Burst valve. How to choose a pressure relief valve in a boiler. Explosion valve on the boiler flue

Read also

Despite constant warnings from buyers of electric heating equipment that such devices must be installed strictly according to the instructions without ignoring all components, it still happens quite often that the safety valve for the boiler is not installed at all.

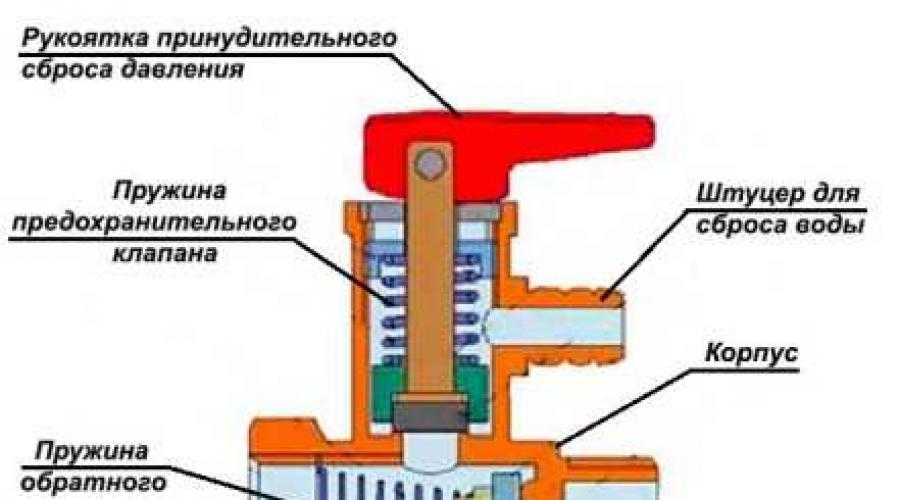

Safety valve device

The safety device consists of two parts:

Check valve

Burst valve

They are both located under one body and each performs its own function. The check valve prevents excess water (which appears as a result of heating the water) from flowing back into the system. The second valve, also known as the blast valve, is activated only if the threshold pressure value is exceeded, usually 7-8 bar.

Based on this information, it is clear that in the event of an emergency or a sharp increase in pressure, the blast valve will release excess water and prevent damage to the electric heater. It also has a lever for forced drainage of water, this is necessary when repairing or dismantling the boiler.

Although every water heater has thermostats that control the temperature, they can break, so a system that has a working safety device is safe and will serve you for many years.

There are also situations where there is no water in the system; proper operation is very important here. check valve, which is installed on the water heater, because all the water will come out of the water heater, and if the thermostat is faulty, the empty boiler will heat up very quickly and the heating elements inside will burn out.

Water leaking from valve

Water leakage is a common occurrence for a safety device, this indicates that it is working properly. But if the water is flowing too quickly or constantly, it may indicate one of these problems:

The spring stiffness is incorrectly adjusted;

Too much high pressure in system;

If to last problem If you have nothing to do with it, then the spring stiffness can only be incorrectly adjusted if you carelessly handle the adjusters.

Jumps in the system can be eliminated with the help of another valve - a pressure reducing valve; it is installed before the safety valve and ensures the supply of stable pressure to the water heater.

No water dripping from the safety valve

If after installing the boiler it does not work even once, even at maximum heating, you should think about the serviceability of the safety device. You shouldn't change it right away, maybe excess water leaks through a faulty mixer, or damage to the pipes.

Sometimes the boiler does not heat up to high temperatures, no higher than 40 degrees. In this case, the safety valve for the water heater does not work due to insufficient pressure build-up inside the boiler, this is normal.

Choosing the right model

Usually a safety device is included with the boiler the desired model. But if it is not there, it is faulty, or you replace it after some time of using the water heater, then you will have to choose the right one yourself.

The main parameter after threading (the size is very easy to select, usually 1/2 inch) is operating pressure. From correct selection this parameter will depend on the correct and safe work boiler Required pressure indicated in the operating instructions that come with each water heater.

There are two problems that may arise as a result of incorrect selection of a safety device:

Constant leakage from the device due to the choice of a lower operating pressure than necessary;

The device will not work at all if a value greater than necessary is selected; such a safety valve will not save in the event of an emergency;

Correct installation of the safety device

1. First, disconnect the boiler from the power supply and drain the water from it.

2. Install the device for supply cold water, at the inlet to the heater. We pack it in the usual way and connect cold water to the second side.

