Options for insulating the foundation of private houses review. Do-it-yourself insulation of the foundation with penoplex. Insulation of various types of foundations

The use of insulation when arranging the foundation is a common way to improve the thermal insulation performance of a building and protect the foundation from negative influence subzero air temperatures. Among other insulation materials, extruded polystyrene foam has gained great popularity. Unlike conventional polystyrene foam, the material has an increased safety margin; in addition, the special shape of the boards allows the installation process to be significantly simplified.

Let's figure out how to insulate the foundation of a house with penoplex from the outside with your own hands. The procedure is very similar to thermal insulation of walls. Special heat-insulating slabs are fixed to the side parts of the foundation, which are located above and below the soil surface. The use of insulation allows you to reduce the rate of heat exchange between the foundation walls and soil layers.

Why insulate the foundation

Some owners of private houses refuse to insulate the basement, trying to save as much as possible Money. At the same time, experts in the field of construction work insist that thermal insulation of this part of the house is simply necessary, and it is better to attach the insulation to the outside of the structure.

General scheme of foundation insulation with penoplex

The following arguments are put forward in favor of insulation:

- After insulation, the foundation becomes protected from negative impact subzero air temperatures. This factor is especially important in places with high humidity. If, when the temperature drops, moisture gets into concrete cracks, it begins to rapidly expand and ultimately tears and damages the concrete structure;

- The degree of protection of the foundation from temperature fluctuations increases. The concrete structure experiences much fewer cycles of compression and expansion, resulting in a building lifespan without overhaul the foundation increases significantly;

- The insulation becomes an additional barrier to groundwater that tends to penetrate to the foundation.

What is the best way to insulate the foundation: from the inside or the outside?

The foundation can be insulated from the inside or outside. Both methods have their advantages and disadvantages.

Internal thermal insulation

To the benefits internal insulation include:

- Improving the microclimate in the basement;

- Effective control of indoor dampness;

- Protecting the basement from groundwater penetration.

The disadvantages of internal insulation include:

- Such thermal insulation does not protect the foundation from soil freezing;

- Moisture easily enters pores concrete base and destroys it;

- The dew point shifts inward.

Insulation from the outside

This insulation method has the following advantages:

- The foundation is reliably protected from freezing;

- The dew point shifts towards the street;

- The concrete base is protected from any negative influence from the environment;

- Significantly increases total term operation of the premises;

- Some insulation materials can provide additional strengthening of the foundation;

- When installing a thermal blind area, you can protect not only the foundation from freezing, but also the soil within a radius of about half a meter from the installed insulation.

For external insulation you will need large quantity time and materials, and this is the only drawback of this method.

It is very important to understand that external insulation of the foundation provides a reliable guarantee of protection for the entire house, and thermal insulation from the inside will only protect the basement from the cold

It is very important to understand that external insulation of the foundation provides a reliable guarantee of protection for the entire house, and thermal insulation from the inside will only protect the basement from the cold

Having assessed all the advantages and disadvantages of external and internal methods, we can conclude that it is better to give preference to external insulation.

In order for the insulation to fully cope with the tasks assigned to it, it is worth remembering that thermal insulation foundation work should only be done after all the walls have been insulated. Be sure to treat all joints between the insulation with polyurethane foam - this will increase the efficiency of the thermal insulation of the room.

By the way, preference is given to insulating the foundation from the inside only if for some reason it is impossible to install insulation from the outside.

What is the best way to insulate?

When planning work on installing thermal insulation for the foundation, the issue of choosing and purchasing suitable insulation is initially resolved. The material for foundation insulation should have the following characteristics:

- Be resistant to deformation against the background of constant pressure from the soil;

- Do not absorb moisture from the soil.

On modern market insulation materials are presented in a wide range, and a beginner in the construction industry may get confused in the abundance of offers. It is worth saying that the common insulation “mineral wool” is not suitable for thermal insulation of the foundation. Not only is it not durable, but it also absorbs moisture well, as a result of which all its positive performance characteristics are negated.

Despite fire resistance and low thermal conductivity, mineral wool has a significant drawback - high hygroscopicity

Despite fire resistance and low thermal conductivity, mineral wool has a significant drawback - high hygroscopicity

At modern construction For private houses, two materials are best suited for foundation insulation:

- Polyurethane foam.

Polyurethane foam - modern insulation material, which guarantees thermal, sound and water protection of the concrete structure. The material is sprayed onto the surface using special equipment in several layers. This application technology eliminates the appearance of gaps and seams. The advantages of the material include:

- Possibility to apply thermal insulation coating without seams or gaps;

- Excellent adhesion characteristics;

- Low thermal permeability;

- Steam protection;

- Increased reliability;

- Long service life;

- There is no need to purchase additional material for steam and water protection foundation.

Chief and pretty significant drawback– special equipment is required to lay the material, as a result the process becomes impossible to implement at home. In addition, polyurethane foam has a high cost.

Penoplex, in turn, does not require special skills or special equipment for installation. Among other things, it has the following advantages:

- The cellular structure does not allow moisture to pass inside, as a result of which the slabs do not collapse over time after freezing;

- Increased strength characteristics;

- Ensuring a long service life of the foundation;

- Low cost;

- Long service life of the material;

- Preservation of thermal insulation characteristics throughout the entire service life;

- Rodents do not use the material as food, unlike regular foam.

Penoplex insulation reduces heat loss by 20% and helps the foundation last longer

Penoplex insulation reduces heat loss by 20% and helps the foundation last longer

Penoplex is an improved version of polystyrene foam. The material allows moisture to pass through very easily, and after several cycles of defrosting and freezing it will simply crumble into segments. Let us add that several years ago on construction market Expanded clay was also in demand as insulation for the foundation. The material is inferior to penoplex due to high cost, as well as reduced efficiency in providing thermal insulation.

Calculation of insulation thickness

Except the right choice insulation, it is necessary to pay attention to calculating its optimal thickness. If the penoplex is of insufficient thickness, this may result in freezing of the foundation and transfer of the dew point inward basement, which will ultimately lead to condensation on the walls and an increase in humidity levels.

You should not take too thick a material: this will not increase the degree of thermal insulation, but the costs will significantly hit the family budget.

Correct calculation of the thickness of the insulation material is the key to warmth in the house, absence of humidity and minimal financial costs.

