Conductors for drilling holes for dowels and confirmat. What is a jig for drilling holes: precision in making furniture with your own hands A tool for precision drilling holes

Read also

The main fastening element in furniture assembly is the confirmat. It is screwed in with pre-drilled holes. It is the drilling of assembly holes in chipboard for confirmations that we will consider in this article.

For assembly chipboard parts we need:

- Screwdriver

- Confirmation bat

- Ruler or tape measure

- Pencil and awl

Hole depth and width

Usually a confirmat size of 6.4*50 is used. Because the thread diameter is 6.4 mm, and the diameter of the confirmation body is 4.4 mm, then for high-quality fastening of parts, the hole diameter must be in the range of 4.5-5 mm and a depth of at least 50 mm.

If the thickness of the hole is greater than the specified one, the confirmat will not hold the parts well; if it is less, its thickness can tear the chipboard.

For drilling, use a confirmat drill with a diameter of 4.5 mm, which is equipped with an additional head for drilling an enlarged hole for the neck of the confirmat, which also makes a countersink for its head.

Of course, you can use a regular drill with a diameter of 5 mm, but for high-quality fastening in the hole you will additionally need to make space for the neck of the confirmat and its head.

In order to perfectly fasten two parts, it is necessary to mark the places of their fastenings as accurately as possible.

On the part that will be applied to the end (the one on which there will be a through hole), you need to make two measurements - along the length (usually 5-10 cm) and from the edge - exactly 8 mm (this is if the thickness of the plate is 16 mm).

On a part that lies perpendicular, mark the drilling point at the end. Here you need to maintain the same distance in length (5-10 cm from the beginning), and in width - strictly in the center (8 mm from the edge).

Markings must be done as accurately as possible, especially along the length, because If the markings are incorrect, your parts may have extra gaps or protrusions when joined.

It is better to make a through hole in the first part, attach it to the second - and immediately use a drill to mark the drilling location at the end of the second part. And then, separately, calmly drill the hole.

We make a hole at a distance of 8 mm from the edge.

The drill should ALWAYS be held strictly perpendicular to the surface.

Before making a through hole, place a piece of unnecessary chipboard under the part. This will prevent chips from appearing on the reverse side.

When the through hole is made, the part can be drilled on the fly to drill holes for the neck and head of the confirmat.

The main rule is that when drilling at the end, the drill must be strictly perpendicular to the end of the part. If you don't hold the drill straight, the drill bit may go sideways and come out, ruining the part.

When drilling, you need to pull the drill out several times so that chips do not clog in the hole.

This option is considered the most accurate and, moreover, the fastest. But in order to make a hole in two parts at the same time, you will need to fix them before drilling. To do this, you may need special clamps, clamps and other devices.

Hole Drilling Tools

In order not to mark 8 mm from the edge both into the layer and at the end each time, you can use a special device, which, by the way, is easy to make yourself.

It is a kind of wooden template with a metal sleeve for a drill inside.

It looks like this, see photo:

And this is a more professional thing:

Look short video for precise drilling of holes in chipboard for confirmations and assembly of furniture parts:

Drilling for dowels

The hole for the dowels is made with an 8 mm drill. Also, in order not to drill through the part, it is advisable to equip it with a depth limiter.

At the end we drill with the same drill to a depth of 20 mm. Do not forget that during any work the drill must be strictly perpendicular to the plane of the part.

Of course, if you picked up a drill for the first time in your life, you won’t do very well. But this activity can be learned quite quickly.

A furniture jig is a simple mechanical device that serves to speed up and simplify the actions when drilling holes. Usage of this device allows you to create technological holes without pre-applied markings and do this with perfect accuracy, as well as a verified inclination. The device is indispensable during assembly. furniture designs, during carpentry work. For use in everyday life and in small-scale production, it is very easy to make a furniture jig with your own hands.

In essence, a furniture jig is an ordinary template with holes required diameter. The working part of the device is a rectangular block made of hard material with holes located according to the required markings. For convenience, it can be equipped with adjusting and locking mechanisms. Based on the simplicity of the design, you can quickly make stencils for furniture with your own hands using available materials.

The jig ensures the desired direction of the drill at an angle of 90 degrees to the surface, eliminating the possibility of deviation. This is especially important when working with narrow parts of furniture, such as the ends of walls or doors. Without this device it is quite difficult to maintain the required angle, which can lead to defects, because even a slight deviation in the direction of the mounting hole can make assembly impossible individual elements into a single structure.

For a perfect fit of furniture elements to each other also great importance has precision location of holes for fasteners. Those who make furniture with their own hands are often faced with the need to create a number of identical holes at a certain distance from each other. To make the work easier, make it faster, it’s easier not to mark up every time, but to use a template.

With the help of a jig you can work with different furniture materials: wood, chipboard, MDF.

Selecting a model for production

Conductors for industrial production can be highly specialized and universal. Templates of the first type are used to perform certain operations on typical parts. Universal devices suitable for working with different materials and objects of various configurations.

By design features And functionality conductors are divided into the following types:

- overhead - when used, they are applied to the surface in desired area, fixing with clamps or holding by hand. Used for drilling holes in flat parts;

- rotary - the working part moves in both vertical and horizontal planes. Used when working with complex elements geometric shape and to create holes, the axis of which should be located at an angle;

- tipping - used to create holes in perpendicular planes.

A marking jig is used to mark the locations for drilling holes. It is much thinner and lighter.

The conductor device can be specially created for a certain type of fastener: dowels, confirmations, screws, corners. There are devices to simplify the process of installing fittings.

According to the type of fixation, furniture jigs can be sliding or fixed. The former move freely along the surface if necessary, the latter are rigidly fixed in in the right place. The presence of an adjustment mechanism will help to combine the device with different types of workpieces.

For large furniture manufacturers, the availability of a variety of additional accessories plays a decisive role, since they significantly reduce time costs. IN in this case The cost of the tools doesn't really matter. A completely different approach to purchasing the necessary equipment from those who have small production for the manufacture of furniture or from independent craftsmen who produce certain types of furniture. In this case, making furniture templates with your own hands turns out to be much cheaper and more practical. The choice of the necessary options and the complexity of the device are determined not only by production needs, but also by the skill and experience of furniture manufacturers.

