment. You should not carry out crimp testing yourself, since such tests must have documentary confirmation, and it is impossible to obtain it without the sanction of the organization.

kamingid.ru

Flushing of central heating systems of apartment buildings WZP 2011-2012.

When preparing multi-apartment housing stock for the autumn-winter heating season, one of the items includes flushing and pressure testing of central heating systems in multi-apartment buildings. Rules and regulations technical operation housing stock, approved by Decree of the State Construction Committee of the Russian Federation dated September 27, 2003 No. 170, determine the flushing of the central heating system of an apartment building (hereinafter referred to as MKD): clause 9.2.9. systems are flushed annually after completion heating season, as well as after installation, major repairs, current repairs with replacement of pipes (in open systems, the systems must also be disinfected before commissioning). The systems are washed with water in quantities exceeding the calculated coolant flow rate by 3-5 times, and complete clarification of the water must be achieved. When carrying out hydropneumatic flushing, the flow rate of the air mixture should not exceed 3-5 times the calculated coolant flow rate. For washing, use tap water or process water. Connecting systems that have not been flushed is not allowed. Flushing the heating system ensures better coolant circulation and heat transfer, and as a result, less energy consumption, which leads to comfortable living during the heating season and savings on payments for this type services. To carry out activities you need to as soon as possible apply for system flushing heating MKD V heat supply organization district. It is necessary to recall that the owners of residential premises of apartment buildings, in accordance with Article 161 of the Housing Code of the Russian Federation dated December 29, 2004 No. 188-FZ, must choose and implement a method of managing an apartment building. The implementation of the chosen management method involves the conclusion of contracts for the supply of energy resources and maintenance by specialized organizations, intra-house utility networks common use of an apartment building.

When preparing multi-apartment housing stock for the autumn-winter heating season, one of the items includes flushing and pressure testing of central heating systems in multi-apartment buildings. Rules and regulations technical operation housing stock, approved by Decree of the State Construction Committee of the Russian Federation dated September 27, 2003 No. 170, determine the flushing of the central heating system of an apartment building (hereinafter referred to as MKD): clause 9.2.9. systems are flushed annually after completion heating season, as well as after installation, major repairs, current repairs with replacement of pipes (in open systems, the systems must also be disinfected before commissioning). The systems are washed with water in quantities exceeding the calculated coolant flow rate by 3-5 times, and complete clarification of the water must be achieved. When carrying out hydropneumatic flushing, the flow rate of the air mixture should not exceed 3-5 times the calculated coolant flow rate. For washing, use tap water or process water. Connecting systems that have not been flushed is not allowed. Flushing the heating system ensures better coolant circulation and heat transfer, and as a result, less energy consumption, which leads to comfortable living during the heating season and savings on payments for this type services. To carry out activities you need to as soon as possible apply for system flushing heating MKD V heat supply organization district. It is necessary to recall that the owners of residential premises of apartment buildings, in accordance with Article 161 of the Housing Code of the Russian Federation dated December 29, 2004 No. 188-FZ, must choose and implement a method of managing an apartment building. The implementation of the chosen management method involves the conclusion of contracts for the supply of energy resources and maintenance by specialized organizations, intra-house utility networks common use of an apartment building.

If the owners of residential premises of apartment buildings do not comply with the above requirements of the law, then local government bodies, in the manner established by the Government of the Russian Federation, recognize the chosen method of management as not being implemented and hold an open competition to select a management organization in accordance with Decree of the Government of the Russian Federation dated 02/06/2007 No. 75 “On the procedure for holding an open competition by a local government body to select a management organization to manage an apartment building,” that is, the management organization will be involved in the management of the apartment building.

www.korenovsk.ru

- 2 unique ways + Video

In order for the heating system to maintain its efficiency and performance for as long as possible, it must be flushed periodically. This simple-to-carry out event allows you to eliminate scale and various kinds garbage.

Flushing and pressure testing of the heating system

According to the rules, flushing the heating system must be carried out by specially trained people. But if you wish, you can do this yourself. Read the provided guide and get started.

Flushing and pressure testing of the heating system

Why flush your heating system?

Have you noticed that some of your friends or neighbors have much warmer radiators than yours at home? There may be several reasons for this, but the most common is the presence of blockages in heating lines. It is to eliminate such troubles and prevent their further occurrence that flushing is performed.

