Ventilated roofing on a flat roof. Ventilation device for soft roofs. Metal roof ventilation device

Big country- large volumes of housing construction. Not only multi-storey, but also private. And every developer needs and needs knowledge on general construction issues, norms and rules, including roofing processes.

Properly executed roofing structures are the key to not only warm home and a comfortable atmosphere, but also the durability of other elements of the structure.

The roofing device is important stage construction of buildings.

Physical heat transfer processes

In a heated house, temperature changes and the presence of moisture in the air in the form of steam and condensation are inevitable. Steam is produced by human or animal activity and penetrates into building construction, cools and moisturizes them. Overwhelming majority building materials allow air to pass through to varying degrees. Therefore, any residential building, individual or multi-apartment, is an air volume in which warm air rises upward through all structures.

In tall multi-storey buildings, a traction effect appears. Warm air rises to the upper floors, this is especially noticeable in the entrances, and penetrates outside through windows and attics. On the lower floors, on the contrary, there is an influx of outside cold air. This process also occurs in a one-story heated house, only with less dynamics.

On the other hand, warm air vapor condenses in structures into water, which not only moistens them, but also has the ability to flow down, filling cavities in the structures. The main function of condensing water vapor is assumed by the uppermost part of the building - the roof. In winter, this process occurs intensively and constantly, and in summer, mainly during the cool night time.

The most modern and effective method prevent or significantly reduce moisture condensation in the roof - make it ventilated naturally or forcefully. Natural cold ventilation will not require energy costs, so its design is preferable. However, there are roofs of complex architecture that lack the strength of natural ventilation, then forced ventilation comes to the rescue.

Ventilation removes warm, moist air into the surrounding space, thereby leaving bearing structures, insulation is dry, extending service life and providing thermal insulation. We need to manage this process, which is done using the so-called roofing pie.

The concept appeared relatively recently and denotes a multi-layer roof structure in which leading place allocated to the creation of ventilation ducts. There are two types of roofing pie: for heated and insulated rooms and for cold roof. Each layer is functionally interconnected with other layers, and the absence of any reduces protective properties whole pie.

If the attic is a cold, uninsulated part of the building, it is done in several successive layers. The following tools will be required for the work.

- hammer;

- drill with drills 4-12 mm;

- wood hacksaw;

- stapler (stapler) electric or mechanical with staples 14x8 mm;

- level, meter ruler, square;

- scissors;

- screwdrivers of different sizes;

- brush-fleet for antiseptic cutting of wooden parts;

- construction sealant.

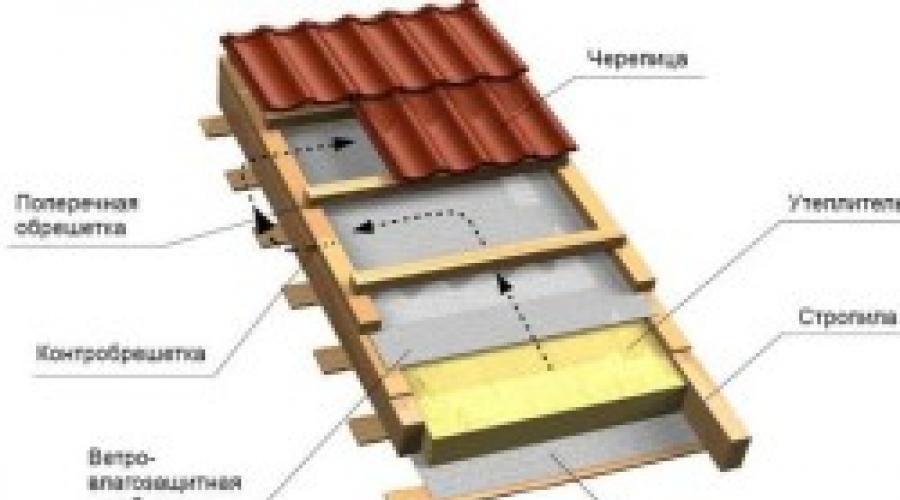

Laying is done on the upper side of the rafters waterproofing film(not to be confused with vapor barrier). The film sag should be 20-40 mm to drain condensate. It is secured along the rafters with a counter-lattice 30-50 mm thick and a width equal to the thickness of the rafters themselves. It is better to glue the film at the attachment point with double-sided tape.

To reduce waste, the film can be laid in horizontal rows from bottom to top and with an overlap of 100-150 mm. The junctions of the strips are glued, creating a continuous web. The water generated from condensation will flow down the film to the roof eaves.

After installing the waterproofing layer, the roofing lathing is sewn across the rafters onto the counter-lattice. The width of the boards and the gap between them are selected depending on the roofing material.

- For ceramic and soft tiles, use an inch board 100 mm wide for the sheathing. It is laid with a gap of 50-100 mm, after which the top is completely covered with building board or waterproof plywood with a thickness of at least 9 mm. An underlying layer is also laid under the soft tiles.

