How to choose a water pressure booster pump. Pump to increase water pressure - how to increase the pressure in the water supply? Purpose and features of use

Read also

Reading time: 7 minutes.

Quite often, the subject of complaints from residents of any private or multi-storey building is low water pressure in the network or simply its absence. The best solution to this common problem is a booster pump.

This device stabilizes the pressure in the system and makes it possible to provide acceptable living conditions, because without it it is impossible to imagine the functioning of either a shower cabin or a shower.

Basic information

Over time, the old standard underwater pipelines lose their capacity and, as a result, they no longer provide the required level of water pressure to residential buildings. By the way, a booster pump or a pump to increase water pressure will be necessary in such a situation; they are suitable for both cold and hot water supply systems.

The equipment compensates for the lack of pressure so that household appliances can work normally. For example, a dishwasher/washing machine “pulls” at least 2 atm; a shower stall requires at least 4 atm. Domestic water supply does not supply required value, often you won’t get even 1.5 atm. (minimum pressure).

Most often, they use designs that operate in manual (manual pumping pump) or automatic mode. The manual pumping pump provides for the operation of constantly switched on pumping equipment. Automatic is preferable and more economical, since it protects the mechanism from operating in the absence of water and increases service life. He is responsible for operating the pump using a water flow sensor.

Pumping units are installed in private houses, apartments, haciendas, and cottages. The main condition for their uninterrupted operation and reliable operation is correct connection water and electrical systems.

Operating principle of pumping devices, main parameters

Key parameters to pay attention to:

- switching mode – automatic/manual;

- degree of pressure;

- size. As a rule, all units are compact, which simplifies their connection to the main pipeline;

- noise level. Thanks to the principle of operation, booster pumps operate almost silently, which allows them to be installed in apartments;

- body material is an important parameter, which determines the level of noise emitted during operation, and Maximum temperature water. Stainless steel is a material that provides corrosion resistance and strength.

The principle of operation of water booster pumps is that the equipment system increases the pressure in the water supply network, depending on the pressure in the water circuit. The mechanism takes liquid from a pipe with low pressure, then increases it to the required value, and then delivers it to the flow point.

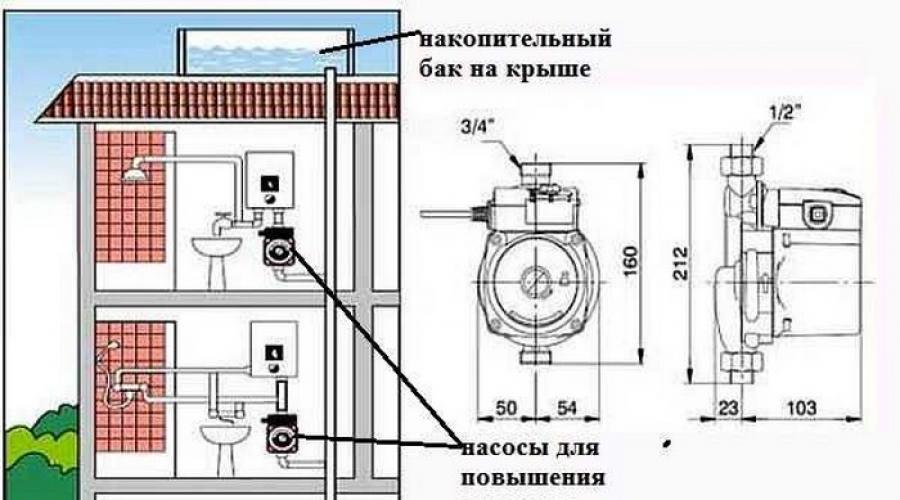

If you are a resident of an apartment located on upper floors, and centralized water supply “suffers”, better advantage give it to a device with a hydraulic accumulator (storage tank) - a pumping station. This is a unit that creates pressure in front of water collection points, equipped with control devices and shut-off valves. The devices are used as large backup units for industrial and domestic purposes. Mounted between the water source and the water supply.

Advantages and purpose of booster pumps

Water pumps are used to increase the water pressure in front of the points where water is collected. In other words, a booster pump is used in cases where the water pressure in a residential area is lower than desired. To do this, the device is connected to central system water supply

In the industrial field, booster pumps are also used, but the dimensions of such installations at enterprises are much larger than the dimensions of products designed to increase pressure in domestic conditions. At the same time, the booster pump in industry is often used only in cases of emergency situations, for example, when there is a need for fire extinguishing.

The advantages of such units include:

- compactness;

- low noise level during operation;

- the ability to pump water with high power;

- relatively cheap cost;

- reliability.

Characteristics and types

This type of equipment is divided according to the type of design, and therefore, devices with different designs may differ significantly from each other. In particular, according to the type of device, pumps that increase pressure can be in the form of self-priming pumping stations, or made in the form of circulation products that increase the pressure level in the pipeline.

Self-priming units consist of a hydraulic accumulator and surface pump, which has the function of sucking liquid. Such equipment is capable of lifting liquid, including in cases where it does not reach the floor on which you live. The water accumulator performs the function of regulating the pressure level in the water supply system. This is achieved through check valves and an air membrane with which the device is equipped. Pressure regulation is carried out using a relay installed in the battery, which, in particular, is responsible for automating the entire process.

