Heat pumps for home heating. How to make a heat pump for heating a house with your own hands: operating principle and assembly diagrams Heat pump for water

Read also

Many members of our portal have been using heat pumps for a long time and consider them the best method of heating. A heat pump is still an expensive device, and its payback period is long. But there are successful experiences of self-manufacturing heat pumps: this allows you to avoid some unrealistic costs.

- Working principle of a heat pump

- How to make a heat pump with your own hands

- Is it profitable to make a heat pump?

Working principle of a heat pump

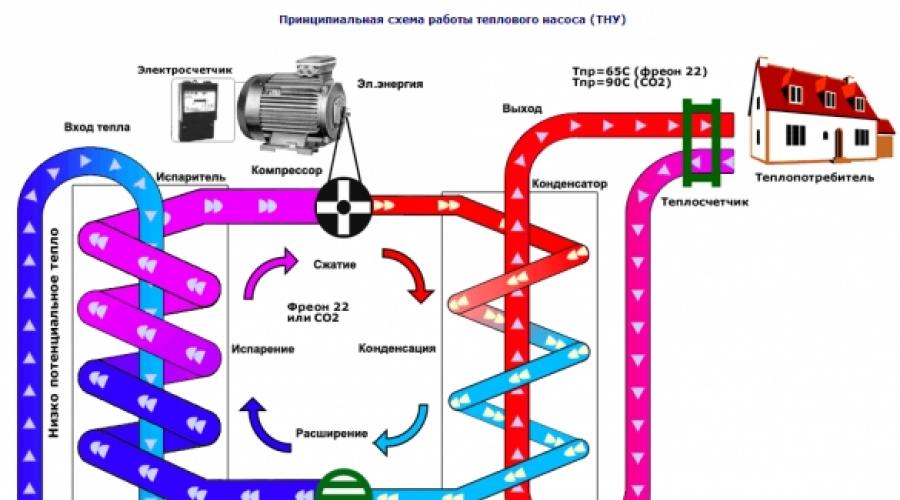

When explaining the principle of operation of a heat pump, people often recall a refrigerator, where the heat “removed” from the food in the chamber is discharged into a radiator on the back wall.

Saga FORUMHOUSE Member

The principle of operation of a heat pump is like a refrigerator: the grate on its back side is heated, the freezer is cooled. If we extend the tubes with freon and lower them into the bath, the water in it will cool, and the refrigerator grill will heat up; the refrigerator will pump heat from the bath and warm the room.

Air conditioners and heat pumps operate on the same principle. The operation of the devices is based on the Carnot cycle.

The coolant moves through the ground or water, in the process “removing” heat and raising its temperature by several degrees. In the heat exchanger, the coolant transfers the accumulated heat to the refrigerant, which becomes steam and enters the compressor, where its temperature rises. In this form, it is supplied to the condenser, transfers heat to the coolant of the OS at home, and, having cooled, again turns into liquid and enters the evaporator, where it is heated by a new portion of the heated coolant. The cycle repeats.

Although a heat pump will not work without electricity, it is a beneficial device because it produces 3-7 times more heat than it uses electricity.

We will look at this using a specific example of our user who made a heat pump with his own hands.

Heat pumps operate on energy from the body's natural sources:

- soil;

- water;

- air.

Collecting heat from the ground (below the freezing depth its temperature is always about +5 - +7 degrees) can be done in two ways:

- horizontal soil collector

- pipes laid horizontally in different ways.

“Brine” flows through the pipes - propylene glycol is often used at FORUMHOUSE, which takes the heat of the earth, transfers it to the refrigerant, and when cooled, it is sent back to the ground collector.

Today, the topic of heating the so-called private sector is extremely relevant. As practice shows, there is not always a gas pipeline there, so people are forced to look for alternative heat sources. Let's talk in this article about what a ground geothermal heat pump is or, as it is called in everyday life, a heat pump. The operating principle of this unit is not known to everyone, just like its design. We will try to sort these things out.

What do you need to know?

You can say that since heat pumps are so efficient, why are they so little widespread. The whole point is the high cost of equipment and installation. It is for this simple reason that many abandon this decision and choose, say, electric or coal boilers. Nevertheless, this option should not be discarded for many reasons, which we will definitely talk about in this article. Once installed, heat pumps become very economical because they use ground energy. A geothermal pump is a 3 in 1 pump. It combines not only a heating boiler and a hot water system, but also an air conditioner. Let's take a closer look at this equipment and consider all its strengths and weaknesses.

Operating principle of the unit

The operating principle of a heat pump for heating is to use the potential difference of thermal energy. That is why such equipment can be used in any environment. The main thing is that its temperature is at least 1 degree Celsius.

We have a coolant that moves through a pipeline, where, in fact, it heats up by 2-5 degrees. After this, the coolant enters the heat exchanger (internal circuit), where it releases the collected energy. At this time, there is refrigerant in the external circuit, which has a low boiling point. Accordingly, it turns into gas. Entering the compressor, the gas is compressed, causing its temperature to become even higher. Then the gas goes to the condenser, where it loses its heat, giving it to the heating system. The refrigerant becomes liquid and flows back into the external circuit.

Briefly about the types of heat pumps

Today there are several popular designs of geothermal pumps. But in any case, their principle of operation can be compared with the operation of refrigeration equipment. That is why, regardless of the type, the pump can be used as an air conditioner in the summer. So, heat pumps are classified according to where they can extract heat from:

- From the ground;

- From a reservoir;

- From the air.

The first type is most preferable in cold regions. The fact is that the air temperature often drops to -20 and below (using the example of the Russian Federation), but the depth of soil freezing is usually insignificant. As for reservoirs, they are not available everywhere, and it is not very advisable to use them. In any case, it is better to choose a ground source heat pump for heating your home. We looked a little at the principle of operation of the unit, so we move on.

