Installing a metal tile roof with your own hands. Installation of metal tiles: step-by-step instructions for finishing your own roof. Installation of an “apron” around the chimney pipe

Metal tiles have firmly entered our lives. This option is all large quantity people choose to cover the roof. It has many advantages, and one of the main ones is considered long term operation and reliability. But for these advantages to really work, the installation must be carried out correctly. What is the technology for laying metal tiles on the roof? What difficulties may arise on the way to achieving this task? This will be discussed in the article.

How much material is needed and how to choose it

Laying metal tiles with your own hands is a completely feasible task. But before you start, you should purchase the material itself, and in the right quantity. In order to determine how many sheets of metal tiles you need, you should do the following:

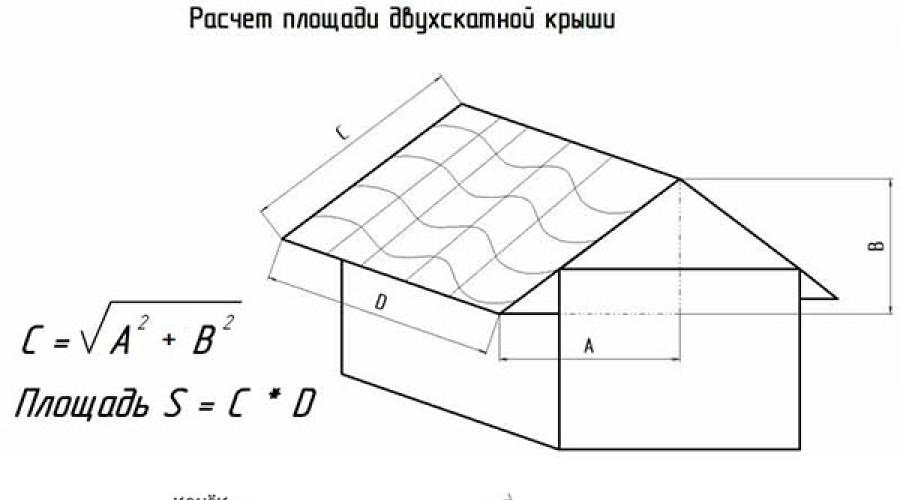

- Calculate the roof area. If the roof is gable, then this will not be difficult. Difficulties with calculations will arise with a more complex roof configuration. For a hipped, broken or other option, you should calculate the area of each slope separately.

- After this, you can decide on the required amount of metal tiles. But even here difficulties may arise. Firstly, the material is laid on the roof with an overlap. Secondly, you should be sure to ensure that the drawing is correct.

- Be sure to add 10-15 percent to the calculated amount of metal tiles. You will not be able to lay the material without cuttings, especially on a roof with a complex configuration.

- The moisture content of the material is no more than 10-12 percent.

- All boards must be the same size, especially their thickness.

- Do not use material with “flaws”, for example, with cracks or areas susceptible to rotting.

- The first step is to secure the cornice and end strip. These additional elements play an important role; they protect the roof of the house. Before installing the cornice strip, nail the front board. Brackets for the drainage are attached to it. After this, installation is carried out cornice strip.

- If the roof has negative angles, then the next step is to install the valley. This element must be placed on a continuous sheathing.

- Next, you can lay the metal tiles themselves. This needs to be done from the cornice. Which side of the roof, right or left, to start with is up to the master himself. This is not important. The first sheet should be placed flush with the eaves and the edge of the roof. The next one is placed on the right or left.

- The installation procedure is simple. First, the bottom row is installed. Next, the next one and so on until the ridge. The best option is if it matches the length of the slope. In this case, the installation will be carried out faster, and the roof itself will be more reliable (there will be few joints). But if the roof is broken or has a complex configuration, then this will not work.

- There is no need to immediately attach metal tile sheets to the sheathing. First, one row is laid out. Next, you should align all the sheets relative to each other and the edges of the roof. After this is carried out. At the same time, for each square meter there must be at least eight screws.

- The fastening points must be strictly above the sheathing boards. The installation instructions indicate that the screws are screwed in one and a half centimeters below the stamping line of the metal tile. At the same time, you can’t be too zealous. The cap should press the metal tile tightly to the base without damaging it.

- The instructions for laying metal tiles indicate the next step - this is fastening upper valley. Its installation is carried out on top of the roofing material. In this case, you need to use special products that improve the tightness of the joints. The valley is the most dangerous place on any roof. This is where leaks most often occur.

- Next, on, comes the laying of additional products. This is the ridge, end strips and so on. It is best that they are from the same manufacturer. In this case, installation will take place without any particular difficulties. In addition, it will provide a more attractive appearance and significantly improve the protection of your home's roof.

- When laying additional materials, you should also be careful about waterproofing and other “add-ons”. This is especially true for the skate. Here, in addition to the seal to improve protection against leakage, other devices should be used that will ensure the presence of a ventilation gap. Without such a “gap,” condensation that forms under the metal tile when temperatures change can quickly damage the rafter system.

After calculation required quantity metal tiles for laying on the roof of your new home, you can go to hardware store. But the purchase itself should be made carefully so as not to purchase low-quality products. To prevent this from happening, you should pay attention to some features.

Firstly, the protective polymer layer of metal tiles should not have chips or cracks. Secondly, the sheets themselves must be smooth, without dents or kinks. In addition, ask the sellers for documentation on the material. It should indicate that the metal tiles are manufactured in accordance with existing GOST standards.

Another tip is to purchase directly from a major manufacturer. In this case, the cost of metal tiles may be thirty percent less. Why the big one? The fact is that many entrepreneurs buy machines for the production of metal tiles. But not all of them have the quality of their products at the required level. Large manufacturers are more sensitive to their reputation.

Preparing the base for metal tiles

Laying metal tiles on the roof is done using lathing. You can do it yourself. To do this you need to prepare the material. As a rule, wooden boards or bars are used for lathing, but a sheet of chipboard can also be used. Last option in the case of metal tiles it is rarely used. For this type of roofing material, the sheathing is made thin.

The boards or bars used must meet the following requirements:

For most often, boards with dimensions of 25 by 100 millimeters are used. If the roof has a complex configuration, then it is better to use thicker bars.

It is very important to determine the pitch of the sheathing. It all depends on. The pitch of laying the boards should be equal to the distance between the waves. But this does not apply to all areas of the roof. At the cornice, the step between the sheathing boards should be smaller, about 2-3 centimeters.

