Do-it-yourself bathhouse from a container. Do-it-yourself sauna from a container - a solvable problem Is it difficult to make a sauna from a sea container with your own hands

Read also

Of course, not everyone can afford to build an expensive bathhouse, but this is not a reason to give up pleasure: mobile mini bathhouses based on a sea container are a fast, effective and economical solution.

Fashion for a healthy lifestyle, a healthy, beautiful body explains the demand gyms, cosmetic procedures, services of nutritionists, massage therapists, etc. But many people still prefer time-tested traditional methods restoration of strength and health, such as visiting a bathhouse.

Now exists a large number of types of baths: each country has its own 8 design features, national traditions and the rituals associated with the bath are very diverse.

Helpful information:

Turkish hammam, Finnish sauna, Roman baths, ofuro or Russian bath chopped sauna– today, every person can choose and build on his plot or in his house exactly the bathhouse that attracts him with its functional properties, especially since modern technologies allow us to carry out construction work of any complexity.

Container-based mobile baths

Metal stoves, along with metal baths, also have a number of advantages, so they are quite often installed in a Russian bathhouse. Such stoves are purchased in special stores or made independently.

For making vertical metal furnace(see diagram above) You will need a metal pipe, the thickness of which is from 5 to 10 mm, the height is 1.8 meters. Next, the pipe is cut into 2 parts: 0.6 m goes to the tank, 0.9 m to the firebox and heater, the remaining material is used to make doors for the ash pan and firebox.

The hole left for the blower should measure 180-200 mm in width and 50-60 mm in height. The grate for the furnace can be purchased at a specialized store (furnace casting store). The firebox door has the following dimensions: 250-300 mm wide and 170-200 mm high.

Another plate is welded above the firebox, where the metal bars 10x10 mm for the heater device. You can buy a special grate for the heater and secure it in the same way as the grate for the stove. The pipe height required to install the heater is 100 mm.

The heater compartment must also be equipped with a door opening with dimensions of 250x300 mm. Next, the heater is filled (not to the top!) with special stones for the bath: if there are stones in your area (for example, diabase), then you can collect them yourself, but remember that rocks, which contain mica, cannot be used in a bathhouse (they contribute to the accumulation of carbon monoxide). A lot of positive feedback about the use of talc chlorite in a sauna stove.

Water tank in a metal furnace vertical design located above the heater. The finished metal stove is lined with brick, which allows it to retain heat longer, although in a bathhouse that is not designed for a large number of visits, brick may not be used for cladding. The furnace is installed on a foundation, for the manufacture of which fire-resistant bricks and concrete mortar are used.

The distance from the wall to the brick-lined stove must be at least 200 mm, to a metal stove - at least 1 meter. The wall near which the metal stove is located can be additionally protected using special foil with insulation (for example, isover). The foil will reflect heat, and the isover will protect the wall of the bathhouse from heating.