- Lathing made of boards 30x100 and in increments of 300-400 mm is made under metal tiles or corrugated sheets;

- For a metal seam roof, use a lathing made of an inch board 150-250 mm wide, sewn onto a counter-lattice with a minimum gap of 20-50 mm.

Finally, the roofing material is laid directly on the sheathing or building slab. It is attached with special nails, screws or clamps to the sheathing. The roof fastening points are protected with sealants, and the sheathing is pre-treated with an antiseptic. Additionally, you can perform rough filing along the rafters from the attic side.

Between the roof there was a ventilation gap equal to the total thickness of the sheathing and counter-lattice. This is 55-80 mm of the height of the under-roof space along the slope of the rafters. In winter, warmer attic air, partially penetrating through the waterproofing, will rise to the roof ridge and be released into the atmosphere without having time to condense moisture. And in summer, the air heated by the roof is also removed from under the roof.

Attic ventilation is important for the under-roof space. It is carried out through dormer windows located on the gables from different sides. Ventilation of the living space, attic and under-roof space are interconnected, and one of their goals is to reduce steam and condensation in the roofing pie.

Ventilated insulated roof design

Often the attic space is used as an attic and is insulated from the roof side. In this case, several more layers are added to the roofing pie. Now there is no attic air gap between the living space and the roof. The warm and humid air of the attic immediately penetrates into the under-roof space. And if you don't accept additional measures Once it is removed, there will be much more condensate and the structures will begin to get wet. Thermal insulation materials will cease to perform their functions and the air in the room will be cold. We'll have to turn up the heating.

In addition to those layers that are already made in the cold roof, they add thick layer insulation placed between the rafters on the inside. If ordinary rafters are 150 mm wide, then the thickness of the insulation between the rafters can be no more than 100 mm. The reason is the need to leave a minimum gap (do not touch) until the waterproofing sag, which reaches 40 mm. If there is a touch, water flowing down the insulation will get into the insulation. To increase the thickness of the layer, timber is sewn onto the rafters required thickness and add insulation.

Then it is covered with a vapor barrier film. The goal is to minimize the penetration of steam from the room into the insulation so that it does not get wet. Wet insulation is no good, it does not retain heat and, in addition, moisturizes the surrounding structures. First, a rough lining is sewn onto the vapor barrier, and then a finishing lining.

Now the path of wet steam to the roof is blocked, and although a small part of it still penetrates, it is carried out into the atmosphere by the under-roof ventilation air flow, without causing harm to the roof structures. And if the warm room itself is not ventilated, where will the steam go? Through all sorts of microscopic pores and cracks it will still go up to the roof. This will also be facilitated by the excess pressure generated in the warm attic room.

Ventilation of the room itself will help relieve excess pressure, reduce the moisture content in the living room and thereby help under-roof ventilation remove moist air into the atmosphere.

Ventilated cornice device

The longitudinal ventilation channels of the roofing pie will not work effectively if, on the one hand, in the lower part, at the very eaves, there is no inflow atmospheric air. On the other hand, it is necessary to allow the humidified air to escape from the very top part of the roof - from the ridge.

Waterproofing film is the strongest of all types of films used in home construction, so it does not allow water or moisture to pass through, even under high pressure.

The waterproofing film is removed and glued with sealant to the metal cornice strip installed in the plane of the sheathing. The roof is fixed on top. Air flow is carried out in 3 ways. Firstly, through the gaps of the profile of the roofing material, secondly, through the gable overhangs and, thirdly, through the micropores of the waterproofing film, drawing vapor from the insulation.

When covering the cornice in its lower part, it is provided ventilation holes or gaps depending on the many design options for the cornice. One of modern methods- This is a continuous lining of the eaves with plastic panels with perforations for roof ventilation.

Creating a ridge hood

Depending on the design of the roof covering, the air flow from under the roof is collected in the ridge and discharged into the atmosphere either through structural gaps along the length of the ridge, or through gable openings. For example, complete with ceramic and metal tiles There are special ridge elements with ventilation gaps. Additionally, there are additional elements for a non-standard ridge shape.

This is the outer part of the roof. The internal structure is performed in a certain sequence.

- the counter-lattice along the rafters is not brought to the geometric height at the same distance of 20-40 mm. The bars of the oncoming slopes do not join;

- sheathing in 2 solid boards from both slopes on the ridge is also performed with a longitudinal gap of 40-80 mm;

- the waterproofing film along the ridge is cut with a hem margin of 200 mm on both slopes;

- between the ends of the counter-lattice and the sheathing along the ridge, a ridge beam of 40x100 mm is installed vertically;

- a waterproofing sheet is attached to it and sealed with sealant;

- From above this structure is covered with a ridge according to the instructions and technology;

- Install ridge end elements on the gable side, in which ventilation holes or gaps are provided.