Consume more electricity than circulation pumps. The minimum consumption of such a unit starts from 2 kW per hour, but this indicator pays off with the power they have. So, for example, with a consumption of two kilowatts per hour, the pump is capable of lifting water from a depth of 12 meters, doing it efficiently and quickly. The cost of such devices is often lower than circulation pumps.

Circulation units are divided into those that operate with cold water and those that pump hot liquid. For pumping cold water simple modifications are made, made of inexpensive plastic. They cannot withstand prolonged contact with hot water and can pump liquid with temperatures up to +40 degrees.

Models designed to work with hot liquid are most often used for installation in hot water supply or heating systems. Such products are made from more expensive metals, for example, from of stainless steel and high quality rubber gaskets.

Circulation devices consume several times less electricity than self-priming pumping stations, however, their power is correspondingly much lower. They require no more electricity in most cases than a light bulb. Circulation pumps increase pressure by 2-4 atmospheres and can pump around 2-4 cubic meters liquids per hour. However, some models are equipped with more powerful engines, and therefore their performance indicators may be higher.

Such pumps are called circulation pumps because they promote the formation of circulation in water supply systems. Such products have small sizes and are very compact. To install them, they are cut into certain sections of the pipeline.

Selecting a booster device and installing it

When choosing pumping equipment for your apartment, it is recommended to proceed from specific parameters and the characteristics that a pump must have to meet your needs. Before purchasing a device, it wouldn’t hurt to seek advice from professionals, as well as consult with someone who already uses similar equipment.

The first thing to do is measure the existing pressure level, which will help you understand what power a future purchase should have. This is important, since you can buy, for example, the most powerful pump, and it will naturally increase the pressure in your pipes, but it may be enough to purchase a product with less power, which will also cope with its task, but at the same time you will not overpay for the device itself, not for the electricity it will consume.

Installing and connecting pumping equipment is not an overly complicated process that requires special knowledge, skills or tools. In most cases, it is enough just to embed the pump into a pipe that is located at the entrance to the water supply system. Circulation products are cut into a certain section of the pipe, then they are well sealed and tightly screwed. When installing circulation modifications, it is important to install the pump in the correct position, which should be indicated by the manufacturer on the packaging or in the instructions for the device.

Suction pumps are more difficult to connect, since for installation you must first assemble the device itself, as well as run incoming and outgoing hoses to it, and then connect the hydraulic accumulator to the unit. In this case, pumping stations, as well as circulation pumps, crash into the water supply system. All these procedures require high-quality settings, which can only be guaranteed by experienced people. However, some confident users connect the pumping station themselves.

Installation of a pump in an apartment that increases water pressure GPD 15-9A (video)

Water pressure booster pump designed to increase water pressure in an autonomous or centralized water supply to the optimal value. The pressure booster pump can be used equally successfully both in private homes and in multi-storey residential buildings.

IN last decades We are all accustomed to a high level of comfort in our homes. Therefore, when there are interruptions or problems in the water supply, it can seriously upset us. And situations when the water in the tap does not have the right pressure, happen, unfortunately, quite often.

Principle of operation

Standard pressure values in household water supply are 4 atmospheres. This is quite enough not only to ensure good water pressure from the tap, but also for the normal functioning of modern household appliances and plumbing equipment. For example, dishwasher and washing machine will not work at a system pressure of less than 2 atmospheres. And in order to use a jacuzzi or take a shower with hydromassage, you will need even more - 3-4 atmospheres.

Considering the deterioration of pipes and equipment centralized system water supply and not always professional installation autonomous supply of water to private houses, it is not surprising that very often the water pressure in the pipeline is insufficient.

What to do in such a situation? Is it really possible to forget about the usual level of comfort and not use modern household appliances? Of course not! Installation can correct the situation pressure booster pump. Today there are quite a large number of such products on the market.

Which pressure booster pump is better?

This unit consists of a pump and a hydraulic accumulator. A pressure switch is responsible for constant pressure in the water supply. Significant disadvantage such equipment is high level noise, so the station is usually installed in utility rooms.

Title=" echo $pagekey;?>" style="float:right; margin:7px 0 7px 7px;">!}

Booster pumps are another type of pump for increasing water pressure in the water supply in case of poor water pressure. This problem is faced by both owners of private houses and apartment owners. The booster is mounted in the pipeline route and put into operation plumbing system significantly increase blood pressure. Thus creating the level of comfort we need. In most cases, such a pump is used in industry or in the housing and communal services system.

Title=" echo $pagekey;?>" style="float:left; margin: 7px 7px 7px 0;">!}

The recirculation pump for increasing the water pressure in the apartment is of the “boost” type. Unlike booster and circulation pumps, such pumps are used in systems hot water, made of more wear-resistant materials and designed for high fluid temperatures.

Along with low pressure in the pipeline, owners of private houses have a need to ensure comfortable temperature in the house. To solve this problem, a pump has been developed to increase the pressure of hot water in the house.

Installing a booster pump itself is not that difficult. In order to do everything correctly, you need to have some plumbing skills - be able to cut pipes and make threads.