There is an arrow on the valve body that indicates the direction of the water; when installed, it should point towards the boiler.

3. We connect the pipe that comes from the blast valve with the sewer. Sometimes it is bought transparent in order to monitor the serviceability of the safety valve.

4. After connecting the boiler completely, it is worth checking it. To do this, fill the tank by prematurely opening the valve to allow air to escape.

5. Then, after drawing water, close the tap and turn on the boiler.

6. We monitor all joints for the presence of water and look at the functionality of the safety valve. If a leak is detected, the inlet and outlet valves are closed, and required area repacked.

Can the safety valve be replaced with a non-return valve?

In no case, the safety device has a check valve inside it, but there is more than one, the blast valve should not be overlooked. If a check valve prevents water from flowing into the system and, roughly speaking, saves you money, then a blast valve prevents the boiler from increasing the pressure inside to critical.

A boiler that has a non-return valve installed instead of a safety valve is a time bomb. The enormous pressure inside the water heater will not destroy the boiler until you open the tap. When you open the tap, the pressure inside the boiler decreases, but water, heated to a temperature higher than 100 degrees, immediately turns into steam, destroys the walls of the boiler and rushes out.

This is a fairly strong explosion, which is accompanied not only by fragments of the body, but also by hot steam and water. Take care not only of yourself, but also of the people around you.

conclusions

Follow the operating instructions; even such a small-looking device makes your life safer. The safety device is very important element and operating the boiler without it is strictly prohibited. Always monitor the operation of the installed protective device, whether water flows from it when necessary or not. All these factors will save your time, money and health.

From correct strapping electric water heater accumulative type(boiler) depends not only on the life of the equipment, but also on the safety of residents. That's how serious things are. And its correct piping is a safety valve for a cold water supply water heater.

What is it needed for

Installing a safety valve prevents the pressure inside the device from increasing above the standard value. What causes blood pressure to rise? As you know, when heated, water expands, increasing in volume. Since the boiler is a sealed device, there is nowhere for the excess to go - the taps are closed, and there is usually a check valve at the supply. Therefore, heating the water leads to an increase in pressure. It may well happen that it exceeds the tensile strength of the device. Then the tank will explode. To prevent this from happening, they install a safety valve for the water heater.

Maybe there is no need to install a safety valve, but simply remove the non-return valve? At a sufficiently high and stable pressure in the water supply, such a system will work for some time. But the solution is fundamentally wrong, and here’s why: the pressure in the water supply is rarely stable. There are often situations when water barely flows from the tap. Then hot water be forced out of the boiler by pressure into plumbing system. In this case, the heating elements will be exposed. They will heat the air for some time and then burn out.

But burnt-out heating elements are not the worst thing. It’s much worse if they get hot, and at this time the pressure in the water supply rises sharply. The water that gets on the hot heaters evaporates, a sharp increase in pressure occurs - with a jerk - which leads to a guaranteed rupture of the boiler flask. At the same time, a decent volume of scalding water and steam escapes into the room under high pressure. What this could mean is clear.

How does it work

It would be more correct to call a safety valve for a water heater a valve system, since there are two of them in the device.

They are located in a brass or nickel-plated case, which looks like an inverted letter “T” (see photo). At the bottom of the housing there is a check valve that prevents the outflow of water from the water heater when the pressure in the system decreases. In the perpendicular branch there is another valve, which, if the pressure is exceeded, allows some of the water to be released through the fitting.

The working mechanism is as follows:

- While the pressure in the boiler is less than that in the water supply (when filling or when the tap is open), the check valve plate is pressed out by the flow of water. As soon as the pressure is equalized, the spring presses the plate against the protrusions of the body, blocking the flow of water.

- When the heating is turned on, the water temperature gradually increases, and with it the pressure also increases. As long as it does not exceed the limit, nothing happens.

- When the threshold level is reached, the pressure compresses the safety valve spring, and the outlet to the fitting opens. Some of the water from the boiler is released through the fitting. When the pressure drops to normal, the spring closes the passage and the water stops flowing.