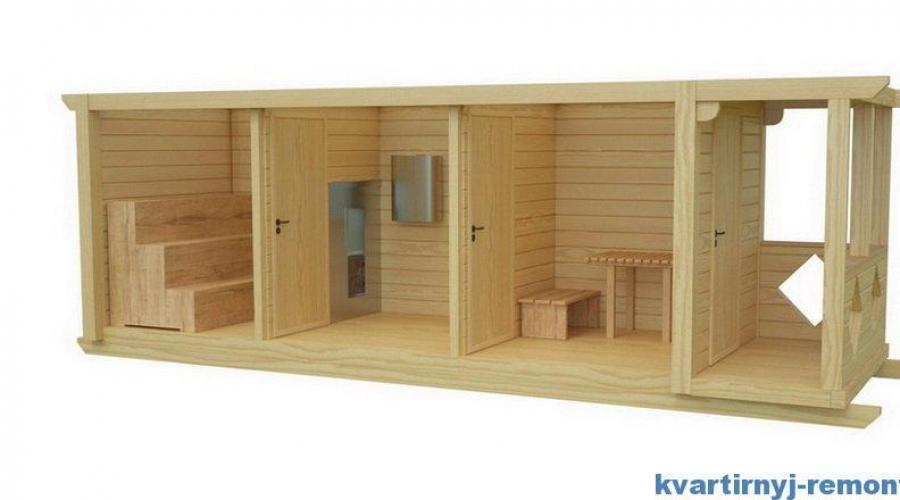

Bathhouse layout based on a sea container

Shipping container buildings have gained popularity because containers are inexpensive; no need to conduct assembly work; components of internal and exterior finishing easy to install. To date, many standard bathhouse designs have been developed based on 20-foot and 40-foot tanks.

Also among the advantages is the mobility of the building - the bathhouse can be transported to another locality using a trawl. Such a building will be quickly heated, thanks to small area. You can easily supply power there, install washing machine. The only drawback: the layout usually does not involve separation of the washing section and the steam room.

Preparatory work

To build a bathhouse, standard 20-foot glazed containers are used. Less commonly, 40-foot configurations: to build a bathhouse from containers is not needed big square. You need to buy new containers, always galvanized. Special requirements apply to the type of foundation: a container bath cannot be placed on simple slab, as the water drainage will be blocked.

The land plot is marked taking into account the expected location of the sections of the future building. The most important thing is to determine the places where the largest amount of water will drain. Next, the foundation is prepared. Very rarely the container is placed on piles. Most often, foam blocks, bricks, and wood concrete are laid around the perimeter. They put it on them wooden frame, onto which the marine packaging is subsequently installed. Take into account the following point: regardless of the type of foundation, the building should not be close to the ground; otherwise, water will not be absorbed, resulting in damage to the structure.

In order for the water to go into the ground, you need to remove the top turf and pour waterproofing impregnation in its place. After this, you can begin building the foundation. The bathhouse should be 10-15 away from the main residential building and the same distance from the nearest wells and reservoirs.

Layout

Everything is standard here. If a 20-foot container is chosen as the basis, then the bathhouse is usually divided into two sections: a dressing room and a shower room (often combined with a steam room). The 40-foot configurations are more like the usual options - a waiting room, separate shower and steam room. It is clear that with a compact footage, each section will hardly accommodate more than one person.

Interior decoration

Internal work begins with the electrical connection and installation of water supply lines. The wiring is routed and hidden in protected boxes and cable channels. Next, you need to lay thermal insulation, vapor barrier and waterproofing in several layers on each floor. It goes without saying that the walls of the container must initially be cleaned with an anti-corrosion compound and treated with protective liquids. The “insides” of the bathhouse are finished with clapboard or timber. The owner determines the configuration of the sunbeds himself. The waiting room is also finished with clapboard.

Exterior works

The outer side is also sewn up with laminated veneer lumber or wood siding, taking into account the presence of a profile with outside. Next they are engaged in laying the drainage system and installing chimney. Final stage- installation of door slabs and porches.

Although such a bathhouse is a budget option, it is fully capable of satisfying hygiene needs. In addition, such a room is very easy to maintain in terms of routine repairs.

24.09.2015

The bathhouse is one of the indispensable places of relaxation, which gives the opportunity to relax not only with the body, but also with the soul. At the same time, all lovers of such useful leisure know that home sauna- the pleasure is not cheap. It is possible to minimize the costs of building your own steam room by building a bathhouse based on a standard block container, which is converted and equipped with all the necessary technical and hardware complex. Original idea The container steam room has already won hundreds of positive reviews and comments from lovers of such a hot holiday.

Advantages of a bathhouse made from a block container

Arranging a steam room in a container block has several significant advantages over constructing a bathhouse using classical construction technologies.

- Minimum material costs. The cost of a block container, together with the price of its re-equipment, costs the customer several times less than the organization of fundamental construction work.

