How to bend plexiglass 10 mm thick. We bend plexiglass at home - new opportunities for creative work. Video: bending plexiglass with nichrome wire

Read also

bend organic glass easy and manual without the use of tools. Successfully used this property plexiglass, which allows for a variety of work. Knowing how to bend plexiglass, you should use one of the existing techniques that allows you to get a good bend of plexiglass.

What should you consider when bending plexiglass?

Plexiglas is a thermoplastic, so it is capable of acquiring sufficient plasticity, which depends on high temperatures. Plexiglass during the manufacturing process can be formed by different temperatures, which determines how it is obtained.

The complexity of the process of bending plexiglass lies in obtaining a bend at the required angle, which is done in the required place. To bend the plexiglass, you can use a heat source.

The bending process is carried out taking into account the direction from the heat source. If bubbles form when the plexiglass is bent, it needs to be dried before the process itself. When starting to bend, it is important to remember that before bending glass, it is best to practice on a small unnecessary piece of material.

If you use blowtorch, then you can warm it up to the required temperature level. When bending plexiglass using a metal pipe, its radius is repeated by the sheet.

Read also:

Review .

How to sharpen a meat grinder knife

Return to contents

Principles of bending plexiglass

A heat source that allows you to heat the plexiglass so that it undergoes bending is best suited for a narrow format. This type The source is made using nichrome wire. A number of small sources can be installed on one line thermal radiation, for example, thin candles for cakes.

This type of source is made by filling a trench using non-flammable material filled with paraffin. You can stick thread into it. In extreme cases, you can use candles.

The second bending method can be used if any part of the plexiglass is covered with a material that has poor thermal conductivity and is non-flammable. IN in this case adjusting the bending angle will be the easiest, which will allow you to change the width of the strip. We should not forget about various cylindrical objects, that is, tubes, used as a template to make the appropriate bend having the desired radius.

When bending has already been completed, the material is gradually cooled, which minimizes internal stress. After this, the voltage is removed by annealing for several hours, maintaining an air temperature of 60-80 °C.

If nichrome wire is heated, it may sag. This will entail an increase in the distance to the plexiglass. The sagging of the wire can be compensated by using a load. When bending a sheet, you cannot put pressure on this material, otherwise the deformation will be incorrect.

Return to contents

Guidelines for proper performance of work

Return to contents

Preparatory stage

To carry out the work efficiently, you will need patience and accuracy. At the same time, you should know how to bend plexiglass correctly in accordance with the technology. Will be needed special tools and materials. This procedure can be carried out using:

- Metal pipe.

- Nichrome wire.

- Blowtorch.

- Crafting table.

- Adjustable power supply.

Before bending plexiglass with wire, it is necessary to dry the plexiglass thoroughly so that no bubbles form at the bend site.

The list of basic steps includes the following main types of operations that allow you to make a bend:

- Surface cleaning.

- Drying.

- Fixing the sheet with tensioning nichrome wire.

- Heating and bending plexiglass.

- Bending to a specific radius.

They begin to prepare the material before performing bending work. The glass must be thoroughly cleaned of dust and dirt. At heavily polluted the material is immersed in the bath. If there is local contamination on the glass, use a cotton swab or rag that is moistened with water. Cotton cloth is used to dry glass.

Cleaning is not carried out using abrasives or synthetic materials. If it is contaminated with oil or grease stains, they can be removed with gasoline or kerosene. Aggressive liquids, that is, acetone or solvent, are not recommended, as they can harm the glass.

If the material was in conditions high humidity and the presence of water vapor, drying must be carried out with special care while maintaining the appropriate temperature of 80 °C. The drying time should be between 1 and 2 hours per mm of thickness.

With a sheet thickness of 3 mm, it may take from 3 to 6 hours. May need a large number of time, which will depend on the temperature level and the amount of moisture absorbed. If drying is not done, bubbles may appear.