Before you begin installation, in order for the equipment to work without breakdowns, pay attention to a few tips:

To make the pump work longer, it is advisable to install a mechanical filter at the inlet. Pipe system mostly old with long-term deposits on internal walls, so if a piece of hard deposit accidentally comes off the pipe and gets into the new pump, it may jam or cause failure.

Install the pump in a dry, heated room. If the temperature drops below zero, the water inside will freeze and this will cause damage to the electric motor.

If possible, try to install the pump on a bypass to the main line, cut off by valves, so that in the event of a breakdown you will not be left completely without water.

The pressure booster pump is connected in the following order:  1.

Turn off the water.

1.

Turn off the water.

2.

On the pipe on which the pump will be mounted, make markings in accordance with the length of the pump and adapters.

3.

Cut the pipe according to the markings.

4.

Cut external threads on both ends of the pipe.

5.

Mount adapters with internal threads to the pipes.

6.

Screw the fittings that should come with the pump into the adapters. During the installation process, make sure that the pump will be installed in the correct position according to the arrows on the body.

7.

Run a three-wire cable to the pump from the electrical panel.

8.

Carry out a test run of the pump, paying attention Special attention There should be no leaks at all joints. For high-quality sealing wrap FUM tape or tow on the thread.

Automatic water pressure booster pump

All modern models In most cases, pumps for increasing water pressure are equipped with at least 2 operating modes: manual and automatic.

At permanent job The pressure in the water pump can rise to very high large values, if it is not stopped in time. In this case, problems with the pipeline may arise, because some pipe connections are designed for a certain pressure. Based on this, more and more homeowners are trying to install automatic pump increasing water pressure.

The essence of automation is that the pump has a special water flow sensor and a power supply regulator to the pump. After the pressure in the system rises to a predetermined level, the sensor records this information and sends a signal to the power regulator.

The power regulator compares the information from the sensor and the user's specified information; if it matches, it stops supplying power to the pump, the pump stops, and the increase in pressure in the system stops.

If the pressure starts to drop again, the sensor sends a signal again and the regulator starts the pump to equalize the pressure. This principle of automation is used both in everyday life and on production lines.

Where to buy a pump to increase water pressure

In order for the pump to work for a very long time and cope with the assigned tasks, it must be made by a reliable manufacturer.

Grundfos UPA 15-90 pressure booster pump.

The pump has compact dimensions and light weight, which makes it easy to mount it on a pipeline to an apartment. This unit is designed to work in cold and hot water. Equipped with protection against overheating and dry running. The pump has 3 operating modes: non-working (water circulates in the system on its own), forced (the device operates constantly and the dry-running protection is not activated), automatic (the pump turns on automatically when high consumption water from 90 to 120 l/h).

Wilo PB-088 EA pressure booster pump.

Small electric pump for installation on a pipeline. Capable of pumping both cold and hot water. Is different low level noise. Equipped with a flow sensor that turns on the unit when water is consumed and turns off when it stops. Capable of operating in two modes: automatic and manual, has protection against overheating and dry running.

Grundfos pump pressure boosting systems are represented by a wide range of models, including:

C.M.B.– automatic pressure booster installation for private houses, gardens or gardens

MQ– more compact system water supply for domestic, agricultural or horticultural purposes.

Moving on to pumping stations, one of the most popular is Gilex.

Has deserved popularity automatic station Gilex Jumbo 70/50. Its power is 1100 W, and its productivity reaches 70 l/min. The volume of the hydraulic accumulator is 24 liters. The station is equipped with an ejector. This makes it possible to increase the suction depth to 9 m. The stainless steel tank is not subject to corrosion.

You can view all the options for such equipment and buy the one you like and is suitable for you in our catalog.

Good equipment usually costs more; if you’re going to spend your money, then firstly on high-quality equipment, and secondly on the best option available on the market.

Comparison of booster and re circulation pump to increase water pressure in the apartment

Booster and recirculation pumps differ fundamentally in parameters and scope of application.

Flow (feed). The pump flow rate shows how much liquid the pump is capable of moving per unit of time, for example liters per hour. Booster pumps are designed to operate in a cold water pipeline and provide water to all consumers, such as sinks and sinks, washing machines, dishwashers, bathrooms, etc. The flow rate of booster pumps can reach 6 m3 per hour. Recirculation pumps mainly pump hot water through a boiler; the flow rate of such a pump is about 1 m3 per hour.

Pressure The pressure shows how high the pump can lift a column of water. Based on the principle described above, a booster pump may need to lift water from the basement to the third floor of your home. The pressure of the booster pump can reach up to 30 meters. The pressure of the recirculation pump is not so high and in many models is limited to 2 meters.

pressure. Both booster and recirculation pumps are designed to work in the piping systems of apartments, private houses or cottages. The operating pressure of both types of pumps is 10 atm

Temperature of the working environment. Booster pumps are designed to increase the pressure in cold water pipelines. The operating temperature at which the pump is capable of pumping water is limited to 35 - 40 degrees Celsius. Recirculation pumps are capable of pumping water with temperatures up to 95 degrees Celsius. The main area of application of recirculation pumps is to ensure the circulation of hot water through a boiler in houses and cottages.

body material. The material of the pump housing also depends on the temperature. The booster pump operates in a low temperature range; the body of such a pump is made of cast iron or stainless steel. Recirculation pumps pump water high temperature, the housings of such pumps are made of brass.

installation length and connection diameter. Both types of pumps are designed for installation in a pipeline. The installation length, depending on the model, ranges from 80 to 160 millimeters. Threaded mounting sleeves are located on the suction and discharge pipes of the pump. Depending on the model, this may be a 1/2, 3/4 or 1 1/4 inch thread. Our catalog contains models of recirculation and booster pumps in any design.