- Mobility. The bathhouse, equipped on the basis of a standard block container, can be transported to a new location at any time. This is especially true when moving. In addition, if for one reason or another the desire to have your own steam room has disappeared, a container bath can always be sold or used to organize your own business.

- Easy heating. Practice shows that heating a sauna made from a block container is much easier than a standard design.

- Speed of construction. A container steam room will please its owner within a few days after the start of construction work, since the entire stage of refurbishment and installation of the unit takes record time.

Features of converting a block container into a bathhouse

It is better to entrust it to professionals who have experience in implementing such projects. Nevertheless, there are some preparatory and facing works, which the customer can easily perform independently, without resorting to the help of specialists.

- A container steam room does not require pouring a super-strong and reliable foundation, however, to increase the stability of the structure, it is recommended to place a cinder block, brick flooring, and asbestos-cement pipes under the container module. In addition to the main function, such a substrate will also provide the required level of ventilation, which is necessary for any bathhouse.

- Particular attention should be paid to internal and external waterproofing. The external façade is usually covered with wood materials, which allows not only to achieve the above-mentioned insulation characteristics, but also gives the steam room a traditional aesthetic appearance.

- Ensuring thermal insulation is one of the main tasks in the process of converting a block container into a bathhouse, since maintaining the air temperature inside the module must be maintained not only through the rapid release of heat, but also through its long delay. It is important that inner covering The walls and ceiling of the steam room withstood sudden temperature changes well.

The idea of building a bathhouse from a container looks quite unusual. It would seem, why equip a bathhouse in a metal box if you can build a lightweight frame building and complete the arrangement of the bathhouse according to all the rules. Perhaps the idea is worth trying to put it into practice. Container structures are used to build comfortable houses and cottages, why not try to at least plan how to make a bathhouse from a container.

What is the value of a container bath

Making a bathhouse from a container box is relatively easy. All you need to do is develop and plan:

- Powerful insulation system metal walls, otherwise in winter the container sauna will turn into a glacier covered with condensation, and in summer in the sun the temperature will easily reach 70 o C;

- Ventilation diagram of the internal space and auxiliary insulation cavities;

- Water supply for shower cabin and steam room;

- Installation of a stove or electrical heating connection for lamps and fan drives.

All this is not difficult to do, if not for one “but”. On the one hand, you can sheathe or overlay metal box bricks, SIP panels, aerated concrete slabs, and problems with room insulation and corrosion protection would be solved. But why then fence the garden with heavy metal body, offhand it turns out that it is cheaper to build a bathhouse without a container insert.

Most owners choose to build a bathhouse from a container, photo, if they require:

Important! For container bath a full-fledged foundation is not required, regardless of whether it is a bathhouse made from a 20-foot container, or whether it is planned to use several 5-ton boxes. A flat area filled with sand and gravel is sufficient.

Several container boxes, one of which is allocated for a dacha, after finishing and connecting communications, can easily serve as a full-fledged country house.

If the five-ton truck will be used as an extension to a regular country house, the task can be simplified. For example, make only a steam room out of a container, and use the premises of a country house for relaxation and washing.

After trimming the side walls, the container body can become a frame for arranging an ordinary stationary bathhouse, built in accordance with all the rules and laws of heating engineering.

To do this, you don’t need to purchase a new or a whole container; you can buy a box with holes in the walls literally for the price of scrap metal, and it will be cheaper than:

- Pour the foundation;

- Spend half a cube quality timber for the arrangement of racks and top - bottom trim frame of the future bathhouse.

It will only be necessary to insulate the bathhouse on a container frame and veneer it both on the inside and on the outside of the building.

Container bath problems

Most developers planning to develop own bathhouse on suburban area, are paying increased attention to container-based steam rooms and sauna projects. Often, three factors keep people from building a bathhouse from a container with their own hands, which many private owners are familiar with only through rumors:

- Significant cost of implementing a bathhouse project from a container;

- The metal of the case is subject to severe corrosion;

- In the summer, the interior of the steel container turns into a stove.