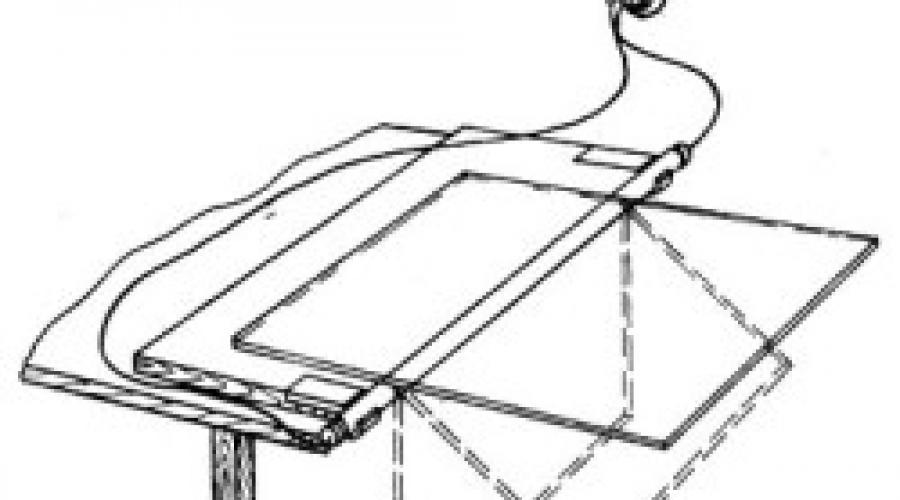

When drying is complete, the sheet should be secured to the edge of the workbench by stretching nichrome wire at the future bend.

In order to bend plexiglass to a certain radius, you need to take a pipe of the required diameter.

It is fixed at a distance from the sheet, which is no more than 0.5 cm. Basic important steps include the installation of a bendable edge of plexiglass at the stop, which cannot be bent to an angle greater than necessary.

Nichrome wire is used after it is connected to a power source that is regulated. After achieving the required glow on the nichrome wire, you should wait until the sheet begins to bend under the influence of its own weight. When the temperature level reaches 150 – 190°C, the sheet is bent. If there is a need to maintain the bending radius, then use metal pipe instead of nichrome wire.

They are increasingly becoming part of our lives. synthetic materials- These are various plastics, fibers, transparent polymers. These include plexiglass. In interior decoration and furniture production, the use of plexiglass is quite common. However, with the help of this material you can add zest not only to the interior; plexiglass is widely used in the manufacture interesting items and DIY souvenirs such as decorative photo frames, clear speaker cases and more.

The use of artificial glass in everyday life is explained by a number of its advantages over natural glass.

- Plexiglas has a lower density, which means it is much lighter than silicate glass.

- It is less brittle due to its amorphous structure and is easier to process (for example, drill or cut). The impact resistance of such glass is almost 5 times higher compared to inorganic glass.

- Plexiglas is a non-splintering material, so it is safer for household use.

- High transparency allows transmission of up to 99% of ultraviolet radiation.

- Plexiglas has increased resistance to atmospheric phenomena, which allows it to be used under a wide range of temperature conditions.

- But the most important advantage of such glass is that it can be easily given almost any shape, for example, you can bend plexiglass at home.

What is plexiglass, and why does it have such wonderful properties? Plexiglas is whole line transparent amorphous polymers consisting of linear or branched macromolecules. This structure makes plexiglass quite fusible and plastic, which allows it to be used in home interior(as a decorative tabletop or transparent shelves).

If you decide to use this polymer in the interior as a decorative element, and there is a need to give it a certain shape, this article will tell you how to bend plexiglass at home.

Tools

- A vice or clamp for fixing the sheet.

- Sharp saw.

- Construction hair dryer for heating to the desired temperature.

- Blank or mold.

- Sanding material.

Preparatory work

Before you start bending the part big size, try to bend a small piece of glass, if you succeed, you can start working.

1. To start working with plexiglass, you need to cut out the part the right size. To cut organic glass, you can use a clamp to firmly fix the sheet of polymer, and a sharp hacksaw for wood. To avoid overheating of the material during cutting, it is recommended to cool the cutting area with water. Do not forget to transfer the glass from the hard clamps of a clamp or vice with a soft cloth. This will protect the plexiglass from scratches.