The technology for laying roof sheathing boards under metal tiles is simple. Work should begin from the cornice. The first board is mounted on the very edge. Next, an indent of 23-28 centimeters is made and the next one is attached. After this, the boards are laid with a step equal to the pitch of the metal tile wave.

You can fasten it using wood screws or using nails. The first option is considered the most reliable. Fastening is done directly to the rafters, with two points.

Before installation, it is very important to treat all boards with special impregnations. Wood is a “capricious” material. It is “afraid” of moisture, fire and biological influence; if the boards are not treated with impregnations, they will quickly rot.

Don't forget about waterproofing. Of course, if you install metal tiles correctly, the roof will not leak. But you can’t do without an additional layer of waterproofing. The fact is that when temperatures change, condensation begins to form under the roofing material. If moisture gets on wooden elements rafter system, then they will begin to rot.

Can be used as waterproofing various materials. Can be laid thick plastic film or a special membrane. As inexpensive option You can also use roofing felt, but you should be careful here. If bitumen gets on the polymer layer of metal tiles, the latter may begin to “deteriorate.”

What you need to lay the material

Laying metal tiles on the roof of a house with your own hands is not a difficult task. But in order for everything to go quickly and without hesitation, you should prepare for work. First of all, you need to acquire all the tools and equipment.

Laying metal tiles on the roof with your own hands is carried out using the following:

You should also prepare and necessary materials. In addition to self-tapping screws and the metal tiles themselves, you should “stock up” on additional products. Any roof of a house is not complete without eaves and end strips, ridge and other details. It is advisable to purchase them from the same manufacturer from whom the metal tiles were purchased.

Installation instructions

Now it’s worth considering the issue of laying metal tiles step by step. The technology of this process is as follows:

In many respects, metal tiles are better than other roofing coverings such as galvanized sheet, slate or bitumen shingles. The installation of this material is usually entrusted to specialists, but if you have a desire, you can do the installation work yourself.

Carrying out calculations

Before starting work, the master should understand quite important point. Externally, a metal roof looks like many rows that run across the slope. The distance between rows is called pitch. If a sheet of tile has a pitch of 35 cm and 6 waves, then it is called a module. On modern market building materials canvases are offered that have a maximum of 10 modules. The minimum value is one.

If you wish, you can order tiles based on custom sizes. However, such material will cost much more. The length of the sheet should not be more than 7 m, and minimum value is 45 cm. You can install the metal tiles yourself (you must study the instructions) yourself. After reading it, you will be able to understand that when making calculations, it is necessary to take into account that the waves and joints form a solid canvas along the length of the slope. If you determine the number of modules, you can calculate the amount of material that should be purchased.

The kit usually includes two-meter steel strips, as well as steel sheets, the color of which is identical to the color of the metal tile. The slats are used for those roofs that have a slope of 30°. However, if desired, tilt adjustments can be made between 11 and 70°. When making calculations, it is important to take into account not the full, but the working, that is, useful width of the material. In the first case the value is 1180 mm, while in the second it is 1100 mm.

First you need to measure the length of the horizontal slope. The calculation must be carried out according to the ridge or cornice. This value is divided by the working width of the sheet, which was mentioned above. The result obtained is rounded to big side, this will allow you to get the number of rows taking into account the overlap. In general, you can determine the area of the covered surface, and then usable area one sheet. The first value is divided by the second, which allows you to get the number of sheets you have to purchase.

Creating a roofing pie

The system includes a vapor barrier layer. It is laid inside the rafters on the side of the house. You can use staples for this construction stapler. This will prevent steam from getting on the insulation. Otherwise, the process of rotting may begin.

The technology for laying metal tiles involves placing the insulation on top of the rafter system. Mineral wool is great for this. For waterproofing, you can use anti-condensation films or classic waterproofing. This is where the preparation ends.

Installation of sheathing

Roof sheathing is necessary in order to ensure ventilation gap between the sheet of metal tile and the film. Otherwise, in the place where the metal is adjacent to the film, the layer will quickly lose its properties.

To sheath the roof, you must use a batten whose length and cross-section are 135 cm and 30 mm, respectively. If you decide to use super-diffusive membranes with permeability, then a counter-lattice is not needed.

Preparation of tools and materials

Order requires compliance with rules. At the first stage, it is necessary to prepare tools and materials, including:

- metal scissors;

- electric drill-driver;

- measuring device;

- marker;

- ladder;

- long rail;

- mounting tape;

- hammer;

- individual protection means;

- waterproofing;

- roofing strips;

- strips for ridge and ends;

- self-tapping screws;

- guide board;

- tiles;

- aero roller;

- decorative overlays;

- boards.

As for the latter, their size should be 2.5x10 cm.

Preparing the base

Due to the fact that metal tiles are light in weight, they do not need a reinforced base, so you will need a regular wooden sheathing from slats. The distance between them is determined by the size of the tiles, so as not to drive the screws into the void during installation. When determining the step, you should also take into account the location of the windows, because there should not be rafters above them.

Thermal insulation

The rules for installing metal tiles necessarily provide for the use of a heat-insulating layer. This stage is required not only to eliminate heat loss, but also to protect against noise during rain. The rafters are covered vapor barrier material, it could be “Izospan” or “Yutafol”. The next step is to lay the insulation layer, then lay out the antioxidant film and fix it to the rafters wooden blocks. The material between them should sag a little so that condensation flows into the drain.

Installation of metal tiles

From metal tiles and materials calculations, you can do it yourself. All instructions for this are presented in the article. Installation of canvases can be carried out in one of two ways. If you carry out work starting from the right, then each new leaf will fit on the previous one. In order for the installation to be correct, four sheets are grabbed and aligned first, and then the connection can be made with a self-tapping screw. This fastener must have good quality, because the service life of the coating depends on it.

Screws must be galvanized with sealing heads made of propylene rubber. This will close the holes when screwing. A thickening will form where the four sheets join. You need to get rid of it by cutting off part of the corner or straightening the capillary groove, which is located under the stamping line.

Installation of individual elements

Installation is carried out with an overlap of 2 cm. The size of the wave must be adjusted to the width of the slope, otherwise the crest may end up on the pediment. The system should be supplemented with a roofing strip, and between it and sheet material it is necessary to place an additional layer of compaction.

