How to convert minutes to millimeters of toe. How to convert angular quantities to linear ones? Learn more about units used in typography and digital imaging

), the issue of correct wheel alignment on the car was involuntarily raised. Correctly set camber, toe and caster angles, as well as incorrect ones, can significantly change the car’s behavior on the road, this should be especially noticeable at high speeds.

1. To begin with, I turned to Tyrnet for optimal angles wheel installation, and it turned out that the factory recommends the following values:

Curb vehicle, front axle:

Camber 0 degrees +/-30 minutes

Caster 1 degree 15 minutes +/- 30 minutes (without ESD)

2 degrees 20 minutes +/- 30 minutes (with EUR)

Linear toe 2 +/- 1 mm

angular 0 degrees 10 minutes - 0 degrees 30 minutes

Rear axle:

Camber -1 degree

Total convergence 10 minutes

2. Next, I picked up a printout of the very first measurements from TO-1 at 2300 km

in DAV-Auto (back in autumn 2012). To my surprise, the work was carried out using the map of the first Kalina (thanks for not using 2110). By that time, the car had been on sale for a whole year, and it was strange that OD did not have the correct parameters in its equipment.

Before:

Caster - good

Camber is normal

Toe-in is good

Rear:

Camber is normal

Convergence - unclear, terribly much

(apparently by-effect from using a card of a different car model)

***********************************************************************************************************************

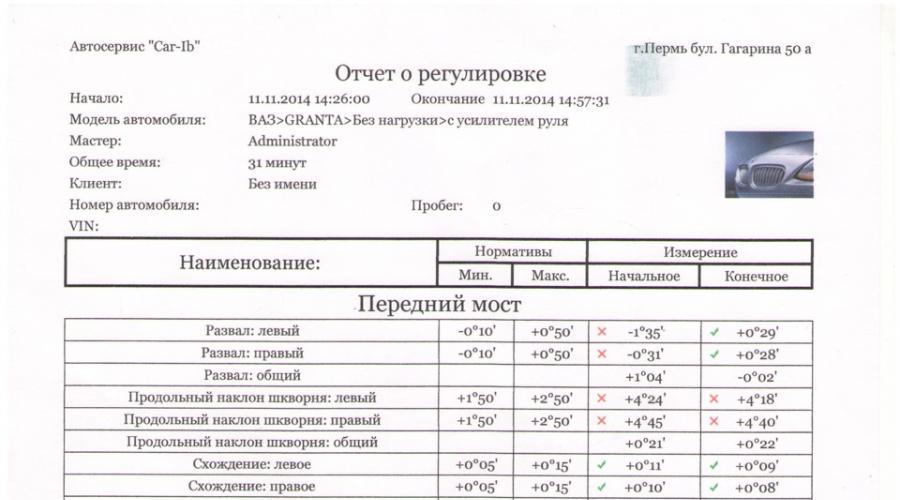

3. Last fall, the springs around were replaced with TechnoRessor -30, after which I went to correct the wheel alignment on a 3D stand in the Kar-Ib garage. By the way, before the measurements they didn’t even check or ask about the tire pressure. In addition, after the adjustments, the steering wheel began to point to the left, but I did not return to them for alterations. The results were as follows:

Two questions arise here:

- why such a huge caster?

- why is the camber on the rear wheels so different?

The only reason for the increase in caster could only be the lowering; no other changes were made to the suspension. But this option was in doubt. Firstly, such a caster would be visually noticeable; the wheels should already be close to the front bumper. Secondly, it’s simply logically difficult to explain how understatement can have such an effect on caster.

But regarding the camber at the rear, there were several options: a bent beam, inaccurate measurements, a crooked wheel.

***********************************************************************************************************************

4. Before the upcoming spring repair of the suspension, I decided to go to the stand again to check and take measurements. But for a reason. The reason was the following - visually it seemed that the right wheel had a negative camber, despite the fact that the right one was level. I thought that the car had gone through a hole somewhere badly. To exclude my cretinism, I showed the wheel to the guys I knew, and they nodded in agreement, saying that the left wheel was indeed “down.” But the 3D stand of the same Kar-Ib showed the following...

In total we see:

- the camber on both wheels is positive! (You need to show your eyes to the ophthalmologist)

- I don’t understand what kind of castor again. The wrecker stated that it had never matched on more than one of their cars! What? Don't go there anymore. In addition, the tire pressure was not checked again before the measurements.

- again, everything is bad with the rear beam, apparently bent, sadness.

***********************************************************************************************************************

5. Having serviced the suspension and installed the crab strut, I began to look for new wheel struts. The car was terribly pulled to the left, I couldn’t stand it for a long time, and instead of having lunch in the middle of the working day, I went to a certain general-purpose car service called “Obereg”, on Karpinsky. There is a computer stand there, but with string pulling and other shamanism. Helped me find Granta in the list of cards, otherwise they wanted to do it after sister Kalina. They didn’t measure the rear axle, they said they don’t do that, well, well. They didn’t give me a printout either, their mechanoid simply closed the program and said “I’m done.” But I remembered everything, the result is as follows:

Front (left/right)

Caster: +1.50" / +2.00"

Camber: +0.15" / +0.20"

Toe: +0.10" / +0.10"

The car drives straight, the steering wheel is straight, no complaints. But I won't go a second time. Yes, and they paid dearly.

***********************************************************************************************************************

Soon there will be manipulations with the suspension again, I’ll go and check the new wheel alignment specialists.

Total costs:

Adjustment in Kar-Iba (autumn) - 800 rubles.

Measurements in Kar-Iba (spring) - 400 rubles.

Adjustment to the Amulet (spring) - 900 rub.

Perhaps I will write in “pieces”. Without being too spread out over several changes in one entry.

I want to tell you about the suspension settings. About wheel alignment. But don’t rush to close the article! Yes, you can go to a specialist. Everything will be sorted out for you. And you will even like it. BUT.

