Width of load-bearing brick wall. Thickness of brick external walls

For increase

click on the photo

All of them offer and implement certain space-planning and Constructive decisions. What is the essence of the approach to the thickness of the walls of your future home? Let's still figure out what determines the thickness of the walls according to GOST of a brick building.

Brick is reliable and efficient material for construction, which has excellent load-bearing capacity. Brick wall laid with a thickness of 250mm, i.e. “in one brick”, impeccably withstands high loads.

Reinforced concrete, metal and wooden structures can be supported on such a load-bearing wall, the thickness of which is 0.25 m.

Large wall thicknesses according to GOST are due to the goal of increasing the thermal performance of the building, as well as noise insulation qualities. This may be due to the location of the structure close to noise sources - highways, interchanges or airports, industrial zones. The climate of the region is also taken into account and the thickness of the walls of the building directly depends on it.

Brick has a fairly high thermal conductivity and therefore, in order to maintain a given temperature, it is necessary to increase the thermal insulation of the external walls of the building.

For example, to create comfortable temperature and humidity in wooden building 200 mm is enough for wall thickness according to GOST. For brick walls, under equal conditions, this figure should be 640 mm. When the thickness of the walls increases according to GOST, the load on the foundation increases proportionally, which entails a significant increase in construction costs.

There are several ways to increase the heat and sound insulation of brick walls:

Increase in thickness brickwork up to 510mm - “two bricks”;

- creation during the construction of a wall air cushion. This technology called "well masonry". The bottom line is that the wall is laid out from two parallel parts into one brick, between which a space is left, which is filled with insulation. It could be expanded clay, slag, lightweight concrete, expanded polystyrene. Thus, the mass of the wall, with the same thickness, decreases, and the insulation capacity increases.

- construction of a ventilated facade using siding, insulating panels, various plaster, facing bricks;

Insulation of the facade with various thermal insulation materials with plastering.

When installing facade insulation the thickness of the load-bearing wall can be 250 mm, 380 mm with a masonry thickness of one and a half bricks, 510 or 480 mm. The difference in wall thicknesses of 1-3 cm is due to the presence of a centimeter layer of binder material located between the brickwork elements.

Brick was and still remains one of the main building materials in low-rise construction. The main advantages of brickwork are strength, fire resistance, and moisture resistance. Below we will provide data on brick consumption per 1 sq.m. for different thicknesses of brickwork.

Currently, there are several ways to make brickwork (standard brickwork, Lipetsk brickwork, Moscow, etc.). But when calculating brick consumption, the method of making brickwork is not important, the thickness of the masonry and the size of the brick are important. Brick is produced various sizes, characteristics and purpose. Main standard sizes bricks are considered to be the so-called “single” and “one and a half” bricks:

size " single"brick: 65 x 120 x 250 mm

size " one and a half"brick: 88 x 120 x 250 mm

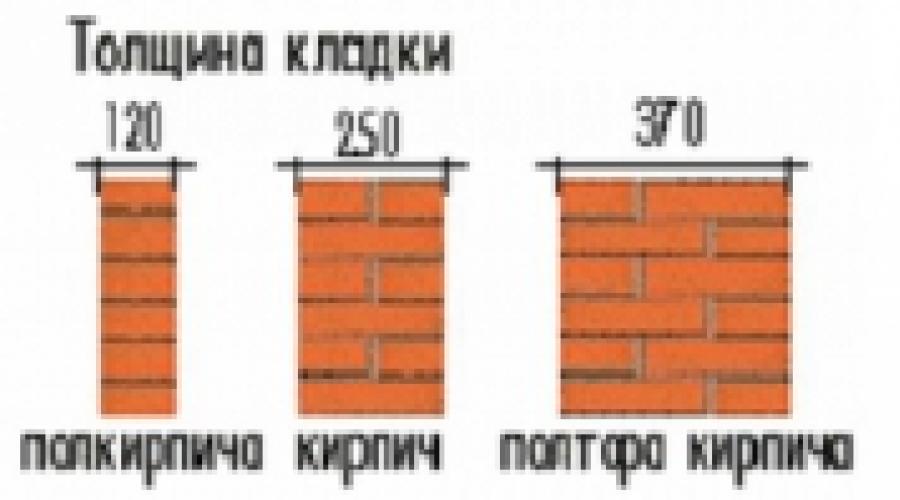

In brickwork, as a rule, the thickness of a vertical mortar joint averages about 10 mm, and the thickness of a horizontal joint is 12 mm. Brickwork Available in different thicknesses: 0.5 bricks, 1 brick, 1.5 bricks, 2 bricks, 2.5 bricks, etc. As an exception, quarter-brick brickwork is found.