Overhead

Turning

Universal

Materials and tools

To manufacture a device, you must first decide on the tasks that it will perform. Accordingly, they are selected required material, from which a furniture template will be made with your own hands. The most durable, reliable and “long-lasting” is considered to be a metal conductor. To create a furniture jig for drilling with your own hands, it is permissible to use wood, plywood, textolite, and plexiglass. This is due to lower labor costs and cheaper materials. All this is important, especially if you are going to make several different templates yourself.

To make a conductor, a piece of reinforcement, a block or a plate is suitable - something that can probably be found in any garage or home workshop. To make a simple marking device, you can take a regular school ruler - wooden, plastic or metal.

Of decisive importance in the manufacture of a jig is the precise calculation of the location of the holes on the workpiece. You can take ready-made diagram or make it yourself. Last option preferable, since the dimensions in the drawings must correspond to the tasks being solved.

Tools you will need:

- drill;

- grinder or jigsaw;

- a set of locksmith tools;

- clamps;

- vice.

When manufacturing a jig, you will need perfectly accurate drilling of guide holes and hardening of the finished device

Drawing of a homemade conductor for drilling holes for confirmations

Manufacturing stages

Let's consider the process of creating a metal conductor device for confirmations. This fastener is most often used when assembling furniture:

- from metal bar square section (10x10 mm), a piece of the required length is cut using a grinder. The ends of the resulting segment are leveled and cleared of burrs using a file. Corners and edges can be rounded for ease and safety of use;

- The hole locations are marked on the workpiece. Their centers should be located at a distance of 8 mm from the side edge (the thickness of the chipboard sheet is 16 mm). There should be 32 mm from the end and between the holes, in accordance with the generally accepted system of furniture fastenings. For marking, you can use a carpenter's angle or caliper. It is better to make marks on the part using a sharp metal object- an awl or a large needle. You can use a core and a hammer to make holes for the initial installation of the drill. When drilling holes, it is important to prevent the drill from moving and make them strictly perpendicular to the surface of the workpiece;

- use a drill with a diameter of 5 mm to make holes;

- to create a stop, you need to cut a piece of the required length from a metal plate (1x25 mm);

- sand the edges with sandpaper;

- bend the workpiece at a right angle, holding it in a vice. Fold the parts, aligning them coaxially;

- fasten the parts in this position using a clamp;

- From the side of the plate along the length of the device and at the end, drill holes corresponding to the size of the screw. Cut threads and fasten parts;

- Cut off the excess thrust plate and process the edges.

Video

Drill attachment - Malco Turboshear TSNS1 scissors. Can handle both slate and slate.

Did you know that a regular drill can do much more than just drill? Its capabilities are significantly expanded by special attachments, attachments and various devices.

Surely not every owner of a drill knows that it can not only drill holes, but also saw, mill, and even turn into lathe or a pump for pumping liquids. Such an enviable versatility of the usual electric drill owes to the abundance of a wide variety of attachments, attachments and devices. It is unlikely that you can find another power tool for which there are as many attachments as for an electric drill.

Of course, the multifunctionality of the drill created by the attachments is in no way capable of replacing a fleet of special professional tools (in terms of cleanliness of processing, accuracy and productivity). But on household level all the additional functions acquired by the drill will fully satisfy the needs of the home craftsman.

The SC 165 quick clamp ensures quick fixation of the workpiece when drilling. The drill holder allows you to quickly secure the drill and perform stationary work. Can be rotated 360 degrees, just like vertically. The same goes horizontally.

Most widely represented drill stops. The simplest stop, installed on the auxiliary handle of the drill (attachment set: auxiliary handle and stop with a metric scale), allows you to drill holes to the desired depth. With it, you will never accidentally drill through a workpiece or a thin partition.

It is more advanced because it controls not only the depth of the hole, but also its verticality relative to the surface being processed. This type of attachment is produced both for construction (drilling in walls and ceilings) and carpentry (furniture) work. The attachment for construction purposes is professional and is a single unit with an additional handle mounted on a powerful drill. Some models have a built-in dust extractor connected to the vacuum cleaner.

|

The simplest stop for a drill is an additional handle. It has an adjustable drill depth stop (metric) |

The professional stop is more reliable and has a convenient metric depth limiter scale. |

|

The parallel stop, in addition to the depth of the hole, sets its perpendicularity. Model for working on vertical surfaces. |

A dust removal attachment is also necessary for a drill. They are equipped with certain models of professional stops. Connects to a vacuum cleaner. |

Carpentry attachments They are structurally similar to the racks of hand cutters, but are manufactured less accurately and are intended only for small household work. And more is not required here: a drill is a low-speed tool (relative to an electric milling machine) and does not provide high precision when processing the surface. The drill is clamped in a basket, which easily moves along two vertical guides.

Angle drilling accessories and attachments They will allow you to drill a hole where it is simply impossible to approach with a conventional drill. Depending on the design and manufacturer, the drilling angle may be different. The most common attachments allow drilling at an angle of 90º.

This The attachment allows you to limit the drilling depth, ensures strict verticality of the hole and allows you to perform (appropriate attachments) some milling work. This is especially important when making furniture at home: inset furniture hinges, holes for assembly fasteners and dowels or grooves. The stop can be equipped with various inserts for side drilling in round or complex profile details. Some models of stops have a dust extraction device connected to the vacuum cleaner. But a professional will prefer a manual milling machine (same operating capabilities, but high quality surface treatment and precision).

Of course, holes in parts can be made most accurately and quickly on a drilling machine. But the drill, complete with it, shows excellent result. As a rule, such a stand is equipped with a convenient clamping vice (for the workpiece). The vice can be moved along the stand frame to the desired position.