Crap. Well, at least in some of my entries I can do without this “but”?

So here it is. Do you want to adjust your suspension better? The plant data is not perfect. They can be changed. So that it would be more pleasant and better to travel.

Moreover, if you want to do a little work with your hands, you can save money.

I'll try to highlight some points. So, to begin with: read in the factory book (or on the Internet) how and how the suspension parameters are adjusted (well, if you don’t know this, of course)

And further. What you've heard about is "it's hard" and "it takes high accuracy" - this is not true. It is enough to be attentive, to understand the head and arms, which do not grow at the level of the middle of the body. And I will help you with the rest.

Front axle:

The first thing you should do is castor. If you change it, you will have to configure the remaining settings again.

How to measure it “in your garage”? Well, there is a way, but you don't need it. I would suggest using the gap between the wheel and the rear of the fender as a guide. this is wrong, but... If you even make a mistake on some side by a few mm, a Muscovite simply will not notice it. He's not that demanding. Although after grooving the stabilizer, I recommend setting up the castor on the stand at least once. You are unlikely to need this later, except after moving trenches, trenches and open drains.

Second in line is collapse. It's easy to measure. It is enough to make a plumb line: tie a nut of about m6 size to 80 centimeters of thread. The tool is ready. Well, plus, out of habit, a ruler with a “zero” from the end will come in handy. You can modify the usual one.

Like this:

Now you can apply a plumb line to the wheel, but not in the center, but slightly to the side of the “bulge” (which is at the bottom due to the weight)

The gap at the top i.e. the wheel is tilted inward, i.e. “minus” camber.

If the gap is at the bottom, then the camber is “plus”, the wheel is “like a Tatra”

I won’t explain how to regulate it.

Experiments yielded the camber that I like most when driving: -0"20"~ -0"50" (this is minus 2-5mm at the plumb line at the top)

Want to turn aggressively? do -1"30" (8-10mm on a plumb line) but on the highway it will be worse.

Do you drive a lot on the highway? Make the wheel straight.

ATTENTION #1. Don't be afraid of mistakes! Even if you make a mistake and install wheels with a difference of 3 mm, neither the Muscovite nor you will NOTICE it when driving!

ATTENTION #2. If you sharpen the stabilizer too much, then the wheels may go too far “in plus” - i.e. collapse the tops outwards. And so much so that the adjustment reserve is not enough. Then simply remove the wheel, unscrew the two bolts (LOWER UNCROSS, but do not knock out, I remind you!) and cut the upper hole in the rack inward. Taking into account that a 2 mm cut is enough to fill the wheel by 5-6 millimeters.

Don't be afraid to do this! The well-known Opel Omega and FW Passat have such cuts straight from the factory. And as you can see, they move without falling apart.

Convergence.

Tools: the same ruler and 5 meters of thin (2-3mm) rubber cord (you can use a regular one, but it’s inconvenient). Cut the cord into 2 pieces.

Tie it to the spare tire bracket from behind and stretch it along the middle of the wheels as in the photo.

Just move your hand with the cord smoothly, touching the front wheel. If you made a collapse, then you can deal with it.

The gap in the front part of the wheel is “toe-in” or “positive”

The gap in the rear is, respectively, “divergence” or “minus”

I always gave everyone +0"05" (plus 0.5mm)

On the cord it will look like "almost level", but with a slight hint of positive.

Rear axle

The measurement principle is the same for both camber and toe. But the adjustment is more difficult.

Let me remind you. The hub axle is screwed to the beam with four bolts with a diameter of 10 mm. Quite a popular scheme.

By changing the fit of the plane using washers, you can adjust both camber and toe.

ATTENTION No. 2 Washers are placed only between the brake shield and the beam (otherwise there have been cases) :)

To adjust, you will need several 10 or 12 washers (which are easier to get) with a thickness of 0.5 mm or thinner. Thin washers with a diameter of 12 are adjustable from the factory in VAZ classics as camber adjusters.

Place washers on the basis of: 0.5mm washer is 1.5-2mm on the wheel. It rarely works the first time.

We measured all the parameters on both wheels, wrote them down, and estimated how many washers would be needed and for which bolts. We checked again. We remove the drum. Unscrewing one bolt at a time, put on the washers one by one.

We measure:

My parameters:

camber -1"20" (minus 8mm at the top of the plumb line)

toe +0"10" (1mm clearance at the front)

(legacy of the famous Audi brand)

So to speak:

If you are doing it for the first time and are worried, then do it, and then go to the stand to check. Ask for a printout of the data and for them to explain which parameter is which and estimate it in millimeters. Try it on the car again and compare it with the printout.

Degrees-minutes to millimeters approximately 10/1 For example.

1"00" = 0"60" = 60 minutes = ~6mm

1"40" = 0"60"+0"40" = 100 minutes = ~10mm

All data together (degrees/minutes):

Before:

castor: +1"30 minimum (I made +2"30)

camber: universal -0"30 -0"50, sport -1"30, track 0"00

toe: +0"05 (total +0"10)

Rear:

camber: -1"20

toe +0"10 (total +0"20)

Get together - don't fall apart! :)

(if you forgot anything or have questions, write in the comments)

Angular quantities are actively used in our lives along with linear ones. Them skill is more important converting one type of quantity into another. Let's look at the "car" example of the possibility of converting some quantities into others.

Thrust and camber angle parameters are usually measured in degrees, but they can be measured and displayed in degrees and minutes. Toe-in parameters are also measured in degrees, but can also be displayed in length parameters. The parameters listed above are considered to be angular, since we are calculating the angle.

One of the most important questions will be: at what tire or wheel diameter is the corner distance measured? It is quite natural that with a larger diameter, the angle distance will be larger. Some nuances should be noted here: when the ratio of inches and millimeters of the reference diameter is used, the value of the standard is used, which is set and reflected on the “Vehicle Specifications” screen. However, if millimeters and inches are indicated as units of measurement, but there is no information about the diameter of the rim, then it is assumed that the diameter is equal to the standard one, that is, 28.648 inches.