Some features of a ventilated roof

Roof ventilation is not an independent process. On the contrary, ventilation or its absence in the premises directly affects the air exchange in the roof. In order to effectively remove destructive moisture from residential premises through the roof, it is necessary to consider the ventilation of all building elements as a single process.

If the shape of the roof is complex, has many transitions, valleys, ventilation processes must be divided into sections and air flows in the roof must be formed separately. As a result effective ventilation the air in the under-roof space should be replaced approximately 2 times within an hour.

The effectiveness of a ventilated roof depends on the slope of the slopes. The steeper they are, the stronger the ventilation process occurs. And, conversely, in roofs with a slope of less than 20%, under-roof ventilation is unstable and effective only under wind pressure.

Always is useful device on the roof there are additional exhaust elements (aerators) that help enhance the natural ventilation of the roof. They should be placed on roofs complex shape when conventional means are no longer sufficient. Aerators are installed near the ridge.

The thermal insulation properties of insulation and the durability of roof structures directly depend on the presence of moisture in them. Therefore, ventilated roofing and the design of room ventilation are economically beneficial even when it is necessary to install forced air exchange.

Construction technology numbers more than a dozen engineering solutions concerning the design. The comfort of residents depends entirely on how well and competently it is done. All the power of the elements - rain, wind, and hail - falls, first of all, on the roof, so its design should be very carefully thought out.

Special requirements for roof construction are imposed in regions with high humidity, frequent rain or fog. Exposure to moisture significantly reduces service life wooden structures and roofing pie even despite treatment special compounds and device. However, it is quite possible to minimize the problem of dampness; installing a ventilated roof will help with this.

The design of a ventilated roof has been developed a long time ago, its high efficiency has been proven by many years of practice. The popularity of this technology is due to the following advantages:

The design of a ventilated roof has been developed a long time ago, its high efficiency has been proven by many years of practice. The popularity of this technology is due to the following advantages:

- high degree of protection of all layers of the roofing cake from getting wet;

- no swelling of the roof covering;

- possibility of using organic;

- economical due to the possibility of installation on top of an old roof.

If a ventilated roof is built on top of an old structure, then the latter “comes back to life”: wooden elements become dry again, moisture is removed from the roofing materials. As a result, the roof appears to be double, its resistance to adverse weather conditions increases, and the whole house becomes truly warm and cozy.

The design of a ventilated roof provides for air circulation:

- between layers of insulation and waterproofing;

- between waterproofing and roofing material;

- in the attic space (as part of the general ventilation of the house).

Thus, the entire roof structure is very well ventilated, due to which it is not only possible to get rid of excess moisture, but also maintain optimal temperature conditions. In this case, competent installation of the sheathing plays a decisive role.

Thus, the entire roof structure is very well ventilated, due to which it is not only possible to get rid of excess moisture, but also maintain optimal temperature conditions. In this case, competent installation of the sheathing plays a decisive role.

The ventilated roof design has a number of varieties, which are related to the purpose of the building. For garages or outbuildings, use a non-insulated option, which consists of the following components:

- rafter system;

- lathing made of wooden slats;

- waterproofing;

- roofing covering.

Used as waterproofing plastic film

, which is attached to rafter legs on slats.

For heated buildings Slab insulation and anti-condensation film are added to the roof structure, which protects wooden elements from condensing moisture. In general, the order of layers in such a roof is as follows:

- two layers of laminated film;

- non-woven material with high moisture absorption capacity;

- polypropylene fabric.

An important part of the roof of this type are vents located at the bottom of the eaves, as well as a ventilated ridge.

Project development procedure

During design work When installing a ventilated roof, the following must be provided:

- Proper drainage. The roof structure must be such that water flows freely from its surface. This is especially true for flat roofs, where due to correct installation depressions often form in the coating in which water accumulates.

- Steam removal exclusively through the roof.

Contrary to traditional concepts, the walls of a house with a ventilated roof should not breathe. For this purpose, their design contains a reinforced vapor barrier layer.

Such roofs began to be built in the 80s of the last century. It was during this period that it became possible to install a heat insulator with ventilation ducts to remove excess moisture. Roofs of this type were most widespread during construction apartment buildings. The roof structure consists of the following layers:

Such roofs began to be built in the 80s of the last century. It was during this period that it became possible to install a heat insulator with ventilation ducts to remove excess moisture. Roofs of this type were most widespread during construction apartment buildings. The roof structure consists of the following layers:

- reinforced concrete floor slab, which is also the basis for the roofing pie;

- vapor barrier;

- slab insulator made of mineral wool, inside of which there is the head of the aerator - a ventilation pipe (excess moisture is removed through this pipe);

- screed from cement-sand mortar;

- waterproofing based on bituminous materials;

- polyurethane;

- a layer of polyurethane-based mastic;

- roofing material

The roof structure is complemented side parapets, which are separated from the roofing pie by bulk or sprayed material. In modern construction polyurethane foam plays this role, providing high insulation and sealing. It is also used to insulate the terminals of aerators.