A drill (almost any) is easily and quickly clamped into the “basket” of the stand and drilling machine ready for work. The compact dimensions of this attachment, smooth feed and accurate metric scale make it a valuable acquisition for a small workshop.

|

A home craftsman can get by with the simplest parallel stop: made of plastic, the dust is localized within itself. |

Parallel fence for carpentry work: guide groove and inserts for side drilling of bars and round parts. |

Removing dust and sawdust in this attachment is necessary. With it, the drill can already work like a simple hand-held milling machine. |

|

There are additional functional holes on the platform of the console, with which you can install a side stop. In this case, the drill is capable of performing all operations hand cutter, for example, select the groove exactly (with the appropriate nozzle). |

||

Can't help but arouse interest. The attachment is easily attached to the table and the machine is ready. Available in several design options. As a rule, a certain set of accessories is offered for it and cutting tool. This type of consoles does not pretend to be professional tool, but many details for custom furniture or a country house can be made on it and quite well. But if you start mass production of turned table legs or balusters using this attachment, it will quickly break, and the drill will not withstand such violence. Our photographs give a clear idea of the design and operating principle of this attachment.

The most famous and widespread are the prefixes that turn drill into electric sharpener. Here we will introduce you to only two specialized attachments of this type: one for sharpening circular saw blades and the other for drill sharpening, chisels and plane knives. The value of attachments lies in the fact that they allow you to avoid the expensive services of professional sharpeners of such tools. With them you will not have problems with either the sharpening angle or the perfect cutting edge (even if you have never done this before). Installing such attachments on a drill does not cause any difficulties.

|

A drill stand plus a drill is a convenient drilling machine. The design of the frame makes it possible to mount a clamping vice on it to fix the workpiece. |

Vises for racks come in different modifications. But their mounting holes must correspond to the grooves in the rack frame. |

|

The vice on the bed can be moved. There are options with the vise rotating around an axis and even with a changing angle of the stand. |

A drill mounted in a stand plus an abrasive attachment allows you to create high-quality concave surfaces. |

Noteworthy: easy to use and compact milling attachment grooves in the ends of cabinet furniture or joinery parts (for corner connections). It is very simple to work with it: there is no need to clamp the workpiece on a workbench, the quality and accuracy of processing is high, the depth of the groove and its level can be set by simple adjustment. This attachment will completely satisfy a professional furniture maker.

For those craftsmen whose work is very diverse, it will not be superfluous to long flexible or angle drive for drill. They are simply installed in the drill chuck and have their own clamping chuck, suitable for any attachments (drills, grinding stones, bits, etc.). These attachments allow you to work with a drill in the most hard to reach places. It certainly wouldn’t occur to anyone to use a drill to pump liquids.

But this is quite real and not without meaning if you use pump attachment installed in the drill chuck. Of course, it is not intended for long-term continuous operation and has a low productivity, but it can and is quite convenient to pump out (viscous) paint from a barrel or dirty water from a basement. By changing the speed of the drill, you change the speed of pumping out liquid. As a rule, the entire body of such a set-top box is made of plastic: the service life is short, but the price is low.

|

The attachment for sharpening disc blades allows you to do it yourself, without resorting to the expensive service of a professional. |

The grooves for corner joints can also be selected using a drill, equipped with a special attachment. It has a dust extraction device. |

Long flexible drive with chuck is another good addition for drill. It works with any attachments. |

|

A small attachment to the drill will help you sharpen a drill, chisel or plane knife to high-quality sharpening. The sharpening angle is adjustable. |

The drill can be used as a screwdriver, suitable for working even in hard-to-reach and inconvenient places. |

The drill can work as a pump. Nozzles come in different capacities (suitable for paint and even dirty water). |

|

Professional template: durable, reduces the labor intensity of marking and drilling standard holes for furniture assembly. |

The furniture template for drilling holes has standard dimensions: holes, distances between them and from the edge of the part. |

This template ensures that the hole is vertical and centered. A plastic template is enough for a home craftsman. |

It is generally accepted that templates significantly speed up many operations and increase the accuracy of processing parts and their assembly. This can be confirmed by the abundance of existing drill templates. We show only the most common patterns that are most often in demand when working with a drill. Among them there are both professional ones (durable and maintain the accuracy of their dimensions) and for home craftsmen (made of plastic).

Template (jig) for drilling precise holes under the dowels.

But regardless of this, they contain all the main standard sizes of furniture holes: for inserting hinges and locks, for furniture ties and dowels, as well as the distance between them and from the edges of the parts. Some templates allow you to dispense with the rip fence.

Without a good dust removal and waste collection system, with independent work, sometimes you can’t do it. The DeWALT DWA500DC dust collector will help with vertical drilling in the ceiling.

Filigree channel drilling

Concern A&M developed special attachment for drilling wood. Under the MILWAUKEE brand it is called Pathfinder, and under the AEG brand it is called 3D bit. The use of such a special drill attachment will greatly facilitate the work of builders, carpenters, carpenters and mechanics, as well as electricians and plumbers, because it can be used to drill inclined holes in hard-to-reach places, gutters and channels for installing cables and pipes.

|

|

|

|

The cutting action of this attachment is carried out in three directions and allows you to cut into material where conventional drills are powerless. The drilling speed with the new attachment is three times higher than with feather drills, and the selection of channels, grooves and grooves is much more accurate, so the holes are even, smooth and without chips. The drill has six edges, which are sharpened with a regular file or emery stone.

|

|

|

We advise you to decide in advance on the nature of the work that you will most often and in large quantities perform. And only after that, start looking for the attachments, attachments and accessories you need for the drill.

Drill attachments for cutting sheet materials

Perhaps it is worth highlighting in a separate category special attachments for the drill, turning it into a unique tool for cutting all kinds of sheet materials. With the help of such an attachment - scissors and a regular, even cordless drill, you can easily cut a metal sheet up to 1.5 mm thick. metal mesh and thick plastic. Manufactured by Malco (USA), a whole family of scissor attachments is called Turboshear.

Such scissors are capable of cutting both along the axis of the tool and perpendicular to it, which allows you to cut squares and rectangles. The attachment will also work on cordless screwdriver and on a powerful drill operating from the network. But don't think that all this will cost a penny. The cost of such attachments - scissors - ranges from 4,000 to 7,000 rubles.

|

|

|

|

Description and features of the device

The jig is a strip with several holes and sleeves. Such a device is fixed to required part, and then carefully insert a drill into the sleeve and make a hole. To secure two parts you will need one jig, making the fixation reliable.