Typically, toe-in reflects the width of the track between the front and rear ends of the vehicle's wheels. Here is the general formula for finding convergence:

Small angles

Of course, everything can be measured in corners. However, angular division is often unnatural and inconvenient, since whole degrees are subdivided into smaller units: arcsecond and arcminute. An arc minute is 1/60th of a degree; arcsecond is 1/60 of the previous unit.

The human eye, under normal lighting, is capable of “fixing” a value approximately equal to 1 minute. That is, the resolution of the human organ of vision perceives, instead of two points that have a distance between them equal to one minute, or even less, as one.

It is also worth considering the concepts of sine and tangent of small angles. Tangent of the angle right triangle It is customary to call the ratio of the sides of the opposite side to the adjacent side. The tangent of angle α is usually denoted as tan α. At small angles (which, in fact, are we're talking about.), the tangent of the angle is equal to the angle measured in radians.

Translation example:

Estimated disc diameter: 360 mm

Toe equal: 1.5 mm

Then we assume that tan α ≈ α= 1.5/360 = 0.00417 (rad)

Conversion to degrees:

α[°] = (180 / π) × α[rad]

where: α[rad] - designation of the angle in radians, α[°] - designation of the angle in degrees

Now let's carry out the conversion process in minutes:

α = 0.00417×57.295779513°=0.2654703°=14.33542"

A special converter will help convert some units.

Thus, we see: converting angular quantities into linear ones is not difficult.

“Angle” parameters, such as camber and thrust angle, are measured in degrees, but can be displayed in either degrees or degrees with minutes. Convergence parameters are also “angular” and, accordingly, are always measured in degrees, but can be displayed both in degrees and in length measures.

The most important question in this situation is: at what diameter of the tire or wheel is this distance measured? The larger the diameter, the greater the distance for a given angle. If the units of measurement are set to the ratio inches or millimeters and reference diameter, then the system uses the reference diameter value set on the Vehicle Specifications screen.If the units are set to inches or millimeters, but the rim diameter is not specified, the diameter defaults to 28.648 inches, which is a simple conversion of 2° of toe per inch (or 25.4 millimeters) of toe.

When toe is displayed as a distance, it refers to the difference in track width between the front and rear edges of the wheels.

Small angles

In principle, it would be possible to measure all angles in radians. In practice, degree measurement of angles is also widely used, although from a purely mathematical point of view it is unnatural. In this case, for small angles special units are used: arc minute and arc second. An arc minute is 1/60th part degrees; An arc second is 1/60th of an arc minute.

The idea of a minute of arc is given by the following fact: the “resolution power” of the human eye (with 100% vision and good lighting) is approximately one minute of arc. This means that two points that are visible at an angle of 1” or less are perceived by the eye as one.

Let's see what can be said about the sine, cosine and tangent of small angles. If the angle α in the figure is small, then the height BC, the arc BD and the segment BE perpendicular to AB are very close. Their lengths are sin α, radian measure α and tan α. Therefore, for small angles the sine, tangent and radian measure are approximately equal to each other: If α is a small angle measured in radians, then sin α ≈ α ; tan α ≈ α

The tangent of the angle of a right triangle is the ratio of the opposite side to the adjacent side. The tangent of the angle α is designated: tan α. And at small angles (namely, these are the ones we are talking about), the tangent is approximately equal to the angle itself, measured in radians.

Translation example linear magnitude to the corner:

Disc diameter: 360 mm AC

Toe: 1.5mm BC

Then tan α ≈ α= 1.5/360 = 0.00417 (rad)

Let's convert to degrees:

α[°] = (180 / π) × α[rad]

where: α[rad] - angle in radians, α[°] - angle in degrees

Typically, toe-in reflects the width of the track between the front and rear ends of the vehicle's wheels. Here general formula finding convergence:

Small angles

Translation example:

Toe equal: 1.5 mm

Conversion to degrees:

α[°] = (180 / π) × α[rad]

Length and distance converter Mass converter Volume converter bulk products and food products Area converter Volume and units converter in culinary recipes Temperature converter Pressure converter, mechanical stress, Young's modulus Energy and work converter Power converter Force converter Time converter Converter linear speed Flat Angle Thermal Efficiency and Fuel Efficiency Converter Number Converter to various systems notation Converter of units of measurement of quantity of information Exchange rates Dimensions women's clothing and shoes Sizes of men's clothing and shoes Angular velocity and rotational speed converter Acceleration converter Angular acceleration converter Density converter Specific volume converter Moment of inertia converter Moment of force converter Torque converter Converter specific heat combustion (by mass) Energy density and specific heat of combustion converter (by volume) Temperature difference converter Thermal expansion coefficient converter Converter thermal resistance Thermal Conductivity Converter Converter specific heat capacity Energy Exposure and Power Converter thermal radiation Heat Flow Density Converter Heat Transfer Coefficient Converter Volume Flow Converter Mass Flow Converter Molar Flow Converter Mass Flow Density Converter Molar Concentration Converter Mass Concentration Converter in Solution Dynamic (Absolute) Viscosity Converter Converter kinematic viscosity Converter surface tension Vapor permeability converter Vapor permeability and vapor transfer rate converter Sound level converter Microphone sensitivity converter Level converter sound pressure(SPL) Sound pressure level converter with selectable reference pressure Brightness converter Luminous intensity converter Illuminance converter Resolution converter computer graphics Frequency and Wavelength Converter Diopter Power and Focal Length Diopter Power and Lens Magnification (×) Converter electric charge Linear Charge Density Converter Converter surface density Charge Volume Charge Density Converter Converter electric current Linear current density converter Surface current density converter Voltage converter electric field Electrostatic Potential and Voltage Converter Converter electrical resistance Electrical resistivity converter Electrical conductivity converter Electrical conductivity converter Electrical capacitance Inductance converter American wire gauge converter Levels in dBm (dBm or dBmW), dBV (dBV), watts and other units Magnetomotive force converter Voltage converter magnetic field Converter magnetic flux Magnetic induction converter Radiation. Ionizing radiation absorbed dose rate converter Radioactivity. Converter radioactive decay Radiation. Exposure dose converter Radiation. Absorbed Dose Converter Decimal Prefix Converter Data Transfer Typography and Imaging Converter Timber Volume Unit Converter Molar Mass Calculation Periodic table chemical elements D. I. Mendeleev

