Do-it-yourself vice for wooden products. Cheap DIY bench vise. Classic homemade vice

Read also

Not all models of machine equipment are produced together with a vice. If purchased separately, they are quite expensive. It is easy to make a machine vice yourself. To do this, you can use handy materials.

Functional purpose of the vice

Technological operations for drilling holes on specially designed equipment are performed using a vice. With the help of the latter, the workpiece is securely fixed, which allows you to adjust the working drill with maximum precision. The metal used to make the equipment is strong, otherwise the device will quickly wear out.

Preparation of materials

To make a machine vice, you should prepare the following materials:

Base;

- Base.

- Metal plate 35 mm wide, 8 mm thick.

- Profile pipe size 20*40 mm, length 5 cm

- Two corners 50 * 50 mm, 10 cm and 8 cm.

- Jaw strips

- A stud with a nut and a bolt head with a hole at one end. There is also a hole at the end of the pin.

- A locking nut should be prepared on the free end of the stud, with a washer placed on top of it.

In order for the equipment to be stable on the platform of the drilling machine, it is necessary to make a base. It is proposed to use a 20*20 mm corrugated pipe as this element. The length of the workpieces can be made different, taking into account the size of the working base of the drilling machine.

For sponges, it is proposed to use strips made from old files. They should first be calcined to ensure strength and two holes should be drilled in each of them for fastening the bolts.

Each part should be sanded individually or cleaned with a wire brush to remove burrs and other metal defects.

Some details have been prepared. You can start making the device.

Manufacturing process

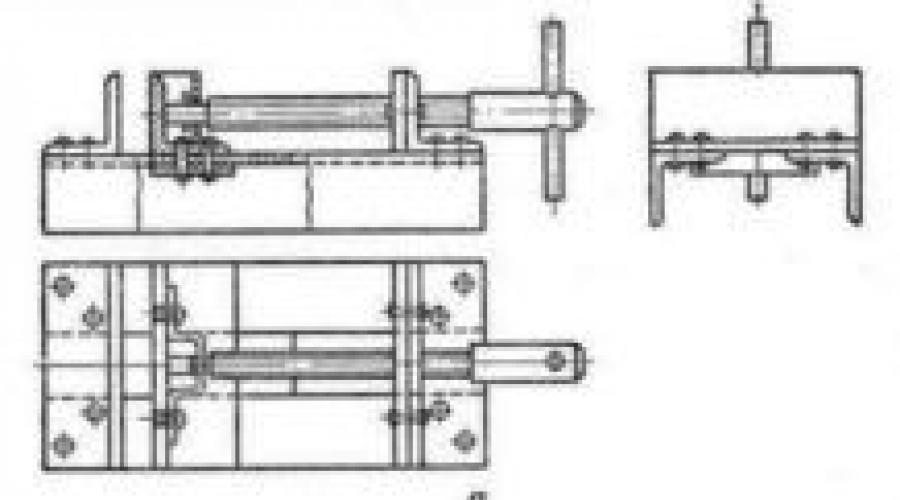

A homemade vice for a drilling machine should be assembled in stages.

Work technology:

- A 20*40 mm profile is installed between a piece of corrugated pipe at a distance of approximately 1/3 from one edge.

- It is recommended to secure the parts to bolted connections so that they can be periodically disassembled and lubricated with technical oil.

- Place the metal plate flat on the side 2/3 of the installed profile, capturing both corrugated pipes.

- This part will be welded on.

- On the opposite side of the base, weld a corner 8 cm long in the center.

- WITH inside a sponge will be attached to it with bolts.

- A 10 cm long corner will be located opposite a smaller corner. And accordingly, the second jaw is also attached to the bolts.

- The jaws should be positioned clearly opposite each other.

- Place the prepared pin with the end on which the nut is located. metal plate. To ensure the rigidity of the connection, welding must be performed.

- The same pin with a washer at the end should be welded to the corner, which will provide direct contact with the workpiece.

- At the free end of the stud, a bolt or screw is installed in the hole of the washer to facilitate rotational movements.

Upon completion of work, it is necessary to clean the equipment with a wire brush, degrease with a solvent, prime and paint the metal surface. This will provide protection from external influences and temperature changes.

The equipment is prepared and drilling machine staffed Hole drilling operations can now be carried out with confidence.

How the equipment works

Homemade vices perform their intended function as follows:

- The free end of the pin with a screw at the end is turned out, which makes it possible to move the movable jaw away from the fixed one.

- A workpiece is placed between the jaws, with markings made in advance for drilling a hole.

- The pin is twisted until the workpiece is securely clamped.