The main argument of opponents of the idea of building a steam room from a container is the rather small number of proposals finished bath from a 20 foot container on the real estate market. This is not entirely true. Firstly, most specialized construction companies We offer custom production according to standard project baths from a container. One of the options, costing about 500 thousand rubles, is given below.

Such a bathhouse made from a 20-foot container photo is divided into three rooms with an area of 10-12 m2:

- Steam room with electric stove;

- The second box is a dressing room and a wash room with a shower;

- The third room is reserved for a locker room and a rest room.

The internal space, 6 m long and 2.2 m wide, is lined with clapboard, the external walls can be finished with siding or block house. Price for finished premises baths from a 20-foot container are clearly overpriced, which limits mass demand for the product.

Secondly, there is a certain shortage of sea containers on the market. Companies involved in the production of premises from sea containers buy them in small quantities from carriers. New or three year old box in good condition will cost at least 40-50 thousand rubles. If you set a goal and build a bathhouse from a 20-foot container for yourself, then with some patience you can find a single box in good condition for 25-30 thousand rubles.

How to prevent corrosion

The metal of most container models has practically no special properties. To protect steel walls from moisture and salts, the surface is phosphated and treated with special primers. If you already have plans to build a bath complex, then it is best to equip the bathhouse with your own hands from a sea container.

Such a building will easily last a couple of decades, while ordinary container boxes can be subject to corrosion due to improper ventilation of the steam room and insulation.

Advice! The simplest way To protect the steel body from corrosion is to use zinc or magnesium anodes. The rods are buried in the ground to a depth of 50-70 cm, and the leads are soldered to metal walls premises.

Decoration of the facade of a container bath

The rectangular shape of the steel box simplifies the task somewhat. In the most budget option The body of the bathhouse can simply be painted in a pleasant color, white or red. Light colors are very popular among developers in the southern regions, where it is important to combat solar heat, heating up in summer period any metal. White paint reduces heating by 30-35%. If we add foil thermal insulation to this, then the problem of overheating can be considered solved.

The second most popular finishing method is wall cladding with a block house, wall paneling or regular siding.

If to wood paneling add a roof and a porch made of wood, then you can successfully hide it under external cladding the very fact of using a container in the construction of a bathhouse.

If the bathhouse is attached to the house, then it would be quite logical to line it with the same material as the main building. For country and mobile bathhouse options, it is best to limit yourself to painting external walls. If the container is new, with factory paint, then such a three-layer coating will last much longer than a semi-handicraft repainting with automotive enamel.

How to properly build a sauna from a sea container

Immediately after purchasing a 20-foot container, the first thing you need to do is check for damage to the walls and places with painted over, putty, rusty holes. A rusty hull costs half the price of a container in good condition, so owners widely use automotive putty and marine paints to mask problem areas. You can identify a hole in the wall with a magnet or a special device.

Which foundation to choose for a bathhouse - container

Despite the fact that a bathhouse can stand for many years even on a simple platform with crushed stone, most owners prefer to install it on a foundation.

A lightweight five-ton container for a steam room is usually installed on columnar supports cast in concrete formwork or built of brick. If the place for the bathhouse is chosen in the forest, or on the shore of a reservoir, then it is recommended to make a crushed stone cushion under the supports. To do this, dig mini-pits according to the number of pillars to a depth of 60-70 cm, fill them with a mixture of fine sand and gravel screening. Such a foundation will support even a forty-foot container.

Often, the owners of the future bathhouse pour it under the container block slab foundation, motivating their decision with insurance against sagging of the building and the desire to install a second floor in the future. This is not for a bath the best option. The container body is so strong that it will withstand even the collapse of 40% of the supports, and the concrete under the floor will require serious insulation of the bathhouse subfloor.