Quarter brick masonry is used for small partitions that do not bear loads (for example, brick partition between the bathroom and the toilet). Half-brick brickwork is often used for one-story outbuildings(barn, toilet, etc.), gables residential buildings. You can build a garage by laying one brick. For the construction of houses (residential premises), brickwork with a thickness of one and a half bricks or more is used (depending on the climate, number of floors, type of floors, individual characteristics buildings).

Based on the given data on the size of the brick and the thickness of the connecting mortar joints, you can easily calculate the number of bricks required to build 1 sq.m of wall made of brickwork of various thicknesses.

Wall thickness and brick consumption for different brickwork

The data is given for a “single” brick (65 x 120 x 250 mm), taking into account the thickness of the mortar joints.

| Type of brickwork | Wall thickness, mm | Number of bricks per 1 sq.m of wall |

| 0.25 bricks | 65 | 31 |

| 0.5 bricks | 120 | 52 |

| 1 brick | 250 | 104 |

| 1.5 bricks | 380 | 156 |

| 2 bricks | 510 | 208 |

| 2.5 bricks | 640 | 260 |

| 3 bricks | 770 | 312 |

Greetings to all readers! What should be the thickness of brick exterior walls is the topic of today’s article. The most commonly used walls made of small stones are brick walls. This is due to the fact that the use of brick solves the problems of creating buildings and structures of almost any architectural form.

When starting to carry out a project, the design firm calculates all structural elements– including calculating the thickness of the brick exterior walls.

The walls in a building perform various functions:

- If the walls are only an enclosing structure– in this case, they must meet thermal insulation requirements in order to ensure a constant temperature and humidity microclimate, and also have sound insulating qualities.

- Load-bearing walls must have the necessary strength and stability, but also as an enclosing material, have heat-shielding properties. In addition, based on the purpose of the building and its class, the thickness of the load-bearing walls must correspond to the technical indicators of its durability and fire resistance.

Features of calculating wall thickness

- The thickness of the walls according to thermal engineering calculations does not always coincide with the calculation of the value based on strength characteristics. Naturally, the more severe the climate, the thicker the wall should be in terms of thermal performance indicators.

- But in terms of strength, for example, it is enough to lay out the outer walls in one or one and a half bricks. This is where it turns out to be “nonsense” - the thickness of the masonry, a certain thermotechnical calculation, often, due to strength requirements, it turns out to be excessive.

- Therefore, laying solid masonry walls from solid brick from the point of view of material costs and subject to 100% use of its strength should only be lower floors high-rise buildings.

- In low-rise buildings, as well as in upper floors In multi-storey buildings, hollow or lightweight bricks should be used for external masonry; lightweight masonry can be used.

- This does not apply to external walls in buildings where there is a high percentage of humidity (for example, in laundries, baths). They are usually built with protective layer from vapor barrier material from the inside and from a solid clay material.

Now I’ll tell you about the calculation of the thickness of the external walls.

It is determined by the formula:

B = 130*n -10, where

B – wall thickness in millimeters

130 – size of half a brick, taking into account the seam (vertical = 10mm)

n – integer half of a brick (= 120mm)

The calculated value of the solid masonry is rounded up to the whole number of half-bricks.

Based on this, the following values (in mm) of brick walls are obtained:

- 120 (a brick floor, but this is considered a partition);

- 250 (into one);

- 380 (at one and a half);

- 510 (at two);

- 640 (at two and a half);

- 770 (at three o'clok).

In order to save material resources (bricks, mortar, fittings, etc.), the number of machine hours of mechanisms, the calculation of wall thickness is tied to bearing capacity building. And the thermal component is obtained by insulating the facades of buildings.

How can you insulate the external walls of a brick building? In the article insulating a house with polystyrene foam from the outside, I indicated the reasons why brick walls cannot be insulated with this material. Check out the article.

The point is that brick is a porous and permeable material. And the absorbency of expanded polystyrene is zero, which prevents the migration of moisture outward. That is why it is advisable to insulate a brick wall heat-insulating plaster or mineral wool slabs, the nature of which is vapor permeable. Expanded polystyrene is suitable for insulating concrete or reinforced concrete bases. “The nature of the insulation must correspond to the nature of the load-bearing wall.”

There are many heat-insulating plasters– the difference lies in the components. But the principle of application is the same. It is performed in layers and the total thickness can reach up to 150mm (for large values, reinforcement is required). In most cases, this value is 50 - 80 mm. It depends on the climate zone, the thickness of the base walls, and other factors. I will not go into detail, since this is the topic of another article. Let's return to our bricks.