Ecology of consumption. Estate: The lack of sufficient water pressure in the system is, of course, not a disaster, but there is little pleasant in such a situation. If you can't wash the dishes or take a shower, then household appliances, such as a washing machine or dishwasher, may simply refuse to work. Fortunately, to solve this kind of problem, pumps have been invented to increase water pressure.

The lack of sufficient water pressure in the system is, of course, not a disaster, but there is little pleasant in such a situation. If you can't wash the dishes or take a shower, then household appliances, such as a washing machine or dishwasher, may simply refuse to work. Fortunately, to solve this kind of problem, pumps have been invented to increase water pressure.

How it works

problem low pressure in the water supply system are solved using two types of devices: circulating and self-priming pumps. The first ones are simpler and easier to install into the system. A conventional circulation pump consists of a rotor, an impeller attached to it and a motor that rotates it all. Usually, if there is water in the system, but its pressure is weak, one or two pumps are enough.

The problem of increasing pressure in the water supply system is solved in two ways: by installing a circulation or centrifugal self-priming pump

But if water does not flow to the upper floors at all, you will have to install a high-power pumping station with a hydraulic tank. Such a device is simply installed as part of the plumbing system in a suitable location. The impeller rotates, giving the water flow additional acceleration.

As a result, the pipes fill with water faster, providing the required level of pressure in the water supply. These are compact devices low power designed to solve local problems. Suction pumps have higher performance and a more complex design.

In addition to a suction pump capable of pumping water to a considerable height, the system is also equipped with a hydraulic accumulator equipped with a special membrane. The operation of this equipment is automated; a pressure switch is used. Water is first supplied to the storage tank and then enters the water supply, providing the necessary characteristics within the system.

Thus, if a centrifugal pump eliminates a problem in a particular area, then suction equipment is used to regulate the entire water supply in a house or apartment. Self-priming booster pumps are capable of lifting liquid to a height of up to 12 m, while their power starts from 2 kW/h.

The pressure boosting pump works as follows. When the water flow reaches 1.5 cubic meters, the motion sensor petal changes position. This causes the pump to turn on automatically. When the water flow stops, the pump turns off. This type of equipment is used both in private cottages and in apartment buildings.

It is especially relevant in high-rise residential buildings, where normal water delivery to the upper floors can be ensured without a special pump. various reasons impossible. Installation of one pump or even a special station with increased power can be a real salvation for residents of the upper floors.

Sometimes you have to use not one booster pump, but two or more. Owners of houses in which the plumbing system was initially designed with errors sometimes face this need. In this case, you will have to calculate the cost of reworking the water supply (if such a possibility exists at all) and the cost of installing additional equipment.

A small pumping station installed in front of household appliances will ensure a normal water supply

It should be remembered that it is intended for pumping hot water. special types technology. They are made of special heat-resistant materials, so they cost more than more simple models, designed for contact only with cold water. There are also universal booster pumps that are suitable for both cold and hot water.

The power of a conventional circulation pump is low and it consumes less energy than some incandescent lamps. When it is included in the system, you can achieve an increase in pressure by about 2-3 atmospheres. If a more serious correction of characteristics is required, preference should be given to more powerful equipment.

Circulation pumps have the property of working “at a dead end”, i.e. they do not need to be turned off even if all the taps are closed and no water is drawn from the system. Supply pumps function in approximately the same way to increase water pressure. These devices are similar in design to circulation models.

If such a pump is turned off, water will circulate freely through its body. As soon as power is supplied to the motor, the pump turns on. The impeller begins to rotate and the water pressure in the system increases. If there is a choice between automatic or manual systems, the former is usually preferred.

Comparing the diagram of a water supply system with and without a booster pump allows you to more accurately imagine the installation procedure for such equipment

This type of equipment is more convenient to use and lasts longer because it does not run idle. Take the pump to manual control makes sense only in cases where it will be used either for a very short time ( temporary option), or extremely rarely (in the summer, at the dacha, only on weekends).

The diagram clearly shows the design of a wet rotor pump. Water flows around the moving parts of the pump and absorbs excess heat.

The concept of dry and wet rotor refers to information about the device's cooling system. In the first case, it is cooled by a flow of air, and in the second, by a flow of pumped water. A wet rotor pump is cheaper, but lasts less due to negative impact sediment that accumulates on working parts during pumping of water. Models with a dry rotor cope with their tasks more efficiently and have a longer service life.

Pump power and system needs

The power of the device must be commensurate with the needs of the system. Not enough pressure is bad, but you don't want too much pressure either. If a pump that is too efficient is selected for the water supply system, the pressure in the system will increase and all its elements will be subjected to unnecessary additional load. This leads to rapid wear and frequent breakdowns.