Thermal resistance is denoted by the Latin letter R. This value is constant, but for each region the value is different and depends on general climatic conditions. For example, for the Moscow region it is equal to 3.28 m 2 K/W. For other regions of Russia, the value can be taken from the table:

| Region | Thermal resistance, m 2 K/W |

| Moscow | 3,28 |

| Krasnodar | 2,44 |

| Sochi | 1,79 |

| Rostov-on-Don | 2,75 |

| Saint Petersburg | 3,23 |

| Krasnoyarsk | 4,84 |

| Voronezh | 3,12 |

| Irkutsk | 4,05 |

| Yakutsk | 5,28 |

| Volgograd | 2,91 |

| Astrakhan | 2,76 |

| Ekaterinburg | 3,65 |

| Nizhny Novgorod | 3,36 |

| Vladivostok | 3,25 |

| Magadan | 4,33 |

| Chelyabinsk | 3,64 |

| Tver | 3,31 |

| Novosibirsk | 3,93 |

| Samara | 3,33 |

| Permian | 3,64 |

| Ufa | 3,48 |

| Kazan | 3,45 |

| Omsk | 3,82 |

Thermal resistance is calculated using the formula:

R = h 1 /λ 1 +h 2 /λ 2

where h 1 is the thickness of the foundation (in meters), λ 1 is the thermal conductivity coefficient of the foundation (for a reinforced concrete foundation λ 1 = 1.69 W/m ° K); h 2 – thickness of the insulation material (in meters); λ 2 – thermal conductivity coefficient of insulation (for penoplex λ 2 =0.032 W/m ° K).

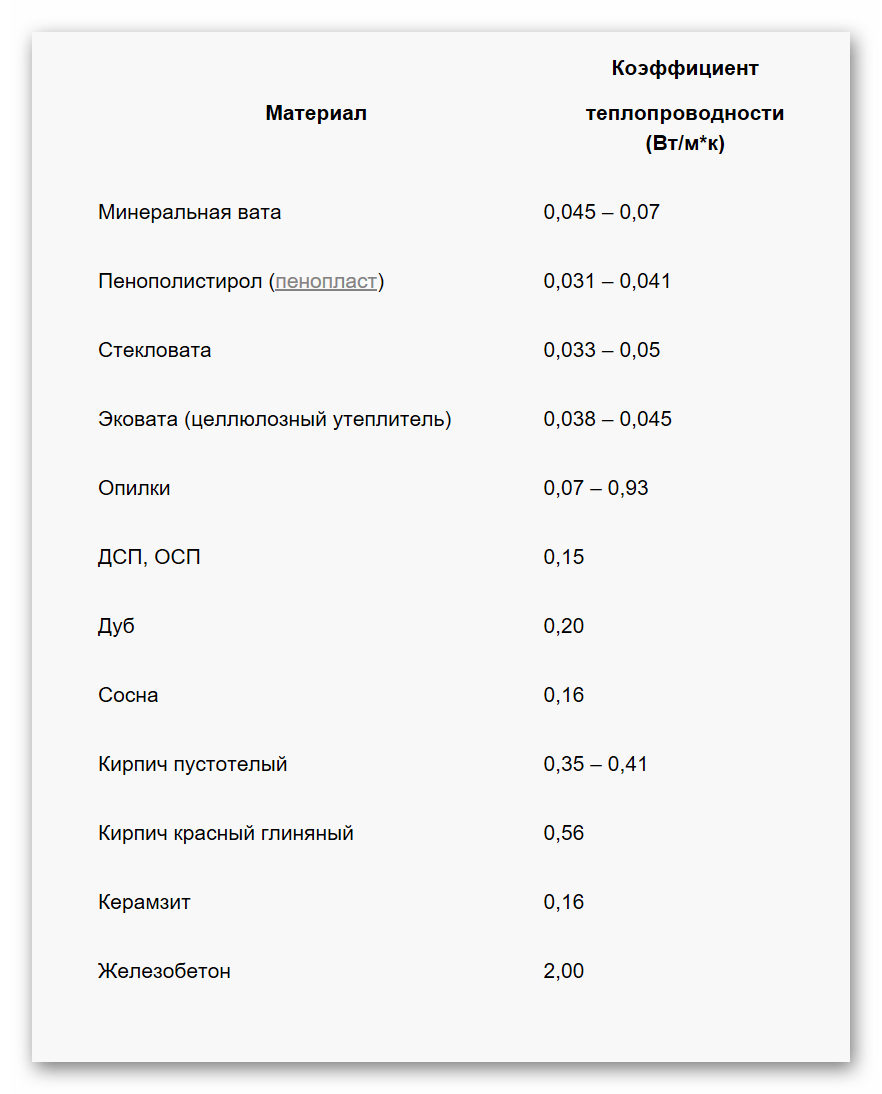

Thermal conductivity coefficient of various materials

Thermal conductivity coefficient of various materials

Therefore, the thickness of the insulation is calculated using the formula:

h 2 = λ 2 (R-h 1 /λ 1)

Let's look at an example of calculating thickness thermal insulation material for a private house in St. Petersburg with a reinforced concrete foundation half a meter thick (h 1 = 0.5 m):

h 2 = 0.032(3.23-0.5/1.69) = 0.094 m, that is, 94 mm.

The value must be rounded up to the nearest centimeter. Thus, the thickness of penoplex for insulating a half-meter reinforced concrete foundation of a house in the Leningrad region is 10 cm.

Insulation technology

Following the sequence of penoplex insulation will allow even novice builders to cope with the process.

It is advisable to carry out work on insulating the foundation at the stage of construction of the future house. This makes the process much easier. But what to do if the house was built several years ago and was not initially insulated?

In this state of affairs, the foundation is excavated to the ground. Ideally, dig to the depth of the soil, but if working resources are limited and it is not possible to cope with such a volume of work, it is worth digging a trench near the foundation for the length of the insulation used.

The thickness of the trench is determined by adding the thickness of the insulation sheet used, as well as the minimum space required to complete the work. Making a trench too wide will be inconvenient, especially if you do not plan to involve specialized construction equipment in the process. A trench that is too small will complicate the work process.

If you decide to use special equipment When carrying out excavations, it is recommended to be careful not to damage the foundation walls

If you decide to use special equipment When carrying out excavations, it is recommended to be careful not to damage the foundation walls

The bottom of the dug trench must be filled with sand, the layer of which should not be less than 20 centimeters. Be sure to compact the sand thoroughly and make a slight slope in the direction opposite to the foundation. Sand will act as additional protection against moisture.

After the foundation has completely dried, it is necessary to begin preparing the future surface for laying sheets. We carefully clean the foundation wall and plinth from adhering soil, damaged pieces of concrete and other contaminants. It is most convenient to clean with a brush with stiff synthetic bristles.