1 millimeter [mm] = 56.6929133858264 twip

Initial value

Converted value

twip meter centimeter millimeter symbol (X) symbol (Y) pixel (X) pixel (Y) inch soldering (computer) soldering (typographic) point NIS/PostScript point (computer) point (typographical) em dash cicero em dash point Dido

Learn more about units used in typography and digital imaging

General information

Typography is the study of the reproduction of text on a page and the use of its size, typeface, color, and other external signs so that the text is better readable and looks beautiful. Typography emerged in the mid-15th century with the advent of printing presses. The placement of text on a page affects our perception - the better it is placed, the more likely it is that the reader will understand and remember what is written in the text. Poor-quality typography, on the contrary, makes the text difficult to read.

Headsets are divided into different types, for example, fonts with and without serifs. Serifs - decorative element font, but in some cases they make the text easier to read, although sometimes the opposite happens. First letter ( blue color) in the image is in Bodoni serif font. One of the four serifs is outlined in red. The second letter (yellow) is in Futura sans serif font.

There are many classifications of fonts, for example, according to the time of their creation, or the style popular in certain time. Yes, there are fonts old style- a group that includes the oldest fonts; newer fonts transitional style; modern fonts, created after the transitional fonts and before the 1820s; and finally new style fonts or modernized old fonts, that is, fonts made according to the old model at a later time. This classification is mainly used for serif fonts. There are other classifications based on appearance fonts, such as the thickness of the lines, the contrast between thin and thick lines, and the shape of the serifs. The domestic press has its own classifications. For example, the classification according to GOST groups fonts by the presence and absence of serifs, thickening in serifs, smooth transition from the main line to the serif, rounding of the serif, and so on. In classifications of Russian, as well as other Cyrillic fonts, there is often a category for Old Church Slavonic fonts.

The main task of typography is to adjust the size of letters and choose appropriate fonts to place text on the page so that it is easy to read and looks beautiful. There are a number of systems for determining font size. In some cases, the same size of letters in typographic units, if they are printed in different typefaces, does not mean the same size of the letters themselves in centimeters or inches. This situation is described in more detail below. Despite the inconvenience caused by this, used on this moment font size helps designers arrange text neatly and beautifully on a page. This is especially important in layout.

In layout, you need to know not only the size of the text, but also the height and width of digital images in order to fit them on the page. Size can be expressed in centimeters or inches, but there is also a unit specifically designed to measure the size of images - pixels. A pixel is an element of an image in the form of a point (or square) of which it is composed.

Definition of units

The size of letters in typography is indicated by the word “size”. There are several systems for measuring point size, but most are based on the unit "soldering" in American and English system measurements (English pica), or “cicero” in the European measurement system. The name "soldering" is sometimes written as "spike". There are several types of soldering, which differ slightly in size, so when using soldering, it is worth remembering which soldering you mean. Initially, cicero was used in domestic printing, but now soldering is also common. Cicero and computer soldering are similar in size, but not equal. Sometimes cicero or soldering is directly used for measurement, for example to determine the size of margins or columns. More often, especially for text measurement, soldered-derived units such as printing points are used. The soldering size is determined in different systems in different ways, as described below.

Letters are measured as shown in the illustration:

Other units

Although computer soldering is gradually replacing other units, and perhaps replacing the more familiar ciceros, other units are also used along with it. One of these units is American soldering It is equal to 0.166 inches or 2.9 millimeters. There is also printing soldering. It is equal to the American one.

Some domestic printing houses and in the literature about printing still use pica- a unit that was widely used in Europe (with the exception of England) before the advent of computer soldering. One cicero is equal to 1/6 of a French inch. The French inch is slightly different from the modern inch. In modern units, one cicero is equal to 4.512 millimeters or 0.177 inches. This value is almost equal to computer soldering. One cicero is 1.06 computer solders.

Round embed (em) and semi-circular embed (en)

The units described above determine the height of letters, but there are also units that indicate the width of letters and symbols. Round and semicircular spacing are just such units. The first is also known as empare or em, from the English word for the letter M. Its width has historically been equal to that of this English letter. Likewise, a semi-circular embed equal to half a round one is known as en. Now these quantities are not defined using the letter M, since this letter may have different size for different fonts, even if the size is the same.

In Russian, the en dash and em dash are used. To indicate ranges and intervals (for example, in the phrase: “take 3-4 tablespoons of sugar”), an en dash is used, also called an en dash. The em dash is used in Russian in all other cases (for example, in the phrase: “the summer was short, and the winter was long”). It is also called em dash.

Problems with modern unit systems

Many designers do not like the current system of typographical units based on rations or ciceros and typographical points. The main problem is that these units are not tied to the metric or imperial system of measurements, and at the same time they have to be used in conjunction with centimeters or inches, in which the size of illustrations is measured.

In addition, letters made in two different typefaces can be very different in size, even if they are the same size at the typographic points. This is because letter height is measured as the height of the type pad, which is not directly related to the height of the character. This makes it difficult for designers, especially if they are working with multiple fonts in the same document. The illustration shows an example of this problem. The size of all three fonts in typographic points is the same, but the height of the sign is different everywhere. To solve this problem, some designers suggest measuring the point as the height of the character.

