Thermal engineering calculation of structures: what it is and how it is carried out. Method of thermal engineering calculation of an external wall Thermal engineering calculation of a brick wall example

Example of thermal engineering calculation of enclosing structures

1. Initial data

Technical task. Due to the unsatisfactory heat and humidity conditions of the building, it is necessary to insulate its walls and attic roof. For this purpose, perform calculations of thermal resistance, heat resistance, air and vapor permeability of the building envelope, assessing the possibility of moisture condensation in the thickness of the fences. Establish the required thickness of the thermal insulation layer, the need to use wind and vapor barriers, and the order of arrangement of layers in the structure. Develop a design solution that meets the requirements of SNiP 23-02-2003 “Thermal protection of buildings” for enclosing structures. Calculations should be performed in accordance with the set of rules for design and construction SP 23-101-2004 “Design of thermal protection of buildings”.

General characteristics of the building. A two-story residential building with an attic is located in the village. Sviritsa, Leningrad region. The total area of external enclosing structures is 585.4 m2; total wall area 342.5 m2; total window area 51.2 m2; roof area – 386 m2; basement height - 2.4 m.

The structural design of the building includes load-bearing walls, reinforced concrete floors made of hollow-core panels, 220 mm thick, and a concrete foundation. The external walls are made of brickwork and plastered inside and outside with mortar with a layer of about 2 cm.

The roof of the building has a truss structure with a steel seam roof, made over lathing with a pitch of 250 mm. The 100 mm thick insulation is made of mineral wool slabs laid between the rafters

The building has stationary electric-thermal storage heating. The basement has a technical purpose.

Climatic parameters. According to SNiP 23-02-2003 and GOST 30494-96, the calculated average temperature of the internal air is taken equal to

t int= 20 °C.

According to SNiP 01/23/99 we accept:

1) the estimated temperature of the outside air during the cold season for the conditions of the village. Sviritsa, Leningrad region

t ext= -29 °C;

2) duration of the heating period

z ht= 228 days;

3) average outside air temperature during the heating period

t ht= -2.9 °C.

Heat transfer coefficients. The values of the heat transfer coefficient of the internal surface of the fences are taken as follows: for walls, floors and smooth ceilings α int= 8.7 W/(m 2 ·ºС).

The values of the heat transfer coefficient of the outer surface of the fences are taken as follows: for walls and coverings α ext=23; attic floors α ext=12 W/(m 2 ·ºС);

Standardized heat transfer resistance. Degree-days of the heating season G d are determined by formula (1)

G d= 5221 °C day.

Because the value G d differs from table values, standard value R req determined by formula (2).

According to SNiP 02/23/2003, for the obtained degree-day value, the normalized heat transfer resistance is R req, m 2 °C/W, is:

For external walls 3.23;

Coverings and overlaps over driveways 4.81;

Fencing over unheated undergrounds and basements 4.25;

Windows and balcony doors 0.54.

2. Thermal engineering calculation of external walls

2.1. Resistance of external walls to heat transfer

Exterior walls made of hollow ceramic bricks and have a thickness of 510 mm. The walls are plastered on the inside with lime-cement mortar 20 mm thick, and on the outside with cement mortar of the same thickness.

The characteristics of these materials - density γ 0, thermal conductivity coefficient in the dry state 0 and vapor permeability coefficient μ - are taken according to the table. Clause 9 of the application. In this case, in the calculations we use the thermal conductivity coefficients of materials W for operating conditions B, (for wet operating conditions), which are obtained from formula (2.5). We have:

For lime-cement mortar

γ 0 = 1700 kg/m 3,

W=0.52(1+0.168·4)=0.87 W/(m·°С),

μ=0.098 mg/(m h Pa);

For brickwork made of hollow ceramic bricks on cement-sand mortar

γ 0 = 1400 kg/m 3,

W=0.41(1+0.207·2)=0.58 W/(m·°С),

μ=0.16 mg/(m h Pa);

For cement mortar

γ 0 = 1800 kg/m 3,

W=0.58(1+0.151·4)=0.93 W/(m·°С),

μ=0.09 mg/(m h Pa).

The heat transfer resistance of a wall without insulation is equal to

R o = 1/8.7 + 0.02/0.87 + 0.51/0.58 + 0.02/0.93 + 1/23 = 1.08 m 2 °C/W.

In the presence of window openings forming wall slopes, the coefficient of thermal uniformity of brick walls with a thickness of 510 mm is accepted r = 0,74.

Then the reduced heat transfer resistance of the building walls, determined by formula (2.7), is equal to

R r o =0.74·1.08=0.80 m 2 ·°С/W.