- drilling accuracy;

- simplicity and speed of creating holes.

It is worth noting that conductors are sometimes used in mechanical engineering, and not just in construction. Moreover, using this device you can make holes in cylindrical workpieces and pipes. The jig also allows you to make perpendicular holes.

Main types of equipment

All conductors used in various industries are are divided into several groups .

Methods and areas of application of the conductor

There are many ways to use this type of equipment. Naturally, the main area is considered building sector .

Furniture industry

When assembling furniture, you may find that some holes are missing. It is for this reason that you will have to drill various parts with your own hands. To ensure that the work does not cause difficulties, it is necessary to use a conductor. This will make furniture assembly accurate and quick. The use of such equipment is really important if you do not have a drilling machine.

Although today there is big choice accessories and fasteners, dowels are still often used in the furniture assembly process. They must be installed very accurately, otherwise the parts will be displaced. To avoid such an unpleasant consequence, you should use a conductor.

Drilling pipes

If it is necessary to prepare holes in pipes and various cylindrical workpieces, the use of a drill will not be best idea, since it often slips off, which means the holes will not have the desired shape. To make the job easier, you should use a universal jig.

It is worth noting that there is special equipment that allows you to perform perpendicular holes. and this is very important when processing rounded elements and edges of workpieces.

Purchased or homemade conductor?

As mentioned earlier, such a product is indispensable in the process of assembling furniture. Some people make these devices with their own hands, while others prefer to buy them.

As mentioned earlier, such a product is indispensable in the process of assembling furniture. Some people make these devices with their own hands, while others prefer to buy them.

Conductors are sold in almost any hardware store, however finished products may not be suitable for specific purposes. It is also important to remember that the cost of the device depends on the purpose, size and manufacturer. The most simple options are inexpensive. which cannot be said about professional equipment with big amount additional functions.

Many consumers prefer to make the conductor with their own hands. For this purpose you will need a metal sheet or wooden plank. Here, holes are prepared that will act as guides. In general, anyone can handle this kind of work.

Making a conductor with your own hands

As already mentioned, you can make a similar product for drilling yourself. To do this you need to prepare welding machine, a grinder, a drill and several plumbing tools. You will also need fittings dimensions 10x10 mm .

- The workpiece is cleaned sandpaper and perform markings. According to accepted standards, the distance between centers should be about 32 mm.

- Next, template holes are drilled.

- The next stage is creating a stop. It could be metal plate 1 mm thick. It is carefully bent and the place for carving is prepared.

- Then both parts are carefully connected.

To ensure that the process of drilling holes does not cause any difficulties, it is worth using a jig. Such equipment is really indispensable in the furniture assembly process. You can buy it, but it’s better to do it yourself, because homemade device will definitely suit your specific needs.

A device for drilling holes at right angles.

When you make any furniture for your home, you constantly face the task of drilling a hole in the piece at a right angle. And no matter how hard you try, the result is not very good. If the drilled hole is too far gone, then some misalignment is possible when connecting two parts.

Catch a right angle without using any special devices very difficult. Available for sale various devices to help the home handyman. But with the help of some devices, holes can only be drilled with a drill having seat for an additional handle, i.e. This attachment is not suitable for cordless drills. Another type of device found on sale for drilling at right angles was more universal, and it could be purchased, but. Price. The price of such devices is steep. For those people who more or less constantly make something out of furniture, purchasing such an attachment may be advisable. But for ordinary person, who makes household items quite rarely, the price is a bit high. The device that the author of the article encountered in 2011 cost more than 800 rubles.

Therefore, when the opportunity once again arose to make another product from laminated chipboard, it was decided to try to make an assistant from scrap materials. We took old chipboard scraps.

And first we made a device for drilling holes in the end of the chipboard panel. We figured it should look like this

This thing will have holes with which you can more accurately position the drill, and it will fit onto the end of the panel.

Before assembling the device, we made markings on it for three holes for euroscrews of different diameters.

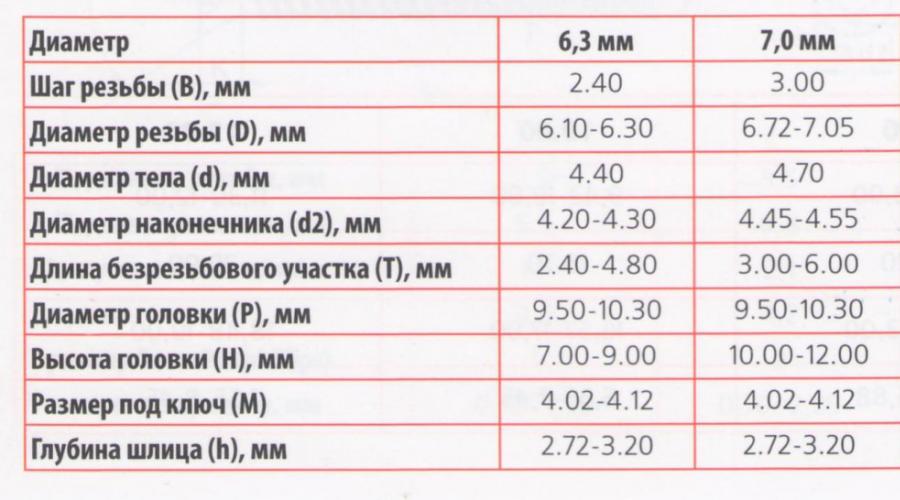

We took three euroscrews with a diameter of 5mm, 6.3mm and 7mm. And holes of 3.5mm, 4mm and 4.5mm were drilled for them, respectively.

We finally assembled the part. We drilled holes for one holder and attached it.

And then we drilled holes for the second holder. When drilling, a piece of chipboard was placed between the holders in order to more accurately drill holes for the second holder. Since the homemade device should “sit” on the end of the panel very tightly and not play.

The device is assembled.

This device is only for drilling holes at right angles in the end of the panel. And in order to position the drill and more or less clearly drill a hole on the plane of the panel from a small piece of chipboard, we made another device. Just in a piece of chipboard, we also drilled 3 holes 3.5mm, 4mm and 4.5mm.