The water pressure in the system must be no less than two atmospheres. This is enough for comfortable water procedures, as well as for starting an automatic washing machine. Although some models are more demanding in terms of operating conditions. For example, if the house has a shower, hydromassage, jacuzzi or other similar devices, the pressure should be higher.

In this case, it is better to increase the pressure in the water supply system to 5-6 atmospheres. Selected species techniques require even higher performance. Therefore, the first step before installing a pressure booster pump should be to study the documentation of household appliances. If you plan to purchase any devices in the future, their characteristics also need to be taken into account.

To create a permanent high pressure The system uses special pumping stations, including a pump and a hydraulic tank. Their operation is controlled using a pressure switch

A specialist can make accurate calculations, but usually preliminary data made “by eye” is sufficient. To determine how much pressure actually exists in the system, you can use a regular liter jar. They open the water and measure how many liters of water pour out of the tap within a minute.

Then you need to deal with your current needs. If the inconvenience is due to the fact that when the tap in the kitchen is open it is difficult to take a shower due to low pressure, it is enough to use a regular pump, which will increase the pressure by a couple of atmospheres. But if the house has an automatic washing machine, shower cabin or other equipment of this kind, you should study the technical documentation.

Each such consumer requires a certain water pressure. Lack of sufficient pressure can lead to expensive equipment running idle. Household appliances, especially foreign ones, are not designed for such operating conditions. A breakdown caused by a lack of normal pressure may be considered a case that does not comply with the warranty conditions.

You can focus on maximum performance by pressure in the water supply system, indicated in the device data sheets. In the presence of large quantity For such equipment, you should seek advice from an engineer. When choosing a water pump model suitable for power to increase pressure, you should also take into account the needs of equipment that you plan to purchase in the future.

How to install a self-priming pump

Installation of this type of pump is no different increased complexity. To do this, you will need approximately the same skills and tools that are needed to install other types of pumping equipment. Schematically, the installation of a booster pump can be represented in the following steps:

- Choosing a location for the accumulator and pump.

- Installation of a hydraulic accumulator.

- Installation of pipes for connecting equipment to the water supply.

- Hanging the pump from the wall.

- Pump and accumulator piping.

- Checking the operation of equipment in automatic mode.

In fact, a pump and accumulator with a pressure switch is a variation of a pumping station. To implement the installation of such a system of devices, you first need to find a place to place the tank. Some craftsmen replace the hydraulic accumulator with a membrane with an ordinary large capacity, for example, a 200-liter plastic tank.

Instead of a pressure switch, the tank is equipped with a float switch to ensure that it automatically fills as needed. Such a tank is installed as high as possible: in the attic or on the top floor. You should immediately think not only about the size, but also about the configuration of the container.

A flat and narrow tank will take less space than the traditional cylindrical model. Although special requirements There is no capacity for configuration. When choosing a location for a container, you should provide access to the tank/hydraulic accumulator or the ability to easily dismantle this element. This is necessary to complete Maintenance, repair or replacement of the device.

The photo shows the installation of check valves during installation plastic tank, as well as the procedure for connecting the inlet and outlet pipes to the water pipe

Hydraulic accumulators are supplied ready for installation, but the tank should be prepared. There are holes in it for water inflow and intake. You can also make a separate one shut-off valve to drain water in an emergency. The pipes for supplying water to the tank and taking it into the water supply system are mounted to one water pipe.

IN modern conditions For the installation of water supply, it is more logical to use easy-to-install and reliable plastic pipes. To prevent air from being sucked into the tank from the pump, and also to prevent water from entering there when the equipment is turned off, both pipes should be equipped with check valves. After this, pipes are installed to connect the tank to the water supply system.

Circulation pumps take up minimal space and do not interfere with the maintenance of household appliances

Once the tank or accumulator has been installed and the necessary water pipes have been laid, you can begin installing the suction pump. Typically, such a device is supplied disassembled. It is first assembled and then installation begins.

If you decide to mount the pump on the wall, you should first make markings for the fasteners. The pump is then suspended and connected to the water supply pipes. Overall, this is not a very complicated operation. Important point- direction of fluid in the pump. It is indicated on the body with special marks.

The pump should be installed in such a way that the water flows from the tank to the water collection points. Thus, the installation and connection diagram for the pressure booster pump is as follows: hydraulic accumulator-pump-consumer. Then the pump is connected.

All connections must be carefully sealed. If you use a booster pump to connect threaded connections, you should use a suitable sealant: FUM tape, linen thread, etc. The amount of sealant should be sufficient, but not excessive. TO plastic pipes the device is connected using special fittings.

After this, you should check the operation of the entire system. If a tank with a float sensor was used, fill it with water. They check not only the operation of the sensor. A container that serves storage tank, should be checked for leaks. If everything is in order, you can proceed to testing the operation of the pump itself.

The pump must be connected to electrical network. It is recommended to move the pump switch lever to the position corresponding to automatic mode. All that remains is to open the nearest water tap and observe the operation of the device. If the installation is done correctly, the pump should automatically turn on and the water pressure will increase noticeably.

Pressure boosting circulation pumps are installed in a similar manner. They choose for them appropriate place in the water supply, and they cut it there. In this case, it is also extremely important to connect the pump correctly, taking into account the direction of fluid flow. If the position of the device is incorrect, the pump will still allow a flow of water.

