Ventilation units KOMPAKT REGO. Ventilation units KOMPAKT REGO Control and protection systems

Read also

The goods are delivered on prepayment

Ventilation units "Compact 1" and "Compact 2" are designed for operation in small spaces: apartments, shops, offices, workshops, etc.

The compact sound- and heat-insulated housing (insulation thickness 25 mm) contains: a filter, a fan, and a heater. The fans of the "Compact 1" and "Compact 2" units are equipped with an asynchronous motor with an external rotor. All units are equipped with EU3 class filters. To indicate the degree of filter contamination, a pressure sensor is included with each installation.

Installation

Installations with an electric heater can be mounted in any position. Installations with a water heater must be installed in a position that ensures normal ventilation of the heat exchanger. They are easily connected to rectangular air ducts. The small size of the units allows them to be installed in suspended ceilings and shallow wall niches. During installation, it is necessary to provide access for servicing the equipment and replacing the filter.

Speed and temperature control

To control the operation of air supply units, control modules SCM and MSS have been developed. They consist of an RCU-30 control panel and an automation panel.

The fan speed of the "Compact 1" and "Compact 2" units is controlled by a three-stage transformer. To regulate the temperature of the supply air at the outlet of the unit, depending on the power of the electric heater, a Pulser or TTC triac temperature controller is provided, and for the water heater OPTIGO.

Motor and heater protection

The engines of the "Compact 1" and "Compact 2" units are protected by built-in thermal contacts with automatic restart. Electric heaters of the units are equipped with two-stage overheating protection. The first stage is set to 55°C and restarts automatically, the second stage is set to 120°C and restarts manually. To protect the water heater from defrosting, a capillary thermostat is provided to protect the heat exchanger at the minimum air flow temperature. Additionally, it is necessary to install a temperature sensor to protect the heat exchanger based on the return water temperature.

Accessories

Air valves, silencers, air distribution and protective grilles, etc.

| Dimensions | Compact 1109M |

||

| A | 320 | ||

| B | |||

| C | mm | 1070 | |

| D | |||

| E | |||

| Noise characteristics | Compact 1109M |

||||||||||

| LwA tot (total noise level) | LwA(noise level in octave range) | ||||||||||

| 31,5 | 63 | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 | |||

| To the entrance | 55 | 62 | 59 | 59 | 56 | 65 | 59 | 53 | 53 | 51 | 45 |

| To the exit | 63 | 70 | 52 | 64 | 62 | 68 | 65 | 65 | 64 | 61 | 55 |

| To the environment | 46 | 53 | 56 | 57 | 55 | 54 | 47 | 43 | 46 | 46 | 41 |

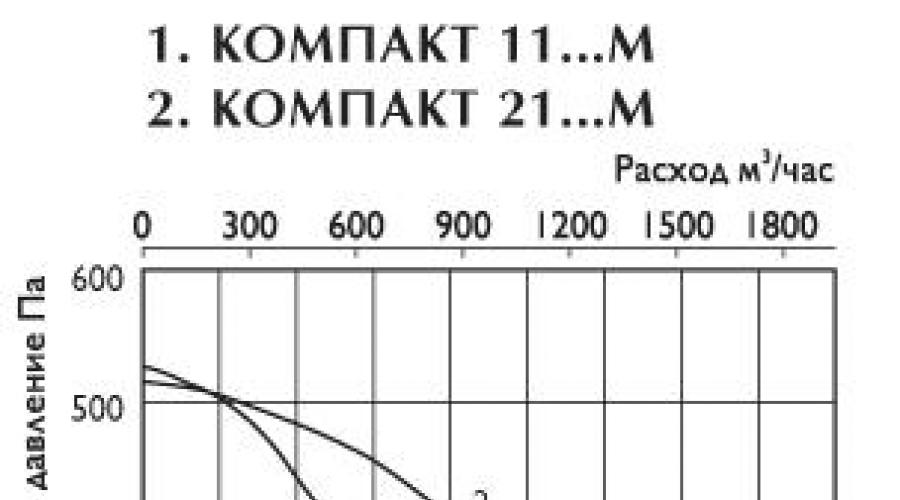

Performance characteristics

Installation

¤ All units are supplied fully assembled and ready for connection.

¤ Electrical connection and installation must only be carried out by qualified personnel in accordance with the installation instructions.

¤ Electrical parameters must comply with the specifications on the installation plate.

¤ All electrical wiring and connections must be made in accordance with safety regulations.

¤ The electrical connection must be made in accordance with the connection diagram according to the terminal markings.

¤ Installations must be grounded.

¤ Units must be installed in accordance with the direction of air flow.

¤ Units must be installed in such a way that there is access for safe maintenance.

Working conditions

¤ The units must not be operated in explosive areas.

¤ The installations must not be used to transport explosive gases, dust, soot, flour, etc.

¤ The units are designed for continuous operation. It is not recommended to turn the equipment on and off frequently.

¤ Noise problems can be eliminated by using a silencer (one of the supplied accessories).

Service

The only maintenance required is cleaning. It is recommended to inspect and clean the filter every month and the fan every six months of continuous operation to prevent imbalance or premature failure of the fan.