Insulation of container walls and ceilings

The main issue in building a bathhouse is always the choice of insulation method. At the first stage, the walls and ceiling are sheathed with wooden slats, providing a ventilation gap. Next, the material is selected.

Metal walls can be insulated in three ways:

Thermal insulation based on polyethylene foam and stone fiber must be sheathed with a vapor barrier. A 20-foot container will require at least one and a half rolls of film.

The insulation layer is sewn up wooden slats, for a three-room bathhouse you will need at least 80 m2 of linden or ash finishing. The gap between the container wall and the fiber must be ventilated after each visit to the bathhouse.

You can insulate the container space by spraying polyurethane foam directly onto the metal and sheathing slats. Next, a layer of vapor barrier, film and decorative finishing. In this case, the dew point moves to the metal surface of the container.

Most the best option insulation is considered internal lining steam room of the container made of stone fiber with an aluminum screen. Layer thickness is at least 50 mm. Next, the outer walls of the bathhouse are covered with penoplex, at least 50 mm thick. The facade of the container is plastered or covered with clapboard.

Arrangement of the bathhouse floor in a container version

Expanded polystyrene insulation is laid on the floor of the bathhouse, onto which a screed of at least 100 mm thick is poured. In shipping containers, the floor is almost always made of thick moisture-resistant plywood, polystyrene foam and concrete screed can be laid directly on a plywood base.

The next step is to lay a layer of mastic waterproofing over the concrete, install larch logs and install a ventilation system for the underground space. A wooden floor is laid on the joists. Most of the water and condensation that gets on the floorboards will be removed from the subfloor by the ventilation system.

The floor in the dressing room is arranged in a similar way; in the locker room or rest room you can lay the tiles directly on the concrete screed, and more low level flooring will make cleaning the premises easier.

How to deal with condensation inside a bathhouse

The steel walls of a container can become a source serious problems, first of all, due to the metal’s impermeability to water vapor. Even if there is special processing metal parts in conditions of warm condensation, vapors detergents, pitting corrosion may form on the walls of the container. Especially if window openings were cut out, holes were drilled for screwing in self-tapping screws, and laying communications.

Wherever there was damage protective covering, the metal will rust. Besides, wooden sheathing, on which the entire internal lining rests, easily absorbs moisture even under a layer of varnish or oil impregnation.

There is only one way to prevent container corrosion - by arranging effective ventilation. In fact, each room of the container is equipped with its own supply and exhaust ventilation, plus one system for ventilating the subfloor and places where condensation accumulates. Ventilation must be turned on every time amateurs light steam they leave the bathhouse and the stove is put out. Due to the accumulated heat, the air accelerated by the fans effectively expels condensation at any air temperature outside the container.

Finishing the interior of the bathhouse

According to the standards, the requirements for cladding with wooden slats apply only to the steam room or sauna. In room Turkish bath the walls of the hot compartment can be finished ceramic tiles.

The dressing room with shower compartment is tiled wood panels, clapboard or board. The space for the shower can be separated by a wall and tiled with ceramic tiles. The shower floor is equipped with a drain without a tray, or a plastic shower cabin is simply installed. All parts of the wooden finishing of the bathhouse must be treated with impregnation with fire-retardant additives.

How to properly install a stove in a steam room

Regardless of what type of heater, wood-burning or electric, will be used to heat the container sauna, it is necessary to measure or calculate the volume of the steam room. Based on the resulting cubic capacity, the required volume for the bath is determined. thermal power heater and its location.

For a sauna built in a container, the most preferable option would be a wood-burning steel or cast iron heater. It will be difficult to heat the huge steel body of the bathhouse using electricity.

The location for installing the stove is selected next to the partition separating the rooms of the dressing room and the steam room of the bath. The housing is mounted closer to the wall of the container so as not to block the passage and simplify the removal of the pipe. In this case part wood cladding the walls behind the stove are removed and replaced with heat-resistant tiles, and the base is laid out of it. There is a carving in the wall next to the stove ventilation window. The second window is cut into the opposite side of the bathhouse wall.