“Ground-water”: how best to place it?

Receiving heat from the ground is considered the most appropriate and rational. This is due to the fact that at a depth of 5 meters there are practically no temperature fluctuations. A special liquid is used as a coolant. It is commonly called brine. It is completely environmentally friendly.

As for the placement method, there are horizontal and vertical. The first type is characterized by the fact that plastic pipes, representing the outer contour, are laid horizontally on the area. This is very problematic, since laying work must be carried out on an area of 25-50 square meters. In the case of a vertical arrangement, vertical wells with a depth of 50-150 meters are drilled. The deeper the probes are placed, the more efficient the geothermal heat pump will work. We have already discussed the principle of operation, and now we will talk about more important details.

Water-to-water heat pump: operating principle

Also, do not immediately discount the possibility of using the kinetic energy of water. The fact is that at great depths the temperature remains quite high and varies in small ranges, if it occurs at all. You can go several ways and use:

- Open bodies of water such as rivers and lakes.

- Groundwater (borehole, well).

- Wastewater from industrial cycles (return water supply).

From an economic and technical point of view, it is easiest to set up the operation of a geothermal pump in an open reservoir. At the same time, there are no significant design differences between ground-to-water and water-to-water pumps. In the latter case, the pipes immersed in an open reservoir are supplied with a load. As for the use of groundwater, the design and installation are more complex. It is necessary to allocate a separate well for water discharge.

Operating principle of an air-to-water heat pump

This type of pump is considered one of the least efficient for a number of reasons. Firstly, during the cold season, the temperature of air masses drops significantly. This ultimately leads to a decrease in pump power. It may not be able to cope with heating a large house. Secondly, the design is more complex and less reliable. However, installation and maintenance costs are significantly reduced. This is due to the fact that you do not need a reservoir, a well, and you also do not need to dig trenches for pipes in your summer cottage.

The system is placed on the roof of a building or in another suitable location. It is worth noting that this design has one significant advantage. It lies in the possibility of using exhaust gases and air that leaves the room again. This can compensate for the insufficient power of the equipment in winter.

Air-to-air pumps and something else

Such installations are even less common than “Air-water”, for which there are a number of reasons. As you may have guessed, in our case, air is used as a coolant, which is heated by a warmer air mass from the environment. There are a large number of disadvantages of such a system, ranging from low performance to high cost. An air-to-air heat pump, the operating principle of which you know, is not bad only in warm regions.

There are also strengths here. Firstly, the low cost of the coolant. Most likely, you will not encounter an air duct leak problem. Secondly, the effectiveness of such a solution is extremely high in the spring-autumn period. In winter, it is not advisable to use an air heat pump, the operating principle of which we have discussed.

Homemade heat pump

Studies have shown that the payback period of equipment directly depends on the heated area. If we are talking about a house of 400 square meters, then this is approximately 2-2.5 years. But for those who have a smaller home, it is quite possible to use homemade pumps. It may seem that making such equipment is difficult, but in reality it is somewhat not so. It is enough to purchase the necessary components, and you can begin installation.

The first step is to purchase a compressor. You can take the one on the air conditioner. Mount it in the same way on the wall of the building. In addition, a capacitor is needed. You can build it yourself or buy it. If you go with the first method, you will need a copper coil with a thickness of at least 1 mm; it is placed in the housing. This may be a tank of suitable dimensions. After installation, the tank is welded and the necessary threaded connections are made.

The final part of the work

In any case, at the final stage you will need to hire a specialist. It is a knowledgeable person who should carry out the soldering of copper tubes, pumping freon, as well as the first start of the compressor. After assembling the entire structure, it is connected to the internal heating system. The external circuit is installed last, and its features depend on the type of heat pump used.

Do not lose sight of such an important point as replacing outdated or damaged wiring in the house. Experts recommend installing a meter with a power of at least 40 amperes, which should be quite enough to operate the heat pump. It is worth noting that in some cases such equipment does not live up to expectations. This is due, in particular, to inaccurate thermodynamic calculations. To prevent you from spending a lot of money on heating and having to install a coal boiler in winter, contact trusted organizations with positive reviews.

Safety and environmental friendliness come first

Heating using the pumps described in this article is one of the most environmentally friendly methods. This is largely due to the reduction of carbon dioxide emissions into the atmosphere, as well as the conservation of non-renewable energy resources. By the way, in our case we use renewable resources, so there is no need to be afraid that the heat will suddenly run out. Thanks to the use of a substance that boils at low temperatures, it has become possible to implement a reverse thermodynamic cycle and, at lower energy costs, receive a sufficient amount of heat into the house. As for fire safety, everything is clear here. There is no chance of gas or fuel oil leakage, explosion, no dangerous places for storing flammable materials and much more. In this regard, heat pumps are very good.

Conclusion

Now you are completely familiar with what a heat pump is and what it can be (working principle). It is possible to make such a unit with your own hands, and in some cases it is even necessary. In this case, you can save about 30% on the purchase of equipment. But again, installation work should preferably be carried out by a specialist, and the same applies to the calculations being carried out.

Whatever one may say, today this is still a fairly expensive type of heating with a long payback period. In most cases, it is much easier to install gas or heat with coal or wood. Nevertheless, for large country houses this is a very promising type of heating. If we talk about the efficiency of the equipment, it turns out that for 1 kW of energy spent we get about 5-7 kW of heat. In terms of cooling, this is 2-2.5 kW output, which is also very good. It is also worth noting that the pump operates silently. That, in principle, is all that can be said on this topic.