Based on the principle of operation, it is clear that water will constantly drip from the fitting. This happens when the water heats up and the pressure in the water supply decreases. If you periodically see water on the fitting, then everything is working normally. But the draining liquid must be drained. To do this, put a tube of a suitable diameter on the pipe and secure it with a clamp. The normal operating pressure of the boiler is from 6 Bar to 10 Bar. Without mechanical fastening The tube will come off in no time, so we select a high-quality clamp and tighten it well. Place the tube into the nearest sewer drain.

One more point: the tube for the fitting needs to be transparent and preferably reinforced (the so-called “herringbone”). Why reinforced is understandable - because of pressure, and transparent - to be able to monitor the performance of the device.

Types and varieties

If we're talking about About conventional safety valves for a water heater, they look almost the same, only the nuances differ. But it is these small details that are responsible for the convenience and safety of operation.

The photo above shows two safety valves with release levers. They are needed for periodic performance checks. The lever flag is lifted up. It pulls the spring behind it, freeing it to release water. This check should be carried out approximately once a month. You can also empty the boiler tank by raising the flag and waiting for everything to drain.

Design Features

The difference in the presented models is that the model in the photo on the left has a lever secured with a screw. This eliminates the possibility of accidental opening and complete discharge of water.

Two more differences are striking. This is an arrow on the body indicating the direction of water movement, and an inscription showing what pressure the device is designed for. Seemingly minor details. But if you can figure out the direction of water movement (look in which direction the poppet valve is turned), then the nominal value is more difficult. How to distinguish, for example, whether it is 6 Bar or 10 Bar? Only checks. How will sellers differentiate them? No way. By boxes. What if they put it in the wrong box? In general, it is better not to take a valve without markings on the body. These are usually the cheapest of the Chinese designs, but the difference in price is not so great that it is worth the risk.

Safety valves - serviceable and not

Also pay attention to the shape of the water drain fitting. The model on the left has a long fitting and has a non-linear shape. The hose fits on it quite easily and is long enough to install a clamp. The shape of the fitting on the model on the right is different - it widens towards the end, but more importantly, the fitting is short. You can still pull the hose onto it, but the clamp is questionable. Unless you crimp it with wire...

The following photo shows the safety valves without a forced pressure release flag. The one on the left has a threaded cap at the top. This is a serviceable model. If necessary, you can unscrew the lid to remove blockages, scale and other contaminants.

The model on the right is the worst option. No markings, forced resets or maintenance. These are usually the cheapest available, but this is their only advantage.

For large volume boilers

All of the above models are suitable for water heaters with a volume of up to 50-60 liters. For boilers bigger size there are other models, many of which have built-in additional devices. Usually this ball valve and/or pressure gauge - to control pressure.

The water drain fitting here has a standard thread, so there will be no problems with fastening reliability. Such devices already have quite high price, but their quality and reliability are much higher.

Not everyone likes appearance I like these devices. For those who attach aesthetics great importance Very attractive devices are being produced. Their price, however, is comparable to the price of an expensive water heater, but it’s beautiful.

Is it possible to install other valves?

Sometimes, instead of a special safety valve for a boiler, a blast valve is installed, which is intended for the emergency release of heating water. Although their functions are similar, the main mode of operation is fundamentally different. The demolition should only work when emergency situations. It is designed for volley discharge of a large volume of liquid. It is not suitable for constantly bleeding small portions of water. Accordingly, it will not work correctly.

Another case is to install only a check valve. It will prevent water from draining when the pressure in the water supply decreases, but it will not save you from increasing pressure in the boiler. So this option doesn't work either.

How to choose and install

Select a safety valve for a water heater based on the pressure for which the unit is designed. This number is in the passport. The volume of the tank also influences the choice. They produce devices with operating limits of 6, 7, 8, 10 Bar. Basically, all units are designed for this pressure. So everything is simple here.

Installation is simple: it is wound onto the thread flax tow or fum tape, after which the valve is screwed onto the pipe. Twist it all the way by hand, then another one or two turns using keys. It is much more important to choose the right place to install it. In this case, this valve is installed directly on the cold water inlet pipe.

Next there may be a check valve, which is also called a shut-off valve. But this is already reinsurance - the same device is available in the safety device, and often after the water meter at the inlet. The installation diagram is shown below. This is one of the normal options.