Conclusion

Arrangement of a bathhouse from a container - not only good way save on materials and work, this also makes the building safer and all-weather. By installing the steel body on the foundation and equipping the steam room, you can use the bathhouse without waiting for completion finishing works throughout the entire room. The rest is to move the façade and interior details to a period when time and funds become available.

In order for a container bath, unusual in domestic conditions, to be convenient and functional, it is important to plan wisely inner space, use Decoration Materials taking into account climatic conditions, introduce full-fledged engineering communications.

Before we begin to analyze the strengths and weaknesses solutions, you need to understand what aspects of building a bathhouse from a sea container will have to be developed independently:

- metal walls need powerful insulation, otherwise winter months a layer of condensation on the walls will turn into ice, and in summer the room will overheat under the influence of the sun;

- the cavities of the insulation and the internal space must be well ventilated;

- water should be supplied to the steam room and washing room;

- it is necessary to supply electricity for lighting and, if necessary, for forced ventilation.

In Moscow and the regions, the construction of such a structure is justified in the following cases:

- if a structure with a strong frame is needed, since construction is planned on sandy quicksand or heaving loams. In such conditions, purchasing and re-equipping a 20-foot container is more rational in terms of investment than relaying crowns from logs or timber;

- when there is a need for compact bath on wheels, which will be convenient to transport to a summer house, construction site, or vacation spot. A small-sized steam room made from a 5-ton container will fit in the back of a Ford or Bull truck;

- if it is not possible to arrange a full-fledged foundation. In most cases, a leveled area with a bed of sand and gravel is sufficient.

When you plan to use the blank as an extension to the dacha, it can be upgraded as a steam room, and a washing room and rest room can be installed directly in the house. If you cut off the side walls, the remaining frame can be used to build a traditional wooden sauna.

Disadvantages of container baths;

- high-quality implementation of the project requires significant financial investments;

- the metal body is vulnerable to corrosion.

It should also be remembered that if insulation is neglected in the summer, the interior space will become very hot.

Design and zoning options

Below is the diagram standard solution:

This bathhouse project from a 20-foot container is formed by three rooms, the total effective area is 10-12 sq. m. The first right block is a steam room with an installed electric oven, the second is a washing room with a shower, and the third is both a locker room and a resting place.

The entire interior is in in this example finished with clapboard; a block house or siding can be used to cover the facade.

Solving typical problems: corrosion, insulation

The key measure here is to prevent the spread of corrosion. To protect steel walls from contact with salts and moisture, they are phosphated and coated with special primers. Installing magnesium or zinc anodes can also help: they are buried half a meter deep, with the leads soldered to the metal body.

It is important to take care of the complete insulation of the structure. The ceiling and walls are sheathed wooden frame, it provides the necessary ventilation gap. It is possible to use one of three insulation methods:

- creating a multilayer sandwich formed by polyethylene foam with a reflective layer in tandem with aluminum foil - all this is installed on a lattice frame;

- inside – polyurethane foam, outside – polystyrene foam;

- stone fiber in the form of mats with additional sizing with foil film.

Polyurethane foam - material for insulating baths from a container

Polyurethane foam - material for insulating baths from a container Last option relevant only for saunas, stone fiber and polyethylene foam need to be covered with a vapor barrier.

The insulation is sheathed wood trim, For standard bath with three indoor units need 80 sq. m slats made of ash or linden. The gap formed between the insulation and the wall of the container must be arranged in such a way that it is ventilated after use of the bath.

For insulation purposes, you can spray polyurethane foam directly onto the sheathing slats and metal. A vapor barrier layer, film and interior lining. In such conditions, the dew point falls on the metal frame.

The floor is insulated using polystyrene foam insulation, and on top it is covered with a screed with a height of 10 cm. Then you need to form a layer of mastic waterproofing, on top of which you can assemble larch logs and begin to ensure ventilation of the underground space.