Heat pump (HP) is a device that carries out the transfer, transformation and conversion of thermal energy. According to the principle of operation, it is similar to well-known devices and equipment, such as a refrigerator or air conditioner. The operation of any TN is based on the reverse Carnot cycle, named after the famous French physicist and mathematician Sidi Carnot.

Working principle of a heat pump

Let's study in more detail the physics of the operating processes of this equipment. The heat pump consists of four main elements:

- Compressor

- Heat exchanger (condenser)

- Heat exchanger (evaporator)

- Connecting fittings and automation elements.

Compressor necessary to compress and move refrigerant through the system. When freon is compressed, its temperature and pressure rise sharply (pressure develops up to 40 bar, temperature up to 140 C), and in the form of a gas with a high degree of compression it goes to the capacitor(adiabatic process, i.e. a process in which the system does not interact with external space), where it transfers energy to the consumer. The consumer can be either the immediate environment that needs to be heated (for example, indoor air) or the coolant (water, antifreeze, etc.), which then distributes energy through the heating system (radiators, heated floors, heated baseboards, convectors, fan coils, etc.). In this case, the temperature of the gas naturally decreases, and it changes its state of aggregation from gaseous to liquid (an isothermal process, i.e. a process occurring at a constant temperature).

Next, the refrigerant is in a liquid state enters the evaporator, passing through a thermostatic valve (TRV), which is necessary to reduce the pressure and dose the flow of freon into the evaporative heat exchanger. As a result of a decrease in pressure when passing through the evaporator channels, a phase transition occurs, and the state of aggregation of the refrigerant again changes to gaseous. In this case, the entropy of the gas decreases (based on the thermophysical properties of freons), which leads to a sharp drop in temperature, and heat is “removed” from an external source. The external source can be street air, the bowels of the earth, rivers, lakes. Next, the cooled gaseous freon is returned to the compressor, and the cycle repeats again.

In fact, it turns out that the heat engine itself does not generate heat, but is a device for moving, modifying and modifying energy from the environment into the room. However, this process requires electricity, the main consumer of which is the compressor unit. The ratio of the received thermal power to the expended electrical power is called the conversion factor (COR). It varies depending on the type of turbocharger, its manufacturer, and other factors and ranges from 2 to 6.

Currently, various types of ozone-friendly freons (R410A, R407C) are used as a refrigerant, which cause minimal damage to the environment.

Modern heat engines use scroll-type compressors that require no maintenance, have virtually no friction, and can operate continuously for 30-40 years. This ensures a long service life of the entire unit. For example, a German company Stiebel Eltron There are HPs that have operated without major repairs since the early 70s of the last century.

Types of Heat Pumps

Depending on the media used for the selection and redistribution of energy, as well as design features and methods of application, there are four main types of HP:

Air-to-air heat pump

This type of equipment uses street air as a low-potential energy source. Outwardly, it does not differ from a conventional split air conditioning system, but it has a number of functional features that allow it to operate at low temperatures (down to -30 C) and “remove” energy from the environment. The house is heated directly by warm air heated in the heat pump condenser.

Advantages of air-to-air HP:

- Low cost

- Short installation time and comparative ease of installation

- No possibility of coolant leakage

Flaws:

- Stable performance down to -20 C

- The need to install an indoor unit in each room or organize an air duct system to supply heated air to all rooms.

- Inability to obtain hot water (DHW)

In practice, such systems are used for seasonal housing and cannot act as the main source of heating.

Air-to-water heat pump

Their operating principle is similar to the previous type, however, they do not directly heat the air inside the room, but the coolant, which in turn is used to heat the house and prepare hot water.

Advantages of TN “Air – Water”:

- does not require the organization of an “external contour” (drilling)

- reliability and durability

- high efficiency indicators (COP) in the autumn and spring periods

Disadvantages of TN:

- Significant reduction in COP at low temperatures (up to 1.2)

- The need to defrost the external unit (reverse mode)

- Impossibility of operation at temperatures below -25 C - -30 C

Such pumps in our climate still cannot act as the only source of heating. Therefore, they are often installed (according to a bivalent scheme) in conjunction with additional heating equipment (electric, pellet, solid fuel, diesel boiler, fireplace with a water jacket). They are also suitable for the reconstruction and automation of old boiler houses using traditional fuels. This allows the system to be operated in automatic mode for most of the year (there is no need to load solid fuel or refuel diesel fuel), using only the power of the HP.

Brine-water heat pump

One of the most common in the Republic of Belarus. Using statistics from our organization, 90% of installed heat pumps are geothermal. In this case, the bowels of the earth are used as the “external contour”. Due to this, these heat pumps have the most important advantage over other types of heat pumps - a stable operating efficiency indicator (COP) regardless of the time of year.

According to established terminology, the external circuit is called geothermal.

There are two main types of geothermal circuit:

- Horizontal

- Vertical

Let's look at each of them in more detail.

Horizontal outline

Horizontal outline is a system of polyethylene pipes laid under the top layer of soil at a depth of about 1.5 - 2 m, below the freezing level. The temperature in this zone remains positive (from +3 to +15 C) throughout the calendar year, reaching a maximum in October and a minimum in May. The area occupied by the collector depends on the area of the building, the degree of its insulation, and the size of the glazing. So, for example, for a two-story residential building with an area of 200 m2, which has good insulation that meets modern standards, about four acres of land (400 m2) will have to be allocated for a geothermal field. Of course, for a more accurate assessment of the diameter of the pipes used and the occupied area, a detailed thermal engineering calculation is required.