After cleaning, it is necessary to level the surface: only a flat concrete wall will ensure a reliable fit of the waterproofing coating.

Leveling the foundation walls is carried out according to the following principle:

- On a surface concrete walls We install beacons, the distance between which must be at least 1 meter from each other. Beacons must be mounted on the entire surface where insulation will be installed in the future;

- Prepare the solution. To do this, thoroughly mix 4 parts sand and 1 part cement in a container, after which we begin adding water. Make sure that the consistency is not too liquid or dry, otherwise the leveled surface will not be reliable;

- Pour the mixture onto the surface from bottom to top;

- We apply a rule to the beacons and with a sharp movement from top to bottom we level the surface, while removing excess solution;

- After the first layer of the mixture has dried a little, you can apply the finishing layer, which will finally level the surface.

To level the walls, it is recommended to use a rule about two meters long, since working with a float takes too much time

To level the walls, it is recommended to use a rule about two meters long, since working with a float takes too much time

This method is suitable for more or less smooth walls. If differences of more than 2.5 centimeters are observed on the surface, a reinforced mesh is additionally used.

You should proceed to the next stage of work only after the cement mixture has completely dried. On average, the process takes from 7 to 20 days. If a recently poured foundation is being insulated, insulation begins no earlier than a month after installation.

It is better to isolate the foundation from moisture penetration in two layers with the application of bitumen mastic and waterproofing Technonikol.

It is recommended to buy ready-made bitumen mastic - it’s easier than preparing the solution yourself. If you decide to do it manually, then be sure to add waste to the mixture. machine oil, which will protect the mastic from cracking when the air temperature drops.

It is most convenient to apply mastic using a roller. The layer thickness must be at least 2 mm. After the bitumen has dried, we proceed to installing Technonikol. The sheets are glued from top to bottom. The back side is melted using a burner, and the joints between the sheets are covered with mastic. The material fills all small pores and cracks and prevents moisture from causing Technonikol sheets to peel off.

To avoid cracking of the mastic under the influence of temperatures, it is recommended to add used machine oil to the solution at the rate of 5 liters of oil per 12 - 15 kg of bitumen

To avoid cracking of the mastic under the influence of temperatures, it is recommended to add used machine oil to the solution at the rate of 5 liters of oil per 12 - 15 kg of bitumen

Installation of penoplex

It is most convenient to install penoplex sheets using an adhesive solution or foam glue. Additionally, you can use dowels in the form of umbrellas, but they violate the integrity of the insulation sheet.

Apply glue to the sheet using a notched trowel, then the insulation will lie smoothly, without gaps between the sheet and the foundation wall.

Experts advise giving preference to foam glue in cylinders. It not only simplifies and speeds up the process, but is also used more economically.

After pressing against the wall, the adhesive should cover at least 40% of the foam board

After pressing against the wall, the adhesive should cover at least 40% of the foam board

If the sheets are laid in two levels, then a checkerboard order must be observed. In this case, the distance and gaps between the insulation sheets should be minimal. The gaps can be additionally treated with foam.

Reinforced mesh and finishing

To enhance the overall strength of the structure and protect the insulation from external sources, it is recommended to use reinforced mesh. The material is used only if the foundation is above the ground and can be damaged in the future.

The mesh is laid on foam sheets, and an adhesive solution is placed on top for fixation.

At the next stage we begin finishing foundation. You can get by with regular plaster, use siding or any other material for exterior finishing.

If desired, the resulting trench can be filled with sand or expanded clay, and the materials will act as an additional layer of insulation.

Backfilling of the trench is not carried out completely, but space is left for the formation of a warm blind area. The work is carried out in several stages:

- At a depth of about 30 cm from the surface of the earth, pour a layer of sand 10 cm thick and compact it thoroughly;

- We spread waterproofing material at the foundation (ordinary roofing material will do, the joints between which are lubricated bitumen mastic). The boundaries should be adjacent to the foundation on one side and extend from it to a width of about a meter;

- We lay foam sheets on the waterproofing layer, and treat all joints with glue or foam;

- Next, a blind area is constructed from concrete mixture. It must be done at an angle from the foundation, which allows for further drainage of wastewater.

The foundation is the foundation of your home, so don’t skimp and do the insulation well

The foundation is the foundation of your home, so don’t skimp and do the insulation well

Only maximum compliance with all the rules for laying insulation on the foundation will protect the foundation of the house from freezing and subsequent premature destruction. Savings on foundation insulation may result in more serious financial costs in the future.

57702 0

Thermal insulation of the foundation is no less important than the thermal insulation of the walls, especially in areas with a harsh climate. Frozen soil cannot protect the foundation of a house from moisture and cold, and the foundation itself, after repeated freezing, begins to collapse faster. To get rid of these problems and reduce the cost of heating your home, you need to know how to insulate the foundation of a house from the outside, and how you can do it yourself.

The foundation of a house is regularly exposed to moisture, increased load, and temperature changes. After the onset of frost, the accumulated moisture freezes, destroying the material, and through cracks in the concrete the cold penetrates into the home. As a result, the house always has cold floors, dampness emanates from under the baseboards, and condensation or frost appears on the basement walls (in severe frosts). For thermal insulation to be effective, the insulation must have the following characteristics:

- low thermal conductivity;

- waterproof;

- good mechanical strength;

- resistance to temperature changes.

There are no strict requirements for the vapor permeability of the material, but insulation materials with low vapor permeability are usually used, just like the concrete foundation itself. The flammability of the material is not of great importance, because the underground part of the building is least susceptible to fire risks.

Which insulation to choose

Mineral wool insulation for foundations is not the best suitable option: They tend to accumulate moisture while losing thermal insulation properties, and are not sufficiently resistant to mechanical loads. Soil pressure will lead to shrinkage of the material, and the effectiveness of insulation will decrease to zero.

Prices for mineral wool

But polymer insulation are free from such shortcomings and fully meet the necessary requirements.

Let's take a closer look at their characteristics.

Expanded polystyrene

Expanded polystyrene, or polystyrene foam, is very widely used in thermal insulation. It is lightweight, its sheets have correct form, and therefore coping with the installation is not a problem even for a novice master. The material is produced various densities and thickness, and depending on this has certain areas of application. Only the densest sheets with a thickness of at least 50 mm are suitable for foundations; the rest are best used for insulating walls and partitions.

In terms of thermal conductivity, foam plastic is much more effective than wood, expanded clay, mineral wool insulation. It almost does not absorb water, is not prone to shrinkage and deformation, and serves as an excellent sound insulator. In addition, polystyrene foam boards fully retain their properties when exposed to salt and chlorinated water, soap solutions, and weak acids. The insulation can come into contact with bitumen mastics, lime, water-soluble adhesive solutions and cement plaster.