Attention! When cutting plexiglass, use only sharp blades. Using dull blades when cutting leads to melting of the glass edges.

If a crack appears on the plexiglass as a result of processing, you can use a little trick to remove it. Moisten the damaged area with very cooled acetic acid and slightly move the edges of the crack, which will allow the acid to penetrate deeper inside. Polish the damaged area. After this treatment, the crack will stick together and will not be noticeable.

2. Before you start bending any plexiglass, in order to avoid defects, you need to clean it. To do this, rinse it thoroughly with water and detergent.

Attention! When cleaning plexiglass, the use of abrasive materials is not allowed, as it can be easily scratched. Use only a soft sponge.

3. After wiping the glass, let it dry thoroughly (about one hour per millimeter of thickness). When the glass is dry, you can begin to shape the plexiglass.

Bending plexiglass

Attention! To avoid burns when heating plexiglass, use thermally insulating gloves or silicone oven mitts.

Depending on the desired result, follow temperature regime. If you are going to bend glass, you need a temperature of 150 degrees. Plexiglas is melted at a temperature of 170 degrees.

Attention! If you decide to melt the polymer and cast something from it, make sure that the casting mold is clean. A mold that is not clean enough can lead to defects on the surface of the product.

To bend plexiglass, there are several heating methods. You can use an electric stove. This method is good for shaping sheets of glass that are not too thick.

Small parts can be “cooked” by simply holding them in boiling water for some time. Once sufficiently warm, use heat-resistant gloves to apply heat to the parts. the required form.

To work with large sheets of greater thickness, it is most convenient to use a hair dryer.

Let's take a closer look at how to do this using a hair dryer:

- The first thing to remember when bending plexiglass is that the material should be bent in the direction opposite to the heated side.

- If you are bending a sheet whose thickness exceeds 5 millimeters, you need to heat it on both sides alternately, and external corner should heat up last.

- Having made sure that the polymer has reached the desired temperature and has become sufficiently plastic, you need to immediately give it the desired shape without waiting for it to cool, otherwise cloudiness may form at the bend, a sign of microcracks in the material. If these measures are not followed, the glass will simply break at the bend.

Before you begin the process of bending plexiglass using a hair dryer, prepare a mold or template for bending.

It could be a tabletop, a piece of pipe, wooden block, some other surface whose shape you want to give to the glass. Heat the area needed for bending, then give it the desired shape. Next, the plexiglass product needs to be cooled properly. Do not expose glass to sudden temperature changes, as this can lead to cracking or other defects. Just leave it to cool for a while at room temperature.

When the part has cooled sufficiently, process the edges of the product. This can be done either mechanically (using sandpaper) or thermally. For rough processing you will need sandpaper, and for finer grinding, abrasive pastes are used, for example, GOI paste, as well as toothpastes and powders. At mechanically When processing edges, do not forget to cool the glass surface with water.

Your product is ready, now you know how to bend plexiglass at home. We hope that with the help of this article you will be able to decorate your interior. big amount beautiful and unique decor items.

Conventional glass, one of the most ancient and universally used materials, no matter how hard you try, cannot be bent. It will burst when heated. The situation is different with organic glass, thermoplastic transparent plastic, also called acrylic, acrylite.

In terms of its characteristics, a high-quality synthetic polymer is practically no different from ordinary glass. However, it is convenient because it can be easily bent if necessary. What needs to be done to make plexiglass change shape? Of course, heat it up. But first it must be prepared.

Drying the material

Removing moisture is necessary to avoid bending damage. The fact is that the internal structure of glass contains water particles, which, when heated, turn into a gaseous state. The appearance of air bubbles nullifies all the work and the product becomes defective. Pre-drying eliminates point accumulation of the gas mixture.