), the issue of correct wheel alignment on the car was involuntarily raised. Correctly set camber, toe and caster angles, as well as incorrect ones, can significantly change the car’s behavior on the road, this should be especially noticeable at high speeds.

1. To begin with, I turned to Tyrnet for optimal wheel alignment angles, and it turned out that the factory recommends the following values:

Curb vehicle, front axle:

Camber 0 degrees +/-30 minutes

Caster 1 degree 15 minutes +/- 30 minutes (without ESD)

2 degrees 20 minutes +/- 30 minutes (with EUR)

Linear toe 2 +/- 1 mm

angular 0 degrees 10 minutes - 0 degrees 30 minutes

Rear axle:

Camber -1 degree

Total convergence 10 minutes

2. Next, I picked up a printout of the very first measurements from TO-1 at 2300 km in DAV-Auto (back in autumn 2012). To my surprise, the work was carried out using the map of the first Kalina (thanks for not using 2110). By that time, the car had been on sale for a whole year, and it was strange that OD did not have the correct parameters in its equipment.

Before:

Caster - good

Camber is normal

Toe-in is good

Rear:

Camber is normal

Convergence - unclear, terribly much

(apparently a side effect of using a card of a different car model)

3. Last fall, the springs around were replaced with TechnoRessor -30, after which I went to correct the wheel alignment on a 3D stand in the Kar-Ib garage. By the way, before the measurements they didn’t even check or ask about the tire pressure. In addition, after the adjustments, the steering wheel began to point to the left, but I did not return to them for alterations. The results were as follows:

Two questions arise here:

- why such a huge caster?

- why is the camber on the rear wheels so different?

The only reason for the increase in caster could only be the lowering; no other changes were made to the suspension. But this option was in doubt. Firstly, such a caster would be visually noticeable; the wheels should already be close to the front bumper. Secondly, it’s simply logically difficult to explain how understatement can have such an effect on caster.

But regarding the camber at the rear, there were several options: a bent beam, inaccurate measurements, a crooked wheel.

***********************************************************************************************************************

4. Before the upcoming spring repair of the suspension, I decided to go to the stand again to check and take measurements. But for a reason. The reason was the following - visually it seemed that the right wheel had a negative camber, despite the fact that the right one was level. I thought that the car had gone through a hole somewhere badly. To exclude my cretinism, I showed the wheel to the guys I knew, and they nodded in agreement, saying that the left wheel was indeed “down.” But the 3D stand of the same Kar-Ib showed the following...

In total we see:

- the camber on both wheels is positive! (You need to show your eyes to the ophthalmologist)

- I don’t understand what kind of castor again. The wrecker stated that it had never matched on more than one of their cars! What? Don't go there anymore. In addition, the tire pressure was not checked again before the measurements.

- again, everything is bad with the rear beam, apparently bent, sadness.

***********************************************************************************************************************

5. Having serviced the suspension and installed the crab strut, I began to look for new wheel struts. The car was terribly pulled to the left, I couldn’t stand it for a long time, and instead of having lunch in the middle of the working day, I went to a certain general-purpose car service called “Obereg”, on Karpinsky. There is a computer stand there, but with string pulling and other shamanism. Helped me find Granta in the list of cards, otherwise they wanted to do it after sister Kalina. They didn’t measure the rear axle, they said they don’t do that, well, well. They didn’t give me a printout either, their mechanoid simply closed the program and said “I’m done.” But I remembered everything, the result is as follows:

Front (left/right)

Caster: +1.50" / +2.00"

Camber: +0.15" / +0.20"

Toe: +0.10" / +0.10"

The car drives straight, the steering wheel is straight, no complaints. But I won't go a second time. Yes, and they paid dearly.

***********************************************************************************************************************

Soon there will be manipulations with the suspension again, I’ll go and check the new wheel alignment specialists.

Total costs:

Adjustment in Kar-Iba (autumn) - 800 rubles.

Measurements in Kar-Iba (spring) - 400 rubles.

Adjustment to the Amulet (spring) - 900 rub.

Perhaps I will write in “pieces”. Without being too spread out over several changes in one entry.

I want to tell you about the suspension settings. About wheel alignment. But don’t rush to close the article! Yes, you can go to a specialist. Everything will be sorted out for you. And you will even like it. BUT.

Crap. Well, at least in some of my entries I can do without this “but”?

So here it is. Do you want to adjust your suspension better? The plant data is not perfect. They can be changed. So that it would be more pleasant and better to travel.

Moreover, if you want to do a little work with your hands, you can save money.

I'll try to highlight some points. So, to begin with: read in the factory book (or on the Internet) how and how the suspension parameters are adjusted (well, if you don’t know this, of course)

And further. What you've heard about, "it's complicated" and "high precision is required" - that's not true. Enough attentiveness, understanding the head and arms, which do not grow at the level of the middle of the body. And I'll help you with the rest.

Front axle:

The first thing you should do is castor. If you change it, you will have to configure the remaining settings again.

How to measure it “in your garage”? Well, there is a way, but you don't need it. I would suggest using the gap between the wheel and the rear of the fender as a guide. this is wrong, but... If you even make a mistake on some side by a few mm, a Muscovite simply will not notice it. He's not that demanding. Although after grooving the stabilizer, I recommend setting up the castor on the stand at least once. You are unlikely to need this later, except after moving trenches, trenches and open drains.

Second in line is collapse. It's easy to measure. It is enough to make a plumb line: tie a nut of about m6 size to 80 centimeters of thread. The tool is ready. Well, plus, out of habit, a ruler with a “zero” from the end will come in handy. You can modify the usual one.

Like this:

Now you can apply a plumb line to the wheel, but not in the center, but slightly to the side of the “bulge” (which is at the bottom due to the weight)

The gap at the top i.e. the wheel is tilted inward, i.e. “minus” camber.

If the gap is at the bottom, then the camber is “plus”, the wheel is “like a Tatra”

I won’t explain how to regulate it.