The obtained value is much lower than the standard value of heat transfer resistance, so it is necessary to install external thermal insulation and subsequent plastering with protective and decorative compositions of the plaster mortar with fiberglass mesh reinforcement.

To allow the thermal insulation to dry out, the covering plaster layer must be vapor-permeable, i.e. porous with low density. We select a porous cement-perlite mortar that has the following characteristics:

γ 0 = 400 kg/m 3,

0 = 0.09 W/(m °C),

W=0.09(1+0.067·10)=0.15 W/(m·°С),

= 0.53 mg/(m h Pa).

Total heat transfer resistance of added layers of thermal insulation R t and plaster lining R w should be no less

R t + R w = 3.23/0.74-1.08 = 3.28 m 2 °C/W.

Preliminarily (with subsequent clarification) we accept the thickness of the plaster lining as 10 mm, then its resistance to heat transfer is equal to

R w =0.01/0.15=0.067 m 2 °C/W.

When used for thermal insulation of mineral wool boards produced by JSC "Mineral Wool" brand Facade Butts 0 =145 kg/m 3, 0 =0.033, W =0.045 W/(m °C) the thickness of the thermal insulation layer will be

δ=0.045·(3.28-0.067)=0.145 m.

Rockwool slabs are available in thicknesses from 40 to 160 mm in 10 mm increments. We accept a standard thermal insulation thickness of 150 mm. Thus, the slabs will be laid in one layer.

Checking compliance with energy saving requirements. The design diagram of the wall is shown in Fig. 1. Characteristics of the layers of the wall and the total resistance of the wall to heat transfer without taking into account the vapor barrier are given in table. 2.1.

Table 2.1

Characteristics of wall layers andtotal wall resistance to heat transfer

|

Layer material |

Density γ 0, kg/m 3 |

Thickness δ, m |

Calculated thermal conductivity coefficient λ W, W/(m K) |

Design heat transfer resistance R, m 2 °C)/W |

|

|

Interior plaster (lime-cement mortar) |

|||||

|

Masonry made of hollow ceramic bricks |

|||||

|

External plaster (cement mortar) |

|||||

|

Mineral wool insulation FACADE BATTS |

|||||

|

Protective and decorative plaster (cement-perlite mortar) |

|||||

The heat transfer resistance of the building walls after insulation will be:

R o = 1/8.7+4.32+1/23=4.48 m 2 °C/W.

Taking into account the coefficient of thermal uniformity of external walls ( r= 0.74) we obtain the reduced resistance to heat transfer

R o r= 4.48 0.74 = 3.32 m 2 °C/W.

Received value R o r= 3.32 exceeds the standard R req=3.23, since the actual thickness of the heat-insulating boards is greater than the calculated one. This position meets the first requirement of SNiP 23-02-2003 for the thermal resistance of the wall - R o ≥ R req .

Verification of compliance with requirements forsanitary, hygienic and comfortable indoor conditions. Calculated difference between the internal air temperature and the internal wall surface temperature Δ t 0 is

Δ t 0 =n(t int – t ext)/(R o r ·α int)=1.0(20+29)/(3.32·8.7)=1.7 ºС.

According to SNiP 02/23/2003, for the external walls of residential buildings, a temperature difference of no more than 4.0 ºС is allowed. Thus, the second condition (Δ t 0 ≤Δ t n) done.

P

let's check the third condition ( τ

int >t grew up), i.e. Is it possible for moisture to condense on the inner surface of the wall at the design outdoor temperature? t ext= -29 °C. Inner surface temperature τ

int enclosing structure (without heat-conducting inclusion) is determined by the formula

τ int = t int –Δ t 0 =20–1.7=18.3 °C.