And now about how you think about drilling holes at right angles with the help of just made “helpers”.

We make markings on the panel. We pass the drill through the device and mark the hole.

After marking, lower the device completely onto the panel, use it to position the drill at a right angle and begin drilling.

Using the same principle, holes are drilled in the end. We passed the drill through the end assistant, marked the hole, pressed the device tightly against the end, and began to drill.

Other section materials:

Drilling at right angles

According to statistics, an electric drill is the most common power tool in household. However, accurately drilling a hole is not so easy. It is even more difficult to make holes at right angles or at an angle. It is no coincidence that people came up with drilling machines. But buying such a bulky device for the vast majority of home craftsmen does not make sense. In addition, not every part is convenient to drill holes on a drilling machine. For example, fitting a long board or furniture panel under a drilling machine is not always convenient. But you want to drill it exactly so as not to spoil it appearance future product. I think many people have encountered a situation where you mark holes on one side of the board, drill it, everything seems to be straight, but as soon as you turn the board over, you’ll be horrified that all the holes are awry.

In order to drill at the desired angle, various devices are used that allow you to accurately guide the drill. Not all such devices are equally convenient, but with their help it is possible to achieve incomparably best result than without them. I believe that if there is a drill at home, then at least one of these devices should also be available. Everything without him beneficial features and the drill's capabilities cannot be fully utilized. Unfortunately, such necessary devices are rarely found on sale.

The most painful parts of such devices are that they have backlash and with their help it is not always possible to move the tool smoothly. Accuracy also suffers from this. In addition, when you hold the drill in one hand, the sole of the device must be pressed against work surface details with the other hand. If the combination of a drill and a device feels like a single whole in your hands, then it’s a pleasure to work with. When there is no such feeling of solidity, discomfort arises, and more effort has to be made during work.

Taking into account practical experience, I would like to propose, in my opinion, a fairly successful and simple design of such a mobile drilling device. Instead of a handle, the device itself is attached to the drill. His base plate has a rubber sole for better grip on the material. The rotary die, parallel to which the drill moves, can change the angle of inclination from 90 to 45 degrees. The fixation of the selected angle is very rigid. It is secured with two screws. If you need to drill at a smaller angle, you need to unscrew and remove the handle so that it does not get in the way. Co removed handle The device folds so that it takes up little space and is convenient for storage. The movement of the drill along the die is ensured by moving a wide and sufficiently long plate in the grooves. The length and width of the plate significantly reduce the likelihood of jamming and ensure smooth movement. The grooves can even be slightly lubricated with silicone grease to improve sliding. The upper spring is much more powerful than the lower one. This provides a smoother “press” of the drill. The lower spring acts as a stretcher so that the structure dangles less. In a word, everything is clear from the given diagrams.

This holder comes with an attachment for drilling holes in edge boards, look.

Furniture jig for drilling holes: types, making your own

Make holes accurately and efficiently in products made from natural wood, chipboard, MDF, metal and other materials, allows this convenient device as a conductor. This device, in particular, is actively used by specialists involved in the production of furniture. At the same time, the conductor can either be purchased in a serial version or made with your own hands.

Universal slider type jig for drilling holes for Euroscrews and dowels

Design features and types

A jig, in essence, is a template for drilling holes, allowing you to make them as accurately as possible. It is used both to create holes, the axis of which is perpendicular to the surface of the part, and for drilling at an angle.

Due to their versatility and simplicity, drilling jigs are widely used in various fields. In particular, in the mechanical engineering industry they have long been used to successfully drill holes in workpieces of various configurations and made of different materials. You cannot work without a conductor in furniture production, where such a device is actively used when assembling furniture, installing accessories on it and performing a number of other technological operations. Construction is another area where conductors find wide application. With their help, in particular, they drill holes in building structures. Conductors are also needed for drilling pipes and solving other tasks.

Even a simple device in the form of a strip with a stop greatly facilitates and speeds up the process of making holes of the same type

As furniture jigs, overhead models made of lightweight materials are most often used to make them more convenient to manipulate. You can purchase such devices prefabricated or make a furniture jig with your own hands. Qualified furniture makers may not use a jig to accurately and accurately drill holes in furniture structural elements, but to do this they must have extensive experience in their field.

The most significant advantage of the jig is that with its help, even a person who is not highly qualified can perform high-quality and accurate drilling of both a hole perpendicular to the surface of the part and an inclined hole. The use of jigs eliminates the need for complex preliminary calculations and marking the locations of future holes, which reduces the labor intensity of assembling a furniture structure and allows such work to be completed in a shorter period of time. Even a novice specialist can understand the use of a jig for drilling for dowels and solving other technological problems.

An overhead jig with a turret head is suitable for drilling standard holes for dowels of any size

Before purchasing or making your own homemade jig, determine what tasks you need to use it for, and based on this data, select its type and design.

Among the jigs for drilling holes, according to the type of design and functionality, we can distinguish whole line categories. Invoices

These jigs are so called because they are placed on the workpiece and secured to it or simply fixed by hand. Through conductors of this type, in particular, they drill holes in chipboards, MDF boards and other flat parts.

Such templates can be used to make holes on cylindrical parts. Conductors of this type are equipped with vertical and horizontal axes of rotation, which makes it possible to make holes at different angles with their help.

These are devices that are especially relevant for small batch production, where the ability to quickly change over the equipment used is important. This type of conductor is endowed with just such functions.

This universal jig is designed for drilling holes for minifix, confirmat, rafix and door hinge

These devices for drilling holes are required in cases where such a technological operation has to be performed in several planes.

Sliding and pinning

The sliding jig, in full accordance with its name, does not require fastening: it is simply applied to the area of the surface of the part where the hole needs to be drilled. Fixed jig devices, although more convenient, somewhat limit the freedom of action of the specialist, which is especially critical when performing drilling work on machines equipped with only one spindle.

Areas of use

Furniture conductors and templates are devices that are practically impossible to do without when assembling furniture structures. The use of jigs allows you to avoid the main problem that arises when drilling holes - the drill entering the workpiece at the wrong angle. Correcting this error takes a lot of time and effort, and it is not always possible to fix it at all. The jig used for drilling holes not only allows you to correctly orient the drill at the processing site, but also prevents the tool from straying from the specified trajectory.

