Air gap between brick and shell rock. Ventilation of brick walls in a country house. Process technology and gap sizes

Read also

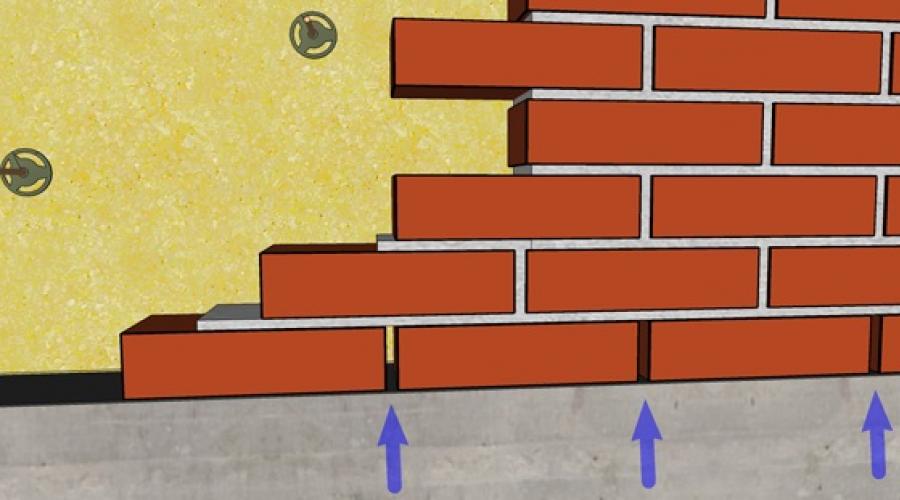

The brick has high level water absorption. Therefore, when facing a house with brickwork, ventilation gaps are made for weathering. excess moisture. Thermal insulation properties brick walls not high enough, and in order to create comfortable conditions for living, insulation is a prerequisite when constructing houses from this building material. When using the method of three-layer masonry of load-bearing structures with internal insulation They also leave gaps for ventilation.

What are clearances and why are they needed?

By gaps we mean the distances between the walls, which promote ventilation and prevent the accumulation of condensation inside the structure. In such gaps you can place thermal insulation material for insulation. With this method brickwork outer wall the house consists of three layers:

- Basic structure.

- Insulation.

- Facing.

It is used to increase the thermal insulation of a home and to save energy resources. Thermal insulation material inside the structure it protects the load-bearing wall from freezing. In addition, it itself is reliably protected from damage. And the existing air gap between the insulation layer and the facing masonry promotes ventilation and evaporation of excess moisture.

Process technology and gap sizes

The width of the hole should not be more than 2 cm.

The width of the hole should not be more than 2 cm. Masonry begins with the construction of a supporting structure. Then they lay out the wall facing bricks, leaving a gap between them for air circulation and, if necessary, for insulation. The distance should be 1.5-2 cm or within 5-15 cm in the case of thermal insulation and depending on the thickness of the material layer. An air cushion is made in order to exclude deviations from the norm in the vapor barrier indicator.

The vapor permeability of all layers must be combined. This will help prevent moisture from accumulating on the internal sides brick structures, which will prevent the formation of mold and mildew, as well as preserve the heat-shielding properties of the insulating material and extend its service life.

Regardless of the presence of insulation inside the wall, for air circulation between load-bearing structure and make special gaps in the form of embroidered vertical seams in the facing masonry. They are located at the top at the eaves and at the bottom at the plinths of the building. The number of such holes depends on the size of the walls, and their width is 2-4 cm.

Gaps when insulating brickwork

The choice of insulation depends on the material external structure at home, since the vapor permeability coefficient of elements of all layers should be taken into account. As insulation you can choose:

You can insulate the wall using polystyrene foam.

You can insulate the wall using polystyrene foam. - mineral wool;

- expanded polystyrene;

- bulk insulation.

When using insulation in the form of plates, all structural elements are fastened together using flexible connections, which are installed on a load-bearing wall. Then they lay out the facing masonry to their level and place it on them. heat insulating material. Waterproofing is attached to the insulating layer and a gap is left for ventilation. To create it, use connections that have a plastic washer with a latch. It presses the insulation against the wall and prevents it from slipping and deformation. The width of the air cushion varies between 4-6 cm. Bulk insulation they simply fill the void formed between the walls without creating air gaps, after the height of the walls being built reaches a meter.

Print this page

When finishing or reconstructing a facade, as a rule, its insulation is done along the way. In pursuit of the best thermal insulation, the customer often forgets or ignores the most important indicator insulation - vapor permeability. This is fraught big problems: wetness, freezing and premature destruction of the load-bearing wall.

Ventilation holes in the facing masonry are necessary to maintain an optimum temperature and eliminate the “greenhouse effect”, which significantly accelerates the destruction of walls. Therefore, every 3-4th vertical seam in each row facing masonry should not be filled with solution. These will be the ventilation ducts.