The diagram shows a ball valve. It is necessary to empty the tank before storing it for the winter (at dachas) or before dismantling it for prevention and repair. But more often they put it on a tee, which is screwed directly onto the inlet pipe of the water heater. A safety valve is screwed onto the tee from below, and a ball valve is placed in the side outlet.

Actually, these are all normal options.

Breakdowns, causes, elimination

In principle, the safety valve for a water heater has only two failures: water either often flows from it or does not flow at all.

First of all, it must be said that bleeding of water when heating is the norm. This is how the system is supposed to work. Water may also be released when the boiler is turned off, if the pressure in the cold water supply pipes is higher than the valve response limit. For example, the valve is 6 bar, and the water supply is 7 bar. Until the pressure drops, the water will be released. If this situation repeats often, it is necessary to install a reducer, and it is best to use water in an apartment or house, but there are compact models of reducers that can be installed at the entrance to the boiler.

How to check the serviceability of the valve? If there is an emergency reset lever, this is easy to do. With the boiler turned off, you need to lift the lever several times to release excess pressure. After this, the dripping stops and does not resume until heating begins.

If water continues to drain, the spring may be clogged. If the model is serviceable, the device is disassembled, cleaned, and then put back in place. If the model is not collapsible, you just need to buy a new valve and install it.

This is what the reducer looks like - to stabilize the pressure on the boiler

Constantly dripping water is unpleasant and hurts your wallet, but not dangerous. It is much worse if, when heating the water, you never see water in the pipe. The reason is that the valve is clogged or the outlet fitting is clogged. Check both options. If it doesn’t help, change the valve.

The safety valve for a water heater only appears from the outside to be a simple, insignificant device. Inside, it's a pretty advanced boiler protection tool.

How does a safety valve work?

So, we take a regular valve from a regular boiler.

Not all valves have a pressure release handle. It does not play any special role in the operation of the valve. So, periodically, once every six months, open and close to check functionality.

Let's take a closer look at what's inside. And inside there are 3 (three) independently operating valves.

1. The safety valve itself

2. Check valve

3. Bypass valve

Safety or blast valve

Its purpose is to prevent an accident. The safety valve consists of a metal rod with a plug at the end (1), a powerful spring (2) and a water discharge fitting (3).

How does he work? Yes, simple.

Let's say our valve says 6 bar. When heated, the water inside the boiler begins to expand. Since there is nowhere for it to go, the pressure inside the tank begins to increase. As soon as the pressure rises to 6 bar, the rod will compress the spring and excess water will flow out through the fitting. In reality, all this happens smoothly and water simply drains out through the fitting.

Check valve

It lets water into the boiler, but not back. Consists of a rubber plug (1), a plastic rod (2) and a spring (3). The spring in the check valve, unlike the safety valve, is weak. She only needs to fix the plug on the valve seat.

You should not expect from this valve the same precise operation as on water check valves. It is not faced with the task of maintaining reverse flow under pressure. It protects the boiler from unauthorized water leakage. Simply put, so that water does not drain from it in the event of an accident or lack of water in the supply line.

Bypass valve

An inconspicuous and very important valve. The bypass valve is a check valve stem (1) with a small spring (2). Opens at reverse side from the check valve. It sounds absurd, but it is true.

Let's try to figure out what's so important about it. There is a safety valve. Its task is to relieve pressure above 6 bar.

What happens to the boiler tank up to 6 bar? The water heats up and expands. The pressure is growing, although not critically: 4 - 4.5 - 5 - 5.5 bar. The boiler is not a rubber ball and its tank is welded from sheet steel, not tank armor. Naturally, deformation occurs. Buck is trying to inflate. Microcracks appear on the enamel and welding seams. I wish this extra pressure could be blown off somewhere on occasion.

And this is where the bypass valve comes to the rescue. How does he work? Apartment. The boiler is heating. The pressure inside him is growing. Turn on washing machine. She begins to draw water. The water pressure in the pipes drops slightly, the bypass valve sees this, opens and releases excess pressure from the boiler into the main line. The pressure in the tank is equalized to water pressure. The boiler continues to heat up. It doesn’t have to be a washing machine, it can be a toilet cistern or any faucet.

How can we sum it up?

The safety valve is the most important part of the water heater. Its presence and performance directly affects the service life of the boiler.