Indoor water vapor pressure e int equal to

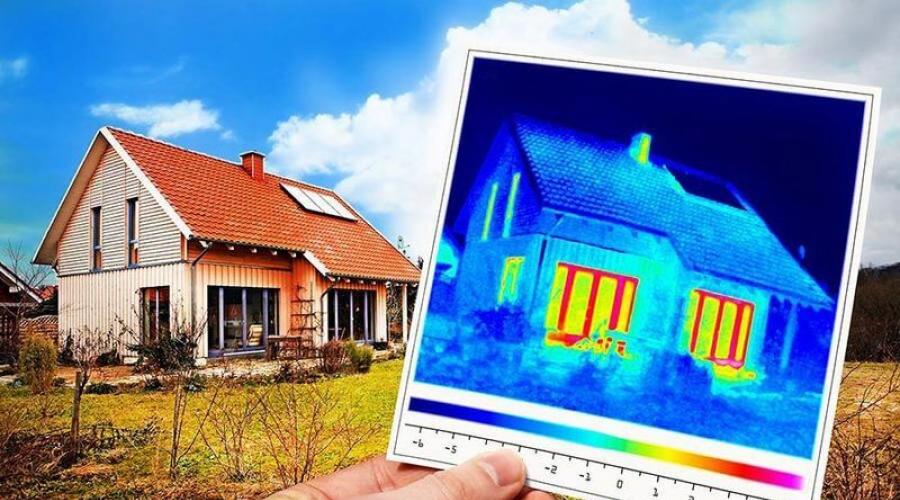

During the operation of the building, both overheating and freezing are undesirable. Thermal engineering calculations, which are no less important than calculating efficiency, strength, fire resistance, and durability, will allow you to determine the golden mean.

Based on thermal engineering standards, climatic characteristics, steam and moisture permeability, materials are selected for the construction of enclosing structures. We will look at how to perform this calculation in the article.

Much depends on the thermal technical features of the building's permanent enclosures. This includes the humidity of structural elements and temperature indicators, which affect the presence or absence of condensation on interior partitions and ceilings.

The calculation will show whether stable temperature and humidity characteristics will be maintained at plus and minus temperatures. The list of these characteristics also includes such an indicator as the amount of heat lost by the building envelope during the cold period.

You can't start designing without having all this data. Based on them, the thickness of the walls and ceilings and the sequence of layers are chosen.

According to GOST 30494-96 regulations, temperature values indoors. On average it is 21⁰. At the same time, the relative humidity must remain within a comfortable range, which is an average of 37%. The highest speed of air mass movement is 0.15 m/s

Thermal engineering calculation aims to determine:

- Are the designs identical to the stated requirements in terms of thermal protection?

- How fully is a comfortable microclimate inside the building ensured?

- Is optimal thermal protection of structures provided?

The basic principle is maintaining a balance of the difference in temperature indicators of the atmosphere of internal structures of fences and premises. If this is not followed, heat will be absorbed by these surfaces and the temperature inside will remain very low.

The internal temperature should not be significantly affected by changes in heat flow. This characteristic is called heat resistance.

By performing a thermal calculation, the optimal limits (minimum and maximum) of the dimensions of walls and ceiling thicknesses are determined. This guarantees the operation of the building over a long period, both without extreme freezing of structures or overheating.

Options for performing calculations

To perform heat calculations, you need initial parameters.

They depend on a number of characteristics:

- Purpose of the building and its type.

- Orientations of vertical enclosing structures relative to the cardinal directions.

- Geographical parameters of the future home.

- The volume of the building, its number of storeys, area.

- Types and dimensions of door and window openings.

- Type of heating and its technical parameters.

- Number of permanent residents.

- Materials for vertical and horizontal fencing structures.

- Upper floor ceilings.

- Hot water supply equipment.

- Type of ventilation.

Other design features of the structure are also taken into account when calculating. The air permeability of enclosing structures should not contribute to excessive cooling inside the house and reduce the thermal protection characteristics of the elements.

Heat loss is also caused by waterlogging of the walls, and in addition, this entails dampness, which negatively affects the durability of the building.

In the calculation process, first of all, the thermal technical data of the building materials from which the building’s enclosing elements are made are determined. In addition, the reduced heat transfer resistance and compliance with its standard value are subject to determination.

Formulas for making calculations

Heat loss from a home can be divided into two main parts: losses through the building envelope and losses caused by operation. In addition, heat is lost when warm water is discharged into the sewer system.

For the materials from which the enclosing structures are constructed, it is necessary to find the value of the thermal conductivity index Kt (W/m x degree). They are in the relevant reference books.

Now, knowing the thickness of the layers, according to the formula: R = S/Kt, calculate the thermal resistance of each unit. If the structure is multilayer, all obtained values are added together.

The easiest way to determine the size of heat losses is by adding up the thermal flows through the enclosing structures that actually form this building

Guided by this methodology, they take into account the fact that the materials that make up the structure have a different structure. It is also taken into account that the heat flow passing through them has different specifics.

For each individual structure, heat loss is determined by the formula:

Q = (A / R) x dT

- A - area in m².

- R - resistance of the structure to heat transfer.

- dT - temperature difference between outside and inside. It needs to be determined for the coldest 5-day period.

Performing the calculation in this way, you can get the result only for the coldest five-day period. The total heat loss for the entire cold season is determined by taking into account the dT parameter, taking into account not the lowest temperature, but the average one.

The extent to which heat is absorbed, as well as heat transfer, depends on the humidity of the climate in the region. For this reason, humidity maps are used in calculations.

There is a formula for this:

W = ((Q + Qв) x 24 x N)/1000

In it, N is the duration of the heating period in days.