The advantage of a flat roof is its low cost and the ability quick installation. Disadvantages: necessity frequent repairs and poor thermal insulation.

Pitched roofs

The design of this type of roof provides excellent air circulation, which penetrates into the under-roof space through the lower overhangs and exits through the ridge. In this way, it is possible to avoid the accumulation of dampness, which causes rotting or the appearance of fungus on the parts of the rafter system and roofing materials.

The design of this type of roof provides excellent air circulation, which penetrates into the under-roof space through the lower overhangs and exits through the ridge. In this way, it is possible to avoid the accumulation of dampness, which causes rotting or the appearance of fungus on the parts of the rafter system and roofing materials.

In some cases a device is required forced ventilation. For this purpose, roof fans are installed on the roof.

As a covering Mostly lightweight materials with a wavy surface are used. A pitched roof can be either cold or insulated. The difference between these two options is the presence of an insulating layer. Mineral wool boards are usually used as an insulator.. Insulation with this material provides the following advantages:

- ease of installation;

- insulated coating;

- absence of cold “bridges”.

The list of roof installation operations is as follows:

- Preparing the base. At this stage, work is carried out to level the surface, eliminate cracks, chips and potholes. A screed made of cement-sand mortar or asphalting floor slabs is best suited for this purpose. The result should be a smooth surface with a slope of 2-3 degrees.

- Laying vapor barrier film and insulation. These layers must be laid in a continuous mass; cracks or breaks are not allowed.

- Installation of a waterproofing layer and cement-sand screed.

- Laying roofing. For flat roofs, fused rolled materials are used as a covering. During installation, the bitumen included in the coating is melted using a gas burner, after which the coating sheet is firmly glued to the base. The rolls are laid in a direction transverse to the slope with an overlap of 80 - 100 mm. During installation, it is necessary to clearly mark the outlets of the ventilation ducts for their subsequent insulation.

Constant ventilation of the insulated roof structure is a necessary condition for the long-term and reliable service of the entire building. The importance of ventilation can hardly be overestimated - thanks to the convective air flow, excess moisture that has penetrated from the roof is removed from the roof structure. warm room. In addition, the insulation and rafter structure can gradually become saturated with atmospheric moisture in summer period or have residual moisture generated during the construction of the house.

In the absence or insufficient ventilation, all elements of the roof are moistened with condensate, especially dangerous consequences are the wetting of thermal insulation and wooden parts of the roof - rafters, mauerlat, columns and crossbars.

The main negative results of ineffective roof ventilation include the following:

|

|

It is easiest to ensure sufficient ventilation on cold (attic) roofs due to the large air volume and the absence of barriers to air circulation. The necessary air exchange is ensured through openings on the eaves, ridge and ridge of the roof, as well as through the gable grilles. The main problems arise in mansard roofs, and they are decided depending on design diagrams insulated roofs, which can be divided into ventilated (with two or one ventilation gap) and unventilated. Last option relatively recently began to be used in Europe, and there is simply no extensive experience in its use in Russia, so it is premature to dwell on it in detail.

|

Roofs with two ventilation gaps, traditionally used since the middle of the last century in the construction of attics, are well known to Russian roofers. The ventilation principle is as follows (Fig. 2): external moisture that has penetrated under the roof is removed through the upper gap between the roof and the waterproofing. These could be raindrops or snow blown in strong wind, melt water or atmospheric moisture that has fallen on the roof and waterproofing in the form of condensation. Structurally, the upper gap in most cases is provided by a counter-batten 40–60 mm thick, which is mounted on top of the waterproofing and serves as the basis for a continuous flooring (roof made of bitumen tiles or slate) or step lathing of tiles, metal tiles and corrugated sheets. In addition, the counter-lattice reduces the risk of damage to the waterproofing during installation. roofing works. The absence of a counter-lattice between the under-roof waterproofing and the roofing material, or its insufficient height, almost always leads to the formation of condensation and other dangerous consequences for the roof and the entire building. |

Rice. 2. Roof structure with two ventilated gaps |

Through the lower ventilated gap between the waterproofing and insulation, water vapor that has penetrated into the roof from the interior of the attic through the vapor barrier is removed. The reasons for steam transportation may be poor quality of the material or defects in the construction of the insulating layer - for example, the overlaps of the rolls of vapor barrier film are not glued or the junctions of the film to the walls, roof windows, mauerlats and other structural elements are not airtight. A very wide range of materials can be used as under-roof waterproofing for a structure with two ventilated gaps: micro-perforated and anti-condensation films, rolled bitumen materials on a continuous flooring and even some vapor barrier films. If installed correctly, such a scheme will work reliably for a long time, and the cost of waterproofing materials for its installation will be less than for modern structures with diffusion films.