The average wall thickness for an ordinary clay brick depending on the area and climatic conditions terrain at the winter average ambient temperature looks in millimeters something like this:

- — 5 degrees — thickness = 250;

- — 10 degrees = 380;

- — 20 degrees = 510;

- - 30 degrees = 640.

I would like to summarize the above. We calculate the thickness of external brick walls based on the strength characteristics, and solve the heat-technical side of the issue using the method of wall insulation. As a rule, a design firm designs external walls without the use of insulation. If the house is uncomfortably cold and the need for insulation arises, then carefully consider the selection of insulation.

Before we begin to consider issues related to calculating the thickness brick wall at home, you need to understand why it is needed. For example, why can’t we build outer wall half a brick thick, because brick is so hard and durable?

Many non-specialists do not even have a basic understanding of the characteristics of enclosing structures, however, they undertake independent construction.

In this article we will look at two main criteria for calculating the thickness of brick walls - load-bearing loads and heat transfer resistance. But before you dive into boring numbers and formulas, let me explain some points in simple language.

The walls of a house, depending on their place in the project diagram, can be load-bearing, self-supporting, non-load-bearing and partitions. Load-bearing walls perform an enclosing function and also serve as supports for slabs or floor beams or roof structures. The thickness of load-bearing brick walls cannot be less than one brick (250 mm). Majority modern houses built with walls of one or 1.5 bricks. Projects of private houses, which would require walls thicker than 1.5 bricks, logically should not exist. Therefore, choosing the thickness of the outer brick wall according to by and large- the matter is decided. If you choose between a thickness of one brick or one and a half, then from a purely technical point of view, for a cottage with a height of 1-2 floors, a brick wall with a thickness of 250 mm (one brick of strength grade M50, M75, M100) will correspond to the calculations of load-bearing loads. There is no need to play it safe, since the calculations already take into account snow, wind loads and many coefficients that provide a brick wall with a sufficient margin of safety. However, there is very important point, which really affects the thickness of a brick wall - stability.

Everyone once played with cubes in childhood, and noticed that the more cubes you stack on top of each other, the less stable the column of them becomes. The elementary laws of physics that act on cubes act in exactly the same way on a brick wall, because the principle of masonry is the same. Obviously, there is a certain relationship between the thickness of the wall and its height, ensuring the stability of the structure. We will talk about this dependence in the first half of this article.

Wall stability, as well as construction standards for load-bearing and other loads, are described in detail in SNiP II-22-81 “Stone and reinforced masonry structures”. These standards are a guide for designers, and for the “uninitiated” they may seem quite difficult to understand. This is true, because to become an engineer you need to study for at least four years. Here we could refer to “contact specialists for calculations” and call it a day. However, thanks to the capabilities of the information web, today almost everyone can understand the most complex issues if they wish.

First, let's try to understand the issue of the stability of a brick wall. If the wall is high and long, then the thickness of one brick will not be enough. At the same time, excess reinsurance can increase the cost of the box by 1.5-2 times. And this is a lot of money today. To avoid wall destruction or unnecessary financial expenses, let’s turn to mathematical calculations.

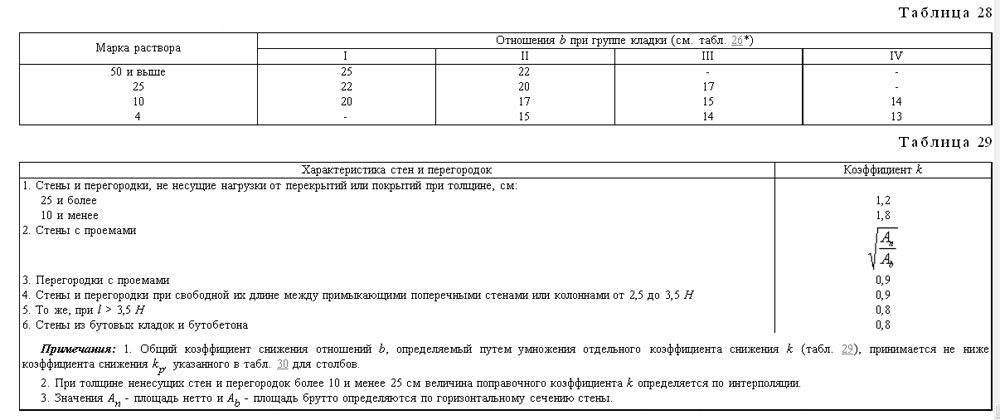

All the necessary data for calculating the stability of the wall are available in the corresponding tables of SNiP II-22-81. On specific example Let's consider how to determine whether the stability of an external load-bearing brick (M50) wall on an M25 mortar with a thickness of 1.5 bricks (0.38 m), a height of 3 m and a length of 6 m with two window openings of 1.2 × 1.2 m is sufficient .