Any boiler equipment installed in a private home or business is a source of danger. The water jacket of the boiler is the same vessel under pressure, and therefore it is considered explosive. To reduce the danger to a minimum, modern heat generators, as well as their wiring diagrams, provide many protective devices and systems. One of the simplest and at the same time common devices is a safety valve in a heating system. This will be discussed in this material.

Where is the safety valve installed?

To answer this question, you must first figure out what it serves. The purpose of installing this simple device is to protect heating systems and prevent high blood pressure coolant in them. This can occur as a result of overheating of water in the boiler, especially for units that burn solid fuel. When the coolant in the boiler tank boils and steam formation begins, this is followed by a pressure surge in the system. The consequences may be:

- leaks and ruptures of heating pipelines, most often at connections;

- destruction polymer pipes and fittings;

- explosion boiler tank, danger of electrical short circuit in the boiler room.

One small valve of a simple design can protect you from all these troubles. Based on the fact that pressure increases to critical limit occurs in the boiler, the safety valve must be installed as close as possible to it, on the supply pipeline. Some manufacturers of boiler equipment complete their products with a so-called safety group, which includes relief valve, pressure gauge and automatic air vent. The group is mounted directly into the water jacket of the unit.

It should be noted that safety valves for heating are not always used in circuits. For example, when the heat source in the house is a gas or electric boiler, then a reset device is not required. The reason is the presence of automatic safety in these types of heat generators and the absence of any inertia. That is, upon reaching set temperature coolant gas-burner or electrical element turn off and heating stops almost immediately.

Another thing is a solid fuel boiler or stove with a water circuit; here the installation of a safety valve is mandatory. When the firewood in the firebox has flared up and the water in the network has reached the required temperature, you need to reduce its heating. The access of air to the combustion chamber is closed and the flame dies out, but the red-hot firebox continues to rise in temperature by inertia. If the process proceeds near the limit values (temperature 90-95 ºС), then vaporization at such moments is inevitable.

As mentioned above, boiling is followed by an increase in pressure, which can be prevented by the safety valve of the heating system. It will automatically open the way out for the formed steam and release it, thereby reducing the pressure to normal. Then the device will close on its own and will be in standby mode again.

Design and principle of operation of the valve

The design of the valve is extremely simple. The body is made of high-quality plumbing brass using hot stamping technology from two cast parts in a semi-solid state. General device safety valve is shown in the figure:

The main working element of the valve is the spring. Its elasticity determines the force of pressure that should act on the membrane that closes the passage to the outside. The latter in its normal position is in a seat with a seal, pressed by a spring. The upper stop for the spring is a metal washer mounted on a rod, the end of which is screwed to a plastic handle. It is used to adjust the valve. The membrane and sealing elements are made of polymer materials, the spring is made of steel.

This whole simple mechanism works like this. In normal (standby) mode, as long as the coolant parameters are within the specified limits, the membrane closes the entrance to the inner chamber. As soon as a situation close to an emergency arises and the pressure in the heating system of a private house increases, the steam-water mixture begins to prop up the membrane. At a certain moment, the pressure force of the coolant overcomes the elasticity of the spring, opens the membrane, enters the chamber, and from it out through the side hole.

When some water leaves the system, the pressure will drop so much that it will not be able to resist the spring and the membrane will close the passage again. It happens that the mechanism operates cyclically, especially if the heating unit is operating at its limit and the coolant temperature is close to the maximum (90-95 ºС). In practice, when the burst valve for a boiler is triggered very often, it loses its tightness and begins to leak.

If you find fresh traces of leaks from the safety mechanism, then this is a clear sign that the heat generator is operating in extreme mode or that there is a malfunction in the heating system, for example, in the expansion tank.

Since not all manufacturers heating equipment If they complete their products with a safety group, you often have to make the choice of a safety valve for the heating system yourself. To do this, you must definitely study specifications boiler installation, namely to know it thermal power and maximum coolant pressure.

For reference. For most solid fuel heat generators famous brands The maximum pressure is 3 Bar. Exception - boilers long burning STROPUVA, whose limit is 2 Bar.

The best option is to purchase a valve with pressure control that covers a certain range. The regulation limits must include the value for your boiler. Then you need to select a product according to the power of the thermal installation, but it’s hard to make a mistake here. The manufacturer's instructions always indicate the limits of the thermal power of the units with which a valve of a particular diameter can operate.