However, the limited advantages of this ventilation scheme are lost against the background of its fundamental disadvantages:

- increased heat loss due to lack of wind protection and unimpeded heat loss from upper layers fiber insulation - the stronger the ventilation, the more energy is lost and, consequently, the homeowner’s heating costs increase;

- the greatest risk of convective transfer of moisture from a warm room to the thermal insulation through any damage to the vapor barrier, since air moving along the lower ventilation gap provokes exfiltration of moisture-saturated air from the attic;

- humidifying the insulation in the summer with moisture contained in the atmospheric air (for example, at a temperature of 28°C and relative humidity 80% of the air can contain up to 24 g/m3 of moisture, which will certainly get into the thermal insulation);

- difficult-to-solve problems of ventilation of insulation on roofs of complex shapes and gentle slopes;

- open gaps in the under-roof waterproofing layer on the ridges and ridges reduce the reliability of the roof from the penetration of external precipitation and force the use of ventilation rolls with dense mesh or tapes made of nonwoven fabric– they protect well from leaks, but significantly impair the ventilation of the roof structure;

- gradual decrease in insulation characteristics due to mechanical entrainment of mineral wool fibers;

|

The fact that in European countries roofs with two ventilated gaps are used less and less (for example, in Germany it is no more than 3% of all new roofs) confirms the desire of investors, architects and roofers to reduce energy losses and improve the reliability of buildings. A design with only one ventilation gap between the roof and the insulation, protected by a diffusion (vapor-permeable) film, is devoid of the above disadvantages. Since the windproof coating, which also performs the function of a waterproofing layer, is laid with an overlap over the ridges and ridges, it is possible to use aeroelements and rolls with relatively large holes– this will allow you to ventilate the roof very effectively without the risk of leakage (Fig. 3). |

Rice. 3. Roof design with one ventilated gap |

Area and cross section ventilation ducts depend on the length of the covering (the length of the slopes), the angle of inclination and complexity of the roof shape, as well as the climatic characteristics of the region. General recommendations contained in reference literature, so I will focus on only some recommendations for the conditions of the European part of Russia:

- practice confirms that the cross-sectional area of the ventilated duct on any section of the roof should be 400–500 cm2/m, which corresponds to a gap height of 4–5 cm;

- a strong increase in the height of the gap will not lead to increased ventilation. On the contrary, this can cause a significant reduction in air exchange under the roof due to the resulting turbulence and increasing resistance to air flow;

- if the length of the coating exceeds 10 m, then it is recommended to use additional elements to enhance ventilation;

- ventilation openings on ridges, ridges, eaves and valleys must be protected from leaves, branches, birds and insects using special ventilation elements offered by roofing system manufacturers;

- any narrowing of ventilation ducts or structural obstacles can lead to poor ventilation and condensation;

- Large air cavities in an insulated roof have significant inertia in terms of air exchange, which can also cause moisture condensation.

- blown through the bottom air gap dust is quite hygroscopic - it accumulates on thermal insulation and can cause it to become moist.

|

Ridge and ridge (rib) |

Rice. 4. Ventilation elements for the ridge |

|

The main mistakes when installing a roof ridge, which can lead to a decrease in ventilation or its complete blocking, are the following:

Separate aerators installed along the ridge cannot always provide good ventilation of the roof, therefore it is recommended to use a fully ventilated ridge on all attic roofs with any roofing material. |

Rice. 5. Installation error: sealing the ridge and ridge

|

|

Eaves overhang Sometimes the space under the roof is occupied by birds to build their nests, which can lead to poor ventilation and damage to the roofing film. But this can only happen because roofers neglect ventilation elements (Fig. 8) that prevent birds from entering, or because they are installed incorrectly. |

Rice. 7. Ventilation options through the eaves overhang lining |

|

Reliable protection air channels on the eaves are a ventilation tape covering the ends of the counter-lattice, as well as an overhang aero element and an overhang grille. A drainage system can provide structural protection from snow - it is recommended to place gutters directly under the roofing material (above the ventilation gap), so even if heavy ice or snowdrift forms, the gap will remain open for air flow. But low-lying gutters without a heating system do not protect the ventilation gap from snow and ice sliding down the slopes. The absence of a snow retention and snow stop system (snow stops evenly distributed over the roof) leads to snow sliding onto the eaves and blocking the access of air to the under-roof space. |