Stages of converting a container into a bathhouse

The first step is to arrange the foundation, then improve the frame and lay communications. At the final stage, the room is finished with installation heating equipment. A list of basic tools and materials will be given as the work is described.

Foundation

Usually the steam room is mounted on a full foundation, but its construction without foundation is also practiced. The first option is relevant in cases where a stationary container bath is designed for long-term operation. The structure is installed on columnar foundation, having a slight recess.

A trench is dug along the perimeter of the planned structure, its depth usually does not exceed 35-40 cm. Its bottom is covered with a cushion of sand and gravel, then a columnar base is assembled. The latter can be represented concrete blocks or brickwork. A layer of roofing material is laid as waterproofing. You need to fix the reinforcement frame on top, on which the bathhouse from the block container will be installed directly.

Electrics

This stage is the starting stage for everyone interior work, since it is important to properly insulate and disguise the wires. In the steam room, where they prevail high temperatures and humidity, it is not customary to place electrically powered components. The network is installed using the following materials:

- wall lantern based on an incandescent lamp;

- boxed machine gun 16A;

- cables forming a socket line;

- Fluorescent Lamp;

- sockets;

- corrugation, thanks to which the electrics will be brought out;

- wires forming the lighting line.

Only double-insulated cables are used, variations with a copper core are optimal, and a special waterproof sheath is preferred. In this aspect, PRN, APPV, PRVD, APRN, PPV and APV have proven themselves well. The shield is placed in a room with good air exchange, at least 1.5 m from the floor.

Single-phase wiring is based on three-core cables. The phase conductor is combined with the terminal input machine. Jumpers help to move the clamps of other machines to the upper terminals from the lower ones. The neutral and protective conductors are combined with similar blocks. The lower contacts of the machines are connected to the phase conductors. Electrical appliances are installed with grounding; sockets must be at least 1 m above the floor.

Ventilation arrangement

The system is based on exhaust and supply openings provided in each room, the latter should be located below. If the bathhouse operates in conditions natural ventilation, vents, vents, and a stove chimney will serve as hoods.

Drainage

Complex outgoing communications are not needed here; it is only important to perform optimal inclination floor in the washing room so that the waste liquid goes to the drain flange. A drainage system should be provided in the shower room.

Subtleties of finishing work

When deciding how to build a bathhouse from a container, you need to rely on the essence of the base material. The metal base requires a special approach when selecting and assembling the skin.

Interior decoration

The most suitable solution for decorating a bathhouse from a container with your own hands is wood, there is no species special requirements, you just need to avoid coniferous raw materials. Construction using wooden lining avoids release during heating toxic substances And unpleasant odors, the surface retains heat and has an aesthetic appearance.

To increase the resistance of the material to moisture, fire, and damage by microorganisms, it is advisable to impregnate the skin protective compounds. Please note: you cannot paint the inside of the bathhouse.

Facade cladding

Exterior cladding can be made using a wide range of materials. Bathhouses built from containers and decorated with clapboard look neat and presentable. It is customary to use aspen here, since as a result of drying it acquires special strength and the ability to serve for a long time. Also in demand are oak and pine variations, glassine and heat-resistant plastic.

Features of choosing and installing a stove

Unlike traditional baths, where it is possible to use a dozen types of devices, compact steam room, based on metal frame, can only function with a wood-burning or electric stove. In cramped conditions free space Many people install a compact metal tank. The easiest way is to buy a factory boiler: on the specialized market you can find small, convenient domestic and foreign models.

When choosing a location for installing heating equipment, you need to take into account important condition: heat under the influence of natural air movement should first of all be directed to the steam room. Therefore, it is recommended to install the stove in the area of the partition separating the washing room from the steam room. A gap of 20 cm must be left between the heating apparatus and the wall in order to comply with fire safety standards.