Symptoms and manifestations of a clogged heating system in a private home

Heating efficiency is reduced due to two main factors, namely:

Cast iron batteries, as well as radiators with big amount sections. The relationship is simple: the more sections and the larger they are, the slower the coolant moves through the system and the higher the likelihood of silting.

Instructions for flushing the heating system

Pneumatic pulse cleaning scheme

There are 2 main methods for flushing the heating system, namely:

- using special hydropneumatic equipment;

- using chemical reagents.

Flushing using the hydropneumatic method

Hydropneumatic flushing of heating systems - instructions

This method is actively used by domestic housing offices and is quite effective. You just need to do everything in accordance with technology.

The principle is extremely simple: first, water is discharged from the system, then it is supplied back. A special pneumatic pump is used to “adjust” the water flow. As a result, under the influence of a fairly powerful pressure, scale and other deposits peel off, and when the water is drained, they are removed from the system.

To carry out this procedure yourself, you will need a pneumatic pump capable of pumping a pressure of more than 6 kg/cm2.

The sequence of actions is as follows.

Before starting work, you must turn off all taps

The end fittings are unscrewed using a wrench

First step. We close the return valve.

Heating system line diagram

Second step. We connect the pneumatic pump to the valve installed after the valve.

Third step. We reset the return line.

Fourth step. Let the pneumatic pump build up pressure above 6 kg/cm2, and then open the valve to which it is connected.

Fifth step. We close off all the risers one by one. We do this so that no more than 10 risers are blocked at one time. Compliance with this rule will make the washing procedure as effective as possible.

Sixth step. We switch the system to reset in the opposite direction. To do this we do the following:

- close the discharge and close the valve connected to the pump, and turn off the device;

- close the open valve, and then open a similar one on the “return”;

- we reset the heating system. To do this, connect the pneumatic pump to the valve in the opposite direction, then open the valve and turn on the pump. The liquid will move in a different direction.

You can determine the required duration of rinsing by eye. Has clear clear liquid started coming out of the system? We can finish! Return the gates and valves to their original positions and turn off the pump.

To collect dirty water Prepare a suitable container. If you wish, you can connect a hose to the battery and ensure that the dirty coolant is discharged into the sewer.

Chemical wash

Chemical pipe flushing diagram

This method can be used only in two cases, namely:

- if it is necessary to clean the heating system with natural circulation built using steel pipes. It is advisable to use chemical reagents in situations where, for any reason, there is no desire to flush the entire system. Most often, blockages are deposited in heat exchangers. The system can silt around the entire perimeter. In the second case, chemical washing will not be of much use;

- if it is necessary to restore the old heating system. Over decades of operation, pipes can become clogged and overgrown so much that the power of the pneumatic pump will not be enough for effective cleaning. It would, of course, be possible to use a more powerful pump, but no one can guarantee that the pipes will not burst under such pressure.

Important! If the pipes are very old, with traces of corrosion and deformation damage, flushing may not have any positive result. Chemical reagents will simply dissolve the rust, causing the pipes to begin to leak. The only one effective solution In such a situation, it will be necessary to replace worn-out highways.

Wash reagent

The principle of flushing is simple: instead of coolant, a special solution containing acid and alkali is poured into the system. Then the mixture is circulated for 2-3 hours (if it is not the natural circulation line that is being cleaned, you will need to connect a pneumatic pump for this), after which it is drained and the pipes are filled with standard coolant.

Reagents for flushing and protecting heating systems

Important! According to the requirements of SNiP, such reagents are prohibited from being discharged into the sewer system. The best option is to neutralize the used mixture using special staff. You can buy it in the same place where you buy the washing solution.

Never use such chemical mixtures to clean aluminum pipes. If the products remain intact after such washing, they will serve significantly less.

It is recommended to carry out mandatory flushing of the system of a private home at least once every 7 to 10 years.

Is it possible to wash a separate battery?

Now you know how to flush the heating system. However, sometimes it becomes necessary to clean a separate battery. There is a solution for this situation too.

Heating battery cleaning scheme

Important! Engage in washing a separate heating radiator it is necessary strictly before the start of the heating season.