Rice. 8. Installation error: ventilation problem due to birds Rice. 8. Installation error: ventilation problem due to birds |

|

Endova (groove) |

Rice. 11. Continuous ventilation duct along the valley Rice. 11. Continuous ventilation duct along the valley |

|

|

Measures such as drilling holes in the rafters are ineffective. Of course, the roofing material also needs to have aerators/ventilation tiles installed along the valley so that air can penetrate both the top ventilation gap and the bottom (Fig. 12). However, such measures can only be relatively effective on roofs with large slope angles (about 45° and above). Snow will accumulate on the gentle slopes in the valleys, which will cover the ventilation elements and prevent the roof structure from being effectively ventilated. In such cases, forced ventilation may be required using inertial turbines, electric roof fans, or high nozzles that will not be covered with snow (Figure 13). |

|

|

The use of such elements can significantly increase the cost of the roofing kit, as a result of which the choice of the customer or his contractor in favor of cheap micro-perforated films will not be justified from the point of view of both the reliability of the roof and the financial costs at the time of construction and especially subsequent operation. On roofs of complex shapes or with small angles tilt, it is reasonable to use only modern diffusion films with high vapor permeability (Sd< 0,2 - 0,4 м) в схемах с одним вентиляционным зазором. Connection to walls, windows and pipes |

|

|

|

Deterioration in ventilation can also be caused by insulation defects, when local heating of the structure due to increased heat loss leads to the fact that the heat flow interferes with or even suppresses convective draft in the ventilation gap. Such problems occur, as a rule, on flat roofs or with complex geometry (Fig. 14). At the end of the article, I consider it necessary to once again focus the reader’s attention on the fact that the reliability, durability and efficiency of a roof equally depend on all its constituent elements - truss structure, insulation, hydro- and vapor barrier, roofing system and ventilation. Errors in the construction or design of any element can lead to severe damage to the roof and the entire building. |

Rice. 14. Installation error: lack of continuous ventilation of the ridge, no aerators on the valley Rice. 14. Installation error: lack of continuous ventilation of the ridge, no aerators on the valley |

|

Formed on the elements roofing structure condensation can cause premature failure. This problem is especially relevant during the period heating season, with a significant difference between the temperature outside and inside the building. In this case, the insulation experiences a serious load, the range of values can reach tens of degrees, as a result of which drops of moisture settle on it, blocking thermal insulation properties material.

The best way to resolve the issue is to install a house roof with ventilation. IN winter period it will ensure effective thermal insulation, in summer time will reduce discomfort due to heat by preventing the flow of heated air. The costs of arranging the roof will increase slightly, but already in the first years of its operation they are guaranteed to pay off.

Ventilated roof design

The main goal when designing a ventilated roof is the choice of building materials. Others will need to be taken into account important points: number of gaps for air passage, lathing pitch, type of waterproofing film and other nuances. Thus, when using materials with polymers, the ventilation space must be larger than when installing natural roofing.

The main task of a ventilated roof is to ensure air circulation and prevent the formation of condensation. The design contains three circuits that provide movement air flow in the following spaces:

- between waterproofing and roofing;

- directly under the roofing;

- between hydro- and thermal insulation.

By design, there are two main types of ventilated roofing:

- non-insulated, main scope of application – utility and industrial buildings;

- insulated - used at all facilities where people stay for a long time: housing, commercial and administrative buildings, other buildings.

Main elements of a ventilated roof:

- rafter system;

- sheathing;

- waterproofing;

- insulation (not on all objects);

- roofing covering.

Advantages of a ventilated roof

An important feature of such roofs is the presence of vents and special gaps in the ridge through which air circulates. One of the options for ventilating a roofing pie is to use thermal insulation material with channels for air flow. It does not matter whether you are installing a copper roof, with metal tiles or bitumen, you will need to designate the exit areas of the ventilation ducts.

The use of a ventilated roof can significantly improve the thermal insulation properties of the roof with virtually no additional costs. There are many advantages to this design:

- the formation of rot, fungi and other microorganisms is practically excluded;

- the risk of swelling of the roofing cake is minimal;

- increases the coating's resistance to most external factors: precipitation, extremely low or high temperatures, rotting and so on.

Using a ventilated roof is one way to extend the life of the roof covering, avoid the formation of condensation and increase the energy efficiency of the structure. When developing a project, you will need to take into account many nuances, so you will have to take a responsible approach to choosing a company that can be entrusted with such work.

Constant and high-quality air exchange under the roof guarantees a long service life of both the roof itself and the entire building. The comfort of people living in the house also depends on ventilation, since it plays a key role in shaping the microclimate.

Peculiarities

Ventilation soft roof is not an independent process. On the contrary, the presence or absence of ventilation in the premises directly affects the exchange of air in the roof. To effectively remove destructive moisture from residential premises through the roof, it is necessary to analyze the ventilation of all elements of the house as an integral process.

If the roof configuration is complex, has many transitions and valleys, the process of removing exhaust air must be divided into sections and air flows in the roof must be organized separately.

As a result of good ventilation, the air in the space under the roof should change approximately 2 times per hour.

The performance qualities of a ventilated roof depend on the slope of the slopes. The steeper they are, the more intense the ventilation process occurs.

And, on the contrary, in roofs with a slope of less than 20%, ventilation of the under-roof space is unstable and effective only under wind pressure.