Devices such as furniture jigs and templates are used both in the production and assembly of furniture, when holes must be made in the elements being connected to accommodate fasteners. In such cases, a jig for dowels or a jig for drilling for confirmation is often used, without which it is not possible to make high-quality holes for fasteners. Such a device is indispensable in cases where it is necessary to make holes, including at an angle, in thin slabs (in particular, when making holes in chipboard or MDF).

A jig for oblique holes is indispensable when constructing hidden connections panels and boards

When using a jig to drill holes, the process of assembling furniture is simple and quick. Using such a device, holes can be drilled at any distance from the edge of the part, regardless of its width.

IN modern furniture Dowels are actively used, which at the same time are a rather outdated fastening element. That is why the doweling jig is used in the production of furniture structures. The main difficulty when using such fasteners is that the axes of the holes made in the parts being connected have a right angle to each other. Accordingly, such holes should be located strictly perpendicular to each other. Without the use of such a device as a dowel jig, it is difficult to perform them.

The jig for making holes in the tubes will be very useful device for home workshop

Furniture production is not the only area in which jigs designed for drilling holes are used. Templates are no less often used to drill a hole in a pipe and other parts that have cylindrical shape. Conductors allow you to make high-quality holes even in small-diameter pipes.

The size and operating principle of modern conductors may vary. Some of the models of such devices are much easier to buy, and some are easy to make with your own hands. The fact that serial devices, especially those for universal use, are not cheap, also speaks in favor of making a furniture jig for drilling holes with your own hands.

Homemade conductor devices

Conductors simplest design, for example, those that are used for drilling holes for confirmation are relatively inexpensive, so many craftsmen are not puzzled by them self-production and purchase production models. Meanwhile, there are those who are even like this simple devices trying to do it with his own hands. The question of how to make a jig for drilling with your own hands often arises and, if necessary, drill non-standard holes.

To make your own jig for dowels or a simpler design jig for confirmations, you can use drawings and videos on the Internet.

When manufacturing a jig, you will need perfectly accurate drilling of guide holes and hardening of the finished device

To manufacture such a device, naturally, you will need a drawing of it. Also needed minimum set tools and equipment:

- electric or hand drill;

- a set of locksmith tools;

- Bulgarian;

- welding machine (for the manufacture of jig devices of a more complex design).

The simplest homemade conductor can be made from available tools and materials that are available in abundance in most home workshops or garages. The use of such materials, which include pieces of metal reinforcement, wooden blocks, metal plates, etc., allows you to significantly save on the purchase of a serial model of the device.

Drawing of a homemade conductor for drilling holes for confirmations

Making a homemade jig for a drill or single-spindle machine takes place in several stages.

- Square reinforcement with a cross section of 10 by 10 mm, using a hacksaw or grinder, must be cut into pieces of the required length.

- The centers of the holes through which drilling will be performed should be at a distance of 8 mm from the edge of the conductor plate. It is at this distance that the center is located chipboards or MDF in which a hole is drilled.

- The pitch between the holes on the jig, in accordance with generally accepted furniture standards, is 32 mm, while the diameter of such holes should be 5 mm.

- If you equip a homemade conductor with a stop, then using such a device will be much more convenient. To create such a stop, you need a metal plate 1 mm thick and 25 mm wide, which is bent at a right angle and fixed to a ready-made jig device made from reinforcement.

- After the structural elements of a homemade conductor are fixed with a clamp, they must be securely connected to each other using threaded fasteners.

Ready-made jig with rotary stops

To minimize the amount of dust generated when using a homemade conductor, its design can be supplemented with a half plastic bottle. Such a simple device can also act as a tray in which the chips generated during the drilling process will be collected.

The method described above allows you to make a simple homemade jig, which greatly facilitates and speeds up the process of assembling any furniture structure.

Attachments, nozzles and accessories for drills

Drill attachment - Malco Turboshear TSNS1 scissors. Can handle both slate and slate.

Did you know that a regular drill can do much more than just drill? Its capabilities are significantly expanded by special attachments, attachments and various devices.

Surely not every owner of a drill knows that it can not only drill holes, but also saw, mill, and even turn into a lathe or a pump for pumping liquids. An ordinary electric drill owes such an enviable versatility to the abundance of a wide variety of attachments, attachments and accessories. It is unlikely that you can find another power tool for which there are as many attachments as for an electric drill.

Of course, the multifunctionality of the drill created by the attachments is in no way capable of replacing a fleet of special professional tools (in terms of cleanliness of processing, accuracy and productivity). But at the household level, all the additional functions acquired by the drill will fully satisfy the needs of the home craftsman.

The SC 165 quick clamp ensures quick fixation of the workpiece when drilling. The drill holder allows you to quickly secure the drill and perform stationary work. Can be rotated 360 degrees, just like vertically. The same goes horizontally.

Most widely represented drill stops. The simplest stop, installed on the auxiliary handle of the drill (attachment set: auxiliary handle and stop with a metric scale), allows you to drill holes to the desired depth. With it, you will never accidentally drill through a workpiece or a thin partition.

Rip fence more perfect, since it controls not only the depth of the hole, but also its verticality relative to the surface being processed. This type of attachment is produced both for construction (drilling in walls and ceilings) and carpentry (furniture) work. The attachment for construction purposes is professional and is a single unit with an additional handle mounted on a powerful drill. Some models have a built-in dust extractor connected to the vacuum cleaner.

The simplest stop for a drill is an additional handle. It has an adjustable drill depth stop (metric)

The professional stop is more reliable and has a convenient metric depth limiter scale.

The parallel stop, in addition to the depth of the hole, sets its perpendicularity. Model for working on vertical surfaces.

A dust removal attachment is also necessary for a drill. They are equipped with certain models of professional stops. Connects to a vacuum cleaner.

Carpentry attachments They are structurally similar to the racks of hand cutters, but are manufactured less accurately and are intended only for small household work. And more is not required here: a drill is a low-speed tool (relative to an electric mill) and does not provide high precision when machining a surface. The drill is clamped in a basket, which easily moves along two vertical guides.