For slab foundations, as well as heavily buried foundations, it is necessary to use polystyrene foam marked PSB-S-50, which is able to withstand heavy mechanical loads and provide reliable protection from swelling of the soil. For columnar and standard strip foundations, PSB-S-35 grade foam is used.

All other varieties are not suitable for foundations due to the low density and fragility of the sheets.

Expanded polystyrene made by extrusion is significantly superior to polystyrene foam in all respects. It is many times stronger, absolutely moisture-proof, and has the lowest vapor permeability and thermal conductivity. Microorganisms also do not develop in it, even under conditions of prolonged exposure to dampness.

Foundation insulation with extruded polystyrene foam - EPS

EPS boards with a smaller thickness have a much greater effect. For thermal insulation of the foundation in a temperate climate, an insulation thickness of 40 mm is sufficient, in northern conditions– about 60 mm (two-layer laying of slabs with a thickness of 30 mm is recommended). For ease of installation and greater packing density, the slabs are equipped with tongue-and-groove joints.

They are attached to the base using an adhesive solution and disc-shaped dowels.

Laying of EPS slabs can be done vertically (when insulating columnar and strip foundations) and horizontally (when installing a slab foundation).

Due to its increased strength, the material perfectly tolerates the load from the concrete layer, does not flatten or shrink, unlike polystyrene foam and polyurethane foam. The most popular brands of extruded polystyrene foam are Penoplex and TechnoNIKOL.

Main characteristics

Sprayed thermal insulation, or PPU, is increasingly used to insulate foundations. Polyurethane foam forms a very durable seamless coating that is resistant to adverse influences. At the same time, it simultaneously performs the functions of vapor and waterproofing, which greatly simplifies the work process. One more useful property this insulation is high adhesion to the base. It adheres equally firmly to stone, concrete, brickwork, wooden structures, easy to apply hard to reach areas, fills the slightest cracks.

Polyurethane foam is applied in two ways - pouring and spraying. The first option is more labor-intensive and expensive, so it is rarely used when insulating private houses. The second method is actively used to insulate the entire building - from the roof to the foundation. Before application, the components are mixed in a foam generating unit with air and the finished mass is sprayed onto the surface under pressure. work surface. Within a few seconds, the composition hardens, and upon completion of the work, you can immediately begin finishing. The only disadvantage of such insulation is that it is impossible to do without installation, and this is an additional cost.

In addition to the described insulation materials, bulk materials, in particular expanded clay, can be used for foundations. It is environmentally friendly, inexpensive, has good thermal insulation characteristics, and is suitable for both vertical and horizontal insulation. But since expanded clay can absorb moisture, losing some of its properties, and the work process requires more effort and time, this insulation It is used less and less, giving way to more modern and effective materials.

Prices for expanded polystyrene

Expanded polystyrene

Foundation thermal insulation technology

Insulation of pile, column and strip foundations can be carried out both during the construction process and during the operation of the house. Before installing the insulation, the base must be prepared, which includes cleaning, sealing cracks, and installing waterproofing. How better preparation, the more effective and durable the result. Slab foundations are insulated directly during construction, because thermal insulation boards are located horizontally under a layer of reinforced concrete.

Strip foundation

The most labor-intensive stage in insulating such a foundation is excavation. The foundation must be excavated to its base or to the level of soil freezing. If possible, it is better to hire special equipment, because digging by hand will take a lot of time and require a lot of physical effort. The foundation is dug around the entire perimeter to a width of at least 1 m, then the bottom of the trench is compacted and covered with a layer of sand and crushed stone.

The foundation walls are cleaned of soil with a stiff brush and left open for 10 days to allow the moisture to evaporate. For this reason, work should be performed in warm and dry time of the year.

Step 1. The dried walls are carefully inspected for damage, and any identified defects are eliminated. Before sealing, cracks are opened and cleaned of dust, and the surface is leveled if necessary. cement-sand plaster. If unevenness exceeds 20 mm, the plaster is additionally reinforced metal mesh. After plastering you must wait completely dry surfaces.

Step 2. Waterproof the foundation. Most convenient to use coating waterproofing, for example, polymer, rubber or bitumen water-soluble mastics. Compositions containing organic solvents cannot be used, since polystyrene foam boards are destroyed upon contact with them.

To improve adhesion, the surface is pre-treated with a bitumen primer, applying it in a thin continuous layer. It takes about a day for the primer to dry, after which you can begin applying mastic.

Step 3. Stir the mastic; if the mass is too thick, add a little water.

Prices for bitumen mastic

For application use a wide brush with dense bristles or a roller. The composition is evenly distributed over the walls in a continuous layer, very carefully coating the corners. The layer should not be transparent, but it should not be made too thick, so that streaks do not form. The mixture is rubbed well over the surface, filling the smallest pores of the depression. When the first layer has hardened, apply the second in the same way. Usually two layers are enough, but if the area is often flooded with groundwater, it is recommended to apply 3 layers of mastic.

Step 4. After the waterproofing has dried (after 5-7 days), you can begin installing foam plastic or EPS. To attach the plates, a special adhesive composition is used, for example, ALLFIX, Ceresit CT 83, Titan.

Installation of insulation is carried out from the bottom up, in horizontal rows, with mandatory bandaging of the vertical seams. Apply glue, press the slab to the surface and check its position with a level. When installing the next slab, it is necessary to align the mounting grooves as tightly as possible so that the joints are barely noticeable.

Advice. When laying thermal insulation slabs in two layers, the joints of the lower layer must be completely covered by the slabs of the upper layer. Combining joints will lead to the formation of cold bridges, which means that the effect of insulation will be lower than planned.

Step 5. As a rule, the underground part of the insulation does not need additional fixation, because after backfilling the material is tightly pressed with soil. But in the above-ground part of the slab it is recommended to strengthen it with dowel nails with wide heads. Fastening is carried out after the adhesive solution has completely dried. To do this, through holes are drilled in the slabs (in the center of the slab and in the corners) and buried 40-50 mm into the base. Next, insert the dowels and hammer them in until they stop.

Step 6. To protect the surface of the slabs from accidental damage, plastering is performed with a fiberglass reinforcing mesh. Apply the adhesive solution to the insulation, spread it in an even layer 40-50 mm thick, lay a mesh on top and forcefully smooth it with a spatula, deepening it into the solution. For convenience, it is recommended to cut the mesh into pieces and overlap them by 10 cm.

