How to distinguish a silicone tube. Connecting tubes and hoses in a moonshine still. Installation on the device

Read also

Silicone as a material was obtained in the middle of the 20th century. He quickly began to advance in the chemical industry and other fields. Silicone hoses, which are flexible tubes, today we have received quite wide application V various fields. Due to their physical and chemical properties, elastic silicone hoses work perfectly in those conditions in which products made from regular rubber there is no possibility to use.

Characteristics

Silicone hoses can be reinforced or unreinforced, flat (smooth) or corrugated. The sleeves are reinforced with fiberglass (single or double) and textile materials. Also, for the purpose of strengthening, they can be reinforced with a metal spiral. This production technology improves several times physical properties pipes.

Single fiberglass reinforcement increases endurance and reliability, double fiberglass reinforcement doubles the resistance to increased pressure. Textile materials improve resistance to bending, dynamic loads and stretching. All these indicators are successfully used to improve technologies in a particular industry.

Silicone hoses have special characteristics.

- Chemical resistance to aggressive environments. Silicone is characterized by resistance to alcohol, alkalis, salts and even gastric juice. In addition, it is phenol and oil resistant. During operation, hoses made of this material do not absorb the odors of the substances being driven and are not destroyed by them.

- Resistance to mechanical stress, bends, cracks and twists. The tubes obtained this property due to the plasticity of the main raw materials and the reinforcement of individual models.

- The composition does not contain toxic components or allergens harmful to human health. In other words, the use of such products is absolutely safe.

- No smell. Besides the fact that silicone does not absorb foreign odors, it itself does not smell of anything.

- Low adhesion, that is, a low degree of adhesion of other substances to the hose.

- Excellent resistance to high temperatures. The heat-resistant material can withstand temperatures up to 300 degrees Celsius, and some pipe models can withstand temperatures up to 600 degrees Celsius.

- Resistant to fire due to heat resistance.

- Cold Compressibility, due to which a hermetically sealed fastening is created.

- Softness and flexibility of silicone hoses. This allows them to be pulled onto larger diameter tubes.

- Ability to withstand very low temperatures(up to -60 degrees Celsius).

- The dimensions of the hose are characterized by its diameter, wall thickness and length. Depending on the purpose, the diameters of the hoses can be from 5 mm or more. The smaller the diameter of the hose, the greater the pressure of the fluid that passes through it.

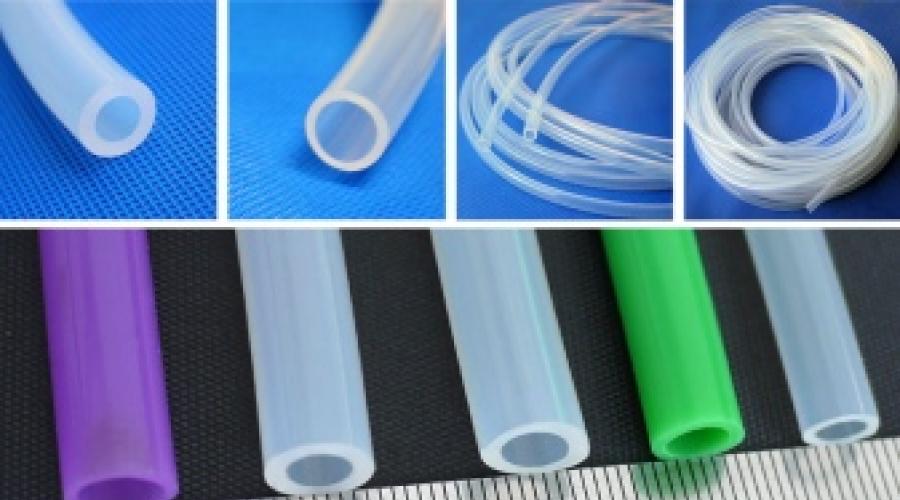

- Color. The product can be transparent or colored.

- Price. The cost of silicone hoses is at least 2 times higher than the cost of products made from other materials (polyvinyl chloride).

Scope of application

Due to their practicality and reliability, silicone hoses have found application in almost all areas.

At home

Silicone hoses are widely used for watering garden plots. Reinforced models that are protected from ultraviolet rays. Silicone tubes can be used in all water purification systems. In addition, reinforced silicone hoses are used as water pipes, and ordinary transparent ones are used as precise hydraulic levels.