When installing windows or pipes located below the ridge, it is necessary to take sheets with one module. For each structural element you will need two such nodes. The step-by-step instructions for installing metal tiles for dummies involves installing an air roller on sloping slopes. This element should be located between the ridge strip and the material. This will prevent precipitation from penetrating under the ridge. The last unit is installed on strips that are located at the ends of the structure. This is done so that the ridge protrudes by 3 cm.

Installing a ridge on a metal tile will require compliance with some nuances if this part of the system is flat. IN in this case all elements are fixed with overlap. Whereas if the ridge is semicircular, then it is necessary to follow the profile lines. When the roof slope exceeds 45°, specific model compatibility ridge strip need to check in advance. It should fit at an angle. If this is not done, the consequences can be disastrous; sometimes you even have to replace the roofing. You can bend and straighten the ridge strips if necessary, so that they follow the angle of the roof.

Arrangement of the valley

Each valley requires an additional board. Installation starts from the bottom and is carried out with an overlap of 30 cm. The bottom strip is cut to the level of the cornice, and flanging should be done along it. It is necessary to lay a seal under the ridge and flange.

There will be a 10 cm gap between the sheets and the axle. Stepping back 1.5 cm from the stamping line, you need to tighten the screws. If you did everything correctly, then after completing the work you can make sure that at the place of fastening the sheet is in contact with the board where the valley is located. If you made mistakes, then the fastenings will be in other places, and the consequence will be that gaps will form on the surface through which the roof will leak.

In order to ensure that when installing metal tiles, step-by-step instruction which is presented in the article, to cover the cut sheets, you need to stock up on decorative overlays. There is no need to lay a sealant between them and the tiles. Products must be installed with a 10 cm overlap. It is important to prevent damage to the valley by self-tapping screws, which are used to secure the linings.

Quite often, the end and beginning of the valley are located on the roof slope. If we take the installation as an example dormer window, then a separate board must be placed under the valley. For a window, a cutout should be made in the sheet, while sealing material is placed along the walls. The plank will be able to cover the eaves overhang. Then the valley strips are installed, which are trimmed along the edges. The part that comes out will fit tightly to the sheet of tile.

Installation of snow guards

Depending on what design features have snow retainers; today several technologies for their installation are known. It is important to take into account the estimated power load, type of roof and location of structures on the surface.

For metal tiles, the instructions for which are presented in the article provide for determining the number of profiles. In the future, they will be fixed to the system brackets. The number of profiles is determined taking into account the geometry of the roof. For those areas where snow accumulation is expected, glass holders should be installed in two levels. With an impressive roof area, the number of rows of the structure increases.

The placement of snow retainers is planned at the stage of designing the coating; in the locations of these nodes, it is necessary to strengthen the sheathing with the help of additional support boards. The technology for laying metal tiles involves the installation of snow retainers, which are fixed using long screws, strengthened to the sheathing. The fasteners must go through the roofing.

When determining the number of fastenings, the angle of inclination of the roof, the design of the sheathing and the length of the slope should be taken into account. The holes for the snow guards must be sealed; rubber gaskets must be used for this. Under bottom mount two seals are installed. The distance between the fasteners should be equal to the limit of 0.5 to 1 m. A profile with an oval cross-section or a pipe is inserted into the brackets. The elements are connected to each other with through bolts.

Another sheathing is made on top of the waterproofing layer, then you can proceed to laying the sheets. After installing the first row, it must be aligned with the cornice. By using roofing screw the canvas is attached in the center. The second sheet is laid overlapping the first.

At the next stage of installing metal tiles (step-by-step instructions are presented in the article and should be studied by you), you can firmly fasten the sheets with self-tapping screws. After this, the metal tiles are attached to the sheathing, but as an exception there is the last sheet, which needs to be fixed only after laying the second row.

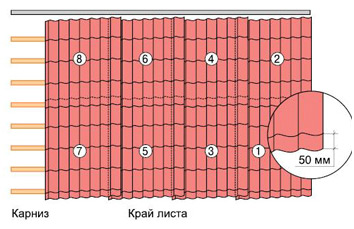

If you want to do installation in several rows, then you need to work from right to left. The first three canvases are laid according to the scheme described above. The screws do not need to be screwed in all the way so that you can align the sheets. The fourth canvas lies above the third, this will cover the entire slope.

After you have laid out all the sheets, you can screw in the screws until they stop. Installation of metal tiles, the step-by-step instructions of which will be of interest to you if you plan to carry out the work yourself, involves installing the ridge last, because the sheets are laid from top to bottom. All subsequent rows must be slipped under the previous ones. It is important to choose screws whose color matches the color of the material. You need to remember that metal tiles are strong, but light enough, so they can be blown away by a gust of wind. It does not matter where the material is located - on the roof or on the ground.

How to avoid mistakes

You must follow the step-by-step instructions for installing metal tiles. It involves following certain rules, among which is the prohibition of working in hard-soled shoes, as well as the prohibition of exposure to the crest of a wave. You cannot step on the canvas with your full foot. Masters need to remember that they should not place their foot perpendicular to the slope. Do not handle the material with bare hands.

Conclusion

Quite often, owners of suburban real estate and houses within the city entrust the installation of roofing materials to specialists. If you also decide to follow their example, then you should be interested in the cost of the work. Installation of metal tiles costs 380 rubles. per square meter. However, to these works it is necessary to add the price of some other services, for example, installation of components. They cost consumers 250 rubles. behind linear meter. carried out for 450 rubles. per linear meter.

However, this list cannot be called complete. It will also be necessary to install layers of thermal and waterproofing, without which the roof will leak and the materials at its base will become saturated with moisture.

Construction is not a cheap industry. And, as you know, there is never too much money, so you can save on labor, i.e. do everything yourself.

Before starting installation work, you should:

- firstly, determine the amount of financial costs;

- secondly, select the design of the future roof;

- thirdly, carefully study the technological process.

In this article

How much does it cost to cover a roof?

Whatever the design of the roof, its cost is made up of four items:

- frame;

- insulators;

- top roofing material;

- wages of workers (in our case this cost item is absent).

The first and easiest way to determine the cost of your roof is to call local companies and ask the manager about the prices for installing a metal roof, after first calculating the area of your roof. Many employees will be happy to provide approximate prices. The second option (calculate everything yourself) is more difficult, but no less accurate and reliable.

Volume calculation

Frame – wooden structure, consisting of main and auxiliary fragments. The first are the mauerlat, rafters, sheathing; the second - tightening, racks, struts. Together they make up the roof truss system.

There is a good online calculator on the Internet, with which you can calculate the volume of lumber, effective loads, see the rafter layout diagram, etc.

But there is one nuance - the calculation is carried out not for all types of roofs, but for single-pitched, gable, mansard (including sloping roofs) and hip ones. That is, if you have more than four slopes, then you will have to count manually. After we have determined the number of boards and timber, we select insulating materials for the metal roof.

Insulating materials

The following insulators will be required for roofing work: steam-waterproofing and thermal insulation.

Metal tiles retain the bulk of atmospheric moisture, but vapors contained in the outside air still get inside. To protect the underlying structural layers, steam and waterproofing is used. The difference between vapor barrier and waterproofing is that the first is aimed at passing vapors from inside the room to the outside, and the second is aimed at preventing external moisture from penetrating into the roof structure. Film vapor and waterproofing insulators combine the functions of both layers and are either perforated or non-perforated. On the packaging of this roll material After the name, indicate a number; it indicates the weight of 1 m2 of film.

In addition to common film insulation, builders also use special polyethylene materials, with inside reinforced with aluminum foil. Such films are rarely used for residential buildings; they are usually laid during the construction of baths, saunas, and swimming pools.

The best sellers on the moisture-proof film market can be considered Isopsan, KLØBER, TechnoNIKOL, DUPONT, but there are also cheaper analogues.

Enclosing material

As mentioned above, the main protective function carries the top roofing layer - metal tiles, which are sheets of thin sheet steel (galvanized), aluminum or copper, coated with a polymer layer and deformed by the cold method. Visually, metal tiles are very similar to ordinary tiles, but they weigh much less - 5 kg/m2, and this is not its only advantage.

We can also name the tangible advantages of a roof under metal tiles:

- durability (15 – 20 years);

- aesthetic appearance;

- ease of installation and repair during operation.

Beauty, of course, is important, but quality characteristics play a decisive role. It is worth paying attention to:

- a steel base containing the necessary alloying elements that improve the strength and rolling properties of the metal;

- class and type protective coating;

- class and type of protective and decorative polymer coating.

The optimal thickness of the steel sheet is from 0.45 to 0.5 mm. With a smaller thickness, difficulties arise in installing a roof made of metal tiles: deflections, breaks and other deformations. The protective base of the metal coating in the production of metal tiles is:

- zinc;

- zinc-aluminum;

- aluminum-zinc;

- aluminum-silicon;

- iron-zinc.

Zinc consumption during production is 225-275 g/m2.

It is used as a protective and decorative layer in the production of metal tiles. the following types coatings:

- polyester (PE);

- polyurethane (Pural);

- polyvinylidene fluoride;

- acrylate;

- plastisol.

For use in an urban environment (except for cases where factories that emit aggressive substances into the environment are located nearby), a polyester coating with a thickness of 25 to 30 microns is optimal. The above coverages "in pure form» do not apply. Foreign and domestic companies apply complex compositions of copolymers with various additives. The recipe for such coatings is kept in the strictest confidence.

In addition to the metal tiles themselves, additional elements will be required for roof installation: valleys, ridge caps, external and internal corners, skating and connecting strips, seam strips; as well as fasteners: studs, self-tapping screws, nails, etc.

After purchasing all the necessary materials, we begin construction.

Metal roofing installation technology

DIY roofing tool

To make a roof with your own hands you will need the following tools:

- ladder;

- metal scissors;

- screwdriver and electric drill;

- long rail;

- mounting tape;

- hammer;

- marker;

- level and tape measure (preferably metal);

- low hardness brush;

- mallet with rubber head;

- hand-held circular saw.

Remember: under no circumstances should metal tiles be cut with a grinder! This can lead to damage to the polymer protective coating, after which corrosion of the base metal will begin to form during operation.

Step-by-step instructions for installation work

The beginning of all work is the installation of the rafter system, carried out in several stages. Installation instructions for both cold and warm roof made of metal tiles can be included in the following installation scheme:

Step 1. Waterproofing the walls

The first step is to waterproof the walls. This can be done using ordinary roofing felt. Timber is laid on the walls from pediment to pediment along the entire length. Afterwards, we check the horizontality of the structures with a level and control the pitch of laying the timber. The Mauerlat is secured with anchor bolts into pre-drilled vertical holes in the beams. Later they begin to install rafter legs to it.

Step 2. Installation of purlins

Installation of purlins helps to simplify the work, since it becomes possible to fasten each pair of rafters separately. The purlin is placed in the highest positions of the front walls and secured in the designed position with anchors or steel corners. The ends of the purlins are also waterproofed.

Step 3. Attaching the rafters

Before you start attaching the rafters to the already assembled elements frame, you should lay out all the rafter boards in the strict sequence of their further installation. We must label all elements to avoid confusion.

We trim the rafter legs and precisely adjust all the gaps and angles. In the upper section, the rafters are connected with overlays. Each joint must have a minimum of 5 nails. First, the outer rafter sections are installed, and then those between them, distributing them along the entire length of the house. At the bottom of the rafters, tie downs are installed. All structures must be verified during installation.

Step 4. Installation work

After installation, alignment and final fastening of the rafter system, we begin roofing installation work. In order for the roof to serve for a long time, and the metal tiles to reliably protect from precipitation, the installation of all fragments is carried out in strict technological sequence, which includes the following steps:

- installation of counter rails;

- laying waterproofing;

- fastening elements of vertical sheathing;

- installation of the initial bars of the horizontal sheathing;

- additional sheathing;

- installation of wind boards;

- installation of brackets for drainage gutters;

- cornice strips;

- installation of metal tiles;

- roof ridge and its seal;

- thermal insulation works;

- vapor barrier;

- attic filing (for attic roofing).

If the roof is cold, then the last three stages are not taken into account.

Metal tiles are suitable for roofs with slopes of at least 14°. The pitch of the transverse wave of metal tiles directly affects the spacing of the sheathing battens. So, with a transverse wave with a range of 300, 350 and 400 mm, the sheathing pitch will be 300, 350 and 400 mm, respectively. The distance between the lowest batten of the sheathing and the one next to it is respectively 230, 280 and 330 mm. The fragments of the sheathing themselves must be subjected to antiseptic treatment.

Continuous sheathing is installed in the places where chimneys pass, at the location of the valleys. Before you start fastening metal tiles, be sure to continuous lathing the lower valley strips should be secured. The overlap of one part onto another is about 100-150 mm. The tiles are installed from bottom to top. The joining areas of metal tile sheets are additionally covered decorative inserts– upper valley strips.

Remember: junction nodes are the most vulnerable places, so their arrangement is approached with special attention. They use sealants for external work, seals, additional layer waterproofing.

Another extremely important aspect at self-installation metal tile roofing - fasteners. Purchase a set of fasteners and metal tiles together from the supplier, otherwise you may lose your warranty rights to the purchased product.

Safety precautions

Construction and installation works – dangerous look activities. Perform all sawing, cutting, drilling, and fastening operations in protective clothing, gloves, and protective masks or goggles. When working for a long time, your hands become sweaty, tools can slip out, damage your fingers and cause infection. Wearing masks and goggles will help protect your eyes from metal dust and Airways from micro-granules of insulation. For which rolled mineral wool materials are used.

Compliance with safety rules is the key to your health.

One of important stages building a house - installing a roof and roofing ( roofing). One of the popular roofing materials can be called metal tiles. And it’s not surprising, because among its advantages are light weight, ease of installation, large color scheme, strength.

Of course, there are also disadvantages - low rigidity, which makes movement on the roof problematic, and significant waste of material when laid on slopes with complex geometry, poor sound insulation, and heating. All of them can be eliminated; for example, the susceptibility of metal to corrosion can be reduced if metal tiles are installed correctly.

Metal roof installation

The manufacturer has already taken care of protecting the metal tiles by creating a multi-layer structure roofing(see picture).

As you can see, the presence of several layers of protective coating suggests that the tiles are made of quality material. Therefore, in order for the roof under such a covering to serve for a long time, you need to adhere to the technology of installing metal tiles.

Basis of choice - parameters of metal tiles:

- Metal tile thickness. Metal tiles are made from thin sheet steel. The thickness of the metal tile sheet is 0.5-0.7 mm, this is noted in SNiP II-26-76 “Roofs”.

Advice. The thickness of the metal within one sheet may vary. Allowable change +/- 5%.

Note, low quality metal bends under strong pressure.

- Thickness of the zinc layer of metal tiles. This parameter cannot be visually tracked. Therefore, read the passport for the coil of metal from which the sheets are rolled. According to the standard, the thickness of the protective coating should be 275 g/m2. If this requirement is not met, it may lead to the result shown in the photo.

- The thickness of the metal tile coating depends on the type (type) of the coating.

- Leaf geometry. Here it is important to pay attention to the fact that the sheets are not only cut evenly, but also do not have any bends along the covering side.

The tight fit of the edges is shown in the photo.

If the geometry of the sheet is poor, the result will be noticeable visually. At best, the joint will be unsightly. In the worst case, water will flow under the sheet. And don’t even expect to tighten such an edge with self-tapping screws.

- Metal tile color. Plays an important role in the case of gradual development. That is, when you need to select a shade. In principle, there are two color coding systems, and if you know your color, you can choose the appropriate one.

Types of metal tile coatings

- PE (polyester) is applied with a thickness of 20-25 microns. Its disadvantage is its rapid but uniform burnout. And also that the snow does not linger for smooth surface leaf.

- PEMA (polyester matte). Its layer is 35 microns. It is more resistant to fading and mechanical damage. The rough surface prevents snow from sliding down quickly. In principle, matte finishes virtually eliminate the need for snow guards.

- PU (pural) and PUMA (Pural matt - matte pural). Coating thickness 50 microns. This coating can be used in regions with aggressive environments.

- PVC (Plastisol). In metal tiles with such a coating, the metal core is the most protected, since the layer is from 100 to 200 microns.

Nuance. The tone will be different. The rate of color fading depends on the metal coating.

Calculation of metal roof tiles

Let us illustrate an example of calculating metal tiles for a gable roof with a slope measuring 8 by 5.

Calculation of the number of sheets of metal tiles required to cover the slope rectangular shape is calculated as follows - the length of the slope along the ridge divided by the width of the sheet.

Nuance. When making calculations, rely on the working width. That is, taking into account overlaps. The sheet dimensions for Monterey metal tiles are shown in the photo.

For example, the length of the slope is 8 m.p. Then you will need 7.27 sheets for work. Round up to the nearest 8 sheets. For two slopes - 15 sheets. Because one sheet is divided in half and used on the second slope.

Nuance. In this case, you will need to start work with half a sheet.

For the convenience of calculating more complex configurations of slopes, you can use the constructor (calculator).

You can make drawings of the roof slopes and draw a diagram for laying metal tiles, i.e. arrangement of sheets.

Nuance. The more complex the slope configuration, the more material waste there will be.

The length of one sheet of metal tile is determined by the height of the slope plus the eaves overhang (about 5 cm). Please note that the longer the sheet length, the less material will go to overlap. But it is difficult to work with a long sheet, and transporting metal sheets big size it's a costly business. Therefore, it is recommended to break a sheet more than 6 m long into parts. To do this correctly, you need to adjust the resulting length by the amount of overlap. The overlap should be at least 0.15 m for slopes with an angle of inclination of more than 25° and 0.2 m for smaller angles. For our example. 5 m.p. divide in half - we will need 1 sheet 2.5 m long, and the second 2.65.

At the same time, the manufacturing technology of metal tiles is such that there are impossible dimensions. Each manufacturer has their own and depends on the equipment used.

Then for the entire roof you need to buy 15 sheets of 2.5 m each and 15 sheets of 2.65 m each.

Calculation of the number of additional elements for metal tiles.

The components include a ridge strip, end and cornice strips, a snow retainer, internal and external valleys.

Calculating additional elements is simple - the total length of the surface to be covered is divided by 1.9 m.p. – (2 m. standard length of the strip, minus an overlap of 0.1 m). For the lower valley divided by 1.7. The overlap is 0.3 m.

For our gable roof you need 5 ridge strips (the length of the slope along the ridge is 8 m.p.); 9 cornice strips ((8+8)/1.9); 11 end. Due to the design of the roof, we do not need a valley.

Special strips. These are custom-made additional elements according to your size.

Self-tapping screws. Their consumption is 7-8 pcs. per sq.m. metal tiles and 3 pcs. by 1 m.p. additional element. The screws should be with a drill, this will simplify installation, and preferably painted in the color of the sheet. This will give the coating a more finished look.

We will need 768 pcs. for sheets and 3x(5+9+11) = 834 pcs. They are usually sold in packs of 250 pieces. Naturally, it is better to take it with a reserve.

Sealing tape for metal tiles. It is recommended to install it under the ridge strip.

Film – equal total area slopes minus overlap allowances. For example, a roll of film usually measures 1.5 by 50 m. = 75 sq.m. The working area of the film is about 65 square meters.

The insulation under the metal tiles is also equal to the total area of the slopes.

The following tools will be useful: a screwdriver, a hammer, a mallet, a tape measure, a marker, a level, a jigsaw or a hacksaw.

Advice. Cutting a sheet of metal tile with a grinder is strictly prohibited. When heated, the coating at the cut site is destroyed and the sheet begins to rust. In addition, sparks can damage the paint throughout the entire sheet.

How to store metal tiles

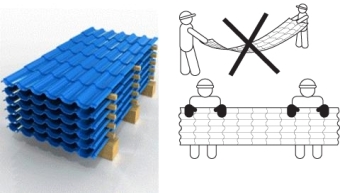

If you purchased the material before you built the rafter system, you need to know how to properly store metal tiles (especially in winter). The sheets must be laid on a flat area, preferably on a pallet. In addition, it is important to protect the metal from moisture, ultraviolet radiation and provide ventilation. If the sheets will be stored for more than a month, they need to be laid as shown in the photo.

Additional strips are also stored in a lying position.

1. Construction of a rafter system for metal tiles

Installation of metal tiles begins at the stage of lathing installation. It is important to initially secure the sheathing boards at the required distance. Namely, the distance between the first and second boards is 300 mm, then 350 mm, 350 mm is the distance from one bend of the sheet to the next. In professional language, the distance is called a tile.

Advice. At the point where the chimney exits, in the valley, near the windows, you need to make a continuous sheathing.

2. Checking the size of the slope

The main thing is that the roof slopes are smooth and flat.

3. Attaching the eaves strip for metal tiles

The eaves board directs water flowing from the roof into the drainage system.

Nuance. Long gutter brackets need to be installed on the eaves board. drainage system. Short ones can be installed after roofing work is completed.

4. Laying a hydrobarrier film under metal tiles

To prevent the attic from getting wet in case of sudden rain, and also to further protect the insulation from getting wet, a water barrier film is used.

The waterproofing film under the metal tiles is laid on the rafter system in accordance with the description, which contains installation instructions. To avoid leakage, it is necessary to ensure an overlap of the film of at least 10 cm. For sloping slopes, at least 25 cm. For hip roofs, up to 50 cm (at the roof ridges). The film is secured with a construction stapler.

Advice. The film is spread parallel to the end if the roof slope is more than 25°. And parallel to the ridge, if less. In this case, you need to maintain a sag of 1-2 cm along the edge of the rafter leg.

At the exit points of the chimney, antenna, etc. you need to extend the film 4-5 cm onto these elements.

5. Installation of counter-lattice under metal tiles

The counter grille is needed to provide a ventilation gap between the film and the metal tile sheet. Otherwise, at the junction of the film and the metal, it will quickly lose its properties.

For installation, a rail with a cross section of 30 mm and a length of 135 cm is used.

Nuance. When using a superdiffusion membrane with high permeability, a counter-lattice is not needed.

6. Installation of the lower valley

A valley for metal tiles is installed if the roof configuration requires it.

Nuance. It is better to install the lower valley not with screws, but with a clamp. This way it will maintain its integrity, which will reduce the likelihood of leaking. You can make your own kleimer from scrap metal.

7. Installation of the first sheet of metal tiles

To avoid deformation, the sheet is lifted onto the roof using runners (see photo).

Nuance. It is better not to install sheets in strong winds. Loose sheets may bend.

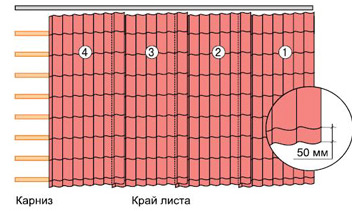

Installation is carried out from right to left, so that each subsequent sheet covers the groove for water drainage on the previous one.

The bottom row of sheets must be mounted so that the sheet hangs 50 mm over the edge of the rafter system. (this is why the distance between the first and second sheathing boards should be 300 mm, not 350). This is necessary to ensure ventilation and ease of water drainage.

Methods for installing metal tiles are shown in the diagram

The technology for laying metal tiles involves aligning the first sheet along the end of the slope and the eaves. If everything is correct, the sheet is attached to the top using one self-tapping screw. The second sheet is installed with the same requirements and secured to the first sheet. After all the rows are aligned along the eaves overhang, the sheets are firmly attached to the sheathing.

Adviсe:

- You need to move around while performing roofing work. Therefore, it is better to wear shoes with soft soles and step only at the bottom of the wave.

- If during the installation process you need to cut the sheet, it is better to paint the cut area with special paint.

- After installing the sheet, you need to remove the protective film from it (if any). Under the influence of ultraviolet radiation, it will crumble and have an ugly appearance. In addition, it will be much more difficult to remove.

8. Fastening metal tiles

Metal tiles are fastened with special self-tapping screws. Availability sealing gum allows you to tighten the screw as tightly as possible without deforming the sheet itself.

The scheme for fastening metal tiles with self-tapping screws is through one wave.

Nuance. Along the length of the end, a self-tapping screw is attached to each tile.

Many people advise mounting the self-tapping screw down the wave. It is not right. Because water flows along the tile gutter, which means that the slightest violation during installation is fraught with the appearance of rust.

The photo below shows that the screw needs to be moved a little to the right.

It is also important to tighten the screw correctly. The fastening rules are shown in the figure.

9. Installation of additional elements

9.1 Installation of valley metal tiles. Depending on the roof structure, an upper valley is installed. When attaching it, try to tighten the screws so that they do not get on the lower screws. If clamps were used, this requirement is omitted.

9.2 Installation of a wind strip on a metal tile. Regardless of the roof configuration, an end (wind) strip must be installed. The overlap of the planks is 10-15 cm. They are fastened with long self-tapping screws. At the rate of 1 self-tapping screw per 1 m.p. planks. The wind strip is laid on top of the tile sheet and fixed with self-tapping screws on both sides.

9.3 Installation of the ridge strip of metal tiles depends on its configuration. When installing a round ridge strip, you need to close the ends with special plugs.

The broken strip fits more tightly to the sheets, so a plug is not needed.

You can protect the ridge of metal tiles from snow and moisture by laying a special ridge sealing tape (ridge seal).

9.4 Next, we install aprons (junction strips) for the metal tiles near the pipes or the junction strip of the slope to the wall. To do this, the wall needs to be grooved 1-1.5 cm. Insert a strip into the resulting strip, and treat the installation site with sealant. It should be noted that the sealant will deteriorate. Therefore, the junction needs to be inspected from time to time and sealed in a new way.

Nuance. It is prohibited to insert the abutment strip into the masonry joint; this may compromise the integrity of the wall. And then the manufacture of a reliable structure at the junction will turn into sabotage.

9.5 Installation of snow guards on metal tiles. Lastly, we install snow retention strips on the sheet of metal tiles. They are simply necessary if the metal tiles are covered with polyester.

Snow guards for metal tile roofs may have the appearance shown in the photo.

Snow guards are often reinforced with an additional strip.

Its cost is low, and the strength of the snow holder increases significantly.

The choice of plank depends on the preferences of the owner, as well as on the intensity of snowfall and the angle of inclination of the roof slope.

How to install snow guards on metal tiles?

The snow retainer bar is located parallel to the cornice in one row or two rows, in a checkerboard pattern.

Final roofing pie shown in photo

10. Roof insulation, installation of vapor barrier film and interior decoration

Installation of metal tiles - video instructions

Mistakes when installing metal tiles

In conclusion, I would like to briefly remind you of the most common mistakes in installing metal tiles:

- an uneven slope will result in a lumpy leaf;

- Incorrectly cut sheets can quickly rust. Therefore, do not use an angle grinder;

- incorrectly screwed screws lead to deformation of the sheet;

- you need to use only high-quality screws with a special rubber seal;

- saving on high-quality seals leads to snow being blown into the roofing pie or moisture getting in;

- It is better to inspect the sheet several times for scratches and paint it with special paint in time, rather than then admire the rusty streaks;

- use special (custom-made) additional elements if the standard ones do not completely cover the openings. Their production will cost you less than the subsequent replacement of an entire assembly or roofing materials;

- do not buy long sheets of metal tiles. Metal has a high coefficient of linear expansion. This means that the sheet will play and over time the screws in it will become loose. Therefore, cut the sheet into several parts;

- on the other hand, the more joints, the greater the likelihood of leakage. Therefore, stick to the golden mean;

- maintain the correct amount of overlap.

Conclusion

As you can see, the installation of metal tiles can be done independently. By adhering to certain rules, laying metal tiles on the roof will be successful and in a short time.

Metal tiles are one of the popular roofing materials, which are characterized by reliability, durability and affordability. To perform coating work efficiently, you must follow the instructions below. But first, let's look at what is so remarkable about this material and what disadvantages it has.

Advantages and disadvantages of metal tiles

Among the advantages of this coating are:

- Light weight, which allows you to cover the roof without much effort;

- The work will not be difficult and special education not required, it is enough to have basic knowledge in this area;

- The service life is very long, which allows for a long time don’t think about covering;

- Affordable price and high wear resistance no less important criterion when choosing roofing material;

- Such material does not burn, but under the influence high temperature does not melt or deform;

- A huge selection and stylish appearance will allow you to find suitable option everyone without exception.

The only drawback that many buyers cite is its noise. But even this can be dealt with if you take care of sound insulation when covering.

We cover the roof with metal tiles correctly: step-by-step instructions

To do this work yourself correctly, you must follow all the rules outlined in the step-by-step instructions. So, where to start:

- Conduct necessary calculations to find out the amount of materials, not forgetting about the insulation and fasteners;

- Cover around the chimney;

- Lay the material using one of the options.

Calculation of the amount of metal tiles per roof

Usually the width of a full sheet is larger work area. This difference can range from 80 to 120 mm. therefore, when purchasing material you need to know exact dimensions working covering.

To perform the calculation correctly, you need to focus on the following formula:

- The greatest length of the material is divided by its width. The resulting figure must be rounded upward.

- First you need to measure the length of the slope, while the overhang of the cornice must also be taken into account;

- The overlap is 0.15 m per row. If it is possible to lay the coating in one row, then the overlap does not need to be taken into account.

Having measured both indicators, they are added together.

If the purchased metal tiles were made to order according to certain sizes, then in order to correctly calculate all the indicators it is better to use the help of specialists.

The sizes of such material range from 70 cm to 12 meters.

But most the best option There will be a covering with dimensions of 4 - 4.5 m.

Apron equipment

Where the chimney passes through the ceiling, care should be taken to take care of the inside of the junction.

Do-it-yourself installation of the apron should be done according to the following scheme:

- The base material must match the color of the strips;

- The groove made in the pipe should be about 15 cm deep, and the slope should be slight;

- Heat-resistant insulation must be installed on the chimney pipe. The place of contact must be glued with tape;

- Where chimney passes the roof level, it is wrapped with a special film.

A decorative apron can be installed when the sheets of metal tiles are laid on the roof. External abutment slats are placed on the chimney so that their upper part moves into the prepared groove. For more reliable protection, the joints are filled with heat-resistant sealant. A bottom part the slats need to be attached with self-tapping screws to the sheathing.

To be good ventilation between the chimney and the rafters, it is necessary that the distance between them be large.

And for protection brick chimney from possible cracking, the pipe must be wrapped with steel with your own hands polymer coating. To ensure good ventilation, it is necessary to leave a small gap, about 20 mm.

Chimney with round must be insulated where the roof surface passes. To do this, you can take a special tape that has the ability to self-expand. It perfectly seals all holes, including the entire diameter.

Installation of metal tiles: sequence of work

To ensure that installing the roofing yourself does not cause much difficulty, you need to take care of the method of supplying the metal tiles to the roof. To do this, it is recommended to make logs.

If the roof large sizes or it is not possible to store all the purchased material near the house, then you can try to make a kind of shelving with your own hands. All materials will need to be transferred there, and then installed. To prevent the sheets from being damaged during storage, they must be arranged with slats during moving.

As soon as the metal tile is in place, the protective film coating should be removed.

If you have to walk on laid material, you need to know how to do it correctly so as not to damage it. The first is caution. Before you step on anything, you need to carefully select a place for it. Secondly, movements should be carried out only along the sheets and step only between the waves of material.

If you need to walk across the covering, then the place where your foot will step should be a fold. Thirdly, you need to wear soft shoes when covering the roof, this will help avoid damage to the material.

If you have to cover it in rainy weather, then water may get into the joints. All moisture is squeezed up under the force of the second sheet. To completely eliminate moisture accumulation, each sheet of material contains a special groove, which helps drain unnecessary water. There are some species that have such a groove on both sides, but mostly it is on one side, on the right. When , make sure that this groove is covered by the subsequent coating.

Having laid the beginning of the row, you can continue to cover in any direction:

- right;

- left.

The direction of installation is chosen for personal reasons regarding convenience. But the beginning of installation should begin from the side on which there are no cuts or bevels. You need to cover, focusing on another roof slope or valley.

If the process begins on the left, then the sheets laid after should lie on the wave of the sheet in front of it. And the groove should be on the left side of the coating.

If the laying principle provides for a direction from the right, then the groove is overlapped using the edge of the next sheet, ending up under the wave of material. The second method of covering is much easier and simpler, since shifting of the laid material is eliminated. But it is also very easy to scratch.

Whatever method of laying this work is carried out, the initial sheets should be placed parallel to the eaves, and the length of the overhang should not be more than 50 mm.

You can cover the roof with sheets using two technologies:

- Place the material in one row;

- Perform multi-layer styling.

How to lay metal tiles in one row

This technology involves installation to the right of the edge. This means that the coating should be leveled, focusing on the ends and cornices. When the first sheet is aligned with them, it needs to be fixed in the middle, not far from the ridge. Subsequent materials are applied with slight overlap. Usually, one wave of sheet is enough for good strength. After aligning the second sheet in relation to the first, it is also fixed, but not in the middle, but together with the previous sheet. Using this method, blocks of 4 sheets are laid out. The resulting block is aligned with respect to the cornice and end and, leaving room for overhang, the entire structure is attached to the sheathing boards. The last sheet in the block must be fastened when the last block has been adjusted. In the figure below, you can take a closer look at this installation method.

Multi-row fastening method

This installation method involves covering the roof according to the following scheme:

- The roof needs to be on the right side. The initial sheet must be leveled relative to the end and cornice. Another covering element is mounted on top and attached to the first sheet, after aligning the two sheets. The next sheet must be mounted to the left of the first covering element, and also fastened to it. The fourth element should be laid on top of the third, and this continues until the end of the roof. Having completed two rows of such covering, the block is fixed on a wooden crate.

In the figure below you can see the described circuit.

Laying material on the ridge

Before laying begins, mark the slope and determine central axis. On one sheet of metal tile you should do the same, mark the central axis. Place the surface of the slope and the sheet of material together; the latter must be secured with a self-tapping screw. Subsequent sheets should be laid on both sides of the ridge using one of the above methods.

What points you need to pay attention to

- should occur only at the point where the sheathing boards touch;

- The bottom sheet must be mounted, passing one wave over the step;

- Subsequent rows are fastened at a short distance relative to the steps;

- When attaching the material from the beginning of the end board, it is necessary to use all the waves;

- The laid material must fit tightly to the sheathing boards;

- When covering vertically, the material is secured using self-tapping screws into the recess of the waves.

Having analyzed the process with your own hands, you need to pay attention to the processing of sheets.

- It is prohibited to use a grinder when working with metal tiles, as the coating can be damaged, and this will lead to further corrosion. For these purposes, it is recommended to use cutting electric scissors or a jigsaw. A hacksaw for metal work is also suitable.

- Areas of damage to the material must be treated with paint to avoid further rusting.

In the figure below, you can see how to lay the material yourself.

In the picture shown, number 3 means waterproofing film;

- Number 4 means sheathing;

- Number 21 - end board;

- Number 22 - outer corner;

- Number 23 is a self-tapping screw.

End strip

If it is installed correctly, then it serves not only as decorative element, but also as a protective one. It allows you to protect fasteners from the harmful influence of factors environment. Preventing moisture from entering is also within her purview.

Endova

It is intended for refining external joints. Lead excess moisture also within her power. When attaching the upper valley, it is necessary to ensure that the screws do not damage the lower valley; this can lead to damage to the waterproofing.

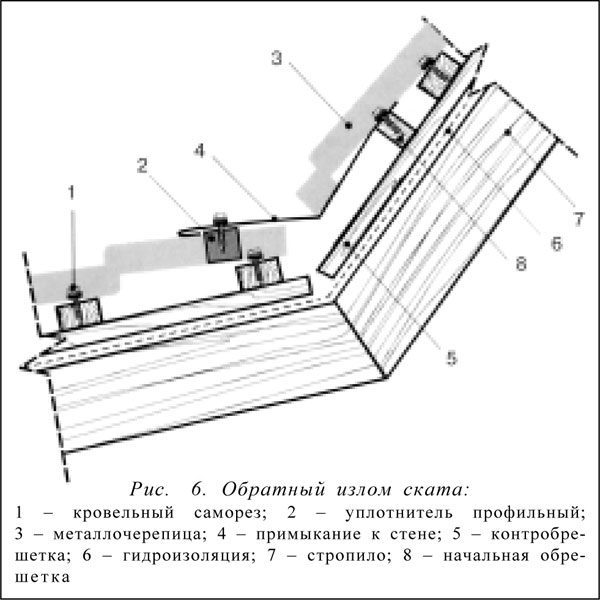

Roofing fractures

There are two types of fractures on the roof:

If the roof has a slope with a straight bend, then the sheathing boards should be placed fairly close to each other. The coating material must cover the area of the direct fracture, with a small protrusion.

If the roof has a reverse bend, then it is necessary to use a wall connection, which will act as a connecting element. Where there is a reverse break, the sheathing boards should be fairly close to each other. And between the metal tile and the junction there should be a layer of sealant.