Step 7 After a day, a final leveling is carried out, and when this layer dries, the surface is treated with a grater and emery cloth.

Step 8 Fill the trench with soil, leaving a distance of about 30 cm to the top. The soil is compacted well to reduce shrinkage. A layer of sand 10-15 cm thick is poured on top, which is also carefully compacted, and then a waterproofing membrane and a layer of insulation are laid at a slight slope from the wall. The final stage is the arrangement of the blind area by pouring a concrete screed.

If it is decided to insulate the foundation with polyurethane foam, there is no need for leveling and waterproofing. After digging a trench and clearing the base of the earth, it is only necessary to eliminate cracks and also remove peelings, if any. When the foundation walls are dry from moisture, you can begin applying polyurethane foam. The spraying machine can be rented from construction company or buy, but if you do not have the skills to work with such equipment, it is better to turn to specialists. After the material has hardened, the trench is filled with soil, and a blind area is made on top, as described above.

Columnar foundation

Thermal insulation of columnar and pile foundations It's done a little differently. To thermally insulate the space between the grillage and the ground, it is necessary to build a fence that acts as a plinth. This design does not bear load, therefore the mechanical strength of materials special requirements No.

Step 1. A narrow trench up to half a meter deep is dug between the foundation pillars, and a third of it is covered with a layer of sand and small crushed stone.

Step 2. A frame of metal rods is laid on top and a layer of concrete mortar is poured.

Step 3. After the concrete has hardened, the space is bricked around the entire perimeter, leaving small vents in the opposite walls for ventilation.

Step 4. When the masonry is dry, insulation boards are glued to the outside and then plastered using reinforcing mesh. After the plaster has dried, the trench is filled with soil and compacted.

Finally it executes decorative finishing base - this can be painting, applying decorative plaster, facing with artificial stone.

Instead of a brick fence, you can install a frame made of timber or a metal profile between the foundation supports. Before installation, the timber must be treated with antiseptic impregnation and dried well. The beams are fastened using metal corners, bolts 65-80 mm long and self-tapping screws, for assembly metal frame It is preferable to use welding. After installation, the frame is sheathed with EPS or foam plastic boards, and corrugated sheets or plinth panels are attached on top.

Slab foundation

With horizontal insulation, the slabs can also be laid in one or two layers. Most often, insulation with a thickness of 50 or 100 mm is chosen for slab foundations. Thermal insulation begins after the foundation pit has been prepared and the sand cushion has been backfilled.

Step 1. The sand layer is thoroughly compacted over the entire area and leveled horizontally. The smoother the base, the denser the insulation will lie.

Step 2. Film and heat-insulating boards are laid on the sand cushion, joining the mounting grooves. In each subsequent row, the joints are shifted by the width of half the sheet.

Advice. When laying insulation in two layers, the lower slabs are placed in rows along the long side of the foundation, and the upper slabs are placed in rows along the short side. This will not only eliminate cold bridges, but will also further strengthen the strength of the thermal insulation layer.

Step 3. Along the perimeter of the foundation, close to the slabs, formwork is installed, inside which a reinforcing frame made of steel rods is mounted. Concrete is mixed and poured.

Step 4. After the concrete has hardened, a blind area is made. Carefully level and compact the sand with a slight slope from the foundation. Lay the slabs tightly and cover them on top waterproofing membrane. The membrane sheets are overlapped by 10-15 cm. Next, they are backfilled with sand, again everything is leveled and compacted.

Prices for thermal insulation materials

Thermal insulation materials

Video - How to insulate the foundation of a house from the outside

Video - Insulating the foundation with polyurethane foam

Video - Insulating a slab foundation

Many novice builders, from among those who are lucky enough to become the owner of their own suburban area, and who wants to carry out most of the work on their own, at first they allow a lot serious mistakes. And one of the quite common ones is ignoring the issues of reliable and insulated foundations.

The resulting “picture” is interesting - about external design As a rule, everyone remembers the basement part of the wall. Without in any way belittling the importance of neat finishing, we agree that it will not subsequently determine the level of comfort of living in the house and the durability of the building’s structural elements, but the quality of hydro- and thermal insulation directly affects this. Therefore, let's look at a very important topic - complete insulation of the foundation base from the outside. By the way, some technologies for thermal insulation of this part of the foundation also require its finishing.

Why is it generally necessary to insulate the foundation, and the basement in particular?

From a layman's point of view, the very formulation of the problem may not seem entirely clear - what is the point of insulating the foundation? After all, for the most part it is not directly adjacent to residential premises, and, it would seem, cannot in any way influence the microclimate in them. And if basements are not created, or they do not require maintaining a certain level of temperature, then why even start one?

This is an extremely common misconception! The foundation, like other structural elements of a building, needs reliable insulation, and this necessity is caused by a number of reasons of various properties. And, probably, first of all, thermal insulation of the foundation is a task aimed at maximizing its strength and durability, on which, of course, the operational life of the building itself directly depends. Let's look point by point and start with the most common - strip foundation.

First of all, it must be said that truly high-quality thermal insulation should include comprehensive insulation of both the vertical walls of the foundation (basement) and the blind area around the perimeter of the building. Otherwise, talking about the effectiveness of such measures will be naive.

- Massive reinforced concrete foundation without thermal insulation, the outside will always be a powerful cold accumulator in winter, from which it will spread to adjacent building structures. It is clear that the floor level of the premises on the first floor, as a rule, is located above the plinth line, and the walls and ceilings have their own insulation. But such a proximity always leads to excessive heat loss and, accordingly, to completely unnecessary unnecessary costs on energy resources used for heating purposes. Practice shows that even just competent insulation of the foundation gives a significant, up to 20–25%, saving effect, all other conditions being equal.

1 – ground level;

2 – foundation base;

3 – basement part foundation;

4 – building wall;

5 – ceiling (floor) of the first floor;

6 – insulation of the external wall;

Of course, the scheme is not a dogma, and some variations are possible. So, in particular, the layer of horizontal insulation (under the blind area) can be located buried, right down to the level of the sole. But even in this case, it must be laid so that there is no gap between it and the vertical thermal insulation of the foundation wall.

We understand the required thickness of insulation

It is probably clear that the thickness of the foundation insulation must obey certain rules. The same Penoplex boards are available in a wide range of thicknesses, and it will not be difficult to purchase the necessary material for single-layer or, if necessary, even two-layer thermal insulation. But how to find the right thickness?

To do this, you can carry out certain thermal calculations, using formulas or even just tabular data.