This is what the installation of a horizontal collector looks like at one of our facilities in Dzerzhinsk (Republic of Belarus):

Advantages of a horizontal collector:

- Lower cost compared to geothermal wells

- Possibility of carrying out work on its installation together with the laying of other communications (water supply, sewerage)

Disadvantages of a horizontal collector:

- Large occupied area (it is prohibited to erect permanent structures, pave asphalt, lay paving slabs, it is necessary to ensure natural access to light and precipitation)

- Lack of possibility of arrangement with ready-made landscape design of the site

- Less stability compared to a vertical collector.

The arrangement of this type of collector is usually carried out in two ways. In the first case over the entire laying area, remove the top layer of soil, 1.5-2m thick, the heat exchanger pipes are being laid out with a given step (from 0.6 to 1.5 m) and backfilling is carried out. To perform such work, powerful equipment is suitable, such as a front loader, bulldozer, excavators with a large reach and bucket volume.

In the second case Laying the ground contour loops is carried out step by step in prepared trenches, width from 0.6 m to 1 m. Small excavators and backhoe loaders are suitable for this purpose.

Vertical outline

Vertical collector represents wells with depths from 50 to 200 m and more, into which special devices are lowered - geothermal probes. The temperature in this zone remains constant for many years and decades and increases with increasing depth. The increase occurs on average by 2-5 C for every 100 m. This characterizing value is called the temperature gradient.

The process of installing a vertical collector at our facility in the village of Kryzhovka, near Minsk:

Studying maps of temperature distribution at various depths on the territory of the Republic of Belarus and the city of Minsk in particular, one can notice that the temperature varies from region to region, and can differ significantly depending on location. So, for example, at a depth of 100 m in the area of Svetlogorsk it can reach +13 C, and in some areas of the Vitebsk region at the same depth it does not exceed +8.5 C.

Of course, when calculating the drilling depth and designing the size, diameter and other characteristics of geothermal probes, it is necessary to take this factor into account. In addition, it is necessary to take into account the geological composition of the rocks being passed through. Only based on this data can you correctly design a geothermal circuit.

As the practice and statistics of our organization show, 99% of problems during the operation of HP are associated with the functioning of the external circuit, and this problem does not appear immediately after commissioning of the equipment. And there is an explanation for this, because if the geocontour is incorrectly calculated (for example, in the territory of the Vitebsk region, where, as we remember, the geothermal gradient is one of the lowest in the Republic), its initial work is not satisfactory, but over time the thickness of the earth “cools” The thermodynamic balance is disrupted and troubles begin, and the problem can arise only in the second or third heating season. An oversized contour looks less problematic, but the customer is forced to pay for unnecessary meters of drilling due to the incompetence of the contractor, which inexorably leads to an increase in the cost of the entire project.

The study of the subsoil of the earth should be especially critical during the construction of large commercial facilities, where the number of wells is in the dozens, and the funds saved (or wasted) on their construction can be very significant.

Water-to-water heat pump

One type of geothermal heat source can be groundwater. They have a constant temperature (from +7 C and above), and occur in significant quantities at various depths in the territory of the Republic of Belarus. According to the technology, groundwater is lifted from a well by a centrifugal pump and enters a heat and mass transfer station, where it transfers energy to the antifreeze of the lower circuit of the heat pump. The operating efficiency of this system depends on the level of groundwater (depending on the depth of rise, a certain pump power is required), and the distance from the intake well to the exchange station. This technology has one of the highest COP values, but has a number of features that limit its use.

Among them:

- Lack of groundwater, or low level of its occurrence;

- Lack of constant well flow, decrease in static and dynamic levels;

- The need to take into account the salt composition and contamination (if the water quality is not adequate, the heat exchanger becomes clogged and performance indicators decrease)

- The need to install a drainage well to discharge significant volumes of waste water (from 2200 l/h or more)

As practice shows, the installation of such systems is advisable if there is a pond or river in the immediate vicinity. Waste water can also be used for economic and industrial purposes, for example, for irrigation, or for organizing artificial reservoirs.

As for the quality of intake water, for example, a German manufacturer of alternative heating systems Stiebel Eltron recommends the following settings: the total proportion of iron and magnesium is not more than 0.5 mg/l, the chloride content is less than 300 mg/l, the absence of precipitated substances. If these parameters are exceeded, it is necessary to install an additional purification system - a preparation and desalting station, which increases the material intensity of the project.

Drilling work for a heat pump.

Based on experience in the installation and operation of geothermal units, we recommend drilling wells of at least 100 m. Practice shows that better performance and stability of a heat engine will be observed, for example, for two wells of 150 m each than for three wells of 100 m each. Of course, the construction of such mines requires special equipment and a rotary drilling method. Small-sized auger installations are not able to provide the required length of wells.

Since the geothermal circuit is the most important component, and the correctness of its arrangement is the key to the successful functioning of the entire system, the drilling contractor must meet a number of criteria:

- It is necessary to have experience in producing this type of service;

- have a special tool for immersing probes;

- provide a guarantee that the probe will be immersed to the designed depth and guarantee its integrity and tightness during the work process;

- after immersion, carry out measures to plug the well to increase its heat transfer and productivity, caulk the shaft of the mine before backfilling.

In general, with proper design and qualified installation, geothermal probes are very reliable and can last up to 100 years.

The process of lowering a geothermal probe into a drilled well:

Geothermal probe on the frame, before performing a leak test (“pressure testing”):

conclusions

Based on our experience in the design of alternative energy systems, we can highlight the main facts that are fundamental when our Customers choose heat pumps:

- full safety and environmental friendliness(no combustion processes or moving parts)

- the opportunity to order the system “today” and enjoy using it in three weeks without any coordination with regulatory and licensing authorities.

- Full autonomy and minimal maintenance(there is no need to be a member of a gas cooperative, to depend on it; there is no need to throw firewood or carry out monthly cleaning of air ducts, organize the access of a fuel tanker, etc.)