Before servicing, make sure that

¤ Power supply has been interrupted.

¤ The fan impeller has stopped completely.

¤ The heater, motor and fan impeller have cooled down completely.

When cleaning the installation

¤ Do not use aggressive detergents, sharp objects or high pressure devices.

¤ Make sure that the fan impeller is not unbalanced and that it is not distorted.

¤ If the fan operation is abnormally loud, check the impeller for misalignment.

¤ Bearings, if damaged, must be replaced.

In case of malfunction

¤ Check whether there is voltage to the installation.

¤ Turn off the voltage and make sure that the fan blades are not blocked and the current protection has not tripped.

¤ Check the capacitor connection. If after checking the unit does not turn on or the fan or heater protection is triggered, contact your supplier.

¤ If the unit is returned, clean the filter, heater, blades and fan motor; connecting wires must not be damaged; It is mandatory to have a written description of the malfunction - a statement.

Air supply units in frame-panel housing COMPACT from a Russian manufacturer of ventilation equipment ARCTOS Designed for use in residential and public buildings. Ventilation units with a capacity of up to 1050 m3/h COMPACT-1 1115M equipped with an electric heater, filter, damper and fan. The unit is standardly equipped with filters of cleaning class G3; a pressure sensor is provided to monitor the degree of filter contamination.

Advantages of supply ventilation units COMPACT:

- Six standard sizes of ventilation units with maximum productivity up to 7000 m3/h.

- Ventilation units have a monoblock, suspended design.

- They are equipped with an electric heater or a 2, 3, or 4 row water heat exchanger.

- The delivery set includes a G3 filter. Filters of higher purity can be supplied upon request.

- The housing is made of aluminum profile and connecting elements. Steel sandwich panels filled with non-hot heat and sound insulating material 25 mm thick.

- Standard control module SCM...N (control panel RCU-30 and automation panel), which provides control of the operation of the air handling unit.

- It is possible to adjust the fan rotation speed using an additional device - a 3-stage transformer.

- regulation of the temperature of the supply air at the outlet of the unit is carried out using a triac temperature controller Pulser or TTS (electric heater), for the Aqua water heater.

- Built-in motor protection with automatic restart.

- Air handling units with an electric heater are equipped with 2-stage overheating protection.

- Installations with a water heater are equipped with a capillary thermostat to protect the heater from freezing at low air temperatures. Additionally, it is necessary to provide a temperature sensor (on the return water pipeline) to protect the heat exchanger.

- The dimensions of the air supply units allow them to be installed in suspended ceilings up to 400 mm deep.

- Large selection of accessories for connecting, installing and controlling the air handling unit.

- The units are supplied assembled and ready for connection.

The advantage of air handling units with an electric heater (heater) is, first of all, simple installation, as well as the absence of problems associated with the possibility of defrosting the water heater. The electric heater ensures quick heating of the supply air to the required temperature. Air supply units COMPACT have specially designed SCM control devices, which controls the operation of all elements (damper, heater, fan), and performs protective functions - protects the fan motor from short circuits and overheating. In addition, the SCM control device monitors the degree of filter contamination.

Frame-panel air handling units from ARCTOS- this is ease of installation, a large range of models and high performance. The installation body, consisting of “sandwich” panels, performs a heat-insulating and sound-proofing function, preventing the spread of noise from the installation site of the equipment into the serviced room.

Our company carries out professional installation of ventilation systems of any level of complexity.

The main advantages of cooperation with us:

installation of turnkey ventilation;

installation of ventilation systems of any type at facilities for various purposes;

use of modern innovative energy-saving technologies;

direct cooperation with the largest manufacturers of climate control equipment;

provision of a complete package of documents;

low prices.

We perform:

installation of exhaust ventilation;

installation of supply ventilation;

installation of supply and exhaust ventilation;

incl. installation of installations with natural and mechanical impulse;

comprehensive development of engineering systems, including ventilation, air conditioning and heating.

Schedule

All installation work is carried out on weekdays. If there is an urgent need, by agreement with the customer, work can be carried out on weekends.

The ClimatSeason company is an official dealer of the largest manufacturers of climate control equipment, including most well-known Japanese, Korean, Russian and European brands.

The official guarantee is provided by:

for supplied equipment (set individually by each manufacturer and ranges from 1 to 3 years);

for installation (1 year).

Conditions for maintaining the guarantee:

correct installation and operating conditions of the equipment;

integrity of the case and seals;

compliance with the terms and frequency of service;

preservation of purchase documents (completed warranty card, cash receipt when paying in cash or invoice when paying by bank transfer)

The procedure for eliminating defects during the warranty period of the equipment:

notification of the seller about identified defects no later than 5 days from the moment of their discovery (the letter is sent by e-mail or regular mail to the address: 125040, Moscow, Verkhnyaya St., 34, building 11 or by e-mail);

visit of a specialist to the site within 5 days from the date of receipt of the message.

Please check the warranty card upon purchase and keep it during the entire warranty period. Before purchasing, we recommend that you carefully read the terms of warranty service and operating instructions for the equipment.