Vertical thermal insulation of the foundation

Let's start with the vertical layer of insulation. The calculation will be based on the following formula:

Rsum = hф/λф + hу/λу

Rsum– total heat transfer resistance (measured in m²×°K/W) that the building construction, V in this case – strip foundation. This is a standardized tabular value established by Construction Norms and Rules (SNiP) for all regions of Russia, depending on the characteristics of their climate. If you wish, you can find tables on the Internet for various areas, this parameter is probably known to all local construction or design organizations, but it will be even easier to take the value from the diagram map below.

Please note that for each region there are three values for this thermal resistance: for walls and enclosing structures, for coatings and for ceilings. In this case, we are interested in “for walls” - in the columns these are the top values, highlighted in purple.

hf And λf– parameters characterizing the thermal characteristics of the foundation tape itself: this is the thickness of the tape in meters ( hf) and the thermal conductivity coefficient of reinforced concrete is a tabular value.

hу And λу– similar parameters of the insulating layer.

This means that if the thermal conductivity coefficient of the selected insulation material is known, then it is easy to calculate its required thickness using simple arithmetic operations.

And in order not to force the reader to plunge into independent calculations, we suggest using a special online calculator, which already contains all the thermal dependencies and the necessary tabular values.

Preserving heat energy with proper insulation

Many owners of private houses, trying to make them cozier and warmer in cold weather, line the walls with insulating materials.

But don’t forget about the foundation. After all, it accounts for a fairly large loss of thermal energy. It is for this reason that the owner needs to know how to insulate the foundation and what can be used in this case.

Today there are many methods for insulating foundations. different buildings, which helps save energy that is spent on heating.

The need for insulation

The floor in a private house is located slightly above the ground level. This is usually due to the fact that the floor in the house must be protected from dampness. Cold also enters the room through the foundation, cooling the floor. Therefore, in buildings with high ceilings, heating is partially wasted.

After all, people often have chilly feet due to cold floors. This makes a person freeze even in a warm room. Therefore, you need to think about insulating your home first.

Even in ancient times, people knew very well how to insulate foundations. For these purposes, piles of auxiliary materials were used. Today, there are sufficient quantities of insulating materials on the market. There is no need to cover the foundation with peat or straw as before. But zavalinki are still being made, although not to the same extent as before.

Insulation materials

Construction material penoplex

Construction material penoplex For insulation foundation elements The following modern materials are now used in buildings:

- expanded polystyrene;

- penoplex;

- polyurethane foam.

To insulate the foundation, the materials used require the following qualities:

- low thermal conductivity;

- minimal moisture absorption;

- sufficient resistance to compression.

After completing the work of insulating the foundation, for example, with polystyrene foam, drainage is also needed to remove excess moisture from the insulated walls. This is mandatory when the foundation is built on wet soil. Drainage is laid below the floor of the house. The basis for the drainage pipes is a layer of crushed stone. Crushed stone is also poured on top of the pipes.

Insulation methods

All methods of foundation thermal insulation are divided into those performed before laying and those performed after construction. Where winters are long and cold, foundations need insulation on both sides: internal and external. After all, the concrete that is used for manufacturing does not have thermal insulation properties.

When constructing the foundation, for the purpose of insulation, materials installed in the formwork are used. The cost of such a foundation is not cheap, but still, in the end it turns out cheaper than saving on this.

If the building has already been built, thermal insulation of the foundation is much more difficult. It happens that the owners, wanting to save money, made a foundation with insufficient depth. In this situation, many problems will arise, since the soil under the building will freeze very much.

Then you will need to dig in the foundation on both sides, and then lay insulation and waterproofing materials there. The basement floor can be sprinkled with expanded clay to reduce freezing. The most popular methods of insulating foundations are using earth or using expanded clay.

Insulating the base with earth

Earth is an inexpensive insulator. You can insulate the foundation in this way without much expense. Such insulation consists of the following: earth is filled up to the floor level. In this case, the entire foundation of the house will be below ground level. But in this case, it is also necessary to have air ducts coming out of the basement. They should be raised higher.

An obvious disadvantage of insulation in this way is its low thermal insulation. But if the foundation is deep enough, you can insulate the house through the floor, or rather, using the basement from the inside.

Insulation with expanded clay

Inexpensive and fast way - Expanded clay insulation

Inexpensive and fast way - Expanded clay insulation For such insulation, the foundation should first be dug up from all sides, completely cleared of soil to the very foundation. Moreover, they dig a trench around the house, approximately 0.8 m wide from the wall. The walls are cleaned of soil residues and prepared for waterproofing and insulation.

Waterproofing the foundation of a private house, as well as insulation with expanded clay, can be done using coating or rolled roofing felt. Usually bitumen mastic is used as the most inexpensive, but effective remedy. Preparing the foundation surface for bitumen coating requires the elimination of sharp corners.

Bitumen insulation against moisture and cold is applied hot or cold. For the hot method, the mastic is preheated to 180 in iron or cast iron cookware. The cold one is simply mixed and applied to the foundation walls with a roller. To improve the quality of work, mastic is applied in two or three layers. This insulation can be combined with earth insulation.

An important step in insulating the foundation using expanded clay is drainage. Where groundwater located at a depth of less than a meter. If expanded clay gets wet, it loses some of its insulating properties, so measures are needed to drain water from the foundation.

For drainage, a pit is dug at a short distance from the foundation. Geotextiles are laid in the pit, crushed stone is poured and then pipes are laid. Holes about a centimeter in diameter are drilled in the pipes. Then the pipes are covered with crushed stone, covered with the edges of textiles and covered with sand on top.

The disadvantage of expanded clay is its high fragility. To insulate the floor in this way, lay on top of the insulation mineral wool and film as protection against moisture.

Insulation with polystyrene foam

Material such as polystyrene foam is the insulation material preferred by professionals. It is used by those who want to completely eliminate heat loss through the foundation or floor. The material is sold in slabs, but for its installation they often use some tricks. In this way the foundation of a wooden house is insulated.

Before fixing the slabs to the walls of the building’s foundation walls, waterproofing is applied to the points of contact and on the sides. The slabs are laid from the lower level of the foundation to the floor. The seams between the plates are filled with foam. The thickness of the insulation is determined by the type of foundation and its parameters.

Foam insulation is also often found. Such insulating material can be used on slightly frozen soils, but provided that it is well protected from dampness.

If the foundation of a wooden house is to be insulated, in a region where it is very cold in winter and the soil freezes strongly and deeply, it is better to use polystyrene foam rather than polystyrene foam for this purpose. It is much stronger, so it can withstand the pressure of frozen soil and will not crumble.