The principle of condensation formation explains how this happens: at the point of contact different temperatures(cold and heat) moisture accumulates on hard surfaces. This often causes “ice walls” or damaged interior decoration. The only way out is to provide moisture with the opportunity to freely evaporate into the atmosphere, i.e. outside the building.

It is also necessary to leave air vents at the top and bottom of the cladding.

In this regard, when constructing facades using the “wet” method (applying mortar finishing layers), vapor-permeable compounds are used. In another case, a ventilated facade system is used.

Wall ventilation, which is placed under the brick - this is a very important part of the work process. If the cladding is carried out by professional masons, then this process will not take much time, but if you want to do everything yourself, then you need to take into account several important points:

- All rows of stones are laid using mortar, but the 34th row is installed without it, this will help ensure natural ventilation walls. Sometimes this type of masonry is not suitable and can be left air cushion between the roof and the wall;

- The ventilation gap should be at least 25 mm, but this is for a wall that is completely flat. When facing wooden house from the timber you need to maintain a gap of 30 mm;

- If the gap is under the beam, then it can be closed using a special strip, without laying a row of bricks.

If the walls of your house provide air gap, then there must be ventilation boxes!

The main advantages of ventilation boxes:

- Ventilate the air gap

- Protect the wall from rodents and other pests

- Protects from precipitation (especially during intense side rain)

- Discharge condensate outside

- Matched to the color of the masonry, they are almost invisible, which does not spoil the impression of the facade

Ventilation and drainage boxes

Ventilation and drainage boxes used in ventilation system facade. They come in two types: and a ventilation and drainage element for a 10 mm seam

Facade ventilation system it is quite simple to create and consists of only two elements: an air gap 10 cm wide with a distance between the heat-insulating layer and the façade layer of 4 cm and ventilation holes - vertical seams between the bricks that are not filled with mortar, into which the ventilated elements of the facade are mounted.

Before startingsoundedand I the first row of masonry must be laid with waterproofing (an apron made of bitumen mass), along which condensate will flow freely through ventilation holes out. Similarly, waterproofing should be laid over each opening of the building.

Ventilation holes located in the first and last rows of brickwork. If the wall height is more than six meters, another row of ventilation holes is additionally located in the middle of the wall. At the same time, the distance from the corners of walls and openings to the first ventilation hole should not be less than 25 centimeters.

Horizontal holes placed at a distance of 1 meter from each other (every 4 bricks). At the same distance, ventilation holes are located under and above the openings, but at least two holes for each opening. Vertically, the holes are placed directly above each other, and in no case in a checkerboard pattern.

Proper placement and installation of fans guarantees them effective application, which means long-term preservation of the reliability, strength and ideal appearance of your facade.

Location of ventilation boxes

Advantages of ventilation boxes:

- Drying inner surface facade, which ensures its durability.

- Salt stains do not appear on the ventilated façade and mold does not form.

- The insulation is drying out. Only dry insulation meets all thermal insulation requirements.

- According to studies conducted in Germany, the thermal resistance of a wall with a ventilated air gap is 6% higher than a similar wall without an air gap.

Distribution of ventilation boxes:

- Ventilation boxes are installed in the vertical joints of the facing masonry with a frequency of: 1 ventilation box - 2-3 bricks

- In buildings up to two floors - 2 rows of ventilation boxes (at the bottom - in the first row of masonry, and at the top - in the last) If the wall insulation turns into insulation pitched roof- in this case there is only one row of boxes - in the first row.

- IN multi-storey buildings- additional 1 row of boxes every two floors.

- Additional ventilation boxes are installed above and below the openings

- The ventilated air gap should be within 30-50 mm.

- At the junction of the foundation and the walls, not only horizontal, but also vertical waterproofing to a height of at least 150 mm must be provided. (according to DIN 1053 T1).

Is the ventilation box a cold bridge?

The ventilation box cannot be a cold bridge. The ventilation box is mounted in the body of the facing brickwork and does not in any way disrupt the continuity of thermal insulation (facing brickwork in multilayer walls freezes and does not perform a heat-insulating function). As a rule, in three-layer or two-layer walls, where the façade is faced with facing or clinker bricks The cold bridge is galvanized anchors or masonry mesh, acting as horizontal connections.

Why is a ventilated air gap needed in two-layer or three-layer walls?

For walls made of vapor-permeable materials(such as ordinary brick, aerated concrete, foam block, ceramic block and shell rock) ventilation gap is mandatory element ventilation of facades.

The ventilation gap in the wall performs the following functions: - removes condensation from the thermal insulation (three-layer walls) or load-bearing wall (two-layer walls), thanks to this the materials retain their original thermal insulation properties; - prevents the appearance of efflorescence on the facing brickwork; - creates favorable microclimate indoors.