In medicine

Silicone has been used in the medical field for more than half a century. Sleeves made from it are productively used in laboratories and hospital facilities. With their help, reagents, medicines, and vitamins are transported. Regular medical droppers also equipped with silicone tubes. Corrugated tubes made of transparent material used in medical equipment.

It is worth noting that in medicine both silicone’s excellent resistance to aggressive environments and smooth surface material, and almost zero adhesive ability, which does not allow bactericidal particles to linger inside the tube

An important indicator when working with silicone in medicine is the fact that The material can withstand repeated sterilization with high temperature air and water steam.

In production

For production purposes, silicone hoses are invaluable in assembly pumping equipment and pneumatics for transporting liquid and gaseous substances. They also carry out protective function(used as electrical insulation to protect against moisture). On food production Silicone hoses perfectly withstand the requirements for compliance with sanitary and epidemiological standards. They are used as protractors for bulk and liquid products such as milk, mineral water, juices, vinegar, alcoholic drinks, and oil. Food hoses can be suction, pressure and pressure-suction.

In agriculture

In modern agriculture you can't do without silicone hoses. For example, they have become indispensable in the manufacture of milking machines. They are also actively used as Consumables to agricultural machinery.

In the chemical industry

Due to their excellent resistance to various aggressive substances, silicone hoses are used to transfer chemical media between process units.

In moonshine

In the production of alcoholic beverages, silicone tubes are used, which do not spoil the taste and smell of the liquid passed through them. Silicone hoses are used both for connecting running water and for running the finished product.

How to distinguish from PVC?

As you know, PVC hoses are two or more times cheaper than silicone products. At the same time, quality indicators here are many times lower. In order to distinguish a silicone hose from a PVC product, you need to pay attention to some signs.

- When a silicone hose is set on fire, its structure does not change; light white smoke and ash of the same color are formed. When PVC is set on fire, it turns black and melts. Acrid black smoke and ash are produced.

- If you place the hose in the refrigerator, the product made of PVC will “stiffen,” while the silicone tube will remain elastic, retaining its physical properties.

- In most cases, silicone is softer than PVC, so it’s a good idea to pick up the tube and squash it. It should be clarified that modern polyvinyl chloride (PVC) is not inferior to silicone in softness. Therefore, it is more reliable to use all three verification methods.

How to choose?

The choice of silicone tube depends on the purpose of its purchase. For example, for moonshine stills and for brewing, products with a diameter of 5, 6, 8, 10 and 12 mm and a wall thickness of 1.5-2 mm are purchased. As a rule, preference is given to simple unreinforced transparent models. If hoses are purchased for hookahs and steam generators, hot air or hot water, they can be colored. Hookah pipes are thick-walled hoses. Moreover, they do not have to be red. Some manufacturers for hot water and air produce hoses made of matte blue silicone.

The most popular option purchased for aquariums are 4mm wide hoses. They are used as components for oxygen installations. The winding length is determined according to needs. It can range from 1 to 10 meters or more. For automotive system For cooling, use special corrugated silicone hoses. Smooth transparent tubes are suitable for vacuum correctors. For air lines, vacuum hoses of red, blue, and purple colors are used.

Reinforced tubes are chosen to equip main lines of dairy production plants, breweries, and meat shops. They are used to transport finished products and raw materials: water, cereals, oils and so on.

Silicone hoses are quite easy to use and can be used at any time of the year. They are designed both for high-temperature conditions and for use in winter at critical low temperatures. They can be easily washed and replaced.

Let's consider what physical and chemical properties Silicone has, and what advantages does it provide:

- temperature stability - temperature range from -60°C to +300°C;

- anti-adhesive properties (non-stick) - on internal walls particles of decomposition products will not accumulate, which can reduce the diameter of the hole and, over time, completely clog the hose;

- chemical inertness - does not combine with other substances, due to which it does not decompose even under the influence of the most aggressive of them;

- flexibility - takes the required shape without deformation or damage after compression, bending;

- resistance to mechanical stress - it is quite difficult to spoil this material at home.

There are several more properties that directly follow from the above. Silicone hoses are convenient to store and transport when folded: they take up little space (compared to metal ones) and easily restore their original shape even after twisting. Flexibility and elasticity simplifies the installation process. The material stretches well, fits onto the fitting and, taking its original shape, is tightly fixed.