The glass is dried at a temperature of approximately 80 °C. If the element being processed small size, then at home you can use the oven. The drying time is determined based on the thickness of the heated part. So, with a value of 1 mm, plexiglass should be exposed to temperatures for one and a half hours. To dry material with other cross section time increases proportionally.

Preparing for bending

To work you will need a table or workbench. The workpiece is fixed in such a way that it can be easily bent down. For this purpose, a piece of glass is placed on the table, with a heavy load placed on top. The area subject to deformation extends further beyond the edge of the device used. The glass is prepared for bending.

Next is taken a heating element, with the help of which plexiglass will be bent - a nichrome wire connected to electricity through a device for regulating the current power. This could be a ballast resistor, a ballast capacitor, or a triac regulator. In addition, a metal tube heated by a burner is also suitable. The distance between the instrument and the glass should not exceed 1.5 cm.

Deformation process

A wire or tube is placed under the intended bend line and heated, respectively, with electricity or a burner. As the temperature rises, the glass begins to soften. When the material at the bending point is heated to a certain value, it itself will begin to bend under the influence of gravitational force and its own mass. There is no need to take any action. All that remains is to wait and remove the heating tool at the right moment.

In order for the glass to bend as required, a limiter should be installed. In this case, the edge being processed will rest against the device, and the curvature will reach the desired degree. If you do not take care in advance to fix the free part of the plexiglass in the appropriate position, it will be more difficult to fix the problem.

You should not rush during the process; putting pressure on the workpiece is not recommended. Bending should occur naturally to avoid defects.

How to bend plexiglass at home video

Often the desire to make their home even more attractive and interesting prompts owners to use very rare and intricate materials in their work. Previously used for decoration vinyl records and metal alloys, matchboxes and scorched wood, textiles and leatherette, as well as much more: experienced master will find a use for everything. Today, polymer plexiglass has gained wide popularity, which can be used both for decorative purposes and as a material for creating intricate devices. household use. Thanks to creative approach, with skillful hands and certain knowledge, you can create truly unique objects from organic glass, which will later become your pride and decoration of your home.

A little about the material

The named material is a polymer alloy that has high strength and at the same time maximum ductility (subject to the use of high temperatures). The composition of plexiglass includes amorphous polymers, which mainly consist of unfolded and linear macromolecules. This composition of the material allows us to achieve its absolute transparency, strength and lightness.

A new material that significantly expanded the capabilities of builders and designers

The advantages of plexiglass used as a material to create decorative elements interior are:

Therefore, organic glass is becoming increasingly in demand among jacks of all trades.

It is worth noting that completely different intricate little things can be created from plexiglass. These can be cute bookcases and fancy shelves, small aquariums or pots under houseplants, semicircular partitions in the room or simple countertops. In some cases, it may be necessary to bend the plexiglass at a given angle.

You can carry out this task at home, following the basic rules for working with plexiglass.

Several principles of working with plexiglass

Before you start melting and bending plexiglass, you need to learn several principles that will help you complete the work as efficiently as possible and without unnecessary waste of material.

- So, to form a part of the required size, it is necessary to cut a piece of material with the desired parameters from a whole plexiglass sheet. This will allow you to get the output economical consumption materials and higher productivity of work performed.

- For work, you must use only clean plexiglass. For these purposes, it is recommended to wash the material.

It is important not to use abrasive materials to clean plexiglass. Only a soft cloth and natural drying of the polymer fabric. Otherwise, noticeable and unsightly scratches and stains will form on the plexiglass, which will spoil appearance material and reduce its transparency.

- After washing the plexiglass, do not immediately begin bending work. Let the material dry. This will take at least a day in a dry room at room temperature. Or blow dry at 80 degrees Celsius.

The principle for calculating the time for drying plexiglass using a hairdryer should be as follows: 1 hour per 1 mm of material thickness in each section.

- When starting to heat plexiglass in order to deform it at the desired angle, keep in mind that heat treatment material must be carried out on the opposite side relative to the bending angle. That is, we heat the top of the material and bend it down.