Connection diagram of the circulation pump to the water supply system. Installation of such a device is very simple, but it is important not to confuse the direction of water flow

But its work will be extremely ineffective, since the device simply will not function. It is detailed in the instructions and on the case correct position pump After installation, the pump is connected to the electrical network and its operation is checked. If the water pressure at the nearest water intake point has increased, it means that the installation was completed correctly.

A small pump to increase pressure is simply cut into the system. Usually, to do this, it is enough to remove a piece of pipe of the appropriate length at the beginning of the water supply

Installing a system with a hydraulic accumulator looks a little more complicated. First you need to understand the structure of the entire structure. The pump is connected to the hydraulic accumulator using special hoses. Then a pressure switch is connected, with which the equipment will be turned on and off.

This figure shows in detail the principle of operation of a pump with a hydraulic accumulator and the procedure for connecting it. The pump fills the tank and then turns off

The configuration of such a relay deserves special attention. Before starting work, it is recommended to carefully study the instructions and recommendations of the manufacturer. If knowledge and skills for high-quality installation and setting up the equipment is not enough, it is better to contact a specialist for advice or completely entrust him with all the work.

To solve a problem with low water pressure in a system, a booster pump is not always necessary. To begin with, it doesn’t hurt to diagnose the condition of the water pipes. Cleaning them or complete replacement can restore normal pressure without additional equipment.

To understand that the problem is in the poor condition of the water pipes, sometimes it is enough to ask neighbors living in apartments on the same floor or above. If their pressure is normal, the pipes almost certainly need to be cleaned. If the picture is the same for everyone, perhaps there are more serious problems concerning the entire water supply system of the house and even the area.

IN high-rise buildings Sometimes water simply does not reach the upper floors. This requires high-power and quite expensive equipment. It makes sense to team up with other residents to share the costs. Good idea- demand a solution to the problem from the organization that receives payment for water supply, since it is the organization that must ensure the supply of water to the consumer.

Lack of water on the upper floors is a violation of the requirements fire safety. When communicating with a water supply service provider, it is worth paying attention to this point and mentioning the possibility of legal proceedings due to non-compliance with legal regulations.

It is best to entrust the installation of equipment in an apartment building to a full-time plumber of the management company. He's with the system too better acquainted, and will be responsible in case of leaks or breakdowns caused by poor installation of equipment.

Video about booster pumps

Clearly the operation of a booster pump in an apartment multi-storey building presented in the following video:

The benefits of any apartment buildings are effectively operating communication systems, which include plumbing. The operation of household appliances, for example, a boiler, washing or washing machine, depends on the quality of its functioning. dishwasher. Helps in some situations installed pump to increase water pressure. It pumps the required level into the system, providing a continuous powerful flow.

A booster pump will be the optimal solution for the local level. It is installed within the apartment and is designed to serve one household. The installation of such equipment will be effective if the problem lies solely in insufficient pressure, but all the pipes are not clogged and the rest of the supply system is fully operational.

The need for arrangement

Pumps to increase water pressure are being introduced into the home hydraulic system often on the upper floors. There, the established norm often reaches the planned values. The optimal value is 5 bar. However, in reality the value in the pipeline sometimes drops to the level of 1 bar.

Such parameters are unacceptable, since in this situation automatic washing machines, which require at least 2 atm. You can only take a shower in the shower stall at 3 atm. Approximately 2-2.5 atm is required to start the boiler. The Jacuzzi will be in working condition at 3-4 atm.

Operational parameters of connected equipment

Before connecting, you need to understand what characteristics booster water pumps have. They differ in the way they start:

- User launch option. The hydraulic device is stably turned on/off by the owner. It is enough for owners to control the presence of liquid in the system, since operation without water leads to rapid failure from overheating. Often a feature of the operation of such circuits is one-time operations followed by shutdown.

- Models for pumping water with automation installed in the system, thanks to special sensors, are connected independently as needed.

When choosing equipment, you should pay attention to the ability to transport a flow of a certain temperature. Design features manifest themselves in the ability to pass water in a limited temperature regime. In specialized retail outlets or on online store websites you can find the following types of devices:

- units capable of working exclusively with cold systems;

- models designed for inclusion in hot flow distribution;

- universal equipment designed to interface with any liquid temperature.

A well-functioning pump, which should not overheat significantly during operation, helps maintain a stable pressure level.

Cooling systems help get rid of overheating.

According to this type, productive models are divided into the following groups:

- The temperature decreases due to the flow passing through the housing. This technique called the “wet rotor” method. She has minimum parameters in terms of noise, but can overheat when working without water.

- For cooling, rotating blades fixed on a shaft are used. The method is called a “dry rotor”. The disadvantage is increased noise at work. The disadvantages are compensated enough high degree performance of a water pressure pump.

Implementation of boost stations

For apartment owners on the upper levels, it is advisable to install a pumping station. Self-priming technology includes the following elements in the circuit:

- hydraulic pump;

- pressure gauge;

- relay;

- hydraulic accumulator.

The principle of operation of the unit is to pre-fill the hydraulic accumulator, independently set the desired output pressure using a relay and start the pump, which ensures the distribution of liquid to consumers.