Thanks to the fact that nothing collects inside, maintenance becomes much easier and faster. But this does not cancel cleaning as a whole. After use, the hose must in any case be rinsed under running water, including inside. And then be sure to dry it. The appearance of fungus is possible even on such wonderful material.

Resistance to damage allows silicone hoses for a moonshine still to be more durable. In terms of service life, they are, of course, inferior to metal tubes, but significantly superior to PVC and rubber. The situation is similar with cost. More expensive than PVC, but more affordable than metal ones.

Selection of silicone hoses

The range of silicone hoses is very wide and allows you to choose them for any equipment, both factory-made and home-made. Vary in size and color scheme. And if the second indicator is not so important, then the size parameters should be given attention.

Depending on the purpose and scope of application, the cross-sectional diameter varies from 2 mm to 50 mm. For moonshine stills, hoses with a diameter of 5 mm to 8 mm are usually used. It is optimal to use hoses with a wall thickness of 1.5-2 mm.

When purchasing a silicone tube for a moonshine still, you may encounter a new difficulty. Polyvinyl chloride is often sold under the guise of silicone. To distinguish them, you need to know some features. Firstly, silicone is softer to the touch and more elastic. But also PVC manufacturers don't stand still. Therefore the most the right way tests are a small laboratory experiment. The main thing is that the seller gives you the opportunity to carry it out.

The behavior of these two materials during combustion is strikingly different. If you try to set fire to the edge of a silicone tube, neither ignition nor melting will occur. A faint white smoke will appear, and the burnt edge will be covered with dense white ash. When exposed to open fire, polyvinyl chloride melts, turns black and emits acrid black smoke. IN in this case It's difficult to confuse them.

There is another way. True, you can only check the goods that have already been purchased. If you put a PVC hose in the freezer, it will freeze and lose its flexibility and softness. Silicone will retain its natural properties. As stated above, the lower temperature threshold is 60°C below zero.

If it is impossible to carry out a fire test, it is better to buy equipment in a specialized store. For example, a high-quality product that is suitable for your purposes can be purchased at a medical equipment store.

Conclusion

Comparing the characteristics of polyvinyl chloride and silicone clearly tips the scales towards the latter. If the cost factor still plays a big role, you can find a kind of compromise.

Tubes for a moonshine still should be made from silicone, intended for the movement of finished moonshine, fusel oils, heavy metals, hot steam. Water supply and drainage can be made from PVC hoses. This is not so critical, but more economical.

In the design of a moonshine still, hoses are needed to supply water to the refrigerator and dephlegmator, as well as to drain the finished moonshine into a receiving container. It is best to use only silicone, since it is he who has optimal characteristics for our craft. For 95% of moonshine stills you will need a silicone tube diameter 8 mm(usually the diameter of the fitting is 10, so we install our “figure eight” made of silicone under tension and everything works great).

We invite you to explore a number of features related to selection, purchase and connection these hoses to the moonshine still. Why are they so better than PVC (polyvinyl chloride) tubes and can polyurethane analogues be used?

You won't believe it. Silicone! Ideally it should be food (IRP-1338), but even the usual one is washed well after the first distillation and does not stink. Always rinse the tubes thoroughly before use, just in case.

In second place is polyurethane. He also has good properties food material, but it is less convenient. It bends poorly, holds uncertainly, does not stretch. Therefore, if you are offered a silicone or polyurethane hose, then give preference to the first option.

On the third is PVC. Polyvinyl chloride quickly begins to smell bad, deform and become tan. It spoils the taste of moonshine over time and is inconvenient to use. It is better to refuse it.

Silicone.

Silicone.  PVC (polyvinyl chloride).

PVC (polyvinyl chloride).  Polyurethane.

Polyurethane.

Where is the best place to buy a silicone hose (cheaper and 100% guaranteed)

A few places where you can actually buy a good silicone tube:

It is on Ali that you can buy a cheap and high-quality hose.

- Ali Express. Chinese online store offers excellent tubes at prices starting from 60 rubles per meter (diameter 8 mm). There are many sellers, the quality is about the same everywhere, so look for free shipping and place your order.

- Automotive store (especially for foreign cars). I don’t know about services for Russian cars, but for foreign cars they definitely sell good silicone hoses with a diameter of 8 mm.