- The cost of a plot for the construction of an individual house without gas supply is much lower and the delivery period does not depend on gas services

- Opportunity remote control via the Internet

- Advanced and innovative equipment of stylish design, which is not a shame to show to friends and acquaintances, which certainly emphasizes the status of the homeowner.

If we have not touched on any questions in this article and you want to ask them personally, you can come to our office at the address: Minsk, st. Odoevsky, 117, Nova Gros LLC and consult with our engineers.

We also have the opportunity to organize free visits to already completed operating facilities.

Contact telephone number: 044 765 29 58; 017 399 70 51

A heat pump is a vapor compression unit that transfers heat from cold, low-grade heat sources to hot, high-grade heat sources. Heat is transferred through condensation and evaporation of a refrigerant, which is most often used as freon, circulating in a closed circuit. The electricity from which the heat pump operates is spent only on this forced circulation.The operating principle of a heat pump is based on the so-called Carnot cycle, which is very familiar to you from the operation of refrigeration units. In fact, the household refrigerator in your kitchen is also a heat pump. When you place food in it, even if it is cold, but whose temperature is still higher than the temperature in the refrigerator chamber, according to the law of conservation of energy, the heat they generate does not go away. Since the temperature inside should not rise, heat is transferred outside through the radiator grille, warming the air in the kitchen. The more food you place in the refrigerator at the same time, the greater the heat transfer will be.

The simplest version of a heat pump would be an open refrigerator placed outside, the radiator of which is located in the room. But let the refrigerator fulfill its direct duties, because there are already special devices - heat pumps, which have much higher efficiency. The principle of their operation is quite simple.

How does a heat pump work?

Any heat pump consists of an evaporator, a condenser, an expander that reduces pressure, and a compressor that increases pressure. All these devices are connected into one closed loop by a pipeline. A refrigerant, an inert gas with a very low boiling point, circulates through the pipes, so in one part of the circuit, cold, it is a liquid, and in the second, warm, it turns into a gaseous state. The boiling point, as is known from physics, can change depending on the pressure; in this system there is an expander and a compressor.Suppose that the coolant circulates outside through pipes laid in the ground, since it has a low temperature, then passing through them, it heats up, even when the external temperature is only about 4-5 ° C. Entering the evaporator, which acts as a heat exchanger, the coolant transfers the resulting heat to the internal circuit of the system, which is filled with refrigerant. Even this heat is enough to change the refrigerant from liquid to gaseous state.

Moving further, the gas moves to the compressor, where it is compressed under the influence of high pressure, and its temperature rises. Once hot, the gas enters the condenser, which is also a heat exchanger. It transfers heat from hot gas to the coolant of the return pipeline included in the heating system of the house. Having given off heat, the gas cools and turns into a liquid state again, while the heated coolant enters the hot water supply and heating system. Passing through the pressure reducing valve of the expander, the liquefied gas again enters the evaporator - the cycle is closed.

In the cold season, heat pumps work to heat the house, and in the heat - to cool it. In this case, the principle of operation is the same, only in summer the heat enters the coolant from the interior, and not from the outside.

Design features of heat pumps

Currently, heat pumps of different designs are used. Thus, an open cycle pump is used when the house is located next to a body of water. In this case, the coolant, water, enters the open circuit, goes through the entire cycle and, cooling, is again discharged into the reservoir.Closed-type geothermal pumps pump coolant - air or water - through pipes buried deep in the ground and laid along the bottom of the reservoir. A closed cycle is considered safer in environmental terms. The closed type includes pumps with a vertical and horizontal heat exchanger, which are used when there are no bodies of water nearby. Vertical heat pumps are used when the area of land on which the house is located is small. Sometimes vertical pumps are installed in wells drilled nearby.

The package of work for installing a heat pump includes carrying out internal electrical work, laying external pipelines and internal air ducts.

Benefits of using heat pumps

The economic benefits of using heat pumps are obvious - their operation is quite cheap, since a little more electricity is spent than when operating a refrigerator. The price of the equipment is also low, as well as the cost of installation and installation. Using a heat pump allows you to get rid of worries about purchasing and storing fuel resources, installing and operating heating equipment; additional rooms in your house are freed up in which the boiler room was previously located.A heat pump is a device that heats water in heating and hot water supply systems by compressing freon, initially heated from a low-grade heat source, by a compressor to 28 bar. Under high pressure, a gaseous coolant with an initial temperature of 5-10 ° C; releases a large amount of heat. This allows you to warm up the coolant of the consumption system to 50-60 °C, without the use of traditional fuels. Therefore, it is believed that a heat pump provides the user with the cheapest heat.

For more information about the advantages and disadvantages, watch the video:

Such equipment has been in operation for more than 40 years in Sweden, Denmark, Finland and other countries that support the development of alternative energy at the state level. Not so actively, but more confidently every year, heat pumps are entering the Russian market.

Purpose of the article: review popular heat pump models. The information will be useful to those who seek to save as much as possible on heating and hot water supply of their own home.

The heat pump heats the house with free energy from nature

In theory, heat can be extracted from the air, soil, groundwater, wastewater (including from a septic tank and water pumping station), and open reservoirs. In practice, for most cases, the feasibility of using equipment that takes thermal energy from the air and soil has been proven.

Options with heat extraction from a septic tank or sewage pumping station (SPS) are the most tempting. By passing the coolant through the HP at 15-20 °C, the output temperature can be at least 70 °C. But this option is acceptable only for a hot water supply system. The heating circuit reduces the temperature in the "tempting" source. Which leads to a number of unpleasant consequences. For example, freezing of drains; and if the heat exchange circuit of the heat pump is located on the walls of the sump, then the septic tank itself.