The workpiece is now placed on the work platform and the drill press is ready to start and perform tasks.

Safety precautions

When performing work, do not forget about your own safety. List of occupational safety measures:

- Wear clothing that protects areas open areas bodies.

- Shoes must be closed type(you cannot work in sandals, flip-flops or slippers).

- Use safety glasses, or better yet, a face shield.

- There must be a headdress on the head.

- There should be no foreign objects in the workplace.

Bench vices are necessary equipment in the workshop of any man, without whom it is difficult to do in one form or another of work.

It is not at all necessary to place them in the garage; you can set up a corner for a vice at home, for example, using a table or an ordinary stool.

Why do you need a bench vise?

When processing or sharpening any part, it is necessary to fix it firmly and reliably, that is, to hold it in a certain position. The photo of the vice shows the operating principle of this equipment.

The parameters and dimensions of the vice are determined depending on what type of tool needs to be firmly held.

The design of a carpenter's vice includes:

- chassis screw;

- handle;

- movable and fixed sponge;

- base plate.

Main types of bench vices

Before making a vice with your own hands, you need to decide on the choice of work associated with it.

All types of vices are divided into two types:

- non-rotary have more simple design and they are easiest to make yourself. The part is fixed strictly in one position.

- Rotary vices are most often adapted for drilling on a machine. During operation, it is possible to rotate the workpiece without unclenching it.

The body material of the vice is most often made of durable cast iron. It is important to know that cast iron is not intended to be exposed to high temperatures, steel metal is suitable for these purposes.

If the work will be carried out with small-sized parts, you should not increase financial costs and make compact small vices.

A small vice with a ball joint base is useful on the farm for processing very small parts that can be secured individually. These are mini-vises with suction cups, mounted on a glass or well-polished surface. But they are suitable for rare non-serious work.

Please note that it is wise to install soft attachments on the fastening part to work with soft details so as not to provoke their damage. A vice with the least amount of play when the jaws are fully extended is the ideal option.

A vice without rotary mechanism, unless, of course, it is useful in work.

Work on making a bench vice at home

Carpenter's vices, made independently at home, will save significantly family budget than their store-bought ready-made “brothers”. And a huge plus is that the product can be made according to personal preferences and for certain individual species works

It is absolutely easy to find material for the structure, it could be: a part technical pipe, used jack, old lathes, presses, etc.

And if you go to a metal collection point, there will undoubtedly be a suitable part for a vice that will cost you a penny.

Classic homemade vice

There are many types of vices, but the most popular and traditional is the type with steel material. Such a vice will be much more reliable than a factory-made one.

The structure consists of:

Note!

- a steel plate of at least 3 mm, but it can be much thicker;

- external and internal channel (120 and 100 mm);

- steel lugs;

- turning cutters 2 pieces;

- a small piece of reinforcement (rod for a gate);

- a nut (2 pieces), a pin or a screw of a certain diameter that corresponds to the rod;

- washer (2 pieces) of the same diameter with the lead screw;

- screw pair 335 mm;

- To secure the propeller chassis, a thick plate is needed.

It is necessary to separate the lead screw with washers on both sides of the plate. One of the two washers must be secured with a cotter pin or a locking ring, so that the part is completely dismountable; you must first weld the screw thread to it.

The handle should also be collapsible on one side, and reverse side It is worth welding it with a nut. It is necessary to weld a nut with a channel from the screws flush to the plate. To make the channel inside with the screw move easier while moving, it is recommended to lightly process it with a file.

Sponges are welded to the so-called ears, made from turning cutters. They are placed on Right place When the lead screw is screwed in, the ears stand at the perfect distance from each other.

But you can also connect them with wire for greater convenience, so in the future it will be more convenient to fix uneven parts, the shape of which is expanded towards the bottom.

Such homemade vice Allows you to process larger parts.

Note!

To perform work in a home workshop, it is recommended to choose the simplest fixed vice for the machine.

It’s not at all difficult to make them yourself; you just have to watch the videos and recommendations, which can be easily found on the Internet and first draw up the drawings correctly.

DIY vise photo

Note!

The presence of a vice allows you to expand the range of work and increase their efficiency. After all, securely fastened parts are easier to process and their quality is higher. Depending on the work being carried out and the characteristics of the objects being processed, a vice of certain sizes and parameters is selected. It can be small models, easily fit on kitchen table, stool and more massive ones for large parts. With a little ingenuity and hard work, you can make any of them yourself.