Disadvantages of area calculation

Calculation based on the area indicator is not very accurate. Here, such parameters as climate, temperature indicators, both minimum and maximum, and humidity are not taken into account. Due to ignoring many important points, the calculation has significant errors.

Often trying to cover them, a “reserve” is provided in the project.

If, nevertheless, this method is chosen for calculation, the following nuances must be taken into account:

- If the height of vertical fences is up to three meters and there are no more than two openings on one surface, it is better to multiply the result by 100 W.

- If the project includes a balcony, two windows or a loggia, multiply by an average of 125 W.

- When the premises are industrial or warehouse, a multiplier of 150 W is used.

- If radiators are located near windows, their design capacity is increased by 25%.

The formula for area is:

Q=S x 100 (150) W.

Here Q is the comfortable heat level in the building, S is the heated area in m². The numbers 100 or 150 are the specific amount of thermal energy consumed to heat 1 m².

House ventilation losses

The key parameter in this case is the air exchange rate. Provided that the walls of the house are vapor-permeable, this value is equal to one.

The penetration of cold air into the house is carried out through supply ventilation. Exhaust ventilation helps warm air escape. The recuperator-heat exchanger reduces losses through ventilation. It does not allow heat to escape along with the outgoing air, and it heats the incoming air flows

It is envisaged that the air inside the building will be completely renewed in one hour. Buildings built according to the DIN standard have walls with vapor barriers, so here the air exchange rate is taken to be two.

There is a formula that determines heat loss through the ventilation system:

Qv = (V x Kv: 3600) x P x C x dT

Here the symbols mean the following:

- Qв - heat loss.

- V is the volume of the room in mᶾ.

- P - air density. its value is taken equal to 1.2047 kg/mᶾ.

- Kv - air exchange rate.

- C - specific heat capacity. It is equal to 1005 J/kg x C.

Based on the results of this calculation, it is possible to determine the power of the heat generator of the heating system. If the power value is too high, a way out of the situation may be. Let's look at a few examples for houses made of different materials.

Example of thermal engineering calculation No. 1

Let's calculate a residential building located in climatic region 1 (Russia), subdistrict 1B. All data is taken from table 1 of SNiP 01/23/99. The coldest temperature observed over five days with a probability of 0.92 is tн = -22⁰С.

In accordance with SNiP, the heating period (zop) lasts 148 days. The average temperature during the heating period with the average daily air temperature outside is 8⁰ - tot = -2.3⁰. The outside temperature during the heating season is tht = -4.4⁰.

Heat loss of a house is the most important point at the design stage. The choice of building materials and insulation depends on the results of the calculation. There are no zero losses, but you need to strive to ensure that they are as expedient as possible

The condition was stipulated that the temperature in the rooms of the house should be 22⁰. The house has two floors and walls 0.5 m thick. Its height is 7 m, dimensions in plan are 10 x 10 m. The material of the vertical enclosing structures is warm ceramics. For it, the thermal conductivity coefficient is 0.16 W/m x C.

Mineral wool was used as external insulation, 5 cm thick. The Kt value for it is 0.04 W/m x C. The number of window openings in the house is 15 pcs. 2.5 m² each.

Heat loss through walls

First of all, you need to determine the thermal resistance of both the ceramic wall and the insulation. In the first case, R1 = 0.5: 0.16 = 3.125 sq. m x C/W. In the second - R2 = 0.05: 0.04 = 1.25 sq. m x C/W. In general, for a vertical building envelope: R = R1 + R2 = 3.125 + 1.25 = 4.375 sq. m x C/W.

Since heat loss is directly proportional to the area of the enclosing structures, we calculate the area of the walls:

A = 10 x 4 x 7 – 15 x 2.5 = 242.5 m²

Now you can determine heat loss through the walls:

Qс = (242.5: 4.375) x (22 – (-22)) = 2438.9 W.

Heat loss through horizontal enclosing structures is calculated in a similar way. In the end, all the results are summed up.

If the basement under the floor of the first floor is heated, the floor does not need to be insulated. It is still better to line the basement walls with insulation so that the heat does not escape into the ground.

Determination of losses through ventilation

To simplify the calculation, they do not take into account the thickness of the walls, but simply determine the volume of air inside:

V = 10x10x7 = 700 mᶾ.

With an air exchange rate of Kv = 2, the heat loss will be:

Qв = (700 x 2) : 3600) x 1.2047 x 1005 x (22 – (-22)) = 20,776 W.

If Kv = 1:

Qв = (700 x 1) : 3600) x 1.2047 x 1005 x (22 – (-22)) = 10,358 W.