Some schemes propose eliminating the hydraulic accumulator; however, this approach will negatively affect the service life of the entire pressure unit. It is advisable to choose a larger tank that will fit into the interior of an apartment or house, as this will allow you to turn on the pumping system less often.

After the volume is pumped into the tank cavity, a shutdown occurs. In this case, the consumer receives a stream from the hydraulic accumulator even in a situation where there is no water supply to the system in this moment. If the liquid completely leaves the tank, the relay will automatically turn on pumping.

Before purchasing a station, it is recommended to check its maximum pressure. You can use popular model Grundfos JP Booster 6-24L, which will provide a head of 48 m and has a considerable tank with a capacity of 24 liters. Its cost is approximately 24 thousand rubles.

How to choose the right pump to increase water pressure

When choosing a suitable pressure booster pump, there are important factors to consider:

- Power characteristics. The more productive the unit is, the wider the number of points it can effectively serve. In calculations it is necessary to monitor the number of consumers, washing machines and plumbing fixtures.

- Noisy. Of course, less noisy devices are preferable, but they may be more expensive.

- Patency. It is important to pay attention to what diameter of water pipes the pump can be combined with. Working sections are specified in the user instructions. Failure to comply with this parameter can lead to work with overloads, breakdowns and a decrease in pressure below the calculated value.

Electrical device design

- Lifting height. When purchasing a pumping station with a lower load, it may not reach the required level.

- Equipment dimensions. The hydraulic unit must fit neatly into the allotted space.

- Reliability. It is preferable to choose proven, well-known brands that have a long warranty period.

VIDEO: What is the difference between a vortex pump and a centrifugal pump

The main selection criterion is the outlet pressure, which should not be less than 4 barrels. Next, they are determined directly with the characteristics of the electrical appliance - dimensions, noise level when turned on, wet or dry, etc. Because the we're talking about about a high-pressure pump, for many it will be a fundamental point - manual or automatic control.

Pump equipment for hot water supply differs from that installed in a cold water system.

In most cases, when choosing, they give preference famous brands. Having overpaid, relatively speaking, specifically for the brand, the user receives high-quality working equipment and warranty obligations, which the seller or manufacturer will certainly fulfill.

Among the priority companies:

WILO- leader in consumer demand according to reviews and store statistics. Considered elementary in management, has worked for more than 7 years in extreme conditions and very reliable in operation.

Grundfos- in some regions even surpassed Vilo. The obvious advantages are silent operation and low weight. Warranty factory period is 12 months.

OASIS- easy to use, high-quality equipment, which is only aspiring to the TOP-10, but has not yet come close.

The leader of domestic production, although it does not enter the European market. All without exception are compact and low noise. The pipes for installation are standardized for Russian water utility systems.

Connection diagram - right and wrong

Water pressure pumps on collectors operate non-stop. In order for the pressure to increase gradually (stepwise), a multi-wheel system is used. During operation, the device is capable of creating a pressure in the system of up to 10 bar.

The best pump models to increase water pressure

In order not to be mistaken with the desired result, choose well-known trade marks: Wilo, Grundfos or Jemix. They are widely represented in online internet stores and in traditional construction supermarkets.

Wilo PB-088EA

A small-sized model capable of working with water of different temperatures. Heat is removed by means of a jet passing inside. Equipped with a built-in flow sensor, which helps to start when liquid appears in the system. The hydraulic device has the ability to operate in both manual mode, and stratifies automatically.

The noise level is minimal. The outside is protected against corrosion. Dry running is blocked. Power is 90 W. The price is approximately 4 thousand rubles.

- Installation and operating instructions Wilo PB-088 EA

Grundfos UPA 15-90

Grundfos UPA 15-90

Compact dimensions allow you to install such a pump to increase water pressure in almost any convenient place. Can be used for any temperature conditions. Has protection against overheating and dry operation. Cooling type - water.

The device has three modes in which it can be turned off, started by hand or started in automatic mode when the flow drops to less than 100 l/h. Power - 120 W. Price - 2634 rubles.

- Installation and operating instructions Grundfos UPA 15-90

Jemix W15GR-15 A

The boost pump maintains the discharge at the set level. Demotion operating temperature created by a fan or dry rotor. The advantages are versatility and an affordable price tag, and the disadvantages are noise during operation. Power - 120 W. Price 3 thousand rubles.

- Installation and operating instructions Jemix W15GR-15 A

VIDEO: Why is it needed and how to assemble a storage tank

The purchase and installation of a booster pump for the water supply system will ensure stabilization of the water pressure in the system. Over time, old underwater pipelines (connections) lose capacity and no longer provide residential buildings with acceptable water pressure.

This makes it impossible to use several points of consumption at the same time. Installation of the device will ensure the functioning of household water appliances, creating conditions for acceptable living.

Application and installation of a water pump for pumping water to the central water supply

The booster pump is used when it is necessary to increase the pressure in existing water supply, connected to central water supply. It creates sufficient pressure in front of the water collection points.

Such devices are also used for industrial purposes in the form of large backup installations that work to mitigate situations associated with accidents.