Buy a flushing faucet from a plumbing store. Additionally, you need to purchase a rubber hose and a fitting with a thread that matches the diameter of the purchased flushing valve. Install the fitting onto the hose.

Direct washing is carried out in the following sequence.

First step. We connect the flushing tap to the heating radiator.

Second step. We connect a fitting with a hose to the flushing valve.

Third step. We direct the second end of the rubber hose into the toilet.

Fourth step. Open the flush tap and leave for 20-30 minutes. While waiting, hold the hose so that it does not jump out of the toilet.

Important! Although it is recommended to flush individual batteries strictly before the start of the heating season, in some situations the need for flushing arises when heating is in full swing. If this is your case, insert the hose deeper, directly into the riser. Otherwise, the hot coolant may destroy the toilet.

Video - Flushing the heating radiator

Table for selecting reagents for flushing the heating system

Pressure testing of the heating system

Manual pressure test pump

Electric crimper

Before starting the system, you need to perform a pressure test. This procedure allows you to detect leaks and other weak spots.

Pressure testing is carried out using a compressor or pump. The main thing is that the equipment can produce pressure exceeding the operating pressure for your system. Check with your local utility company for this figure.

The sequence of actions is as follows.

First step. Visually examine the heating circuit for visible defects. We remember suspicious places.

Second step. We connect the pump to the heating system (connection instructions were given earlier) and apply a pressure that exceeds the operating pressure by 1-2 atm. First turn off the emergency pressure relief valve.

Pressure testing of the heating system

Pressure testing of the heating system

Third step. We connect a pressure gauge to the pump. We record pressure readings within 1-2 hours. If they don't change, everything is fine with the system. If the pressure drops, leaks occur. Leaks are very easy to detect. It is enough to apply a soap solution to the system elements. Bubbles will appear in defective areas.

Lubricate the pipes and connections with soapy water

Detected damage is repaired in a suitable way (cold welding, astringent solution, etc.). After repairing the defects, the tests must be repeated. If the pressure remains at the same level, you have done everything. You can supply coolant to the circuit and turn on the heating system.

Flushing the heating system allows you to remove blockages and scale, thereby increasing the efficiency of the line and extending its service life. Now you have all the necessary information to conduct your own necessary measures.

Good luck!

Video - Hydropneumatic flushing of the heating system

Video - Chemical flushing of the heating system

Brief excerpts from regulatory documentation, rules and SNiP for heating pressure testing .

Analyzing the statistics of the questions you ask and understanding that many questions regarding pressure testing of the heating system for the majority of our audience remain incomprehensible to you, we decided to make a selection from the necessary points and Rules for pressure testing, approved by the Ministry of Fuel and Energy of the Russian Federation and SNiP.

1. Rules for the technical operation of thermal power plants.

Developed and approved by the Ministry of Fuel and Energy of the Russian Federation. No. 115 dated March 24, 2003

clause 9.2 Heating, ventilation, air conditioning, hot water supply systems.

Hydraulic tests of equipment at heating points and heating systems should be carried out separately.

Heating points and heating systems must be tested at least once a year, with a test pressure equal to 1.25 working pressure at the heating network inlet, but not less than 0.2 MPa (2 kgf/cm2).

9.2.11 To protect against internal corrosion Heating systems must be constantly filled with deaerated, chemically purified water.

9.2.12 Tests for the strength and density of system equipment are carried out annually after the end of the heating season to identify defects, as well as before the start of the heating period after repairs are completed.

clause 9.2.13 tests for strength and density of water heating systems are carried out at test pressure, but not lower than:

Elevator unit, water heaters for heating systems, hot water supply - 1MPa (10kgf/cm2 or 10Ati.)

Heating systems with cast iron heating devices, stamped steel radiators - should be taken as 0.6 MPa (6 kgf/cm2 or 6Ati)

Panel and convector heating systems - 1.0 MPa (10 kgf/cm2 or 10Ati).

For heaters of heating and ventilation systems - depending on the operating pressure set technical specifications manufacturer's plant.

Minimum value test pressure during hydraulic testing it should be 1.25 working pressure, but not less than 0.2 MPa (2 kgf/cm2 or 2Ati).