Rotary and plate heat exchangers provide effective ventilation of residential buildings. The efficiency of the former is higher, it reaches 90%.

Example of thermal engineering calculation No. 2

It is required to calculate losses through a 51 cm thick brick wall. It is insulated with a 10 cm layer of mineral wool. Outside – 18⁰, inside – 22⁰. The dimensions of the wall are 2.7 m in height and 4 m in length. The only outer wall of the room is oriented to the south; there are no external doors.

For brick, the thermal conductivity coefficient Kt = 0.58 W/mºC, for mineral wool - 0.04 W/mºC. Thermal Resistance:

R1 = 0.51: 0.58 = 0.879 sq. m x C/W. R2 = 0.1: 0.04 = 2.5 sq. m x C/W. In general, for a vertical building envelope: R = R1 + R2 = 0.879 + 2.5 = 3.379 sq. m x C/W.

External wall area A = 2.7 x 4 = 10.8 m²

Heat loss through the wall:

Qс = (10.8: 3.379) x (22 – (-18)) = 127.9 W.

To calculate losses through windows, the same formula is used, but their thermal resistance, as a rule, is indicated in the passport and does not need to be calculated.

In the thermal insulation of a house, windows are the “weak link”. A fairly large portion of the heat is lost through them. Multilayer double-glazed windows, heat-reflecting films, double frames will reduce losses, but even this will not help avoid heat loss completely

If the house has energy-saving windows measuring 1.5 x 1.5 m², oriented to the North, and the thermal resistance is 0.87 m2°C/W, then the losses will be:

Qо = (2.25: 0.87) x (22 – (-18)) = 103.4 t.

Example of thermal engineering calculation No. 3

Let's perform a thermal calculation of a wooden log building with a facade built from pine logs with a layer 0.22 m thick. The coefficient for this material is K = 0.15. In this situation, the heat loss will be:

R = 0.22: 0.15 = 1.47 m² x ⁰С/W.

The lowest temperature of the five-day period is -18⁰, for comfort in the house the temperature is set to 21⁰. The difference will be 39⁰. Based on an area of 120 m², the result will be:

Qс = 120 x 39: 1.47 = 3184 W.

For comparison, let’s determine the losses of a brick house. The coefficient for sand-lime brick is 0.72.

R = 0.22: 0.72 = 0.306 m² x ⁰С/W.

Qс = 120 x 39: 0.306 = 15,294 W.

Under the same conditions, a wooden house is more economical. Sand-lime brick is not suitable for building walls here at all.

The wooden structure has a high heat capacity. Its enclosing structures maintain a comfortable temperature for a long time. Still, even a log house needs to be insulated and it is better to do this both inside and outside

Heat calculation example No. 4

The house will be built in the Moscow region. For the calculation, a wall made of foam blocks was taken. How the insulation is applied. The finishing of the structure is plaster on both sides. Its structure is limestone-sand.

Expanded polystyrene has a density of 24 kg/mᶾ.

Relative air humidity in the room is 55% at an average temperature of 20⁰. Layer thickness:

- plaster - 0.01 m;

- foam concrete - 0.2 m;

- expanded polystyrene - 0.065 m.

The task is to find the required heat transfer resistance and the actual one. The required Rtr is determined by substituting the values in the expression:

Rtr=a x GSOP+b

where GOSP is the degree-day of the heating season, a and b are coefficients taken from table No. 3 of the Code of Rules 50.13330.2012. Since the building is residential, a is 0.00035, b = 1.4.

GSOP is calculated using a formula taken from the same SP:

GOSP = (tv – tot) x zot.

In this formula tв = 20⁰, tоt = -2.2⁰, zоt - 205 is the heating period in days. Hence:

GSOP = (20 – (-2.2)) x 205 = 4551⁰ C x day;

Rtr = 0.00035 x 4551 + 1.4 = 2.99 m2 x C/W.

Using table No. 2 SP50.13330.2012, determine the thermal conductivity coefficients for each layer of the wall:

- λb1 = 0.81 W/m ⁰С;

- λb2 = 0.26 W/m ⁰С;

- λb3 = 0.041 W/m ⁰С;

- λb4 = 0.81 W/m ⁰С.

The total conditional resistance to heat transfer Ro is equal to the sum of the resistances of all layers. It is calculated using the formula:

Substituting the values we get: Rо arb. = 2.54 m2°C/W. Rф is determined by multiplying Ro by a coefficient r equal to 0.9:

Rf = 2.54 x 0.9 = 2.3 m2 x °C/W.

The result requires changing the design of the enclosing element, since the actual thermal resistance is less than the calculated one.

There are many computer services that speed up and simplify calculations.