Angle drilling accessories and attachments They will allow you to drill a hole where it is simply impossible to approach with a conventional drill. Depending on the design and manufacturer, the drilling angle may be different. The most common attachments allow drilling at an angle of 90º.

This The attachment allows you to limit the drilling depth. ensures strict verticality of the hole and allows you to perform (appropriate attachments) some milling work. This is especially important when making furniture at home: inserting furniture hinges, holes for assembly fasteners and dowels, or cutting grooves. The stop can be equipped with various inserts for side drilling in round parts or with complex profiles. Some models of stops have a dust extraction device connected to the vacuum cleaner. But a professional will prefer a manual milling machine (the same operational capabilities, but high surface quality and accuracy).

Of course, holes in parts can be made most accurately and quickly on a drilling machine. But also a drill, complete drill stand- guide attachment. shows excellent results. As a rule, such a stand is equipped with a convenient clamping vice (for the workpiece). The vice can be moved along the stand frame to the desired position.

A drill (almost any) is easily and quickly clamped into the “basket” of the stand and the drilling machine is ready for work. The compact dimensions of this attachment, smooth feed and accurate metric scale make it a valuable acquisition for a small workshop.

A home craftsman can get by with the simplest parallel stop: made of plastic, the dust is localized within itself.

Parallel fence for carpentry work: guide groove and inserts for side drilling of bars and round parts.

Removing dust and sawdust in this attachment is necessary. With it, the drill can already work like a simple hand-held milling machine.

There are additional functional holes on the platform of the console, with which you can install a side stop. In this case, the drill is capable of performing all the operations of a manual milling cutter, for example, selecting a groove exactly (with the appropriate attachment).

Can't help but arouse interest attachment to a drill that turns it into a wood lathe. The attachment is easily attached to the table and the machine is ready. Available in several design options. As a rule, a certain set of accessories and cutting tools is offered for it. This type of attachment does not pretend to be a professional tool, but many parts for individual furniture or a country house can be made quite well using it. But if you start mass production of turned table legs or balusters using this attachment, it will quickly break, and the drill will not withstand such violence. Our photographs give a clear idea of the design and operating principle of this attachment.

Compact wood lathe from a drill

A compact wood lathe is the dream of any home craftsman. There are several types of turning attachments for drills. They differ not only in their design, but also in the set of cutting tools offered for them.

The most famous and widespread are the prefixes that turn drill into electric sharpener. Here we will introduce you to only two specialized attachments of this type: one for sharpening circular saw blades and the other for sharpening drills, chisels and plane knives. The value of attachments lies in the fact that they allow you to avoid the expensive services of professional sharpeners of such tools. With them you will not have problems with either the sharpening angle or the perfect cutting edge (even if you have never done this before). Installing such attachments on a drill does not cause any difficulties.

A drill stand plus a drill is a convenient drilling machine. The design of the frame makes it possible to mount a clamping vice on it to fix the workpiece.

Vises for racks come in different modifications. But their mounting holes must correspond to the grooves in the rack frame.

The vice on the bed can be moved. There are options with the vise rotating around an axis and even with a changing angle of the stand.

A drill mounted in a stand plus an abrasive attachment allows you to create high-quality concave surfaces.

Noteworthy: easy to use and compact milling attachment grooves in the ends of parts of cabinet furniture or joinery (for corner joints). It is very simple to work with it: there is no need to clamp the workpiece on a workbench, the quality and accuracy of processing is high, the depth of the groove and its level can be set by simple adjustment. This attachment will completely satisfy a professional furniture maker.

For those craftsmen whose work is very diverse, it will not be superfluous to long flexible or angle drive for drill. They are simply installed in the drill chuck and have their own clamping chuck, suitable for any attachments (drills, grinding stones, bits, etc.). These attachments allow you to work with a drill in the most difficult to reach places. It certainly wouldn’t occur to anyone to use a drill to pump liquids.

Attachment - water pump for Bosch drill

The nozzle is a water pump. Capacity up to 2500 l/h.

But this is quite real and not without meaning if you use pump attachment installed in the drill chuck. Of course, it is not intended for long-term continuous operation and has a low productivity, but it can and is quite convenient to pump out (viscous) paint from a barrel or dirty water from a basement. By changing the speed of the drill, you change the speed of pumping out liquid. As a rule, the entire body of such a set-top box is made of plastic: the service life is short, but the price is low.

The attachment for sharpening disc blades allows you to do it yourself, without resorting to the expensive service of a professional.

The grooves for corner joints can also be selected using a drill, equipped with a special attachment. It has a dust extraction device.

A long flexible drive with a chuck is another great addition to a drill. It works with any attachments.

A small attachment to the drill will help you sharpen a drill, chisel or plane knife to high-quality sharpening. The sharpening angle is adjustable.

The drill can be used as a screwdriver, suitable for working even in hard-to-reach and inconvenient places.

The drill can work as a pump. Nozzles come in different capacities (suitable for paint and even dirty water).

Professional template: durable, reduces the labor intensity of marking and drilling standard holes for furniture assembly.

The furniture template for drilling holes has standard dimensions: holes, distances between them and from the edge of the part.

This template ensures that the hole is vertical and centered. A plastic template is enough for a home craftsman.

It is generally accepted that templates significantly speed up many operations and increase the accuracy of processing parts and their assembly. This can be confirmed by the abundance of existing drill templates. We show only the most common patterns that are most often in demand when working with a drill. Among them there are both professional ones (durable and maintain the accuracy of their dimensions) and for home craftsmen (made of plastic).

Drilling template

Sometimes at home you need to make holes in blanks made of wood, metal, chipboard or other material.

And the presence of a screwdriver does not help and does not allow making holes strictly at an angle of 90, we are not talking about oblique holes at different angles.

To facilitate the processing of materials, a drilling jig is used.

These devices are widely used in the furniture industry.

Today in our article, we will talk about the types of conductors, their scope of application and the ability to make them yourself.

Types of conductors

It should be noted that these devices are used not only for drilling holes, but also when milling, turning and trimming are performed.

Let's look at the main types of devices.