Experiments yielded the camber that I like most when driving: -0"20"~ -0"50" (this is minus 2-5mm at the plumb line at the top)

Want to turn aggressively? do -1"30" (8-10mm on a plumb line) but on the highway it will be worse.

Do you drive a lot on the highway? Make the wheel straight.

ATTENTION #1. Don't be afraid of mistakes! Even if you make a mistake and install wheels with a difference of 3 mm, neither the Muscovite nor you will NOTICE it when driving!

ATTENTION #2. If you sharpen the stabilizer too much, then the wheels may go too far “in plus” - i.e. collapse the tops outwards. And so much so that the adjustment reserve is not enough. Then simply remove the wheel, unscrew the two bolts (LOWER UNCROSS, but do not knock out, I remind you!) and cut the upper hole in the rack inward. Taking into account that a 2 mm cut is enough to fill the wheel by 5-6 millimeters.

Don't be afraid to do this! The well-known Opel Omega and FW Passat have such cuts straight from the factory. And as you can see, they move without falling apart.

Convergence.

Tools: the same ruler and 5 meters of thin (2-3mm) rubber cord (you can use a regular one, but it’s inconvenient). Cut the cord into 2 pieces.

Tie it to the spare tire bracket from behind and stretch it along the middle of the wheels as in the photo.

Just move your hand with the cord smoothly, touching the front wheel. If you made a collapse, then you can deal with it.

The gap in the front part of the wheel is “toe-in” or “positive”

The gap in the rear is, respectively, “divergence” or “minus”

I always gave everyone +0"05" (plus 0.5mm)

On the cord it will look like "almost level", but with a slight hint of positive.

Rear axle

The measurement principle is the same for both camber and toe. But the adjustment is more difficult.

Let me remind you. The hub axle is screwed to the beam with four bolts with a diameter of 10 mm. Quite a popular scheme.

By changing the fit of the plane using washers, you can adjust both camber and toe.

ATTENTION No. 2 Washers are placed only between the brake shield and the beam (otherwise there have been cases) :)

To adjust, you will need several 10 or 12 washers (which are easier to get) with a thickness of 0.5 mm or thinner. Thin washers with a diameter of 12 are adjustable from the factory in VAZ classics as camber adjusters.

Place washers on the basis of: 0.5mm washer is 1.5-2mm on the wheel. It rarely works the first time.

We measured all the parameters on both wheels, wrote them down, and estimated how many washers would be needed and for which bolts. We checked again. We remove the drum. Unscrewing one bolt at a time, put on the washers one by one.

We measure:

My parameters:

camber -1"20" (minus 8mm at the top of the plumb line)

toe +0"10" (1mm clearance at the front)

(legacy of the famous Audi brand)

So to speak:

If you are doing it for the first time and are worried, then do it, and then go to the stand to check. Ask for a printout of the data and for them to explain which parameter is which and estimate it in millimeters. Try it on the car again and compare it with the printout.

Degrees-minutes to millimeters approximately 10/1 For example.

1"00" = 0"60" = 60 minutes = ~6mm

1"40" = 0"60"+0"40" = 100 minutes = ~10mm

All data together (degrees/minutes):

Before:

castor: +1"30 minimum (I made +2"30)

camber: universal -0"30 -0"50, sport -1"30, track 0"00

toe: +0"05 (total +0"10)

Rear:

camber: -1"20

toe +0"10 (total +0"20)

Get together - don't fall apart! :)

(if you forgot anything or have questions, write in the comments)

Angular quantities are actively used in our lives along with linear ones. The more important is the ability to convert one type of quantity into another. Let's look at the "car" example of the possibility of converting some quantities into others.

Thrust and camber angle parameters are usually measured in degrees, but they can be measured and displayed in degrees and minutes. Toe-in parameters are also measured in degrees, but can also be displayed in length parameters. The parameters listed above are considered to be angular, since we are calculating the angle.

One of the most important issues the question will arise: at what value of tire or wheel diameter is the angle distance measured? It is quite natural that with a larger diameter, the angle distance will be larger. Some nuances should be noted here: when the ratio of inches and millimeters of the reference diameter is used, the value of the standard is used, which is set and reflected on the “Vehicle Specifications” screen. However, if the units of measurement are specified as millimeters and inches, but there is no information about the diameter rim, then assume that the diameter is equal to the standard, that is, 28.648 inches.

Typically, toe-in reflects the width of the track between the front and rear ends of the vehicle's wheels. Here is the general formula for finding convergence:

Small angles

Of course, everything can be measured in corners. However, angular division is often unnatural and inconvenient, since whole degrees are subdivided into smaller units: arcsecond and arcminute. An arc minute is 1/60th of a degree; arcsecond is 1/60 of the previous unit.

The human eye, under normal lighting, is capable of “fixing” a value approximately equal to 1 minute. That is, the resolution of the human organ of vision perceives, instead of two points that have a distance between them equal to one minute, or even less, as one.

It is also worth considering the concepts of sine and tangent of small angles. The tangent of the angle of a right triangle is usually called the ratio of the sides of the opposite side to the adjacent side. The tangent of angle α is usually denoted as tan α. At small angles (which, in fact, are what we are talking about), the tangent of the angle is equal to the value of the angle measured in radians.

Translation example:

Estimated disc diameter: 360 mm

Toe equal: 1.5 mm

Then we assume that tan α ≈ α= 1.5/360 = 0.00417 (rad)

Conversion to degrees:

α[°] = (180 / π) × α[rad]

where: α[rad] - designation of the angle in radians, α[°] - designation of the angle in degrees

Now let's carry out the conversion process in minutes:

α = 0.00417×57.295779513°=0.2654703°=14.33542"

A special converter will help convert some units.

Thus, we see: converting angular quantities into linear ones is not difficult.