Thermal calculations are directly related to the definition. You will learn what it is and how to find its meaning from the article we recommend.

Conclusions and useful video on the topic

Performing thermal engineering calculations using an online calculator:

Correct thermal engineering calculation:

A competent thermotechnical calculation will allow you to evaluate the effectiveness of insulating the external elements of the house and determine the power of the necessary heating equipment.

As a result, you can save money when purchasing materials and heating devices. It is better to know in advance whether the equipment can cope with the heating and air conditioning of the building than to buy everything at random.

Please leave comments, ask questions, and post photos related to the topic of the article in the block below. Tell us how thermal engineering calculations helped you choose heating equipment of the required power or insulation system. It is possible that your information will be useful to site visitors.

If you are planning to build

small brick cottage, then you will certainly have questions: “Which

thickness should the wall be?”, “Do you need insulation?”, “Which side should you put it on?”

insulation? etc. and so on.

In this article we will try in

understand this and answer all your questions.

Thermal calculation

enclosing structure is needed, first of all, in order to find out which

thickness should be your exterior wall.

First, you need to decide how much

floors will be in your building and depending on this the calculation is made

of enclosing structures according to load-bearing capacity (not in this article).

According to this calculation we determine

the number of bricks in your building's masonry.

For example, it turned out 2 clay

bricks without voids, brick length 250 mm,

mortar thickness 10 mm, total 510 mm (brick density 0.67

It will be useful to us later). You decided to cover the outer surface

facing tiles, thickness 1 cm (be sure to find out when purchasing

density), and the inner surface is ordinary plaster, layer thickness 1.5

cm, also do not forget to find out its density. A total of 535mm.

In order for the building not to

collapsed, this is certainly enough, but unfortunately in most cities

Russian winters are cold and therefore such walls will freeze. And so as not

The walls were frozen, we needed another layer of insulation.

The thickness of the insulation layer is calculated

in the following way:

1. You need to download SNiP on the Internet

II 3-79* —

“Construction Heat Engineering” and SNiP 23-01-99 - “Construction Climatology”.

2. Open SNiP construction

climatology and find your city in table 1*, and look at the value at the intersection

column “Air temperature of the coldest five-day period, °C, security

0.98" and lines with your city. For the city of Penza, for example, t n = -32 o C.

3. Estimated indoor air temperature

take

t in = 20 o C.

Heat transfer coefficient for internal wallsa in = 8.7 W/m 2 ˚С

Heat transfer coefficient for external walls in winter conditionsa n = 23W/m2·˚С

Standard temperature difference between internal temperature

air and the temperature of the inner surface of the enclosing structuresΔ tn = 4 o C.

4. Next

We determine the required heat transfer resistance using the formula #G0 (1a) from building heating engineering

GSOP = (t in - t from.trans.) z from.trans. , GSOP=(20+4.5)·207=507.15 (for the city

Penza).

Using formula (1) we calculate:

(where sigma is the direct thickness

material, and lambda density. Itook it as insulation

polyurethane foampanels with a density of 0.025)

We take the insulation thickness to be 0.054 m.

Hence the wall thickness will be:

d = d 1 + d 2 + d 3 + d 4 =

0,01+0,51+0,054+0,015=0,589

m.

The renovation season has arrived. I was scratching my head: how to make good repairs for less money. There are no thoughts about credit. Relying only on existing...

Instead of putting off major renovations from year to year, you can prepare for it so that you can survive it in moderation...

First, you need to remove everything that remains from the old company that worked there. We break the artificial partition. After that we rip everything off...

The purpose of the thermal engineering calculation is to calculate the thickness of the insulation for a given thickness of the load-bearing part of the outer wall, which meets sanitary and hygienic requirements and energy saving conditions. In other words, we have external walls 640 mm thick made of sand-lime brick and we are going to insulate them with polystyrene foam, but we don’t know what thickness of insulation we need to choose in order to comply with building standards.

Thermal engineering calculations of the outer wall of a building are carried out in accordance with SNiP II-3-79 “Building Heat Engineering” and SNiP 23-01-99 “Building Climatology”.