A useful addition is the construction of auxiliary exhaust components (aerators) on the roof, which help to enhance the natural ventilation of the roof. They should be installed on roofs of complex configurations, when ordinary means are no longer sufficient.

Aerators are installed near the ridge. In roof coverings made of fused materials, consisting of two layers, aerators are installed on the bottom layer of material.

The thermal characteristics of insulation and the durability of roof structures directly depend on the presence of moisture in them. As a result, a ventilated roof and room ventilation device are economically viable, even when forced air exchange is required.

Advantages and disadvantages

The main purpose of the ventilation system is to ensure the passage of atmospheric air, which facilitates the extraction of heated air from under the roof covering. The exhaust air provides ventilation to the attic.

If under-roof ventilation is done correctly, then such air flow occurs naturally and there is no need to use additional mechanical equipment.

Aerators are produced various diameters and heights. Their size and quantity are selected depending on the area of the roof made of flexible tiles.

Having a ventilated space under the roof has the following advantages:

- stable cool and dry condition of the attic;

- outside air from attic space able to leave naturally;

- load-bearing roof components, coverings and thermal insulation layers are not exposed to high humidity;

- absence of conditions for the formation of mold and rot, prevention of damage to roofing finishing materials;

- reduction in electrical energy costs.

Experts have found that when using soft coverings the main disadvantage is the accumulation of excess moisture in the screed and thermal insulation.

Increased humidity of these roof layers provokes a number of negative consequences, such as:

- Bloating roof covering resulting from its heating in summer due to the delamination of bitumen-polymer materials under the influence of high temperature.

- Increased thermal conductivity causes accumulated under waterproofing material moisture, which impairs thermal properties. It has been theoretically proven that with an increase in moisture content by 1-2%, the heat-conducting properties of the material increase by 30-40%. This leads to increased costs for heating the facility. Along with heat loss, oversaturation of roof layers with moisture can lead to the formation of mold.

- Destruction of the waterproofing layer and screeds are caused by the penetration of moisture into the material. After the temperature of the surrounding atmosphere decreases, the moisture absorbed into the material crystallizes and its volume increases. This process entails the appearance of microcracks and destruction of the screed. Similar negative processes occur in the waterproofing layer, destroying its integrity.

Varieties

Roof aerators come in various designs and sizes. They are used to ventilate the space under the roof, eliminate condensation and remove moist air outside. Before purchasing an aerator, you need to understand the features of their design and types.

Spot

These aerators are otherwise called roof point valves. They are mounted on roofs that do not have a ridge - hipped and flat. Myself roof aerator made of high-strength plastic, resistant to mechanical stress and impact sun rays(burnout).

It has 4 parts in its structure: a flask, a protective umbrella for it, a tube and a filter mesh.

According to the configuration of the flask, they are divided into flat and bottle. Bottle roofs are installed on single-pitched and hip roof types, and flat roofs are installed on flat roofs. Such aerators function productively if they are placed evenly throughout the roof. As a rule, one deflector is needed per 20 m2 of roof, but, if possible, it is better to install two.

Skate continuous

According to the name, they are installed on pitched roofs, equipped with a skate. They are a permanent exit located at the very top of the slope. The ridge aerator is implemented in the form of a square equipped with through holes, which are called vents.

Ventilations can be point vents (made at a distance of 6-8 m from each other) and slot vents (5 cm gap). There is a protective mesh to prevent insects from entering the roof. Such a device is mounted along the entire ridge and attached to the roofing material. Its individual components form an integral system. The aerator perfectly retains moisture and allows air to pass out, preventing it from stagnating in the attic.

How to choose?

On soft roofs, various deflectors are used, the choice of which depends on the type of roof.

When choosing an aerator, preference should be given to products that have certificates from a trusted manufacturer.

At the time of buying Special attention It is required to pay attention to the completeness of the set and the absence of mechanical damage (scratches, chips, cracks and deformation).

When choosing aerators for a soft roof, you need to take into account the complexity of its structure, the climate and the level of moisture saturation in the attic. As a rule, one point aerator must be installed per 100-150 m2.

When installing a ridge aerator, a different approach is used. A ventilation slot is constructed along the entire length of the joint, and air enters from under the overhangs, where a specialized aero element (perforated tape) is placed on the slot.

All types of aerators come with a range of technical specifications which they must comply with:

- withstand temperatures from -50? C to +100? C;

- resistance to chemicals, which may be contained in sediments;

- corrosion resistance.

How to install?

Each type of aerator has a specific installation procedure.

Point devices are mounted on roofs flat type and roofs with a slope of less than 12 degrees. They can also be used as a complement to ridge aerators.

Let's take a closer look at the technology for installing point aerators:

- We determine the location of the aerators. Place the base of the aerator on the installation site and trace the outline with a pencil. According to the applied mark using electric jigsaw make holes.