Features of assembly of clamping devices

Vices are used to hold various parts in a given position, which facilitates and increases the accuracy of their processing. All of them are divided into two groups: carpentry and metalworking. The latter are intended primarily for working with soft materials: wood, plastic, etc. Machine tools are used to work with hard materials, so the clamping jaws have a lower protrusion height for ease of processing products.

When making a vice at home, in order to optimally adapt it to your needs, you can make any changes to the design of the standard model. For example, to process small parts provide a rotating mechanism. When planning to make a vice with your own hands, pay attention to the following nuances:

- Material. To increase the reliability and durability of the product, high-quality steel is chosen.

- Product size. If you have to process mainly small parts, then it is better to make a compact model.

- Thread pitch. Fine threads ensure efficient clamping and smooth operation.

- Sponges. Their size and shape are chosen taking into account the material and type of workpiece. Flat jaws are less damaging to soft materials.

Tubular vice design

Homemade clamps can be made from any available materials. For example, a fairly simple and effective design is made from metal pipes. To do this, it is necessary to select pipes in such a way that one of them fits tightly into the other. Productsmust be seamless without internal weld seam . The size is arbitrary, as it is selected based on the purpose clamping device and characteristics of the processed parts.

The manufacturing procedure will be as follows:

- Supports are welded to the bottom of a larger diameter pipe, which will serve as the basis of the structure. On the back side - back wall from steel sheet 3-5 mm thick, with pre- drilled hole and a welded running nut. Opposite the front support, a rear fixed jaw is welded at the top point.

- Another steel plug 3-5 mm thick is welded on the outside of the movable pipe. To move it, a fastener is made from a stud, lock nuts and thrust washers. At the protruding end of the stud, an eye is welded for inserting a knob. The front jaw is attached to the top point of the movable pipe.

- At the final stage, hardened steel plates with pre-applied notches are screwed onto the jaws. Their presence will increase the clamping area and ensure reliable fixation of the objects being processed.

To facilitate movement on all moving parts: surface inner pipe, stud threads - apply a grease that has low fluidity.

Clamps are made from a square or rectangular profile in a similar way. Their main advantage is the longitudinal movement of the moving part in the complete absence of rotation, which is typical for a tubular structure.

Vice from corners

A simple bench vise can be made from metal corners of any size. In addition to them you will need following materials and tools:

- metal rod with a diameter of 20 mm for making a lead screw;

- pins for guides in the amount of two units, but in a simpler design they are not used;

- bolts, nuts, washers;

- electric drill, welding machine, hammer, file, hacksaw.

The sequence of actions will be as follows:

- The lead screw is made from a rod. Since it is difficult to make a screw of the required characteristics at home, it is better to entrust this operation to specialists.

- A base is created from two longitudinal and transverse corners; in the lower part, plates with ready-made holes are necessarily welded through which the machine vice will be attached to any stable surface.

- The fixed jaw is already welded and is part of the base. Therefore, having drilled a hole in it required size (equal to the diameter screw), weld the nut under the lead screw. The thread can be cut directly into the body of the angle, but a nut is a more reliable option.

- The movable jaw is made separately, always providing for a fastening mechanism. To do this, a U-shaped plate is welded on the reverse side. A hole is drilled at the end of the screw for a pin, which is used to secure the pre-inserted washer.

- Guide pins are attached to the sides of the jaws, but their presence is not a prerequisite.

On last stage, securing ready product to the working base, check the operation of all mechanisms.

It is very difficult to hold a metal workpiece with your hands and process it at the same time; in this case, we recommend making DIY machine vise. If you need to rigidly fix a part at an angle, you won’t envy the master at all. For such work, a vice is simply necessary. But most manufacturers do not include accessories, which automatically increases the cost of the equipment. Factory milling vices are relatively inexpensive and, nevertheless, some craftsmen manage to make homemade analogues with their own hands.

Corrugations on jaws reduce the supporting surface area and increase the holding force therefore, it is advisable to have them on a bench vice. But on drilling machines, the force is applied differently, so you can do without corrugations. But if you really want, you can make longitudinal corrugations (along the long side) and a couple of transverse ones to hold round parts. Corrugations are made at angle grinder help and a guide pressed with clamps to the jaws. Good jaws for drilling vices can be made from a coarse file. Pieces of file can be glued to the vice on epoxy resin with the addition of metal dust (aluminum powder). An important addition to the drill vise jaws is a step

DIY machine vice video

Making a rotary vice with your own hands

To make a rotary vice with your own hands, you need skills in metalworking, welding and appropriate equipment. Homemade device made by hand from stainless steel.

- A clamp is made that will hold a homemade vice on the workbench.

- We cut out two steel plates with our own hands, in which we drill 3 holes for the guides. We weld the carriage and assemble the structure: insert a threaded pin into the middle hole, and smooth pins along the edges - guides for the pressure jaw. We attach a handle to the free end of the screw pin for ease of control.

- We screw a fixed jaw onto the bolts with our own hands, we recess the bolt heads into the tangent surface, we place the nuts with outside. To make a holder for the pressure jaw, we use welding. The holder is a corner with three triangular stiffeners. The horizontal part of the holder is bolted to the carriage. We also fix the sponge itself with bolts. This will allow you to change the jaws in the future, for example, you can make additional ones from a corner for fixing pipes.

- We make a hinge with our own hands to change the position of the workpiece. To do this again you will have to use welding machine. The position is secured using a threaded pin and a pair of nuts.

You can make your own vice from scrap materials. For this, screws with a 20 mm thread and a length of 150 mm are used. They can be removed from sports corner. The threads of such screws are designed to withstand significant loads.

Homemade carpentry vices can be made from scrap materials.

Design features

It is recommended to make a carpenter's vice with your own hands using long screws. The distance between the jaws of the tool depends on this indicator. The studs are replaced with other fasteners. To secure the handle in the screw, you will need to make a slot. If necessary, expand the hole with a file.

A homemade tool must be equipped with a screw and a ring. A fixed sponge is made from a board. She is nailed to the table. To do moving part workbench, you will need a board 20 mm thick and 18 mm wide. The length of the sponge should be 50 cm.

To make a hole for the screw, use a feather drill. It is recommended to first adjust it to a diameter of 21 mm. To make a hole for the studs, you will need a drill with a diameter of 10 mm. Screws and studs are inserted into the holes.

In order for a homemade vice to process short workpieces, the pins are rearranged. 2 additional holes are made in the board. To work with long boards, a drilling machine with long screws is made.

Application of pressed nuts

Carpentry tools with a pressed nut are made from metal staples. To prevent the key from breaking off the nut when clamping the workpiece, it must be pressed in. To do this, you will need to heat the key jaws over a fire.

Carpentry tools can be made from shock absorbers and M18 nuts. Holes are made in the corners of 1 elements. To fix them together, bolts with a countersunk head are used. For self-made The following materials can be used for the vice:

- metallic profile;

- hairpin;

- nuts;

- welding;

- corners.

First, 2 sections are cut from the profile. The third strip is cut lengthwise at an angle. The bottom is cut out of a long strip using magnetic corners. The workpieces are tried on and cleaned to ensure good adhesion with the welding machine. The vice support is aligned with magnetic angles. The next stage involves welding the last elements and support. To give the tool greater strength, metal strips are used.

Additional work

Diagram of a carpenter's vice.

The front lip of the vise is then welded to the guide. It is first placed with the cutout facing down. The next step is to manufacture the frame. A metal strip is welded to the last element. Its tasks include limiting the travel of the guide and holding the threaded fastener.

The nuts are welded to the frame. The stud is screwed in first. The hole for the rod is marked and drilled in the plate. The last part is welded on. Steel fastener screwed to the frame. The nut is screwed onto the 1st element.

The rod is inserted onto the frame so that the pin passes through the hole. 2 nuts are screwed on top. The pipe is passed through it. Excess pieces of metal tape are cut off. The rear lip is welded to the workpiece and to the bed. If necessary homemade instrument paint. To do this, you will need to clean them with a felt circle, the rod is lubricated with a special lubricant. The vice is being assembled.

Conclusion on the topic

At home, you can make metalworking and carpentry vices. To make 2 tools, use water and gas pipes. It is necessary to select pipes with different diameters. A product with a smaller diameter is inserted into a larger analogue and fixed by electric welding.

The smaller product is equipped with a flange with an M18 nut. The threaded rod is inserted into small pipe so that the pre-fixed nut rests against the flange with big hole. Other fastener screws onto the protruding end of the pin. A welding machine is used to fix the 1st element.

The end of the threaded rod is screwed into the nut of a pipe with a large diameter. The next step is to install the pressure plate and support plate on the vice. Sponges are made from square pipe, and the paws are from the corner.

For ease of use, a nut is welded to the protruding end of the stud. In this case, the possibility of installing a metal rod in it is taken into account. This technology will allow you to rotate the axis while easily controlling the vice.

Homemade vices may have some negative characteristics:

- simultaneous rotation of the inner tube with the pin;

- the pipe must be in the appropriate position (this will require installing a clamp).

When making a homemade vice from 2 scraps in the shape of squares, you should adhere to the technology described above.