On the section of the pipeline from the boiler to the place where the relief valve is installed overpressure it is strictly forbidden to place shut-off valves. In addition, you cannot place the device after circulation pump, do not forget that the latter is not able to pump the steam-water mixture.

To prevent splashing of water throughout the furnace room, it is recommended to attach a tube to the outlet of the valve that drains the discharge into the sewer. If you want to visually control the process, then you can place a special drain funnel on the vertical section of the tube with a visible break in the stream.

Conclusion

The pressure relief safety device is considered very reliable due to its simple design. When making a choice, you should pay attention to the quality of the material and not chase a cheap product. No less important is correct setting valve by maximum pressure boiler installation.

Safety, explosion, bleed valve. As soon as it's not called, mixing various functions and purpose, without looking at the design and characteristics. Moonshiners still argue until they are hoarse about the need for a safety valve, despite the huge number of fatal accidents. Just type in a search engine: “explosion” moonshine still” to think seriously about this problem.

Theory

An alcohol-containing liquid is boiling in a cube. If the steam outlet is blocked, pressure will begin to build. At the same time, the boiling point of the liquid will increase. Energy generously pours into the cube and accumulates every second, but this process is not endless. Sooner or later, mechanical depressurization of the cube will occur. For example, a clamp will break and the lid will shoot into the ceiling. If it all ended there, then there would be nothing to discuss. Easy repair kitchens, replacing a chandelier - everyday matters.

However, after depressurization, the pressure in the cube drops sharply, as a result, all the accumulated energy is released and leads to a sharp, explosive boiling of the entire volume of the bulk (alcohol-containing liquid in the cube). The resulting alcohol vapor flies out of the cube, simultaneously taking with it a fair share of the bulk.

Danger in numbers

For example, there were 40 liters of raw alcohol in the cube; the excess pressure that blew the lid off was only 0.5 atmospheres, which is close to reality. As a result, approximately 10 liters of boiling raw alcohol will fly out of the cube and flood everything around, scalding people and pets. Approximately another 10 liters will turn into steam and instantly form an explosive concentration of alcohol vapor in the room. If the moonshiner is a poor student who neglects basic skills and worked on an open fire, the explosion will be immediate.

If the distiller was smart and worked on closed heat sources, for example, heating elements, but got confused and decided to quickly pull the plug out of the socket or simply flip the switch - an explosion will occur immediately after this from a small spark that jumped when the contacts were opened.

Well, if the owner was not in the kitchen at that moment and his not scalded body retained the ability to think, then he would slowly and carefully open all the windows, create a draft and, perhaps, avoid more severe consequences.

The consequences of a volumetric explosion are very impressive - this is a wall to the neighbors, flying across the road balcony block. There are other miracles. When nothing happens directly in the kitchen, but an explosive mixture ignites from a spark in next room and destruction will occur there.

A bleed valve is needed to prevent this scenario. Alcohol vapor is not a gas; when released, it will not accumulate to an explosive concentration. Once in the air, alcohol vapor immediately begins to condense and settle on walls, windows, and floors. Fly into the hood or window. It will stink, warning the owner about non-standard situation. The likelihood of an explosion becomes much less, although this does not protect against fire.

As statistics show, large diameters of columns do not at all relieve their owners from the risks of working with fire and explosive liquids. This is the specificity of our hobby.

Safety valve parameters

The main danger when distilling moonshine is not the mechanical destruction of the apparatus parts itself, but the creation of an explosive concentration of alcohol vapor due to a sudden depressurization of the cube.

In practice, this determines the requirements for the safety valve.

During the second distillation, the pressure in the cube is 500 mm of water. Art. is considered an emergency, because it indicates flooding of the column. But should it be prevented with a bleed valve? Definitely not.

If the valve bleeds at 400 mm water. Art., then on the one hand the column will not sink, but on the other hand we will simply get an imitation of it normal operation. As soon as the valve is activated, the reflux will fall down, disrupting the careful separation of fractions. As a result, the output will be ordinary fortified moonshine, and not a distillate purified from impurities. The valve must not interfere or contradict technological processes flowing in the apparatus.

Let's take another example. When the pressure in the cube increases, the thermometer may shoot out and depressurization will occur - well, good, again it bleeds off excess without the threat of explosion. There is no need to install a valve to prevent this event; it should be treated as a backup system.