Internal insulation

Internal insulation Schematic representation of proper insulation You can also insulate the foundation from the inside. This can be done by simply covering the walls of the basement insulating material

The material that can be used as insulation is called extruded polystyrene foam. Plates of this material are glued to the walls of the basement special glue. But this insulation is not necessary.

You can insulate the foundation of private housing construction yourself, both from the outside and from the inside. The main thing in this situation is to take into account all the advice of professionals in order to thermal insulation work were done correctly and with high quality.

The foundation is the most important part of any home. The durability of the entire structure depends on its strength and correct manufacturing. IN winter months it is susceptible to moisture and low temperature. This leads to rapid destruction.

Insulating the foundation helps solve this problem. You can carry out such work yourself. The main thing is to choose the right one necessary materials, study technology.

Many people think, why protect the foundation of a building on the street if you can do it from the inside. In fact, insulating the foundation of a house from the outside is an important procedure that is carried out by qualified workers even at the construction stage. But it can also be done for old buildings.

This helps solve several problems at once:

- reduce heat losses of the building, reduce heating costs in the cold months;

- prevent cracks from appearing in the foundation of the house;

- avoid dampness in the basement;

- eliminate the possibility of mold appearing under the ceiling of the first floor.

Insulation allows you to extend the life of the structure. Properly selected materials protect the foundation from moisture and frost.

Important! Building codes do not directly indicate the need to insulate the base of buildings that do not have a basement. However, a reinforced concrete structure still needs protection. Therefore, such structures also need to be insulated, but this can only be done at the construction stage.

Key requirements for insulation

The choice of insulation for the foundation must be approached responsibly. Mineral wool left over from interior decoration cannot be used for this purpose. Water will accumulate in it, which will lead to rapid destruction of the entire structure.

The material must meet the following requirements:

- low thermal conductivity;

- resistance to sudden temperature changes;

- sufficient mechanical strength;

- resistance to aggressive environmental influences;

- waterproof.

Vapor permeability does not play a big role. But it is better to give preference to materials with low throughput. Do not pay attention to the flammability of the insulation, as it will be covered with soil.

Choosing insulation for the foundation

The answer to the question of how to insulate the foundation of a house from the outside is ambiguous. Present in modern stores a wide range of materials. When choosing, they are guided by the type of soil on which the building is erected, climatic conditions region, as well as the degree of load on the structure. There are five insulation products that have an optimal price-quality ratio.

Expanded polystyrene

Expanded polystyrene or polystyrene foam - inexpensive, practical material. It is widely used for thermal insulation various designs, including foundations.

Among its advantages are:

- ease of installation;

- light weight;

- excellent thermal insulation qualities;

- foam does not absorb moisture;

- does not shrink during operation;

- does not lose its properties under the aggressive influence of salt or chlorinated water, acids, alkalis;

- it can be used together with mastics, lime, plaster and other materials.

Expanded polystyrene comes in the form of large rectangular sheets. It cuts easily with a regular knife. Therefore, even a novice master can handle its installation.

A significant disadvantage of expanded polystyrene is its low strength. It is damaged even by minor mechanical impacts. Therefore, such material needs additional protection, for example, brick lining.

For heat and moisture insulation of the foundations of houses, it is better to purchase polystyrene foam with a thickness of at least 50 mm. Its price on average across the country varies from 2500 to 3000 rubles per cubic meter. Service life – up to 40 years.

Important! When heated strongly, foam releases substances harmful to health into the air. Therefore, if there is a sauna in the basement of the building, it is better not to use such material.

Extruded polystyrene foam (EPS) is a type of foam. During production, another one is added technological process– extrusion. Thanks to this, the characteristics of the material are improved.

EPPS has the following properties:

- high density;

- complete impermeability to moisture and steam;

- sufficient strength;

- chemical and biological inertness.

- light weight.

To insulate the foundation, a 40 mm thick EPS board is sufficient. It is mounted using adhesive or disc dowels.

Most popular trademarks EPPS steel Penoplex and TechnoNIKOL. The cost of a cubic meter of such material varies from 4,500 to 5,000 rubles. The service life, subject to installation technology, is 50 years.

Polyurethane foam

Polyurethane foam (PPU) is a liquid insulation material that is applied to the base using a special sprayer. It hardens quickly, forming a durable coating.

Compared to polystyrene foam and EPS, it has the following advantages:

- when using polyurethane foam, a continuous surface without joints is obtained, which increases thermal insulation characteristics material;

- the product fills cavities and cracks that exist in the concrete foundation, which prevents its destruction;

- easy to apply on complex shaped surfaces;

- has high adhesive properties.

PPU is resistant to aggressive environmental conditions. It can withstand sudden temperature changes, does not deform, and does not release toxic substances into the air.

The price for two canisters of PU foam components weighing 50 kg each on average ranges around 25,000 - 30,000 rubles. With a layer thickness of 5 cm, this is enough to process about 40 square meters surfaces. The service life of polyurethane foam is up to 40 years.

Expanded clay

Expanded clay is a material obtained from melted clay. Recently it has been rarely used, since in terms of characteristics it is significantly inferior to polyurethane foam, polyurethane foam and polyethylene foam. Its main advantage is its low price. 1 cubic meter costs about 1,500 rubles.

Expanded clay is distinguished by its environmental friendliness. Since only natural ingredients are used in its production, it does not emit any harmful substances. The service life of such material is more than 50 years.

Its significant drawback is fragility. If the technology for manufacturing the insulating layer is violated, the expanded clay granules crumble. This worsens its thermal insulation properties. The downside of expanded clay is also the need for a blind area when laying it.

Mastics

Mastic is a liquid multicomponent composition based on bitumen. More often it is used as a base layer before laying other materials, since its thermal insulation properties are very low.

To achieve a positive result, you need to apply it in three to four layers.

The mastic well fills cracks and voids in the base, which increases the strength of the structure. It reliably protects against moisture.

Polystyrene foam insulation technology

The cheapest and in a fast way How to insulate the foundation is the use of polystyrene foam. To install it you will need minimum set tools: knife, hammer drill, construction mixer. You will also need to purchase glue for PPS, primer, plaster, construction mesh, disc dowels.

The work is divided into several key stages:

- If the house has already been built, then its foundation will have to be dug up. To do this, a trench is made around the perimeter of the building about a meter wide and equal to the height of the foundation. Remains of soil are removed from surfaces. Leave for a week to allow the moisture to evaporate.

- Surfaces are primed with a latex-based composition. This will help protect cracks and cavities from moisture. For this purpose, you can use mastic.