- In specialized moonshine stores. Small sellers may sell you a fake, but normal guys will always sell you decent material.

- Large construction stores (Leroy Merlin) . And also where there is plumbing, goods for the garden and home... In general, a lot of places.

If you are not in a hurry, the easiest way is to order from China. Very low prices and decent quality.

What does a silicone hose look like and how to distinguish it

Main characteristics and distinctive features various materials:

- Silicone transparent, whitish, soft. Stretches well. It does not burn or smoke black, and when heated it emits white ash.

- Polyurethane usually red or blue (for hot and cold water). It is harder and bends much worse.

- Everything else is PVC or other material that does not suit us.

In the video below you can see how to do it correctly distinguish silicone from PVC using ignition and burning.

I have never done this myself, but in the video everything is clearly visible and understandable. Good way!

How to connect a hose to a moonshine still and water

To connect to the moonshine still we use union. Two fittings at and two at the refrigerator. The water supply goes to the lower connection, and the water drainage goes to the upper connection.

Fastening is usually not required because silicone with a diameter of 8 mm fits normally on a 10 mm fitting. As a last resort you can use metal clamp(for reliability).

The hose can be connected to the tap using fitting, diverter or sealant covers. All these methods are described in detail in the publication about, so we will not dwell on this point.

It is necessary to thoroughly prepare for the process of making strong alcoholic drinks. The accessories without which it is impossible to brew moonshine must include a moonshine still, a distillation column, a steamer and a number of other devices, including connecting hoses. They are needed to release the finished product, supply water, remove and pass steam, as well as organize other processes necessary to prepare the drink according to all the rules.

Those who are going to make moonshine for the first time may think that connecting hoses play an insignificant role. However, the appearance, reliability and type of material can greatly affect the taste characteristics, strength and quality of the drink. Experienced moonshiners use systems with silicone tubes, rather than cheap PVC analogues.

Benefits of silicone

What is better to choose: silicone elements or PVC products, which are more affordable. The cost should not become key factor when making moonshine. After all, not every polyvinyl chloride can withstand aggressive influences for a long time. chemical compounds, high temperatures and other factors that arise during moonshine brewing.

We should not exclude the risk that during the preparation of a drink, the tubes will collapse at the most inopportune moment, and as a result of exposure to high temperatures contained in the material. hazardous substances will get into the prepared product.

Advantages of silicone hoses:

Silicone tubes were able to acquire all of the above advantages thanks to a special manufacturing technology.

The basis for this material is special organosilicon compounds, which, when other compounds are added to them and exposed to temperature, as well as due to chemical reactions and certain manipulations turn into finished silicone surfaces.

The basis for this material is special organosilicon compounds, which, when other compounds are added to them and exposed to temperature, as well as due to chemical reactions and certain manipulations turn into finished silicone surfaces.

The technology used is one of the most modern. Therefore, silicone has all necessary properties for wide, effective and safe use in various fields:

- in the food industry,

- medicine,

- everyday life

- wherever you need to provide a reliable and secure connection.

Features of choice

Today, manufacturers offer many options for silicone hoses, differing in working diameter. In relation to moonshine construction, tubes with a diameter of 5, 6, 8 mm and a wall thickness of 1.5-2 mm are usually used. For determining exact dimensions tubes, it is necessary to take into account the characteristics of the system, but in most cases, products with the above dimensions are sufficient.

Place of purchase

Today, not only specialized retail outlets are engaged in the sale of silicone hoses, but also many online stores, offering favorable delivery conditions. You can find many resources online where anyone can order necessary components, including the coil, and along with them the main equipment, as well as a number of auxiliary devices. Silicone tubing is best suited for connecting areas between the distillation column, cold water source and other devices.

Today, not only specialized retail outlets are engaged in the sale of silicone hoses, but also many online stores, offering favorable delivery conditions. You can find many resources online where anyone can order necessary components, including the coil, and along with them the main equipment, as well as a number of auxiliary devices. Silicone tubing is best suited for connecting areas between the distillation column, cold water source and other devices.

Particular attention should be paid to the manufacturer of the product, as this can greatly affect the quality of the hose. But problems with this arise very rarely, since most companies offer proven products that meet all the requirements for them.

How to distinguish silicone

Unfortunately, understand by appearance Whether the product offered is a silicone or PVC hose is very difficult for the average consumer. But there are proven ways to find out whether a product is silicone.