Table 1

Thermal performance indicators of the building materials used (according to SNiP II-3-79*)

|

Scheme no. |

Material |

Characteristics of the material in a dry state |

Design coefficients (subject to operation according to Appendix 2) SNiP II-3-79* |

||||

|

Density γ 0, kg/m 3 |

Thermal conductivity coefficient λ, W/m*°С |

Thermal conductivity λ, W/m*°С |

Heat absorption (with a period of 24 hours) S, m 2 *°C/W |

||||

|

Cement-sand mortar (item 71) |

1800 |

0.57 |

0.76 |

0.93 |

11.09 |

||

|

Brickwork made of solid silicate brick (GOST 379-79) on cement-sand mortar (item 87) |

1800 |

0.88 |

0.76 |

0.87 |

9.77 |

10.90 |

|

|

Expanded polystyrene (GOST 15588-70) (item 144) |

0.038 |

0.038 |

0.041 |

0.41 |

0.49 |

||

|

Cement-sand mortar – thin-layer plaster (item 71) |

1800 |

0.57 |

0.76 |

0.93 |

11.09 |

||

1-internal plaster (cement-sand mortar) - 20 mm

2-brick wall (sand-lime brick) - 640 mm

3-insulation (expanded polystyrene)

4-thin-layer plaster (decorative layer) - 5 mm

When performing thermal engineering calculations, the normal humidity regime in the premises was adopted - operating conditions (“B”) in accordance with SNiP II-3-79 t.1 and appendix. 2, i.e. We take the thermal conductivity of the materials used according to column “B”.

Let's calculate the required heat transfer resistance of the fence, taking into account sanitary, hygienic and comfortable conditions using the formula:

R 0 tr = (t in – t n) * n / Δ t n *α in (1)

where t in is the design temperature of the internal air °C, accepted in accordance with GOST 12.1.1.005-88 and design standards

corresponding buildings and structures, we take equal to +22 °C for residential buildings in accordance with Appendix 4 to SNiP 2.08.01-89;

t n – estimated winter outside air temperature, °C, equal to the average temperature of the coldest five-day period, with a probability of 0.92 according to SNiP 23-01-99 for the city of Yaroslavl is taken to be -31 °C;

n – coefficient accepted according to SNiP II-3-79* (Table 3*) depending on the position of the outer surface of the enclosing structure in relation to the outside air and is taken equal to n=1;

Δ t n - standard and temperature difference between the temperature of the internal air and the temperature of the internal surface of the enclosing structure - is established according to SNiP II-3-79* (Table 2*) and is taken equal to Δ t n = 4.0 °C;

R 0 tr = (22- (-31))*1 / 4.0* 8.7 = 1.52

Let us determine the degree-day of the heating period using the formula:

GSOP= (t in – t from.trans.)*z from.trans. (2)

where t in is the same as in formula (1);

t from.per - average temperature, °C, of the period with an average daily air temperature below or equal to 8 °C according to SNiP 23-01-99;

z from.per - duration, days, of the period with an average daily air temperature below or equal to 8 °C according to SNiP 01/23/99;

GSOP=(22-(-4))*221=5746 °C*day.

Let's determine the reduced heat transfer resistance Ro tr according to the conditions of energy saving in accordance with the requirements of SNiP II-3-79* (Table 1b*) and sanitary, hygienic and comfortable conditions. Intermediate values are determined by interpolation.

table 2

Heat transfer resistance of enclosing structures (according to SNiP II-3-79*)

|

Buildings and premises |

Degree-days of the heating period, ° C*days |

Reduced heat transfer resistance of walls, not less than R 0 tr (m 2 *°C)/W |

|

Public administrative and domestic, with the exception of rooms with damp or wet conditions |

5746 |

3,41 |

We take the heat transfer resistance of enclosing structures R(0) as the greatest of the values calculated earlier:

R 0 tr = 1.52< R 0 тр = 3,41, следовательно R 0 тр = 3,41 (м 2 *°С)/Вт = R 0 .

Let us write an equation for calculating the actual heat transfer resistance R 0 of the enclosing structure using the formula in accordance with the given design scheme and determine the thickness δ x of the design layer of the enclosure from the condition:

R 0 = 1/α n + Σδ i/ λ i + δ x/ λ x + 1/α in = R 0

where δ i is the thickness of individual layers of the fence other than the calculated one in m;

λ i – thermal conductivity coefficients of individual layers of the fence (except for the design layer) in (W/m*°C) are taken according to SNiP II-3-79* (Appendix 3*) - for this calculation, table 1;

δ x – thickness of the design layer of the outer fence in m;

λ x – thermal conductivity coefficient of the design layer of the outer fence in (W/m*°C) are taken according to SNiP II-3-79* (Appendix 3*) - for this calculation, table 1;

α in - the heat transfer coefficient of the internal surface of enclosing structures is taken according to SNiP II-3-79* (Table 4*) and is taken equal to α in = 8.7 W/m 2 *°C.

α n - heat transfer coefficient (for winter conditions) of the outer surface of the enclosing structure is taken according to SNiP II-3-79* (Table 6*) and is taken equal to α n = 23 W/m 2 *°C.