Invoices

This type of jig is placed on top of the workpiece. It can lie either freely or be pressed using bolts or clamps. They are valued for their simplicity of design and low cost.

Rotary

The device body is equipped with bushings that adjust the rotation axes in horizontal, vertical and inclined planes. These models of jigs are designed for drilling cylindrical products.

Sliding

The name speaks for itself, the jig is not attached in any way, it is simply placed where the hole needs to be made.

Tiltable

Capable of making holes in several planes.

Stationary

They do not have rotating elements and are capable of moving the part and processing workpieces of the same type.

Universal

These conductors have a function such as readjustment. This allows small businesses to quickly and conveniently switch to the production of a new product.

Description of conductors

Let's start with the concept of a jig - this is a so-called template, the use of which allows for comfortable and ultra-precise drilling.

Moreover, you can drill either perpendicular to the surface or at any angle. If you use a conductor, then you do not need any special qualifications to do complex calculations, make markings where the holes will be, which saves a lot of time.

Areas of application

As we can see, due to the versatility and simplicity of their design, conductors are widely used in different areas activities.

Mechanical engineering

In the mechanical engineering industry, they are used for drilling holes in various workpieces made from common materials. Conductors are used that repeat the drawing with exact observance of all dimensions. Also used when drilling holes of mixed type is required.

Furniture manufacturing

The most widespread use of conductors is in furniture production. Furniture conductors are used for installing fittings, assembling furniture and many other technological processes.

At the same time, furniture assembly is neat, precise and fast. A large amount of furniture contains dowels, which must be installed very precisely and there is no need for a conductor.

The most common jig for dowels is doweling. They mainly use overhead conductors made of lightweight materials.

Construction

Another area in which jigs are widely used for drilling holes is construction. They are used to drill technological holes in building structures, for example.

Main advantages of use

You can buy a conductor or make it yourself.

But before choosing a model, you should decide for what tasks it will be used and, based on all this data, you should choose the type and design of the tool.

So why should you use jigs for drilling holes?:

- Intuitively clear use, which does not require professional skills.

- Low price of the device, as well as the possibility of self-production.

- Saves a lot of time.

- There is no need to mark the surface to be treated using.

- Maintain precision when drilling.

A jig for drilling holes is an integral part not only of production, but it will also be useful in home life.

How to make a conductor with your own hands

Since there are many types of conductors, we will consider original design and analogue respectively. So, let's begin.

Jig for perpendicular drilling

Its main purpose is to make holes in thick workpieces at an angle of 90. In essence, it is a set of bushings combined in one body. Usually these are overhead conductors, which are widely used in furniture assembly.

Just place the device on the surface and you can start drilling right away, without punching. There is one drawback: the device should be held tightly, especially at the beginning of work. Because vibration can cause the device to shift.

This type of conductors can be made with your own hands.

- As a base, you can use a wooden block, a piece of textolite, or reinforcement with a square section of 10x10 mm.

- We treat the surface well, clean it and begin marking.

- Please note that the center of the holes should be 8 mm. from the edge of the workpiece. This is due to the fact that 8 mm. this is half the thickness of a chipboard sheet.

- According to standards, there should be exactly 32 mm between the centers of the holes.

- After that, we make holes with a diameter of 5 mm in these centers.

A homemade jig can be used, but for more convenient use, a stop should be designed; for this, metal 23-25 mm wide is used. and 1 mm thick, after which the sheet is bent at an angle of 90 and attached to the jig. Also, bushings of different diameters can be inserted into the base of the conductor.

Conductor for pipes and cylindrical blanks

Everyone knows that making a hole in a sloping surface is problematic; the end of the drill constantly jumps off. This type of conductors is fixed in a given position and allows you to work with high precision.

This type of conductors can be made quickly and independently.

- To do this, we need a block of hard wood, loosened diagonally. And we attach a piece of plywood to the edge of the block using self-tapping screws.

- Then we make holes of the required diameter in the wooden block.

That's it, the conductor is ready for work. To make the holes less likely to break, they can be reinforced with metal sleeves, which are made from round pipes different diameters.

Jig for drilling holes at an angle

This type of drilling is rarely used.

Suitable when it is almost impossible to hold a drill or screwdriver at the desired angle.

It should be noted here that in metal products this type of hole is made only with a milling cutter. As for wooden products, there are ready-made solutions in the form of kits.

It’s easy to use these jigs: we press the workpiece tightly to the base, set the specified height and as a result we get smooth and beautiful oblique holes at an angle. Yes, if we don’t need a through hole, then don’t forget to put a stop ring on the drill itself.

On your own this type The devices are difficult and problematic to manufacture. There's enough simple ways and options, but they are not accurate. So, for example, a drill is placed on a prepared inclined surface and our workpiece is drilled at the resulting angle, as we understand, the accuracy suffers greatly.

Jig for drilling holes for dowels

Their main purpose is to maintain the alignment of the holes, into which dowels will subsequently be installed. That is, when you apply the jig to both sides of the product, you get a perfect joint.

As you understand, this type of conductors can be made independently. If you have a flow of workpieces with the same geometry, it will be convenient for you to use an overlay template. It is advisable to use hardboard or other material as a template. transparent material(plastic).

We mark and drill holes. It is advisable to drive brass or copper tubes into the holes so that the drill does not break the calibration hole.

Universal device

When you use blanks various forms and sizes, then you will need a universal device. The most interesting thing is that this device can be made from scrap materials.

- For this we need plywood about 15 mm thick.

- We make three identical blanks.

- We make holes along the edges into which dowels are installed as legs.

- We make one hole in the middle, which we reinforce with a metal tube.

- Let's make three metal strips with symmetrically located holes, they will serve as a shoulder. These shoulders are responsible for the linearity of the holes of the future conductor.

- We make cuts in the plywood blanks and install metal shoulders, securing everything. Our universal self-centering jig is ready.

Conclusion

Any universal jig for drilling holes is made to save time and money. Whether you make it yourself or buy it ready-made in a store is up to you to decide.

It should be noted here that for one time or use at home it is enough to buy the simplest conductor, and if you practice constantly, then you should dig professional equipment for drilling holes, which is expensive (Wolfcraft).