Pipeline tests are carried out in the following order and must be carried out in compliance with the following basic requirements:

- test pressure must be provided at the top point (mark) of the pipelines; the water temperature during testing should be no higher than 45°C, air is completely removed through air venting devices at the highest points;

- the pressure is brought to the working level and maintained for the time necessary to inspect all welded and flange connections, fittings, equipment, instruments, but not less than 10 minutes;

- If no defects are detected within 10 minutes, the pressure is brought to the test pressure.

The pressure must be maintained for 15 minutes and then reduced to working pressure. The pressure drop is recorded using a control pressure gauge.

Systems are considered to have passed the tests if, during testing:

No “sweating” of welds or leaks from heating devices, pipelines, fittings and other equipment were detected.

When testing the strength and density of water and steam systems heat supply within 5 minutes of drop does not exceed 0.02 MPa (0.2 kgf/cm 2 or 0.2 Ati).

When testing the strength and density of systems panel heating within 15 minutes the fall does not exceed 0.01 MPa (0.1 kgf/cm 2 or 0.6 Atm).

When testing the strength and density of hot water supply systems for 10 minutes, the drop does not exceed 0.05 MPa (0.5 kgf/cm 2 or 0.5 Ati).

When testing the strength and density of plastic pipeline systems within 30 minutes, the drop does not exceed 0.06 MPa (0.6 kgf/cm 2 or 0.6 Ati).

The results of the inspection are documented in a Strength and Density Test Certificate.

If the strength and density test results do not meet the specified conditions, leaks must be identified and repaired, and then the system must be retested.

During testing, spring pressure gauges of an accuracy class of at least 1.5 with a diameter of at least 160 mm, with a division value of 0.01 MPa (0.1 kgf/cm 2 or 0.1 Ati) are used.

2. SNiP 3.05.01-85 “Internal sanitary and technical systems”

4.6. Testing of water heating and heat supply systems must be carried out with the boilers and expansion vessels turned off using the hydrostatic method with a pressure equal to 1.5 working pressure, but not less than 0.2 MPa (2 kgf/cm 2 (2Ati)) at the lowest point of the system.

The system is considered to have passed the test if, within 5 minutes of being under test pressure, the pressure drop does not exceed 0.02 MPa (0.2 kgf/cm) and there are no leaks in welds, pipes, threaded connections, fittings, heating devices and equipment.

3. SNiP41-01-2003 “Heating, ventilation and air conditioning”

4.4.8 Hydraulic tests of water heating systems must be carried out at positive temperatures in the premises of the building.

Heating systems must withstand, without destruction or loss of tightness, a test water pressure exceeding operating pressure in the system by 1.5 times, but not less than 0.6 MPa.

The test pressure value during hydraulic testing of heating systems should not exceed the maximum test pressure for heating devices, equipment, fittings and pipelines installed in the system.

A heating system is essential for every home or business these days. But even if she herself High Quality, it is impossible to do without external intervention. Heating systems are subject to certain standards and requirements that must be strictly observed. First of all, this concerns reliability and long service life.

If you leave things to chance, the result will be disastrous: sudden blockages, breakdowns and system failure. Therefore, in order to prevent such troubles, it is necessary to carry out preventive maintenance of the heating system. This is necessary for the timely removal of radiators, batteries and pipes from destructive deposits. Most effective way The heating system will be flushed.

Cause of the problem

The main reason that a heating system can suddenly fail is scale. Accumulating inside pipes or batteries, it acts very insidiously, ultimately leading to mechanical wear of the system.

As a result, significantly more energy and fuel are spent on heating the room, and the level of heat transfer is noticeably reduced. According to research, even a thin layer of scale of 1 mm impairs heat transfer by as much as 15%. This is very unprofitable, since significant amounts are spent on fuel.

If no measures are taken in this situation, the process will only progress. The coolant simply will not be able to break through the layer of deposits on the walls of the pipes. As a result, an effect called “ thermal resistance", which directly affects the sharp decrease in temperature indicators.

Therefore, in order to avoid troubles and repair costs, it is worth flushing the heating system on time. Combined with an acceptable cost, the procedure is reliable and has a long-term effect.

Washing technology: main nuances

You shouldn’t start right away with the washing process. First, you need to carry out diagnostics, which will allow the technician to quickly understand the composition of the scale, and then select the appropriate equipment.

A special technological map will help you navigate the washing process. At the end of the procedure, the walls of the pipeline are treated with a special compound. This is done to avoid reappearance corrosion, scale and deposits.