“Angle” parameters, such as camber and thrust angle, are measured in degrees, but can be displayed in either degrees or degrees with minutes. Convergence parameters are also “angular” and, accordingly, are always measured in degrees, but can be displayed both in degrees and in length measures.

The most important question in this situation is: at what diameter of the tire or wheel is this distance measured? The larger the diameter, the greater the distance for a given angle.If the units of measurement are set to the ratio inches or millimeters and reference diameter, then the system uses the reference diameter value set on the Vehicle Specifications screen.If the units are set to inches or millimeters, but the rim diameter is not specified, the diameter defaults to 28.648 inches, which is a simple conversion of 2° of toe per inch (or 25.4 millimeters) of toe.

When toe is displayed as a distance, it refers to the difference in track width between the front and rear edges of the wheels.

L=L 2- L 1

Small angles

In principle, it would be possible to measure all angles in radians. In practice, degree measurement of angles is also widely used, although from a purely mathematical point of view it is unnatural. In this case, for small angles special units are used: arc minute and arc second. An arc minute is 1/60th partdegrees; An arc second is 1/60th of an arc minute.

The idea of a minute of arc is given by the following fact: the “resolution power” of the human eye (with 100% vision and good lighting) is approximately one minute of arc. This means that two points that are visible at an angle of 1” or less are perceived by the eye as one.

Let's see what can be said about the sine, cosine and tangent of small angles. If the angle α in the figure is small, then the height BC, the arc BD and the segment BE perpendicular to AB are very close. Their lengths are sin α, radian measure α and tan α. Therefore, for small angles the sine, tangent and radian measure are approximately equal to each other: If α is a small angle measured in radians, then sin α ≈ α ; tan α ≈ α

The tangent of the angle of a right triangle is the ratio of the opposite side to the adjacent side. The tangent of the angle α is designated: tan α. And at small angles (namely, these are the ones we are talking about), the tangent is approximately equal to the angle itself, measured in radians.

An example of converting a linear quantity into an angular one:

Disc diameter: 360 mm AC

Toe: 1.5mm BC

Then tg α ≈ α= 1.5/360 = 0.00417 (rad)

Let's convert to degrees:

α[°] = (180 / π) × α[rad]

where: α[rad] - angle in radians, α[°] - angle in degrees

Length and distance converter Mass converter Converter of volume measures of bulk products and food products Area converter Converter of volume and units of measurement in culinary recipes Temperature converter Converter of pressure, mechanical stress, Young's modulus Converter of energy and work Converter of power Converter of force Converter of time Linear speed converter Flat angle Converter thermal efficiency and fuel efficiency Converter of numbers in various number systems Converter of units of measurement of quantity of information Currency rates Women's clothing and shoe sizes Men's clothing and shoe sizes Angular velocity and rotation frequency converter Acceleration converter Angular acceleration converter Density converter Specific volume converter Moment of inertia converter Moment of force converter Torque converter Specific heat of combustion converter (by mass) Energy density and specific heat of combustion converter (by volume) Temperature difference converter Coefficient of thermal expansion converter Thermal resistance converter Thermal conductivity converter Specific heat capacity converter Energy exposure and thermal radiation power converter Heat flux density converter Heat transfer coefficient converter Volume flow rate converter Mass flow rate converter Molar flow rate converter Mass flow density converter Molar concentration converter Mass concentration in solution converter Dynamic (absolute) viscosity converter Kinematic viscosity converter Surface tension converter Vapor permeability converter Water vapor flow density converter Sound level converter Microphone sensitivity converter Converter Sound Pressure Level (SPL) Sound Pressure Level Converter with Selectable Reference Pressure Luminance Converter Luminous Intensity Converter Illuminance Converter Computer Graphics Resolution Converter Frequency and Wavelength Converter Diopter Power and Focal Length Diopter Power and Lens Magnification (×) Converter electric charge Linear charge density converter Surface charge density converter Volume charge density converter Electric current converter Linear current density converter Surface current density converter Electric field strength converter Electrostatic potential and voltage converter Electrical resistance converter Electrical resistivity converter Electrical conductivity converter Electrical conductivity converter Electrical capacitance Inductance Converter American Wire Gauge Converter Levels in dBm (dBm or dBm), dBV (dBV), watts, etc. units Magnetomotive force converter Magnetic field strength converter Magnetic flux converter Magnetic induction converter Radiation. Ionizing radiation absorbed dose rate converter Radioactivity. Radioactive decay converter Radiation. Exposure dose converter Radiation. Absorbed dose converter Decimal prefix converter Data transfer Typography and image processing unit converter Timber volume unit converter Calculation of molar mass D. I. Mendeleev’s periodic table of chemical elements

1 millimeter per minute [mm/min] = 0.0166666666666666 millimeter per second [mm/s]

Initial value

Converted value

meter per second meter per hour meter per minute kilometer per hour kilometer per minute kilometer per second centimeter per hour centimeter per minute centimeter per second millimeter per hour millimeter per minute millimeter per second foot per hour foot per minute foot per second yard per hour yard per minute yard per second mile per hour mile per minute miles per second knot knot (UK) speed of light in vacuum first escape velocity second escape velocity third escape velocity speed of rotation of the Earth speed of sound in fresh water speed of sound in sea water(20°C, depth 10 meters) Mach number (20°C, 1 atm) Mach number (SI standard)

More about speed

General information

Speed is a measure of the distance traveled in a certain time. Speed can be a scalar quantity or a vector quantity - the direction of movement is taken into account. The speed of movement in a straight line is called linear, and in a circle - angular.

Speed measurement

Average speed v found by dividing the total distance traveled ∆ x on total time ∆t: v = ∆x/∆t.

In the SI system, speed is measured in meters per second. Kilometers per hour in the metric system and miles per hour in the US and UK are also widely used. When, in addition to the magnitude, the direction is also indicated, for example, 10 meters per second to the north, then we are talking about vector velocity.

The speed of bodies moving with acceleration can be found using the formulas:

- a, With initial speed u during the period ∆ t, has a finite speed v = u + a×∆ t.