The main parameter of the water supply system is the degree of water pressure in the system. Acceptable pressure in the pipe will allow the entire water supply system to operate. European standards prescribe its value to be 4-4.5 atmospheres. Less pressure will not ensure the operation of the washing machine and dishwasher, shower hydromassage cabin, jacuzzi, geyser.

For stable water pressure, designs operating in two modes are used:

- manual mode, which involves the operation of a constantly switched on pump;

- automatic mode, which ensures the operation of the pump using a water flow sensor. Such products are preferable. They are protected in the absence of water mode.

Water pumps are installed in apartments, private houses, country houses, cottages. The main condition for their reliable and proper operation– skillful connection of electrical and water systems according to the attached instructions.

Read also our article about and methods.

Old apartment buildings require pipe replacement. It would be the best option to increase pressure in apartments. But this process is long, labor-intensive, and therefore unpromising. Some residents solve the problem with water pressure by installing pipes of a smaller diameter, but this measure is expensive and not always effective. Installing a booster pump with a storage tank in the water supply system eliminates the problem.

Available wide choose a wide variety of devices, according to design features water supply in apartments. The industry produces products installed on a hot water riser. Such designs allow you to change the pressure in the pump using adjusting screws.

Some types of devices increase pressure when the hot water tap is opened directly. They are applicable when using household devices: showers and water heaters.

If there is insufficient water pressure in the house, minimal diagnostics are carried out, including checking the serviceability of shut-off valves(faucets, valves), permeability of risers, presence of household contamination of pipes. Having confirmed that there is insufficient pressure in neighboring apartments, it becomes necessary to purchase a pumping station for the entire house.

A pumping station is a type of water booster pump that has a hydraulic tank or accumulator. They are installed between the water supply and the water source, generating pressure in the water supply system. If one is installed in the house, but the water pressure in the apartments is not sufficient, it is replaced with a more powerful one. Sometimes it is enough to replace the accumulator or pump, or adjust the pressure using a pressure switch that monitors the operation of the accumulator and pump.

Operating principle of a water pump

The principle of operation of any booster pump for water supply is that the equipment system increases the pressure in water supply network depending on the pressure available in the water circuit.

Advantage individual system heating in a private house or apartment lies in the short distance of passage of the coolant from the heating source to the battery. Forced circulation assumes the presence of a pump pumping water through heating elements: batteries, registers, pipes.

The pump is installed on the return water supply pipe, first draining the coolant or turning off the existing taps on the pipeline. The correct installation of the pump will be indicated by an arrow, the direction of which coincides with the direction of movement of the coolant. After installing the coarse filter and the pump itself, the system is filled with water, removing air by opening the central screw. The unit is connected to the network using a regular electrical plug.

The booster pump is installed strictly in a horizontal position. It will not only contribute to his quiet operation, but will also prevent damage to the rotor.

Pay attention to the installation of the pump terminal box, preventing water or condensation from entering it. It is strictly prohibited to operate the unit in the absence of coolant in the system. The pump, equipped with a thermostat, is installed away from water heaters that can affect the operation of the thermostat.

At large sizes indoor water consumption increases significantly. Installing one pump may not fully provide the required pressure. In such cases, several pieces of equipment are installed.

How to choose a booster pump for a private home

When choosing a product, we evaluate the condition of the plumbing system. The choice of a unit of the required power depends on this.

When choosing and purchasing a pump for pumping water, you must take into account its main characteristics:

- performance;

- power;

- performance;

- size;

- guarantee period;

- price.

The units differ technical characteristics and the method of cooling the engine and housing. Products with “wet” and “dry” rotors are purchased.

The cooling process of devices of the first type is carried out by the liquid itself. They are silent in operation, but are demanding on the quality of pumped water, requiring constant and timely maintenance.

The motor housing of units with a dry rotor is cooled using an impeller. They are practical and reliable, although a little noisy. This type of pump is in great demand when purchasing.

Some booster pumps are made with a fixed pressure rise value, other models may have several operating modes, are made with several sensors, control units, and have the ability to connect to a control panel.

Pressure boosting stations are purchased when there is no water in the taps. The presence of good water pressure from the neighbors below indicates that it is not reaching your riser.

Review of manufacturers of pumps that increase pressure in water supply systems

- Products high power And High Quality offered by the company

TAIFUN. A wide range of products can satisfy the most sophisticated buyer. - Danish pumps

GRUNDFOS They are small in size and quiet in operation. They are manufactured with two types of housings: stainless and cast iron. The products are reliable and have a long service life. - Products of the German concern

WILO have gained fame due to the high quality of their products. The concern's branches are located in many countries around the world. The functional parameters of the manufactured units allow them to be used both in private houses and apartments. The product is resistant to corrosion and high class protection.

Cost calculation

Sheets for calculating the cost of the device are processed by employees who offer goods that best meet the customer’s conditions.

Those wishing to purchase the product fill out a questionnaire and send it in any acceptable way.

You can find out how installation is done by watching the video:

Installing a pump that increases the pressure in the water supply ensures uninterrupted operation of all gas and water appliances and provides the opportunity to use water in bathrooms, Jacuzzis, and showers at any time of the day. The downside is the problem of space in the apartment when installing a hydraulic accumulator. You need to remember this nuance when installing a tank of 200-300 liters.