And yet, how to flush the heating system?

The main methods of flushing the heating system are as follows:

- chemical

- hydrodynamic

- hydropneumatic

Each of these methods has its own advantages and disadvantages. They will be discussed in more detail below, and will provide a fairly complete picture of the process of flushing the heating system.

Chemical flush type

The most popular type of heating system flushing nowadays, which gives remarkable results. The main advantage is the almost complete removal of harmful deposits from pipes in the shortest possible time. The effect is achieved through the use of solvents and compositions based on alkalis and acids.

The general design consists of a container with a solution, a special pump and several hoses. When selecting cleaners, the master focuses not only on the type of scale, but also on the metal from which the pipes are made. It can be: cast iron, steel, aluminum, various alloys. After all, in addition to cleaning, it is very important not to damage the metal of the heating system.

For aluminum battery The use of acidic or alkaline liquids is strictly prohibited. If even a microscopic part of the heating system is damaged, chemical flushing is also not allowed.

The main disadvantage of the process is the extreme toxicity and danger of the chemical liquids used in the work. Protect from contact of the caustic solution with skin and eyes! A toxic composition that accidentally gets into the sewer can lead to irreparable consequences.

Flushing heating systems can be done in stages and last several days. Heating equipment can continue to operate as before during the flushing process.

If the process completes successfully and complete removal deposits, the service life of the heating system can increase up to 20 years. Bandwidth batteries are much improved, heat is not lost, which means major repairs are not required.

Hydrodynamic type of flushing

Basic meaning this process consists in the active interaction of water with sediments and scale. This is somewhat more expensive than chemical washing, but the result is of better quality.

After the desired section of the heating system has been selected, a stream of water is directed at it, which is under very high pressure. Water is supplied through nozzles required diameter and size.

Hydrodynamic type of flushing - best option for cast iron batteries. Using chemicals, removing scale from this metal is quite problematic. The hydrodynamic system copes with this problem perfectly.

One of the main advantages of hydrodynamic washing is environmental friendliness. This is due to the fact that the process uses only water and not acids with solvents. In order to achieve the desired effect, a special mechanism is used to create a pressure of at least 200 atmospheres.

However, not everything is as simple as it seems at first glance. The main difficulty is that the radiator will need to be delivered to a service center. With the help of a special composition, the layer that is planned to be removed is softened. And only then the walls of the heating system are subjected to water treatment.

Hydropneumatic flushing

A type of heating system flushing that has no analogues in its effectiveness at present. This happens because the craftsmen use a unique device called a “pneumatic gun” in their work.

The pneumatic gun easily and quickly removes scale and the oldest deposits. It efficiently rinses batteries and pipes at a distance of 50 m. In this case, the diameter of the elements should be no more than 150 mm. The device is very compact and quite easy to use.

The main advantage of a pneumatic gun is that it is successfully used for spot cleaning of heating mechanisms, affecting the most hard to reach places. During the hydropneumatic flushing process, it is not necessary to disconnect heating devices from the general system, which is also very important.

Flushing the heating system: guarantee of longevity

Flushing the heating system: guarantee of longevity

Summing up

No matter how perfect the operating conditions are, scale and deposits will always appear on the walls of the pipes. Therefore, it is very important to choose, taking into account individual characteristics correct scheme flushing the heating system: chemical, hydrodynamic, hydropneumatic.

Flushing the heating system is a very effective measure, but you should not let it become critically clogged. Scheduled cleaning of the heating system must be combined with periodic maintenance. Otherwise, heat transfer activity will decrease to a minimum, and then you will have to resort to the last resort - comprehensive flushing of risers, radiators and pipes.

By flushing your heating system, you greatly increase the productivity, efficiency and quality of its operation. After this procedure, the heating system will serve you for a very long time.

We hope you liked our article and now you know exactly how to flush the heating system.

Flushing the heating system video

Scheduled flushing and pressure testing of the heating system supports stable work heating networks. Flushing heating circuits allows you to clean internal surfaces from formed scale, rust, plaque and deposits. Periodic pressure testing ensures heat transfer at a given pressure as established by the standards. Well-maintained equipment helps reduce energy costs and maintain productivity and high heating system performance.

What is flushing and pressure testing of a heating system?