- A body moving with constant acceleration a, with initial speed u and final speed v, It has average speed ∆v = (u + v)/2.

Average speeds

Speed of light and sound

According to the theory of relativity, the speed of light in a vacuum is the highest speed at which energy and information can travel. It is denoted by the constant c and is equal to c= 299,792,458 meters per second. Matter cannot move at the speed of light because it would require an infinite amount of energy, which is impossible.

The speed of sound is usually measured in an elastic medium, and is equal to 343.2 meters per second in dry air at a temperature of 20 °C. The speed of sound is lowest in gases and highest in solids X. It depends on the density, elasticity, and shear modulus of the substance (which shows the degree of deformation of the substance under shear load). Mach number M is the ratio of the speed of a body in a liquid or gas medium to the speed of sound in this medium. It can be calculated using the formula:

M = v/a,

Where a is the speed of sound in the medium, and v- body speed. Mach number is commonly used in determining speeds close to the speed of sound, such as airplane speeds. This value is not constant; it depends on the state of the medium, which, in turn, depends on pressure and temperature. Supersonic speed is a speed exceeding Mach 1.

Vehicle speed

Below are some vehicle speeds.

- Passenger aircraft with turbofan engines: The cruising speed of passenger aircraft is from 244 to 257 meters per second, which corresponds to 878–926 kilometers per hour or M = 0.83–0.87.

- High-speed trains (like the Shinkansen in Japan): these trains reach maximum speeds from 36 to 122 meters per second, that is, from 130 to 440 kilometers per hour.

Animal speed

The maximum speeds of some animals are approximately equal to:

Human speed

- People walk at speeds of about 1.4 meters per second, or 5 kilometers per hour, and run at speeds of up to about 8.3 meters per second, or 30 kilometers per hour.

Examples of different speeds

Four-dimensional speed

In classical mechanics, vector velocity is measured in three-dimensional space. According to special theory relativity, space is four-dimensional, and the measurement of speed also takes into account the fourth dimension - space-time. This speed is called four-dimensional speed. Its direction may change, but its magnitude is constant and equal to c, that is, the speed of light. Four-dimensional speed is defined as

U = ∂x/∂τ,

Where x represents a world line - a curve in space-time along which a body moves, and τ is the "proper time" equal to the interval along the world line.

Group speed

Group velocity is the speed of wave propagation, describing the speed of propagation of a group of waves and determining the speed of wave energy transfer. It can be calculated as ∂ ω /∂k, Where k is the wave number, and ω - angular frequency. K measured in radians/meter, and the scalar frequency of wave oscillation ω - in radians per second.

Hypersonic speed

Hypersonic speed is a speed exceeding 3000 meters per second, that is, many times faster than the speed of sound. Solid bodies moving at such speeds acquire the properties of liquids, since, thanks to inertia, the loads in this state are stronger than the forces that hold the molecules of a substance together during collisions with other bodies. At ultrahigh hypersonic speeds, two colliding solids turn into gas. In space, bodies move at exactly this speed, and engineers who design spacecraft orbital stations and spacesuits must take into account the possibility of a collision between the station or the astronaut with space debris and other objects when working in outer space. In such a collision, the casing suffers spaceship and a spacesuit. Hardware developers are conducting hypersonic collision experiments in special laboratories to determine how severe impacts the suits, as well as the skin and other parts of the spacecraft, such as fuel tanks and solar panels, testing their strength. To do this, spacesuits and skin are exposed to impacts from various objects made of special installation with supersonic speeds exceeding 7500 meters per second.

Angular quantities are actively used in our lives along with linear ones. The more important is the ability to convert one type of quantity into another. Let's look at the "car" example of the possibility of converting some quantities into others.

Thrust and camber angle parameters are usually measured in degrees, but they can be measured and displayed in degrees and minutes. Toe-in parameters are also measured in degrees, but can also be displayed in length parameters. The parameters listed above are considered to be angular, since we are calculating the angle.

One of the most important questions will be: at what tire or wheel diameter is the corner distance measured? It is quite natural that with a larger diameter, the angle distance will be larger. Some nuances should be noted here: when the ratio of inches and millimeters of the reference diameter is used, the value of the standard is used, which is set and reflected on the “Vehicle Specifications” screen. However, if millimeters and inches are specified as units of measurement, but there is no information about the diameter of the rim, then it is assumed that the diameter is equal to the standard one, that is, 28.648 inches.

Typically, toe-in reflects the width of the track between the front and rear ends of the vehicle's wheels. Here is the general formula for finding convergence:

Small angles

Of course, everything can be measured in corners. However, angular division is often unnatural and inconvenient, since whole degrees are subdivided into smaller units: arcsecond and arcminute. An arc minute is 1/60th of a degree; arcsecond is 1/60 of the previous unit.

The human eye, under normal lighting, is capable of “fixing” a value approximately equal to 1 minute. That is, the resolution of the human organ of vision perceives, instead of two points that have a distance between them equal to one minute, or even less, as one.

It is also worth considering the concepts of sine and tangent of small angles. The tangent of the angle of a right triangle is usually called the ratio of the sides of the opposite side to the adjacent side. The tangent of angle α is usually denoted as tan α. At small angles (which, in fact, are what we are talking about), the tangent of the angle is equal to the value of the angle measured in radians.

Translation example:

Estimated disc diameter: 360 mm

Toe equal: 1.5 mm

Then we assume that tan α ≈ α= 1.5/360 = 0.00417 (rad)

Conversion to degrees:

α[°] = (180 / π) × α[rad]

where: α[rad] - designation of the angle in radians, α[°] - designation of the angle in degrees

Now let's carry out the conversion process in minutes:

α = 0.00417×57.295779513°=0.2654703°=14.33542"

A special converter will help convert some units.

Thus, we see: converting angular quantities into linear ones is not difficult.