- To bend plexiglass, it is enough to use a heating temperature of 150 degrees, and to melt the material and pour it into prepared forms, you need a temperature of at least 170 degrees.

Important: to properly bend plexiglass at home, you need to heat an area of the material three times greater than its thickness. That is, if your plexiglass has a thickness of 3 mm, then in order to bend it evenly and beautifully, you need to heat up such an area along the line of the intended bend, the width of which will be equal to 9 mm. With this thickness of plexiglass, it will be sufficient to treat it with a heat device on one side of the material. If the thickness of the plexiglass exceeds 5 mm, then it will need to be heated on both sides along the intended fold line.

- After bending the plexiglass, it is important to let it cool naturally. Do not use water or cold air as a cooler. It may cause harm finished product in the form of cracks, bubbles, etc.

Ways to bend at home

Necessary materials

In order to give the plexiglass the desired configuration, you can use one of several popular methods:

- Heating the material using a hair dryer;

- By boiling;

- Using nichrome wire.

Depending on the method of bending the plexiglass, you will need a heating element ( construction hair dryer, nichrome wire or a saucepan of boiling water). In addition, prepare:

- Hacksaw for metal;

- Vise for reliable fixation of the plexiglass plate;

- Shape for bending (pipe, block, tabletop, etc.);

- Abrasive material for grinding the edges of the product;

- A little water (to cool the material while cutting it).

Preparatory work

If your future product requires the use of a small piece of plexiglass, then you first need to cut it off from the overall fabric. To do this, securely fix the plexiglass in a vice and cut the required piece with a hacksaw. In places of fixation, do not forget to lay soft material, which will prevent damage to the plexiglass.

Can be used for cutting plexiglass hand saw, and a jigsaw

Important: use only a sharp hacksaw. Otherwise, the material may be damaged and deformed. Cool the cutting line with water while cutting plexiglass. This will avoid overheating of the plexiglass and its possible melting.

If a crack appears on the material during cutting, do not worry. You can remove it with a little trick: treat the edges of the split with chilled acetic acid. Using the method of shifting the plexiglass at the split site, allow acetic acid penetrate deeper into the pores of the material. Then squeeze the plexiglass at the crack. The material will melt and the polished crack will not be noticeable.

Bending by boiling method

This is the easiest way to bend plexiglass, requiring virtually no additional tools.

Remember to use protective gloves to avoid burns.

5. Leave the part formed from plexiglass until it cools completely.

Using a hair dryer

If you have to bend a fairly large piece of plexiglass, then use a hair dryer for this purpose. Its power will allow you to process large area organic polymer material in an extremely short time.

Using nichrome wire

Using nichrome wire carefully stretched under plexiglass, you can bend the material in a straight line without effort. To do this you need to do the following:

Video: bending plexiglass with nichrome wire

We present to your attention short video, which will clearly demonstrate how to bend plexiglass using nichrome wire.

Durable and lightweight, plexiglass is gaining increasing popularity in modern design and the construction sector. This allows you to easily expand the possibilities when creating artistic solutions, because by giving it various, even the most bizarre, forms, you can achieve a fresh and elegant atmosphere in any room.

Not only for interior decoration Plexiglas may be suitable; it also finds its application in creating unusual items interior Unlike natural glass, it artificial analogue boasts one amazing advantage. The fact is that it is easy to bend, so even at home you can get the necessary shape to realize any idea.

What should you stock up on before folding?

Before you get to work, it’s worth stocking up on some tools that will be useful for the described method. In addition to the workpiece itself, you will need:

- a device for heating a sheet of plexiglass, such as a construction hair dryer, gas burner or a blowtorch;

- a form or template for bending the type of shape you want to get from your workpiece;

- hand protection - heating to high temperatures can result in burns, so it is better to protect yourself and prepare silicone grips or thermal insulating gloves.

Preparatory stage

The main stage of preparation of the workpiece is cleaning its surface. Any grease or oil stains must be removed from the surface to avoid negative consequences for plexiglass during its subsequent deformation, namely warping and the formation of air bubbles, which will no longer be possible to remove.