The most popular HPs for the needs of CO and DHW are geothermal (using the heat of the earth) devices. They are distinguished by their best performance in warm and cold climates, in sandy and clayey soils with different groundwater levels. Because the soil temperature below the freezing depth remains almost unchanged throughout the year.

Operating principle of a heat pump

The coolant is heated from a source of low-potential (5...10 °C) heat. The pump compresses the refrigerant, the temperature of which rises (50...60 °C) and heats the coolant of the heating system or hot water supply.

During the operation of the HP, three thermal circuits are involved:

- external (system with coolant and circulation pump);

- intermediate (heat exchanger, compressor, condenser, evaporator, throttle valve);

- consumer circuit (circulation pump, heated floor, radiators; for hot water supply - tank, water points).

The process itself looks like this:

Thermal energy removal circuit

- The soil heats the saline solution.

- The circulation pump lifts the brine into the heat exchanger.

- The solution is cooled by a refrigerant (freon) and returned to the ground.

Heat exchanger

- Liquid freon, evaporating, takes away thermal energy from the brine.

- The compressor compresses the refrigerant, causing its temperature to rise sharply.

- In the condenser, freon transfers energy through the evaporator to the coolant of the heating circuit and becomes liquid again.

- The cooled refrigerant flows through the throttle valve to the first heat exchanger.

Heating circuit

- The heated coolant of the heating system is drawn by the circulation pump to the dissipating elements.

- Transfers thermal energy to the air mass of the room.

- The cooled coolant returns through the return pipe to the intermediate heat exchanger.

Video with a detailed description of the process:

What is cheaper for heating: electricity, gas or heat pump?

We present the costs of connecting each type of heating. To present the general picture, let’s take the Moscow region. Prices may differ in regions, but the price ratio will remain the same. In the calculations we assume that the site is “bare” - without gas or electricity.

Connection costs

Heat pump. Laying a horizontal contour at MO prices - 10,000 rubles per shift of an excavator with a bucket bucket (removes up to 1,000 m³ of soil in 8 hours). A system for a house of 100 m² will be buried in 2 days (true for loam, on which you can remove up to 30 W of thermal energy from 1 square meter of circuit). About 5,000 rubles will be required to prepare the circuit for operation. As a result, the horizontal option for placing the primary circuit will cost 25,000.

The well will be more expensive (1,000 rubles per linear meter, taking into account the installation of probes, piping them into one line, filling with coolant and pressure testing), but it will be much more profitable for future operation. With a smaller occupied area of the site, the output increases (for a 50 m well - at least 50 W per meter). The pump's needs are covered and additional potential appears. Therefore, the entire system will not work for wear, but with some reserve power. Place 350 meters of contour in vertical wells – 350,000 rubles.

A gas boiler. In the Moscow region, for connection to the gas network, work on the site and installation of the boiler, Mosoblgaz requests from 260,000 rubles.

Electric boiler. Connecting a three-phase network will cost 10,000 rubles: 550 for local electrical networks, the rest for the distribution board, meter and other contents.

Consumption

To operate a HP with a thermal power of 9 kW, 2.7 kW/h of electricity is required - 9 rubles. 53 kopecks at one o'clock,

The specific heat during combustion of 1 m³ of gas is the same 9 kW. Household gas for Moscow region is priced at 5 rubles. 14 kopecks per cubic meter

An electric boiler consumes 9 kW/h = 31 rubles. 77 kop. at one o'clock. The difference with TN is almost 3.5 times.

Exploitation

- If gas is supplied, then the most cost-effective option for heating is a gas boiler. The equipment (9 kW) costs at least 26,000 rubles, the monthly payment for gas (12 hours per day) will be 1,850 rubles.

- Powerful electrical equipment is more profitable from the point of view of organizing a three-phase network and purchasing the equipment itself (boilers - from 10,000 rubles). A warm house will cost 11,437 rubles per month.

- Taking into account the initial investment in alternative heating (equipment 275,000 and installation of a horizontal circuit 25,000), a heat pump that consumes electricity at 3,430 rubles/month will pay for itself no earlier than in 3 years.

Comparing all heating options, provided that the system is created from scratch, it becomes obvious: gas will not be much more profitable than a geothermal heat pump, and heating with electricity in the next 3 years is hopelessly inferior to both of these options.

Detailed calculations in favor of operating a heat pump can be found by watching a video from the manufacturer:

Some additions and experience of effective operation are highlighted in this video:

Main characteristics

When choosing equipment from a wide variety of specifications, pay attention to the following characteristics.

| Characteristics | Range of values | Peculiarities |

|---|---|---|

| Thermal power, kW | Up to 8 | Premises with an area of no more than 80 - 100 m², with a ceiling height of no more than 3 m. |

| 8-25 | For one-level country houses with a ceiling of 2.5 m, an area of 50 m²; cottages for permanent residence, up to 260 m². | |

| Over 25 | It is advisable to consider for 2-3 level residential buildings with ceilings of 2.7 m; industrial facilities - no more than 150 m², with a ceiling height of 3 or more. | |

| Power consumption of main equipment (maximum consumption of auxiliary elements) kW/h | From 2 (from 6) | Characterizes the energy consumption of the compressor and circulation pumps (heating elements). |

| Scheme of work | Air-to-air | The transformed thermal energy of the air is transferred into the room by a flow of heated air through a split system. |

| Air - water | The energy removed from the air passed through the device is transferred to the coolant of the liquid heating system. | |

| Brine-water | The transfer of thermal energy from a renewable source is carried out by a sodium or calcium solution. | |

| Water-water | Through the open primary circuit, groundwater carries thermal energy directly to the heat exchanger. | |

| Outlet coolant temperature, °C | 55-70 | The indicator is important for calculating losses on a long heating circuit and when organizing an additional hot heat supply system. |

| Mains voltage, V | 220, 380 | Single-phase - power consumption no more than 5.5 kW, only for a stable (lightly loaded) household network; the cheapest - only through a stabilizer. If there is a 380 V network, then three-phase devices are preferable - a larger power range, less likely to “sag” the network. |