Turning to table 26 (table above), we find that our wall belongs to the first group of masonry and fits the description of point 7 of this table. Next we need to find out the permissible ratio of the height of the wall to its thickness, taking into account the brand masonry mortar. The required parameter β is the ratio of the height of the wall to its thickness (β=Н/h). In accordance with the data in table. 28 β = 22. However, our wall is not fixed in the upper section (otherwise the calculation was required only for strength), therefore, according to clause 6.20, the value of β should be reduced by 30%. Thus, β is no longer equal to 22, but to 15.4.

Let's move on to the definition correction factors from table 29, which will help you find the cumulative coefficient k:

- for a wall 38 cm thick, not load-bearing, k1=1.2;

- k2=√Аn/Аb, where An is the area of the horizontal section of the wall, taking into account window openings, Аb - horizontal sectional area excluding windows. In our case, An= 0.38×6=2.28 m², and Аb=0.38×(6-1.2×2)=1.37 m². We perform the calculation: k2=√1.37/2.28=0.78;

- k4 for a wall 3 m high is 0.9.

By multiplying all correction factors, we find the overall coefficient k = 1.2 × 0.78 × 0.9 = 0.84. After taking into account the set of correction factors β =0.84×15.4=12.93. This means that the permissible ratio of the wall with the required parameters in our case is 12.98. Available ratio H/h= 3:0.38 = 7.89. This is less than the permissible ratio of 12.98, and this means that our wall will be quite stable, because condition H/h is satisfied<β.

According to clause 6.19, one more condition must be met: the sum of height and length ( H+L) the wall must be less than the product 3kβh. Substituting the values, we get 3+6=9<3×0,84×15,4×0,38=14,7. Условие соблюдено с большим запасом. Проведите самостоятельно расчет устойчивости аналогичной стены, но толщиной в один кирпич (0,25 м), и узнайте, будет ли ее устойчивость допустимой.

Brick wall thickness and heat transfer resistance standards

Today, the overwhelming majority of brick houses have a multi-layer wall structure, consisting of lightweight brickwork, insulation and facade finishing. According to SNiP II-3-79 (Building heating engineering) external walls of residential buildings with a requirement of 2000°C/day. must have a heat transfer resistance of at least 1.2 m².°C/W. To determine the calculated thermal resistance for a specific region, it is necessary to take into account several local temperature and humidity parameters. To eliminate errors in complex calculations, we offer the following table, which shows the required thermal resistance of walls for a number of Russian cities located in different construction and climatic zones in accordance with SNiP II-3-79 and SP-41-99.

Heat transfer resistance R(thermal resistance, m².°C/W) of the layer of the enclosing structure is determined by the formula:

R=δ /λ , Where

δ - layer thickness (m), λ - coefficient of thermal conductivity of the material W/(m.°C).

To obtain the total thermal resistance of a multilayer enclosing structure, it is necessary to add up the thermal resistances of all layers of the wall structure. Let's consider the following using a specific example.

The task is to determine how thick a sand-lime brick wall should be so that its thermal conductivity resistance matches SNiP II-3-79 for the lowest standard 1.2 m².°C/W. The thermal conductivity coefficient of sand-lime brick is 0.35-0.7 W/(m°C) depending on the density. Let's say our material has a thermal conductivity coefficient of 0.7. Thus, we obtain an equation with one unknown δ=Rλ. We substitute the values and solve: δ =1.2×0.7=0.84 m.

Now let’s calculate what layer of expanded polystyrene needs to be used to insulate a 25 cm thick sand-lime brick wall in order to reach a figure of 1.2 m².°C/W. The thermal conductivity coefficient of expanded polystyrene (PSB 25) is no more than 0.039 W/(m°C), and that of sand-lime brick is 0.7 W/(m°C).

1) determine R brick layer: R=0,25:0,7=0,35;

2) calculate the missing thermal resistance: 1.2-0.35=0.85;

3) determine the thickness of polystyrene foam required to obtain a thermal resistance equal to 0.85 m².°C/W: 0.85×0.039=0.033 m.

Thus, it has been established that in order to bring a wall made of one brick to the standard thermal resistance (1.2 m².°C/W), insulation with a layer of polystyrene foam 3.3 cm thick will be required.

Using this technique, you can independently calculate the thermal resistance of walls, taking into account the region of construction.