- Expanded polystyrene sheets are attached using glue. You need to press them lightly with your hand so as not to damage the material. In areas of the foundation located above the ground level, the sheets are fixed with disc-shaped dowels. You will first have to drill holes for them using a hammer drill. The sheets are very light, so insulating the foundation of a house with expanded polystyrene from the outside can be done alone.

- The seams formed between the EPS boards are sealed with polyurethane foam or rubbed with glue.

- The last step is filling the trench with soil. The soil is thoroughly compacted.

PPS, which is located above ground level, does not look aesthetically pleasing, so it will have to be plastered. Before this, a construction mesh is placed on it. Drying time of the layer is 2 days.

Features of applying polyurethane foam

Insulating the foundation base from the outside with polyurethane foam requires special equipment. It is often not advisable to purchase it for finishing a private house. It is more profitable to seek help from professionals.

The work is divided into several stages:

- A trench is dug along the perimeter of the building. The foundation is cleaned of contaminants. There is no need to apply primer or mastic to it. Liquid polyurethane foam will independently fill all cracks and voids.

- The surfaces are dried. Remove crumbling fragments.

- Polyurethane foam is applied. The thickness of the coating is maintained in the range from 3 to 5 cm. In some cases, applying a second layer of polyurethane foam is allowed.

- Wait for the insulation to dry completely. After this, a trench is dug. Finishing work is carried out on areas of the foundation that rise above the ground surface.

If the surface being treated has small area, then you can use polyurethane foam, available in cans. It reminds polyurethane foam, applied in the same way.

Backfill method of insulation

Insulating the foundation from the outside with expanded clay does not reliably protect surfaces from moisture. The moisture absorption coefficient of this material reaches 20%, while for PPS it is about 4%. Expanded clay is several times cheaper, and therefore it continues to be used.

The installation process is divided into several stages:

- A trench at least half a meter wide is dug around the building.

- A layer of waterproofing film is laid on the bottom and walls of the resulting pit.

- Fill in expanded clay and level it.

- Cover with a layer of film on top.

- Pour a layer of sand.

The final stage is the installation of a blind area. This additional protection foundation from low temperatures and moisture. In addition, it performs a decorative function.

How to organize water drainage from the base?

Melt and rain water eventually lead to the destruction of the foundation. Often even proper insulation cannot save in such a situation. Therefore, it is important to organize the drainage of liquid from the base of the house. For this purpose they produce drainage system open or closed type.

It's easiest to do it yourself open drain. It consists of ditches about 0.5 meters wide and 1 m deep, dug along the entire perimeter of the building. The walls of such a trench are beveled at an angle of 30 degrees to best stock water. Liquid from the pits should move to the drainage well. Therefore, the efficiency of such a system is much higher if the site has a slope.

Closed drainage has become the most popular recently. It consists of pipes that are dug into the ground outside the building around the perimeter. They are laid at an angle to allow water to flow independently into the drainage well. Pipes must be wrapped with geotextile.

Insulation of various types of foundations

The choice of materials and methods of work will depend on the type of foundation of the house. There are three main options.

Tape

A strip foundation consists of a closed system of beams placed under all the walls of the building. They are made of reinforced concrete, rubble stone or brick. Frame buildings are often built on this basis.

In this case, the choice of ways to insulate the foundation of a house is widest. You can use any materials: EPS, EPS, polyurethane foam, expanded clay.

When carrying out work, observe the following sequence of actions:

- They dig a trench around the perimeter of the building. If the foundation is shallow, this can be done manually with a shovel. Otherwise, it is better to use special equipment.

- The bottom of the trench is covered with layers of sand and crushed stone for better moisture removal.

- All foundation surfaces are cleaned. Leave to dry for a week.

- Apply a layer of waterproofing. It is better to use polymer or bitumen mastic. If insulation is carried out with liquid polyurethane foam, then this stage can be skipped.

- After the waterproofing layer has dried, installation of the insulation begins. The material is laid from top to bottom in horizontal rows.

- The structure is left for several days to dry completely. After this, you can bury the trench. If necessary, finishing work is carried out in the above-ground part of the foundation.

Your home should not only be beautiful, warm, but also safe. Therefore, it is important to take a responsible approach to the choice of materials used. Purchase all products only from specialized construction stores. Always check that the seller has certificates and other accompanying documentation for the products.

Columnar and pile

Column and pile structures are a system of free-standing supports. A grillage is subsequently laid on them - a frame onto which the pressure of the load-bearing walls of the building is distributed.

Both types of such foundations are similar, but have a number of differences. The pile is buried at a distance of 5 meters or more. It has a smaller cross-sectional area. Can be screw or driven. Its sole functions and side surface. The pillars are dug in just below the freezing point of the soil. They have a large cross-section and rest only bottom on the ground.

Insulating the foundation takes longer and is more difficult than others. First of all, you need to create a foundation wall, which is called a fence. It is on this that the insulation will subsequently be attached. It can be made from brick or metal profiles on which a wooden board is laid.

An important stage of the work is the insulation of each pillar or pile from moisture. To do this, each support is wrapped in roofing felt. Metal constructions coat them well with mastic, and coat the wooden ones with a special solution that prevents rotting. The grillage beams also need to be treated. Further process insulation will be similar to a strip foundation.

Slab

Slab foundation – monolithic design made of reinforced concrete. It is the most reliable and durable. It can be built on any type of soil.

Insulation of such a base from the outside is possible only at the construction stage. There is no opportunity to do this later.

The process is divided into several stages:

- The soil at the base of the dug pit is compacted.

- A geomembrane is lined to protect against groundwater.

- The pillow is made from a mixture of crushed stone and sand. This will improve load-bearing capacity soil.

- A layer of waterproofing is laid. Any roll material is used for this.

- Sheet insulation is installed. It is better to use PPS or EPS.

- A slab is being made.

If insulation was not carried out at the construction stage, then the only option is to lay the material under the floor screed of the first floor.

Insulation of the foundation of an old wooden house

The choice of method for strengthening the foundation of a house from the outside with your own hands depends on the type of foundation. In old buildings it often turns out to be wooden piles. In this case important stage becomes design processing protective compounds preventing rotting.

Wooden pillars or piles quickly collapse, so it is better to strengthen them by covering them with bricks. You can build new ones from metal or reinforced concrete next to the old supports. The further process of insulating the foundation is no different from that described above.

Protecting the foundation of a building from cold and moisture is an important procedure. If you are not sure about own strength, it is better to entrust the work to professionals. This is the only way to keep your home intact for many years.