But if the lid of a saucepan or pressure cooker rips off, the exhaust will be instantaneous. Clamps, depending on the quality of workmanship, can fly off even at a pressure of 1 atm. This is already a subject of control. In addition, as shown above, depressurization even at an excess pressure of 0.5 atm. can create an explosive concentration of vapors in the room. Here's another point.

Conclusion: in order not to interfere with the settings of the column, the safety valve must operate at a pressure not less than double the emergency pressure - 1000 mm of water. Art. = 70 mmHg Art. = 9.8 kPa = 0.1 bar. The closer its operation is to 0.5 bar, the more severe the consequences will be in case of failure. That's all the logic.

Safety valves from different manufacturers

Let's start with the most illiterate and have no idea about the parameters of the processes in the device. Such manufacturers install burst valves from pressure cookers on their cubes. Note - not bleeders, but disruptive ones or, in other words, emergency ones.

Pressure cooker valve

Pressure cooker valve This cheap valve actually operates at a pressure of 1.2 to 1.5 atm. - the line of last hope for a pressure cooker. It is clear that for the purposes of distillation and rectification it is useless, since a broken clamp and an explosion are possible up to the threshold of its operation.

A working pressure cooker bleeder valve looks like this; it should not be confused with an emergency one.

Bleed valve

Bleed valve The working valve in the pressure cooker maintains an excess pressure of 80-110 kPa (0.8-1.1 atm.). The safety valve is activated when a pressure forms inside the pressure cooker that exceeds the operating pressure by 50 kPa (i.e. at 1.6 atm), which can occur if the operating valve is clogged. Activation of the safety valve allows steam to escape from the pressure cooker and makes it safe to use. But not in our case. Its characteristics are, of course, closer to the required range, but not that much.

You can try to remake the emergency valve. To do this, you need to disassemble it, throw away the spring and the red ball. In place of the ball, install a weight weighing about 36 grams. This will reduce the response threshold to 700-1000 mm of water. Art., but even this alteration does not guarantee normal operation of the valve. The stem easily warps and the valve does not close, and after a dozen operations, the design, not intended for this mode, easily becomes dirty in the area of the silicone o-ring and ceases to be airtight. As a temporary solution to the situation, this alteration has the right to life, but not for permanent use.

The use of safety valves from heating systems and other water heating equipment faces the problem of the inability to adjust the response pressure to the required value.

Safety valve for heating system

Safety valve for heating system As a rule, for these systems pressure above 1.5-8 bar (150-800 kPa) is considered emergency. For moonshine, these are completely prohibitive values. The principle of their operation is simple, but even replacing the springs with less rigid ones often does not give desired result, since the valve simply stops pressing tightly against the seat.

Therefore, thinking equipment manufacturers were forced to develop their own valves that operate at a pressure of about 900-1000 mm of water. Art. (70 mmHg).

Option for the correct safety valve

Option for the correct safety valve  Option for the correct safety valve

Option for the correct safety valve These are fairly simple valves with a low cost of about 350 rubles with spare membranes costing 40 rubles. They are installed on a standard fitting with a ½” thread.

How to make a safety valve for a moonshine still with your own hands

Let's take a closer look at the valve design.

Safety valve design

Safety valve design Take an old hose from a shower or flexible hose and remove the nuts from it. We complete with a fluoroplastic gasket and a silicone gasket. The gasket can be taken from a beer cap. All that remains is to collect everything. True, it will differ from the original in that it has a washer with a groove for the membrane. The thickness of the membrane is 1 mm, and the grooves are 1.3 mm; with careful installation it will work.

There is another one that is quite simple and functional system preventing problems associated with excess pressure. The idea is simple: a tube is put on the drain fitting, allowing you to fill (1) or drain (3) stillage. During the distillation process (2), this tube is placed 600-800 mm above the cube and discharged into the sink. The height of the bend of the tube above the stillage level determines the excess pressure in mm of water. Art., after which the liquid will begin to flow into the sink. Naturally, the drain valve must be open.

Overpressure prevention system

Overpressure prevention system Simple, reliable and allows for many modifications.

These are inexpensive and not complex devices allow you to avoid serious risks when brewing moonshine. Don't neglect their use.