The thermal resistance of a building envelope with successively arranged homogeneous layers should be determined as the sum of the thermal resistances of the individual layers.

For external walls and ceilings, the thickness of the thermal insulation layer of the fence δ x is calculated from the condition that the value of the actual reduced resistance to heat transfer of the enclosing structure R 0 must be no less than the standardized value R 0 tr, calculated by formula (2):

R 0 ≥ R 0 tr

Expanding the value of R 0, we get:

R0=1 / 23 + (0,02/ 0,93 + 0,64/ 0,87 + 0,005/ 0.93) + δ x / 0,041 + 1/ 8,7

Based on this, we determine the minimum value of the thickness of the heat-insulating layer

δ x = 0.041*(3.41- 0.115 - 0.022 - 0.74 - 0.005 - 0.043)

δ x = 0.10 m

We take into account the thickness of the insulation (expanded polystyrene) δ x = 0.10 m

Determine the actual heat transfer resistance calculated enclosing structures R 0, taking into account the accepted thickness of the thermal insulation layer δ x = 0.10 m

R0=1 / 23 + (0,02/ 0,93 + 0,64/ 0,87 + 0,005/ 0,93 + 0,1/ 0,041) + 1/ 8,7

R 0 = 3.43 (m 2 *°C)/W

Condition R 0 ≥ R 0 tr observed, R 0 = 3.43 (m 2 *°C)/W ≥ R 0 tr =3.41 (m 2 *°C)/W

Creating comfortable conditions for living or working is the primary task of construction. A significant part of the territory of our country is located in northern latitudes with a cold climate. Therefore, maintaining a comfortable temperature in buildings is always important. With rising energy tariffs, reducing energy consumption for heating comes to the fore.

Climatic characteristics

The choice of wall and roof design depends primarily on the climatic conditions of the construction area. To determine them, you need to refer to SP131.13330.2012 “Building climatology”. The following quantities are used in the calculations:

- the temperature of the coldest five-day period with a probability of 0.92 is designated Tn;

- average temperature, designated Thot;

- duration, denoted by ZOT.

Using the example for Murmansk, the values have the following values:

- Tn=-30 degrees;

- Tot=-3.4 degrees;

- ZOT=275 days.

In addition, it is necessary to set the estimated temperature inside the TV room; it is determined in accordance with GOST 30494-2011. For housing, you can take TV = 20 degrees.

To perform a thermal engineering calculation of enclosing structures, first calculate the value of GSOP (degree-day of the heating period):

GSOP = (Tv - Tot) x ZOT.

In our example, GSOP = (20 - (-3.4)) x 275 = 6435.

Basic indicators

To select the correct materials for enclosing structures, it is necessary to determine what thermal characteristics they should have. The ability of a substance to conduct heat is characterized by its thermal conductivity, denoted by the Greek letter l (lambda) and measured in W/(m x deg.). The ability of a structure to retain heat is characterized by its resistance to heat transfer R and is equal to the ratio of thickness to thermal conductivity: R = d/l.

If the structure consists of several layers, the resistance is calculated for each layer and then summed up.

Heat transfer resistance is the main indicator of the external structure. Its value must exceed the standard value. When performing thermal engineering calculations of the building envelope, we must determine the economically justified composition of the walls and roof.

Thermal conductivity values

The quality of thermal insulation is determined primarily by thermal conductivity. Each certified material undergoes laboratory tests, as a result of which this value is determined for operating conditions “A” or “B”. For our country, most regions correspond to operating conditions “B”. When performing thermal engineering calculations of the building envelope, this value should be used. Thermal conductivity values are indicated on the label or in the material passport, but if they are not available, you can use reference values from the Code of Practice. Values for the most popular materials are given below:

- Masonry made of ordinary brick - 0.81 W (m x deg.).

- Sand-lime brickwork - 0.87 W (m x deg.).

- Gas and foam concrete (density 800) - 0.37 W (m x deg.).

- Coniferous wood - 0.18 W (m x deg.).

- Extruded polystyrene foam - 0.032 W (m x deg.).

- Mineral wool slabs (density 180) - 0.048 W (m x deg.).

Standard value of heat transfer resistance

The calculated value of heat transfer resistance should not be less than the base value. The basic value is determined according to Table 3 SP50.13330.2012 “buildings”. The table defines the coefficients for calculating the basic values of heat transfer resistance of all enclosing structures and types of buildings. Continuing the started thermal engineering calculation of enclosing structures, an example of the calculation can be presented as follows:

- Rsten = 0.00035x6435 + 1.4 = 3.65 (m x deg/W).

- Rpokr = 0.0005x6435 + 2.2 = 5.41 (m x deg/W).

- