Cement with or without additives is better. Which cement to choose? Review of types and main characteristics. Comparison of old and new markings

Read also

Choosing cement

One of the most used binders in construction is cement, the predecessor of which was known back in Ancient Rome. The amount of this powder sold by construction sites and manufacturers exceeds tens of thousands of tons per year. Not every House master knows which cement to choose for the foundation and the manufacture of other structures. The types and characteristics of the material, its labeling will be discussed further.

Dependence of concrete grade on cement grade

During the construction of foundations various types cement is used to make special construction mixture called concrete. In addition to the described binder, it contains various fillers, among the most common of which are the following:

Cement dependencies

- Sand;

- Crushed stone;

- Sawdust;

- Slag;

- Expanded clay.

Each filler imparts certain properties to the final mixture. additional properties and quality. Classic concrete consists of cement, crushed stone and sand mixed with the addition of water. The quality of the mixture is mainly influenced by the binder.

Concrete is classified according to the load it can withstand. To determine it, laboratory tests are carried out on samples and the mixture is marked according to them, depending on the composition and one or another type of binder. For certain types of buildings it is advisable to use different compositions depending on the required strength characteristics.

It is impossible to answer unequivocally which cement is better for the foundation. The quality of the binder is influenced a large number of various factors. It should be remembered that the indicated tabular characteristics of concrete correspond to freshly prepared cement of a particular brand. After a certain storage time, the quality of the powder decreases sharply. This must be taken into account when choosing the ratio of mixture components.

Among the most common grades of concrete are mixtures marked M400 and M500. The traditional ratio of components of mixtures of cement, sand and crushed stone is distributed in the ratio 1:3:5. Moreover, the quality and brand of the binder has a direct impact on its quantity. So, there is more cement high class can be added to the mixture in smaller quantities, and less high-grade - in larger quantities.

The type of cement used for the foundation will ultimately determine not only the durability of the base of the building, but also its bending and tensile strength. These are the loads that concrete strips and piles most often have to experience. In order to learn how to choose the right cement to use for the foundation, you need to understand how they differ.

In the last century, there were two main types of binders for concrete mixtures - Portland cement (PC) and slag Portland cement (SPC). They differed in the composition of the powder mixture and, as a result, in strength characteristics. The marking of mixtures was carried out in accordance with GOST 10178-85, which existed since 1985.

In addition to the name, the brand of cement for the foundation of a house and other types of work contained a digital designation that corresponded to the strength determined under load before the failure of the test sample. According to the old designation system, the following brands were distinguished:

- M300 - withstood a load of up to 300 kg per 1 cm 2 surface area;

- M400 – corresponded maximum pressure at 400 kg/1cm 2 ;

- M500 - withstood pressure of 500 kg/1 cm2;

- M600, accordingly, could withstand up to 600 kg of load per 1 cm 2.

The above characteristics cannot clearly recommend which brand of cement is better for and which for garden gazebo. Of course, a larger load is necessary for heavier buildings. But you can get concrete with high performance by changing the ratio of cement of a lower grade in the direction of increasing its quantity in the total mixture.

When choosing what kind of cement is needed for the foundation of a house, you need to pay attention to such indicators as the presence and quantity of mineral components. This criterion is also present in the labeling and is designated by the letter “D” with digital designation. The most widely used cement grades are D0 and D20.

To decide which brand of cement to use for the foundation, it is necessary to clarify the effect of mineral additives on the quality of the binder. Thus, the D0 indicator indicates the complete absence of additional components, which in turn guarantees maximum quality of future solutions. At the same time, the grade of cement with the D20 index contains up to 20% of various impurities, which reduces its strength characteristics and cost. Deciding, for example, what kind of cement for the foundation summer gazebo would be better suited, preference can be given to something less durable and construction costs can be reduced.

When choosing which brand of cement is needed for pouring the foundation, you need to become familiar with the additional characteristics of the binder indicated in the labeling. Among the most common abbreviations are the following:

- PL - indicates the presence of plasticizers in the composition. Such cement can be used for the foundation if high frost resistance of the concrete structure is required.

- VRC is an abbreviation for waterproof mixtures with an increasing volume as they harden. This type of foundation cement is recommended for construction on soils with high humidity.

- B - means cement with a reduced time required for complete hardening. If builders are faced with the problem of what cement to use for the foundation of a house with a limited time frame for completing the work, this brand of cement is the best choice.

- SS is an abbreviation for sulfate-resistant cements. In private housing construction, this mixture is rarely used, since its main application is the construction of hydraulic structures.

- N - a grade of cement with this designation has undergone additional rationing using clinker. This additive provides high strength characteristics of concrete and mortars.

- BC – stands for “ white cement" His distinctive feature is light shade after hardening. Foundation cement whose brand contains the letters BC is rarely used. Its main purpose is to finish the surfaces of walls and other building structures.

In 2003, our country adopted new GOST to designate cements. Its number is 31108-2003. According to him, completely different designation principles were introduced. Without knowing them, it is difficult to determine what kind of cement to fill the foundation with. Let us list the main differences from GOST of 1985:

- Instead of grades, strength classes have been introduced to characterize the binder.

- For all strength classes, quality indicators are introduced after 28 days, and for some after 7 or even 2 days.

It should be noted that the 2003 standard does not cancel the Soviet GOST. Currently, when choosing what kind of cement is needed for the foundation, it is enough to know the old designations, since they are present on all packaging of any manufacturer along with the new ones.

We evaluate the quality of cement

Good concrete can never be made from low-quality cement. You need to learn to identify it by external indicators. When determining which cement is best for the foundation of a house, we pay attention to the following indicators:

- Date of manufacture – the quality of the binder decreases in direct proportion to its storage time. It is better not to use cement produced more than six months ago for critical parts of the building, which is the foundation.

- Consistency. Ideally, the cement should be loose, not caked or crumpled. You can check this by carefully feeling and turning the package over several times. All recommendations about what brand of cement is needed for the foundation are given for high-quality material.

- Package. It should not be broken or wet. Experts also do not advise purchasing cement whose packaging does not contain information about the manufacturer and production date.

Thus, choosing which cement is best for the foundation is quite difficult. It is necessary to take into account all the operating conditions of the concrete, soil conditions and the desired timing of the pour. Not every brand of cement is suitable for solving this problem.

The basis of any construction is the foundation, and the basis of the foundation is cement, so everyone who starts construction faces the question: which cement is better for the foundation? The choice of components for the foundation of a building, especially cement, is a very important point.

Scheme of fillers included in cement mortar.

What is the foundation made of?

Materials and tools for making the foundation:

- cement;

- sand;

- crushed stone;

- water;

- concrete mixer;

- shovel;

- construction mixer.

They say that better cement or maybe only cement - a building material that plays a key role in the performance of the concrete mass, increasing its characteristics in interaction with water.

Return to contents

Important material characteristics

When choosing cement for foundation construction, you should pay attention to the following characteristics:

- water resistance;

- frost resistance;

- sulfate resistance;

- corrosion resistance

- air resistance;

- swelling and shrinkage of cement;

- grinding fineness.

Water resistance is the ability of cement to successfully withstand the effects of water, and this impact does not lead to destruction of concrete structures. Water resistance concrete mortar for the foundation it is best to check in the following way. Two identical ones are made concrete cubes. One of them, in dry form, is crushed in a press and its strength is determined. The second cube is pre-soaked in water and then destroyed in the same way. Saturation with water leads to a weakening of interparticle bonds, and the strength of the sample decreases. The ratio between the strength of saturated and unsaturated samples is called the material softening coefficient. The softening coefficient of concrete is 0.8, which confirms its water resistance.

Frost resistance - this characteristic means that repeated freezing and thawing do not affect the quality of cement, but this property appears only if special modified additives are used to improve frost resistance. The packaging contains markings indicating the frost-resistant properties of the building material.

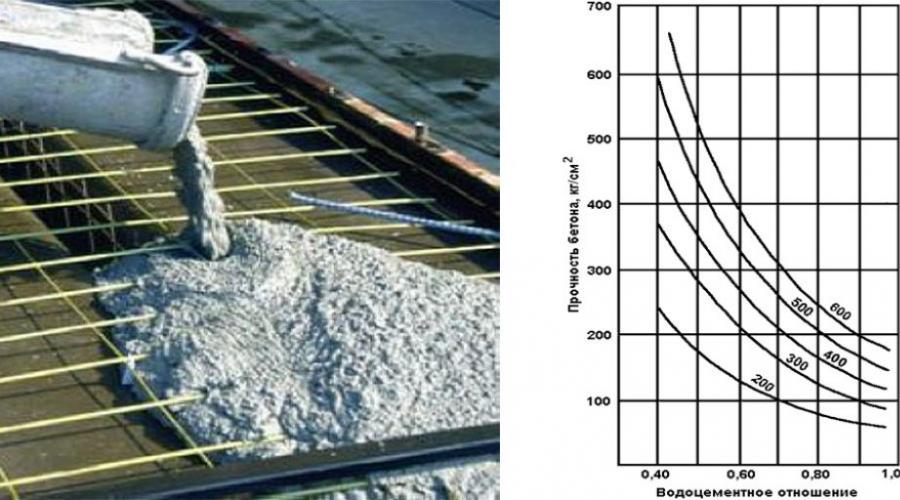

Graph of water to cement ratio for different grades of cement. Cement grades are indicated above the curves.

Sulfate resistance – important characteristic cement, its ability to withstand long-term exposure to a liquid sulfate environment. The sulfate environment, acting on the cement stone, forms ettringite, a sparingly soluble compound, the appearance of which leads to the formation of microcracks. These microcracks, merging with each other, destroy the concrete. Additives that improve the frost resistance of cement have an ambiguous effect on sulfate resistance. Therefore, before choosing a material for the base, you should carefully study its composition.

Corrosion resistance determines service life concrete structures and is characterized by the ability to successfully withstand the effects of aggressive environment. The corrosion resistance of cement depends on the presence of cracks, micropores and capillaries in the concrete, through which water containing solutions of alkalis and acids enters the stone structure.

Air resistance characterizes the ability of cement to retain all its properties in the open air. useful characteristics. Air resistance depends on the storage and transportation conditions of the cement powder. Deterioration of characteristics during storage should be taken into account when mixing the solution. Recommendations for use should provide information about necessary conditions powder storage.

Swelling and shrinkage are determined by the ability cement stone change your volume. When swelling, the mass of concrete increases due to the absorption of moisture from the environment. This process does not reduce the strength of concrete. Shrinkage occurs when cement stone hardens in a dry air environment.

The fineness of grinding affects the speed of setting and strength gain of concrete. The better the powder is crushed, the higher these properties are.

Return to contents

Marking of cements

Construction powder for foundations is divided into groups:

- without additives;

- with additives.

To construct the foundations of structures, you need pure Portland cement or pozzolanic and slag Portland cement with additives that improve its properties. To better understand the characteristics of the material and determine which type is the best, you need to know the markings and be able to decipher the information on the packaging.

There are 2 types of markings, which were adopted in 1985 and 2003. In the first marking, the letters indicate the type of cement:

- M – grade, PTs – Portland cement, addition of the letter Ш – slag Portland cement (SPC), material for waterproofing NTs – prestressing cement;

- numbers from 100 to 700 indicate the maximum load that the foundation can withstand;

- the number of additives in the material is indicated by the letter D with a number, D0 informs about the complete purity of the material;

- the following letters indicate the class of cement: N - normalized, B - quick-hardening, PL - plasticized; SS – sulfate resistant.

The 2003 marking reads as follows:

- name – CEM;

- the presence of additives is indicated in Roman numerals: I – without additives and II – with additives;

- CEM II has subtypes A and B, which indicate the amount of additives in the cement;

- the letter Ш indicates that the cement is slag granulated, and the letter P means pozzolan;

- numbers from 22.5 to 52.5 indicate the class of minimum compressive strength, which is achieved 28 days after pouring the base;

- the letters N and B mean the ability to harden: N - normally hardening, B - quickly hardening.

If you answer the question of which cement to choose, then experts recommend mixed brands of Portland cement: slag and pozzolan. These brands differ in content active additives consisting of slag or volcanic rocks.

If you use mixed grades to build a foundation, then construction works should be started in the spring so that the concrete gains strength before frost, since mixed cements do not have sufficient frost resistance. But these species are ideal for wet and sulfate soils due to their high resistance to aggressive environments.

To fill the foundation, it is customary to buy the most quality cement with a high grade of strength. This is due to frequent loads placed on the structure: the weight of the building, soil displacement, exposure to precipitation and capillary water, freezing of the base in winter time. Portland cement from M400 and above has proven itself, but in some cases it is allowed to use a less expensive brand. Each specific grade is selected according to the construction and operating conditions; it is also important to maintain the correct proportions and carry out concreting taking into account the requirements of the pouring technology.

The strength of cement is indicated by the letter index “M”, followed by an additional abbreviation: d0 - without additives, d20 - with 20% impurities. Varieties that have a specialized purpose are labeled separately, but they are rarely used when pouring foundations. When determining which cement is best for the foundation, the future load, the presence of a basement and soil conditions are taken into account. It is recommended to choose:

1. M200 - when pouring the base for prefabricated panel structures.

2. M250, M300 - for the foundation of a log house.

3. M350–M400 - for brick buildings. This is minimal acceptable brand, suitable for the construction of buildings with a basement, the foundation of a bathhouse and for objects on clay soils.

4. Portland cement M400 d0 - when mixing concrete for pouring the foundation of a private house, regardless of the number of storeys in an area with moving soil or a high level groundwater.

5. PC M400 d20 - for the same structures, but with lower requirements for frost and water resistance. This brand of cement is recommended for preparing foundations and constructing small buildings.

A binder with a minimum strength of M100 is suitable only for pouring a concrete pad over a backfill of crushed stone and sand when constructing strip foundation types. In turn, Portland cement with a high grade (M500) is not economically profitable to use in private construction; it meets the requirements of industrial and residential construction. But if the other components in the concrete for pouring are inferior in quality (for example, crushed stone with low strength was purchased), then the use of an expensive type becomes not only justified, but also a necessary action. Recommended brand for columnar and pile foundations- Portland cement M400.

For correct definition soil conditions and groundwater levels are measured; this is best done in the summer. For sedentary, dry and sandy soils, it is allowed to use cement for pouring the foundation with a strength of M250. For clay soils and loam minimum is M350. The same strength is the initial strength when building houses with a basement. For masonry mortar when constructing foundations from blocks, it is recommended to choose M400 cement without additives; in general, this brand is considered optimal in terms of the price/result ratio and meets almost any requirements of private construction.

The influence of slags and impurities

Despite the fact that for the foundation of a house it is better to use Portland cement without mineral additives (they lead to a decrease in the strength of structures), in some cases mixed varieties are also needed. Their main advantage is their cost-effectiveness (with the exception of formulations with modifying and specialized additives, they, on the contrary, are more expensive); the PPC M400 d20 brand is considered an example of a good price/quality ratio.

The advantages of using slag and pozzolanic cements include sulfate resistance; they should be chosen when there is a high proportion of salts in the soil or other aggressive influences. But they reach the required strength more slowly, so foundations are laid on their basis in the spring. A significant disadvantage of cement mixed with slag is that it reduces the frost resistance of concrete; it cannot be used on moving soils.

Cooking proportions

To pour the foundation, you should make concrete with a grade of at least M200. The quality of work directly depends on the use of the correct components, their preparation and mixing in proven proportions. Ideally this is: fresh Portland cement without lumps, dry and sifted river sand, gravel or crushed stone from hard rocks, clean (drinking) water. Coarse-grained filler is selected with a grain size of no more than 30 mm, preferably with a square flakiness; it must be cleared of debris and, if possible, washed. The mixing is carried out in a concrete mixer; this is required not only to reduce the labor intensity of the process, but also to obtain the desired structure.

The ratio of cement, sand and gravel depends on the type of base. Yes, for columnar foundations it is better to choose a proportion of 1:3:4 with a W/C of no more than 0.65; the same mixture is suitable as a masonry mortar when building it from blocks. In this case, a grade of cement not lower than M400 is used. For belt type for the foundation, these proportions are 1:4:6, with the same W/C ratio equal to 0.65. Excess water is unacceptable; it leads to disruption of the hardening processes and the formation of cracks.

The method of preparing concrete for pouring the foundation, taking into account the grade recommended by the standards, has proven itself to be effective. A proven proportion is selected: 1 part cement, 3 sand and 5 gravel. W/C ratio in in this case depends on the required concrete parameters:

| Expected grade of concrete | Cement strength grade | ||

| 300 | 400 | 500 | |

| 200 | 0,55 | 0,63 | 0,71 |

| 250 | 0,5 | 0,56 | 0,64 |

| 300 | 0,4 | 0,5 | 0,6 |

| 400 | Not preparing | 0,4 | 0,46 |

The humidity of the sand plays a huge role; using undried sand or preparing the solution in damp weather leads to a violation of the proportions. In general, the concrete should be workable, but not liquid; it is recommended to leave some of the water and add it in small portions to the concrete mixer for last minutes rotation.

What else do you need to consider?

The quality of cement is inversely proportional to its shelf life, and taking into account the fact that high-quality cement is purchased for pouring foundations (that is, quickly losing its properties), it is necessary to use the freshest powder of a light gray or greenish color that spills through your fingers. The attached certificate is checked, if the volume of work allows, then the material is purchased in plastic big bags, the packaging is opened immediately before preparing the solution.

Strengthening the strength of concrete is very simple: just add fiber or plasticizers, but this method increases costs. Strip foundations must be reinforced; for them it is recommended to purchase gravel or hard crushed stone with maximum size fractions up to 20 mm. Regardless of the type of structure, waterproofing work is provided.

Cost of materials.

Cement is one of the main building materials. It is preferred by many builders due to its high strength and bonding characteristics, in addition, it allows you to connect almost any materials. Choosing good cement is not always easy and you need to understand that there are different types of it, which are characterized by strength grades. This is what distinguishes the mixture of household and industrial use. Every year new manufacturers appear, various additives are added to dry mixtures, and the article will help determine which cement is better in 2019 for screeds, masonry, blind areas and reinforced concrete structures.

Features of choice

IN construction stores presented very a large assortment cement, so its choice is often complicated, especially if the work is carried out by beginners. Determining the best cement for various purposes is possible by understanding its features and properties. When choosing, you need to look at the following characteristics:

- Compound. The basic material is considered to be crushed substances, including limestone, clay, min. additives. Based on the recipe and dosage of substances, different types of mixtures appear, the most popular being Portland cement. This product is suitable for construction and concrete products.

- Strength. No less important parameter for any type of mixture. This is the product marking. Mixtures M400, 500 and 600 are available on the market, which is the most durable and can withstand heavy loads. The first 2 types are suitable for household needs.

- Purity. Often, manufacturers make marks on the pack in the form of the letter D and a numerical value. This indicates the presence of additives, for example, D20 includes about 20% fillers and other excipients. D0 – pure cement without additives.

- Hardening speed. Based on the main type of work, the solution in liquid form should harden differently. If CEM I is indicated on the package, the mixture will quickly set and harden. For the M400 brand, CEM V is considered the norm.

- Packing. Many manufacturers use special bags or paper bags with many layers. If construction is being carried out, it is better to buy 50 kg packaging; for small-scale work, it is more profitable to buy 5-30 kg bags.

- Best before date. Often, mixtures will have a shelf life of 3-6 months, but when purchasing, you need to understand the storage period, transportation time and other indicators. You can check the quality by hitting the corner of the bag; if it is already petrified, then you should refuse the purchase.

The article describes different variants dry mixtures for household and industrial tasks. The rating is based on the opinions of consumers and experts to make it easier for a potential buyer to decide which brand of cement is better. For this purpose we present brief characteristics with pros and cons.

TOP cement M400

This cement is perfect for floors, screeds, and masonry walls inside a house or apartment. The brand is characterized by an optimal strength value, so it is suitable for medium loads. In addition, the choice is good for waterproofing ground floors and damp areas.

Holtzim M400

Manufactured by a Russian company that is known abroad and has many years of experience. The products are characterized by white color, which will be up to 74%. The composition uses a special clinker, in which minimal amount iron, which makes cement unique in its category. Diatomite and gypsum are also added to the composition to increase the degree of light reflection. Positive reviews of the product from ordinary consumers and experts were received due to the quality of the mixture and the strength of the finished solution. The only drawback is the difficulty of purchasing at construction retail outlets.

pros:

- Great quality.

- White color.

- Affordable price.

- Versatility and ability to be used for construction or repair.

Among the disadvantages is the difficulty of purchasing in stores.

Portland M400 Hercules

This product is considered the best for floor screeding, as it is characterized by high strength and can withstand any household loads. In addition, the liquid solution dries quickly and makes it possible to walk on the screed within a day after pouring. This helps speed up repairs and other work without harming the floor itself. They are sold in small 5 kg bags with handles that are easy to carry. Other features include a long service life and the elimination of cracks.

Pros:

- Environmentally friendly, as can be seen from the packaging and the “ECO” icon.

- Can be used in a dry building or basements, cellars and buildings with high humidity.

- Contains up to 5% gypsum.

- Includes active mineral additives to enhance strength.

- Does not take over the influence of corrosion from the steel that is nearby.

- Impact resistance.

- Long service life.

- It is not affected by frost and can withstand up to -40 degrees without changing its characteristics and properties.

- Grey colour.

Minuses:

- Small packaging, only 5 kg.

- For a small pack it turns out high price within 50 rubles and above.

- The shelf life is up to 2 months, so after purchase it is necessary to carry out repairs immediately.

- Cannot be used for outdoor use.

Eurocement M400 D20 CEM II A-Sh 32.5

High quality look cement from Russian manufacturer, which is liked by specialists and ordinary people. The mixture meets all international requirements and is used by many countries. This option is suitable for domestic and industrial applications. The mortar is used to make floor slabs, reinforced concrete products, screeds, foundations and walls. It is packaged in bags and has a shelf life of six months.

pros:

- Affordable price.

- Resistance to frost, temperature changes and moisture.

- Excellent quality of the dry mixture and the finished solution.

- Wide range of possibilities for use.

There are no downsides to the product from this manufacturer.

Cement CEM II 32.5 (M400 D20) gray De Luxe

Perfect option for blind areas and outdoor work, since the mixture is made for outdoor use. When hardened, the formation of cracks is excluded; they do not appear even after several years, which eliminates the need for constant sealing. The finished solution has good strength, which helps to securely fix any materials and elements. After drying, the made blind area will withstand up to 330 kg per 1 sq. cm. It is packaged in 50 kg bags, so it is profitable to buy for large construction projects.

Pros:

- Affordable price, only about 260 rubles for 50 kg of cement.

- Resistant to moisture and low temperatures.

- Long period of operation of the frozen solution.

- Includes additives that increase strength and hardening time.

- The optimal temperature range for work is +5-30 degrees.

- A month after pouring, maximum hardness and the ability to withstand peak loads are achieved.

- Setting occurs within 75 minutes, so it can be used to remove defects that appear during pouring.

- Meets GOST requirements.

Minuses:

- Only 50 kg packages are available for sale.

- Shelf life up to six months.

- Cannot be used at temperatures below +5 degrees.

TOP cement M500

When choosing which cement is best for the foundation, you should definitely pay attention to this brand. It is characterized by high strength and is suitable for floors that bear heavy loads, for masonry load-bearing walls and pouring the foundation for the building.

Eurocement 500 Super

This product has many positive reviews, and cement is often used in the construction of houses. It is recommended to use for pouring foundations, building walls, screeds. Specialists often buy it because of its quality, the mixture meets GOST standards, the solution sets quickly, which helps reduce the time of the main process. In addition, the consumer receives protection from moisture and frost.

pros:

- High quality composition.

- Strength.

- Durability of the poured solution.

- Fast drying.

- Wide scope use.

There are no downsides to this brand.

Holcim Tared 50kg CEM II/A-K(SH-I) Class 42.5N

This option is considered one of the best for pouring a foundation for a house, since the solution can withstand heavy loads. This allows the mixture to be used for buildings of 2-3 or more floors. Hardening is optimal, the dry mixture is included minerals preventing the appearance of cracks or peeling. The product is sold in 50 kg bags, which is convenient during construction.

Pros:

- Great for load-bearing structures thanks to its strength.

- Can be used indoors and outdoors.

- The maximum bending strength is 78 kg/cm2.

- Includes mineral and plastic substances.

- Withstands loads within 433 kg/cm2.

- Does not have a blue tint, the color is gray.

- Affordable price within 300 rubles per bag.

- Excellent adhesion.

- Optimal hardening time, which helps remove defects in the form of smudges or sagging.

Minuses:

- If you work in the cold, setting may occur with the formation of small voids.

- It is inconvenient to grasp the carrying bag.

EuroCement 500 Extra D20 CEM II

The product is characterized by optimal drying speed and durability. After preparing the solution, it is convenient to pour it into voids and level the surface. The mixture is not afraid of frost, so it can be used even in winter. Quality at high level, but at temperatures below +10 degrees hardening will be slow.

pros:

- Excellent quality.

- Easy to use.

- A long period storage

- No cracks appear during shrinkage.

Minuses:

- High price.

- If the temperature is low, the hardening process will be slow.

Stone flower M500 D20

This the best option for laying bricks, foundations and others important works. Cement is characterized by a high degree of strength, which is 500 kg/cm2. The composition contains polymers to accelerate hardening and eliminate cracks when drying. To increase adhesion, the manufacturer adds glue and other elements, which also make the solution insensitive to weather. Sold in packages of 40 and 50 kg.

Pros:

- Optimal hardening time, which is suitable for mixing the solution, laying it with further leveling.

- The solution is easily prepared using technology or manually.

- Affordable price.

- Availability of mineral supplements.

- Suitable for outdoor or interior work.

- High strength.

- Ecological cleanliness.

- Meets GOST.

- Resistance to frost and moisture.

- The ready-made and hardened solution serves for a long time and retains its properties.

- High degree adhesion to materials.

Minuses:

- Shelf life up to six months.

- The corners of the bags are smooth, so it is inconvenient to carry and take the goods.

TOP cement M600

This is a good cement for foundations and floors in garages, parking lots, and warehouses with heavy equipment. The mixture can withstand very heavy loads; the finished solution is used for reinforced concrete products.

CimSa M600

Product from a Turkish manufacturer, white. The composition is made for finishing work, which achieves evenness and smoothness of the surface. After repair processes, cracks do not appear during drying, the solution is not exposed to external factors. In concrete products, cement helps protect metal products from corrosion. The product is characterized by low moisture absorption, strength and frost resistance.

pros:

- White color.

- Not affected weather conditions.

- The formation of cracks is excluded.

- Protects fittings from corrosion.

This is the best brand of cement, which has no identified disadvantages.

Adana Super White M-600

Another high quality Turkish product. The company itself is young, but is actively developing, offering high-quality products that meet international standards and requirements. Cement has high strength, can withstand heavy loads, and also looks beautiful after pouring. The color of the solution is 90% white, which is convenient for concrete products, creating architectural details, monuments, etc.

pros:

- Excellent aesthetic and decorative properties.

- Great opportunities for use.

- Strength.

- Endurance.

The main disadvantage is the overpriced product.

White polymer cement M600 Rusean

This option is the best in its class for creating precast concrete products, this is achieved for 2 reasons: excellent strength and pleasant White color. This allows it to withstand heavy loads and eliminates the need for additional painting of concrete products. Whiteness is achieved thanks to the polymer in the composition.

Pros:

- Very fine grinding, which helps to use the mixture for self-leveling floors.

- Setting occurs within 1.5 hours, which is enough to level the surface.

- High density material that simplifies packaging and transportation.

- Nice white color.

- Minimal shrinkage.

- Frost resistance.

- Doesn't flake.

- High plastic qualities.

- Can be used in the role finishing material.

- Suitable for indoor and outdoor work.

Minuses:

- High cost per 30 kg bag.

- To maintain whiteness, you need to add quartz sand.

Having studied the features of each brand and best products in its segment, even a beginner can pick up best option for construction or repair work. The article is made for informational purposes and does not force you to purchase a specific product.

The invention of cement marked a turning point in the history of construction technology. Cement is the basis for the production of building structures, the construction of monolithic load-bearing elements buildings. It is cement that binds solid fillers into a single mass - concrete. The foundations of buildings and structures are mainly constructed from concrete. The foundation solution is prepared in strict proportions of cement, sand, crushed stone and water. Properly selected cement for the foundation allows you to obtain a durable stone monolithic foundation of the building. It is very important to determine which cement is best for the foundation.

What is cement

The word cement comes from the Latin expression "cementum", which means broken stone. There is a second name for the material – Portland cement (PC). PC production is complex technological process. The starting raw material is rock– limestone. The rock is fired in kilns. Then pieces of burnt rock - clinker - are crushed in special milling installations (screens). The clinker is crushed to a powder state.

Cement brand

Various ingredients are added to the powder to form a mixture of a certain brand. The brand is designated by the letter “M” and a number. Samples of each batch of material are tested in the factory laboratory. Samples from a frozen solution of PC and sand (1:3) in the form of prisms 40x40x160 mm are tested under compression until complete destruction. The load threshold determines the cement grade number.

Thus, M 200 means that the hardened cement mortar can withstand a load of up to 200 kg per 1 cm 2 of its surface. Modern industry building materials produces cementitious materials of the following grades: 50, 100, 200, 300, 400, 500 and 600.

For the construction of foundations of various objects, PC grades 200 - 400 are mainly used. PC M 600 is used for the construction of special-purpose facilities.

Concrete grade

Like PC, concrete also has its own marking. The foundation mortar is a water-based mixture of crushed stone, cement and sand called concrete. The grade of concrete directly depends on what grade of cement will be used. Each type of concrete is intended for monolithic foundations under a certain load from the weight of the structure:

- M 100 is used for small bases wooden houses, garages and outbuildings;

- M 200 is used for the foundations of one- and two-story private houses made of lightweight structures;

- M 250, 300 should be used for the foundations of houses with several floors;

- M 400 is used in the construction of the foundations of multi-storey buildings.

For a foundation, the concrete composition may include different brands cement. For example, for the foundation of a private house made of concrete M 300, cement M 400 or M 500 is needed. The proportions of the solution for the foundation are observed in the following ratio:

- 1 hour PC M 400 + 1.9 hours sand + 3.7 hours crushed stone + water.

- 1 hour PC M 500 + 2.4 hours sand + 4.3 hours crushed stone + water.

Preparation of concrete mortar for the foundation

Manufacturing process concrete mixture– a critical stage in the formation of the monolith of the foundation of the building. Any deviation from the quality and quantity of the components of the concrete solution will lead to loss bearing capacity foundation. Concrete is prepared in different ways: this is a manual, mechanized and factory method of making foundation mortar.

Manual method

To mix concrete manually, you can use any sealed container: old bath, trough or welded structure from auxiliary material. Before starting work, in addition to the container, you need to prepare the following materials:

- clean washed sand without clay inclusions;

- cement for pouring the foundation;

- crushed stone or gravel;

- filtered water, if collected from a natural reservoir;

- wide (grabber) and bayonet shovel.

The concrete preparation process is carried out as follows:

- Cement and sand are poured into the container.

- Using a shovel, thoroughly mix the mixture until smooth.

- The mixture is poured with water, and everything is mixed too.

- When the cement mortar is ready, crushed stone is added to it.

- After final mixing, the concrete is ready to pour.

Video of preparing concrete by hand:

Mechanized method

For the mechanized preparation of concrete poured into the foundation formwork, a concrete mixer is used. The mechanism is a metal rotating drum located on a wheel frame. The drum is driven by an electric motor and has a rotating axis for tipping.

An example of pouring a foundation using a concrete mixer

Before starting the process of preparing poured concrete, make advance paynemt needs Supplies. Determine what brand of cement is needed in order to prepare the cement mortar. In this calculation, cement grade M 400 was used for the mixture.

Initial data: strip foundation– 5 m 3 of concrete, concrete mixer – 180 l, concrete grade – M 300.

Calculation of the need for materials for pouring a foundation with a volume of 5 m 3

Accurate calculation of the need for the materials that make up the concrete solution allows you to avoid unnecessary costs in the construction of a monolithic building foundation. In order not to regret the shortage of certain materials, you should always add 5 - 7% to the calculated amount of concrete components for unforeseen losses.

- 1 batch of a concrete mixer will amount to 180 liters of prepared concrete mixture. For this volume you will need cement M 400 - 31.4 kg/24.2 l, sand - 39.7 kg/26.5 l, crushed stone - 95.6 kg, water 17 l.

- Therefore, to get 1 m 3 of concrete, you need to make a solution for the foundation in the amount of 5.55 batches. This will amount to 398 kg of M 400 cement, 503 kg of sand, 1210 kg of crushed stone and 215 liters of water.

- The entire foundation will require 400 – 1990 kg of cement, respectively.

- If we make similar calculations for other brands of binder, it turns out that the entire foundation will require M 300 - 2500 kg, M 500 - 1705 kg.

The higher the cement grade number, the less it is required. However, one should take into account the fact that the stronger the cement, the more expensive it is. The owner of the construction site must choose for himself which cement is best to buy for pouring the foundation.

Factory production of concrete

For large volumes of construction of the foundation of a building, concrete is ordered from the mortar unit of the concrete plant. Concrete mortar unit (BRU) is an installation for the production of concrete. The BRU includes a concrete mixer with a control panel, a skip hoist, dispensers for cement, water, solid fillers and various additives. BRU produces concrete mortar of various grades.

At the request of the customer, the BRU manufactures liquid concrete V the right amount V certain time. Delivery can be carried out by trucks with a sealed body or concrete truck.

A concrete truck is a vehicle equipped with a rotating container and an unloading device. At the BRU, concrete is loaded through a batcher into the drum of a concrete truck.

When the drum is unloaded, the blades begin to rotate in the other direction. The mixture enters the foundation formwork through a special unloading device. On different models For concrete trucks, the drum volume ranges from 6.5 to 8 m 3 .

When ordering concrete mortar from BRU, the construction owner does not need to think about which cement is best to use for the foundation. A concrete truck delivers ready-made concrete of the required grade to the construction site.

Pouring the foundation with concrete

The foundation formwork is poured in good weather. Concreting is carried out using a continuous method. It is impossible to interrupt pouring for more than 6 - 10 hours. Otherwise, the solidity of the building’s base will be disrupted, and this in turn will cause big problems for reworking a concrete monolith.

Ideal time for concrete works this summer. This time of year temperature regime most favorable for high-quality hardening of the monolithic base of the structure. To avoid excessive drying out or waterlogging, the poured foundation must be covered plastic film. The film will protect the hardening solution from direct sunlight and rain. B strongly hot weather The foundation is periodically watered.

From all of the above, we can conclude that the choice of cement depends on many factors. First of all, this is the price of the material, its quantity, as well as the method of laying the solution.

A mistake in choosing cement of greater strength will not cause harm, except for unnecessary financial costs, but the use of less durable binder material can cause big trouble.