All these stains are quite clearly visible upon detailed examination, so removing them will not be difficult. Often it is enough to rinse the workpiece warm water with the addition of a small amount of synthetic detergent. If there is a need to remove complex greasy spots, you can use kerosene or gasoline - they break down fat molecules at once.

Be sure to remember not to use hard abrasive materials when cleaning. They contribute to the appearance of scratches, from which there is practically no escape. An ordinary soft kitchen sponge will do a good job of cleaning plexiglass.

At the end of washing, the plexiglass should dry. At room temperature, drying time varies depending on the thickness of the workpiece. It is customary to proceed from the calculation of 1 hour per 1 millimeter of glass thickness. Only after the plexiglass has dried can you begin bending it.

Before bending plexiglass at home, make sure that you are satisfied with the size and shape of the workpiece. If desired, make a plexiglass blank using a hacksaw. Check that the hacksaw blade is not dull, because only well-sharpened teeth will allow you to obtain the required quality of the processed edge.

Rules and process of bending plexiglass

After preparatory work it is necessary to decide on the place that should be bent. Be sure to draw a line along which you want to bend the workpiece with a marker. Let us focus on several points that must be observed before starting work:

- Since plexiglass acquires the ability to bend when exposed to high temperatures, heating equipment should be selected based on the size of the surface that you are going to bend. This means that it is not necessary to heat the entire piece of glass if you have marked one fold line - local heating is sufficient for this.

- The area to be heated must have a width that is two or more times greater than its length. Compliance with this point will significantly reduce internal stresses glass after it has cooled.

The choice of heating source also depends on the size of the piece of plexiglass. So, for example, for thin sheets(up to 3-5 mm) good simple will do electric stove. For thick workpieces, it is better to prepare a construction hair dryer, with which you can quickly achieve required temperature heating For plexiglass it is 150 degrees.

In addition, it is worth remembering that such thick workpieces must be heated on both sides - this is necessary in order to prevent cracks from appearing during bending.

Let's move on directly to how to bend plexiglass at home. The process can be divided into several stages.

- The entire piece of plexiglass or a separate section is heated. To do this, you should act on the material for some time. heating device, and so that the heated side is opposite to the direction of bending. In the case of thick sheets, the latter heats up the side on which the outer bending angle will be located.

- Reaching the required temperature is determined by eye - the material will become more pliable and slightly cloudy from the inside.

- Keep a prepared form or template on hand for bending, which can serve as either a rectangular or round surface.

- As soon as you understand that the material is ready, it must be bent immediately, it is advisable to use minimal amount movements and obtain the required shape as quickly as possible, without allowing the material to cool. If you miss this moment, then microcracks may appear in the structure of the plexiglass, which subsequently begin to destroy the part from the inside.

The blanks are very small size can be modified by simply leaving them in boiling water for 5-7 minutes. The material will have time to soften so much that you can give it a completely different shape with your own hands. A prerequisite here is to work with special gloves that will not allow high temperature damage your limbs.

By the way, it is worth noting that plexiglass can also be melted at home. Only for this it needs to be heated even more - at least to 180 degrees. This can be done to make polymer glass castings.

The casting forms prepared in advance can be different, but the glass itself in the molten state spreads well and completely fills even the thinnest areas of the mold. Before casting, you need to make sure that the mold is cleaned of dirt in order to avoid both the unsightly appearance of the resulting casting and possible defects that dirt can cause.

After folding

You can finish the instructions on how to bend plexiglass at home by describing the final stage, which is cooling finished part. Special conditions There is no need to create it; just leave it at room temperature for a couple of hours. But it is important to isolate the material from possible sudden temperature fluctuations. Failure to cool slowly can lead to the formation of cracks on the surface or structure of the plexiglass.

After cooling, you receive a new product that has retained everything positive traits plexiglass. Safe and beautiful material, who received new uniform, will still be able to for a long time to please its owner, while it took very little time and effort to create it.