Model summary table

In the article, we examined the most popular models and identified their strengths and weaknesses. The list of models can be found in the following table:

| Model (country of origin) | Peculiarities | price, rub. |

|---|---|---|

|

Heat pumps for heating small spaces or domestic hot water |

||

| 1. | Air-water system; works from a single-phase network; the protruding condensation line is inserted into the water tank. | 184 493 |

| 2. | "Brine-water"; power supply from a three-phase network; variable power control; possibility of connecting additional equipment - recuperator, multi-temperature equipment. | 355 161 |

| 3. | Air-water heat pump powered by 220V mains and with frost protection function. | 524 640 |

| Equipment for heating systems of cottages for permanent residence | ||

| 4. | “Water - water” scheme. In order for the HP to produce a stable 62 °C coolant in the heating system, the capabilities of the set of compressor and pumps (1.5 kW) are complemented by an electric heater with a power of 6 kW. | 408 219 |

| 5. | Based on the air-water circuit, the potentials of cooling and heating devices are realized in one device, consisting of two blocks. | 275 000 |

| 6. | “brine-water”, the device heats the coolant for radiators up to 60 °C, can be used when organizing cascade heating systems. | 323 300 |

| 7. | In the same housing with the geothermal pump there is a storage tank for the hot water supply system, for 180 liters of coolant | 1 607 830 |

| Powerful heat pumps for heating and hot water supply needs | ||

| 8. | It is possible to extract heat from soil and groundwater; operation as part of cascade systems and remote control are possible; works from a three-phase network. | 708 521 |

| 9. | "brine-water"; control of the compressor power and the rotation speed of the circulation pumps is carried out through frequency adjustment; additional heat exchanger; network – 380 V. | 1 180 453 |

| 10. | “water-to-water” operating diagram; built-in primary and secondary circuit pumps; The possibility of connecting solar systems is provided. | 630 125 |

Heat pumps for heating small spaces or domestic hot water

Purpose – economical heating of residential and auxiliary premises, maintenance of the hot water supply system. Single-phase models have the lowest consumption (up to 2 kW). To protect against power surges in the network, they need a stabilizer. The reliability of three-phase is explained by the characteristics of the network (the load is distributed evenly) and the presence of its own protective circuits that prevent damage to the device due to voltage surges. Equipment in this category does not always cope with simultaneous maintenance of the heating system and hot water supply circuit.

1. Huch EnTEC VARIO China S2-E (Germany) – from RUB 184,493.

The Huch EnTEC VARIO cannot be operated independently. Only in conjunction with the storage tank of the hot water supply system. The HP heats water for sanitary needs, cooling the air in the room.

The advantages include low energy consumption of the device, acceptable water temperature in the DHW circuit and the function of cleaning the system (by periodic short-term heating to 60 ° C) from pathogenic bacteria that develop in a humid environment.

The disadvantages are that gaskets, flanges and cuffs must be purchased separately. Be sure to be original, otherwise there will be drips.

When calculating, you must remember that the device pumps 500 m³ of air per hour, so the minimum area of the room in which the Huch EnTEC VARIO is installed must be at least 20 m², with a ceiling height of 3 meters or more.

2. NIBE F1155-6 EXP (Sweden) – from RUB 355,161.

The model is declared as “intelligent” equipment, with automatic adjustment to the needs of the object. An inverter power supply circuit for the compressor has been introduced, making it possible to adjust the output power.

The presence of such a function with a small number of consumers (water points, heating radiators) makes heating a small house more profitable than in the case of a conventional, non-inverter HP (which does not have a soft start of the compressor and the output power is not regulated). Because at NIBE, at low power values, the heating elements are rarely turned on, and the heat pump’s own maximum consumption is no more than 2 kW.

In a small facility, the noise (47 dB) is not acceptable. The optimal installation option is a separate room. Place the harness on walls not adjacent to the rest rooms.

3. Fujitsu WSYA100DD6 (Japan) – from RUB 524,640.

“Out of the box” only works for heating in one circuit. An optional kit for connecting a second circuit is available, with the possibility of independent configuration for each. But the heat pump itself is designed for heating a room up to 100 m², with a ceiling height of no more than 3 meters.

The list of advantages includes small dimensions, operation from a household power supply, adjustment of the output temperature from 8 to 55 °C, which, according to the manufacturer, should somehow affect the comfort and accuracy of control of connected systems.

But everything was canceled out by low power. In our climate, heating the declared 100 m², the device will work for wear and tear. This is confirmed by the device’s frequent transitions to “emergency” mode, with the pump turning off and errors on the display. The case is not guaranteed. Fixed by restarting the equipment.

“Accidents” affect energy consumption. Because when the compressor stops, the heating element comes into operation. Therefore, the joint connection of CO and underfloor heating (or DHW) circuits is permissible in a facility with an area of no more than 70 m².

Equipment for heating systems of standard cottages for permanent residence

Geothermal, air and water (removing thermal energy from groundwater) devices are presented here. The declared output power (at least 8 kW) is enough to provide heat to all consumer systems of country (and permanent residence) houses. Many heat pumps in this category have a cooling mode. The implemented inverter power circuits are responsible for the smooth start of the compressor; due to its smooth operation, the delta (temperature difference) of the coolant is reduced. The optimal operating mode of the circuit is maintained (without unnecessary overheating and cooling). This allows you to reduce power consumption in all operating modes of the HP. The greatest economic effect is in air-to-air devices.