Building codes and the rules regulate the sequence and technical nuances performing work on flushing and pressure testing of heating. They contain diagrams and instructions that serve as mandatory guidelines. Based on the provisions set out in SNiP, the essence of the concepts of “flushing” and “pressure testing” follows. This is a complex of works, including chemical, hydropneumatic cleaning, hydraulic testing and adjustment heating equipment.

What does flushing involve?

Washing prepares heating network to tests; apply different ways cleaning internal walls pipeline. Compressors or special installations are used for these purposes.

Flushing pump for heating systems

The composition of pipe deposits contains divalent iron oxide, oxides of magnesium, calcium, copper, zinc and trivalent sulfur oxide. Is it worth removing such plaque? The presence of plaque leads to increased load on heating equipment, provokes breakdowns and bursts, and at the same time reduces the efficiency of operation of the heating main.

Comparison: uncleaned and new pipe

Important! Heating systems should be flushed every 5-7 years. Missing deadlines can lead to disruption of the heating season and interruptions in the operation of the system.

The essence of the crimping procedure

Crimping is hydraulic test system in order to check it for leaks and breakdowns, adjust pressure indicators according to standards. Tests are carried out by introducing pressurized water or air into the system using a hydraulic pump.

Electric pump for crimping

Pressure testing is carried out in following cases:

- upon completion of heating installation (system commissioning);

- when replacing heating devices and pipeline parts;

- when preparing the system for the heating season.

Among the most important indicators affecting the coolant and heating quality is working pressure. The maximum pressure values depend on the number of storeys and type of building. Disruptions in the movement of the coolant caused by deposits in pipes, leaks, and equipment breakdowns lead to sudden changes in pressure.

Important! If the pressure is 40% or more higher than the operating indicators, flushing and pressure testing of the heating is mandatory.

Sequence of work for pressure testing the heating system

How to prepare a heating system for pressure testing

The main purpose of crimping work is to check heating circuit for tightness. Injected during testing overpressure provokes the failure of components and devices that are unsuitable for further use and helps to identify emergency areas.

On preparatory stage The entire heating system is turned off and the coolant (antifreeze or water) is drained. Before pressure testing, inspect the components, valves and other shut-off valves, and cut off the heating circuit with a plug from the common line. If necessary, restore the pipeline insulation and change the stuffing box seals.

Heating system pressure testing process

The procedure itself includes the following steps:

- filling the system with water or air under permissible pressure (1.5 times higher than the working pressure), hydraulic or pneumatic equipment;

- identifying problems in the system;

- identification of leaks, water and air outlets.

Important! When testing, the following parameters should be taken into account:

- type of pipeline (what material, wall thickness);

- characteristics of fittings;

- number of storeys of the building;

- type of wiring.

To avoid pipeline rupture, pressure gauge readings are monitored during the inspection. To detect leaks in multi-storey building, the release of air or water is carried out at a pressure higher than the working one by 30%. The specified value is monitored for half an hour; if the readings remain stable, then the crimping is considered complete.

A drop in pressure indicates depressurization or leaks in the heating circuit. The location of the accident is located. Before repairs, the water is drained (partial drainage is allowed), the tightness is restored, and then pressure testing is carried out again.

At what pressure are tests carried out?

To choose the right pressure for crimping, they are guided by operating pressure indicators: for private houses - 1.5-2 atmospheres, for low-rise buildings with centralized network– 2-4 atmospheres, in 9-storey buildings – 5-7 atmospheres, in high-rise buildings – 7-10 atmospheres, from the thermal power plant along the heating main the coolant pressure is 12 atmospheres.

Indicators of permissible pressure in pipes

Pressure testing when starting up new heating equipment is carried out under pressure twice as high as standard values. All subsequent tests are done at an increase in pressure of 20-50% of operating values.

Who does heating pressure testing?

The responsibility for preparing heating systems lies with the organizations operating the premises. Residential buildings are serviced by utility workers of management companies. In administrative production premises such work is performed by maintenance personnel.

Based on safety standards and position professional approach, if it is necessary to pressurize and flush the heating, it is better to contact certified personnel. Qualified crimpers are proficient necessary knowledge and technology. In addition, they have special equipment and the ability to work unhindered thermal unit.

Video: flushing the heating system and heat exchangers