- We install the skirt (base) of the aerator over the finished hole and fix it with self-tapping screws or nails. For a stronger fixation, you can additionally use glue. In this case, apply to the inner segment of the skirt bitumen mastic, glue it to the base and secure it with nails.

- Coat the top of the skirt with bitumen glue.

- We overlap the skirt soft tiles, trimming the shingles where they touch.

- We put the aerator mesh on top of the skirt and screw it with self-tapping screws. Then we install the cap (lid), snap it in place and also screw it in with self-tapping screws.

We install the remaining point aerators in the same order.

Installation of a ridge aerator is quite simple; it is installed along the entire length of a pitched ridge and its variety - a hip roof, the slope of which ranges from 12 to 45 degrees. There are two methods for installing a ventilated soft roof ridge.

Installation technology:

- We cut a ventilation groove in the solid base using a circular saw. It can be single (at the highest point of the ridge) or consist of two parts (on the sides of the ridge). The total thickness of the ventilation gap should be 3-8 cm (depending on the instructions of the manufacturer of the aerator used). The ventilation groove should end 30 cm before the edge of the ridge on both sides, that is, the covering remains continuous.

- Areas where the ventilation gap has not been cut are covered with ridge tiles.

- We install the aerator. Each section is fixed using special roofing nails or screws screwed through the existing factory holes.

- We lay ridge tiles on top of the aerator profile. We lay its petals overlapping, using standard installation technology along the ribs. The only difference is the fastening elements. In this case, we nail the tiles to the aerator with special roofing nails.

- We seal the joints between the aerator and the roof with silicone-based sealant. It is necessary to ensure that a depression does not form around the device for ventilation of the under-roof space. These depressions will retain water and snow, which over time will certainly find a place to seep under the roof.

The second method involves fixing wooden blocks at the highest point of the roof slopes. It turns out to be a kind of lathing for the ridge strip. We nail plywood strips to the top of the bars, forming a triangle. We form ventilation gaps between the bars, and cover the entire structure, as in the previous case, with shingles.

If the height difference on the roof is quite large and the total height of the structure is at least 7 meters, then instead of aerators you can install small box valves together with ridge ventilation.

Houses with hip or hip roof architecture do not have gables. But this is not a problem for the ventilation device. It is based on the same principles as gable roofs, but at the same time we must not forget that it is necessary to construct inlet gaps to ensure the passage of air along the entire perimeter of the roof. How many stingrays hip roof would not have, each of them should be ventilated.

A half-hip roof gives a great desire to forget about the ventilation of the space under the roof, since its inclined end elements have relatively small dimensions. Ventilation system here it can be built according to the principle of ventilation on the main slopes of the roof.

It is a little more difficult to calculate the ventilation of the end slopes of a Dutch (hip) roof, since there is a window directly above them. This is an obstacle to the use of pipes, but, nevertheless, an aerator or grilles can be installed there.

In all the described cases, if the roof lining is made of wood, then it should not be monolithic, since air must pass through its gaps into the space under the roof. But in parallel with the above installation rules, it is also necessary to make the correct calculation so that normal draft is formed under the roof. Otherwise, all this will not function.

Regardless of the method of installation, ventilation must guarantee:

- passage of air vapor;

- protection of the space under the roof from precipitation and melting snow;

- No moisture should pass through the ridge structure;

- ensuring the evaporation of excess liquid from the room.

When installing ventilation of the under-roof space with your own hands, you must take into account a number of important points.

- If you intend to get a stronger effect from the movement of air currents, then it is necessary to use steam and water barriers located under the sheathing. They are specialized meshes that easily allow air to pass through, but prevent the passage of moisture and steam.

- To ensure ventilation under an ordinary roof pitched roof a small number of vents placed in the lower and upper parts in equal numbers will suffice. If necessary, you can supplement the ventilation system with a fan for forced exhaust.

- If you install the fan in a structure that is located in an area with higher than normal humidity, then the fan must be equipped with a higher electric motor power. Fans must be installed parallel to the roof structure. Inserting a device into a finished roof is more difficult and will cost significantly more.

- The combination works great on the roof– full ridge ventilation and auxiliary elements to enhance air flow. If, for example, in winter one of them is damaged, the rest will remain in working order. The under-roof space will be one hundred percent protected from condensation accumulation.

- Also It is necessary to pay attention to the total component of all precipitation falling during the year. In areas with heavy snowfall, it is necessary to raise the air ducts higher high level, otherwise snow drifts will block low-mounted aerators.

- And the last thing - the desire to save money when installing roof ventilation can end badly, being a source of problems with both the roof covering and structural elements. Proper organization effective air exchange is a guarantee that the roof will last for decades without the need for repairs, providing thorough protection for the entire structure and comfortable living conditions.

It is not so difficult to arrange ventilation under the roof with your own hands for any type of roof, and it has positive effects similar design a considerable amount.

Rice. 13. Forced ventilation elements for flat roofs

Rice. 13. Forced ventilation elements for flat roofs