4. Vaillant geoTHERM VWW 61/3 (Germany) – from RUB 408,219.

The use of well water as the primary coolant (VWW only) made it possible to simplify the design and reduce the price of the HP without loss of performance.

The device is characterized by low power consumption in the main operating mode and low noise level.

The downside of Vaillant is its demands on water (there are known cases of damage to the supply line and heat exchanger by iron and manganese compounds); work with salt-containing waters should be avoided. The situation is not guaranteed, but if the installation was carried out by service center specialists, then there is someone to file a claim with.

A dry, frost-free room with a volume of at least 6.1 m³ (2.44 m² with a ceiling of 2.5 m) is required. Dropping under the pump is not a defect (condensation is allowed to drain from the surfaces of insulated circuits).

5. LG Therma V AH-W096A0 (Korea) – from RUB 275,000.

Air-to-water heat pump. The device consists of 2 modules: the outer one takes thermal energy from the air masses, the inner one transforms and transfers it to the heating system.

The main advantage is versatility. Can be configured for both heating and cooling the object.

The disadvantage of this LG Therma series is that its (and the entire line’s) potential is not enough for the needs of a cottage with an area of more than 200 m².

An important point: the working units of a two-component system cannot be spaced more than 50 m horizontally and 30 m vertically.

6. STIEBEL ELTRON WPF 10MS (Germany) – from RUB 323,300.

The WPF 10MS model is the most powerful of the STIEBEL ELTRON heat pumps.

Among the advantages are an automatically adjustable heating mode and the ability to connect 6 devices into a cascade (this is a parallel or serial connection of devices to increase flow, pressure or organize an emergency reserve) system with a power of up to 60 kW.

The downside is that organizing a powerful electrical network for simultaneous connection of 6 such devices is only possible with the permission of the local branch of Rostechnadzor.

There is a peculiarity in setting the modes: after making the necessary adjustments to the program, you should wait until the control lamp goes out. Otherwise, after closing the lid, the system will return to the original settings.

7. Daikin EGSQH10S18A9W (Japan) – from RUB 1,607,830.

A powerful device for simultaneous provision of heat from CO, DHW and heated floors of a residential building with an area of up to 130 m².

Programmable and user-controlled modes; All serviced circuits are controlled within the specified parameters; there is a built-in storage tank (for DHW needs) of 180 liters and auxiliary heaters.

Among the shortcomings is the impressive potential, which will not be fully utilized in a house of 130 m²; a price due to which the payback period is extended indefinitely; automatic adaptation to external climatic conditions not implemented in the basic configuration. Environmental thermistors (thermal resistors) are optional. That is, when the external temperature changes, it is proposed to adjust the operating mode manually.

Equipment for objects with high heat consumption

To fully meet the thermal energy needs of residential and commercial buildings with an area of more than 200 m². Remote control, cascade operation, interaction with recuperators and solar systems - expand the user’s capabilities in creating a comfortable temperature.

8. WATERKOTTE EcoTouch DS 5027.5 Ai (Germany) – from RUB 708,521.

The DS 5027.5 Ai modification is the most powerful in the EcoTouch line. Stably warms up the heating circuit coolant and provides thermal energy to the hot water supply system in rooms up to 280 m².

Scroll (the most productive existing) compressor; adjusting the coolant flow rate allows you to obtain stable output temperature readings; color display; Russified menu; neat appearance and low noise level. Every detail is for comfortable use.

When the water points are actively used, the heating elements are turned on, causing energy consumption to increase by 6 kW/h.

9. DANFOSS DHP-R ECO 42 (Sweden) – from RUB 1,180,453.

Powerful enough equipment to provide thermal energy to the hot water supply system and heating circuits of a multi-level cottage with permanent residence.

Instead of an additional heater for DHW, the flow of hot water from the heating circuit supply is used here. By passing already hot water through the desuperheater, the heat pump heats the water in the additional DHW heat exchanger to 90 °C. A stable temperature in the CO and DHW tank is maintained by automatically adjusting the speed of the circulation pumps. Suitable for cascade connection (up to 8 TN).

There are no heating elements for the heating circuit. Additional resources are taken from any combined boiler - the control unit will take from it as much heat as is required in a particular case.

When calculating the space for installing a heat pump, it is necessary to leave a gap of 300 mm between the wall and the rear surface of the device (for ease of control and maintenance of communications).

10. Viessmann Vitocal 300-G WWC 110 (Germany) – from RUB 630,125.

Groundwater serves as the primary coolant. Hence the constant temperature on the first heat exchanger and the highest COP coefficient.

Among the advantages are a low-power auxiliary electric heater on the primary circuit and a proprietary controller (essentially a wireless remote control) for remote control.

Minus - the performance of the circulation pump, the condition of the main line and the primary circuit heat exchanger depend on the quality of the groundwater being distilled. Filtering is required.

Groundwater analysis will help eliminate the occurrence of difficult-to-solve problems with expensive equipment. Which should be done before purchasing a water-to-water heat pump.

Editor's Choice

Many years of experience in the production and operation of heat pumps in Northern Europe allowed our compatriots to narrow down the search area for the most profitable way to heat their home. Real options exist for any request.

Do you need to provide heat to the domestic hot water circuit or the heating system of a residential building up to 80 - 100 m²? Consider the potential NIBE F1155– its “intelligent” filling saves money without compromising heat supply.

A stable temperature in the underfloor heating, CO, and DHW circuits of a cottage of 130 m² will be ensured – a DHW heat exchanger (180 liters) is used here.

Produces a constant heat flow simultaneously for all consumers. The ability to create a cascade of 8 HP allows you to provide heat to an object with an area of at least 3,000 m².