To do this, you need to bring a fire source to the edge of the tube and observe what the smoke will be like. If it has an unpleasant pungent odor and is black in color, then most likely it is a fake. An original silicone hose will produce light smoke, and combustion of the material will necessarily be accompanied by the formation of white ash.

You can use this technique if you decide to buy a hose on the market. But if you purchase silicone tubes in a specialized store, medical laboratory You don't have to resort to this method. In such places, all products comply with GOST requirements, and therefore there is no reason to doubt its authenticity.

Cleaning Rules

Each moonshine brewing cycle must be completed with cleaning connecting pipes. Although it is known that silicone does not absorb odors or react with other compounds, the possibility of off-odors that may arise from distillation residues cannot be ruled out.

To remove them effectively, you can use special brushes. However, in most cases, simply rinsing the tubes with running water is sufficient. After removing foreign substances, the hoses must be allowed to dry; to do this, they should be suspended. If you notice serious signs of wear on the product, which can be identified by discoloration and deterioration in elasticity, you should not continue to use such tubes.

To remove them effectively, you can use special brushes. However, in most cases, simply rinsing the tubes with running water is sufficient. After removing foreign substances, the hoses must be allowed to dry; to do this, they should be suspended. If you notice serious signs of wear on the product, which can be identified by discoloration and deterioration in elasticity, you should not continue to use such tubes.

If the above facts do not fully convince you that silicone tubing is preferable to PVC hoses, think about the possible damage that can occur due to the use of a conventional connecting device. In this case, you can expect the following:

- Spoiled taste of the drink;

- The need to stop the distillation process due to a broken element connection or damage.

Also remember that you will have to spend money on buying a new connecting hose. If a leak occurs directly during the brewing of moonshine, then you will also lose a certain amount of alcohol.

The moonshine brewing process must be approached responsibly. Even such a minor detail as incorrectly selected connecting tubes can seriously affect the quality of the drink. Despite the fact that this element can be considered as an object for saving, experienced moonshiners do not recommend purchasing budget options tubes for moonshine system.

If they suddenly fail, not only will the taste of the alcohol deteriorate. In addition to this you will have to spend additional funds to purchase a new connecting element, not to mention the fact that you will be forced to interrupt the process of making alcohol in order to purchase a replacement connecting element and restore the system’s functionality.

Attention, TODAY only!

Silicone is a representative of polymers and belongs to the group of elastomers. physical characteristics which he has this material, allow it to be used in experimental-level situations and conditions.

Application

Silicone hose is produced for many industries and has wide application in various fields. Silicone hoses are used as seed lines, milk lines, oil and gas lines, for supplying pesticides, for irrigation, spraying liquids across fields organic fertilizers, for manure removal and for many other purposes. During their production, everything is taken into account necessary requirements and the loads that they must meet in accordance with established norms and standards. To give the products a certain rigidity, thanks to which the shape is maintained, they are made reinforced. Such a hose is a flexible structure made of plasticized PVC or silicone or polyurethane, inside of which a uniformly impact-resistant spiral made of rigid polyvinyl chloride is soldered.

A little history

The silicone hose was originally developed exclusively for use in technical field activities. But gradually it also began to be used in the field of food transportation. Products made from this material are widely used due to a number of specific qualities that they possess.

Its first and, perhaps, main advantage is its use in cases where conventional elastomers cannot be used. Silicone hose stands for quality and reliability, which is why it is in wide demand in extreme conditions and unconventional situations.

Temperature

This product can withstand a fairly wide range of absolutely different temperatures- from minus 60°С to plus 300°С. In addition, the silicone hose is highly resistant to sea and fresh water, as well as to salts, alcohols, phenols, oils, solutions of alkalis and acids and other aggressive media.

Advantages

The suction hose can be used where there is increased influence of electric fields and active UV radiation. An important quality of the material from which such products are made is that even when it burns surface layer(SiO2) remains on the hose itself, which ensures electrical insulation. Another significant advantage is that silicone hose is non-toxic and physiologically inert. Regardless of the temperature, its properties will remain unchanged. This product, with all its advantages, will retain its strength, elasticity and durability.

Silicone hoses on the Russian market

Every year this material only improves its qualities, becomes more in demand and available in price category for more more consumers. Many Russian enterprises in the production of silicone hoses are quite capable of competing with foreign suppliers.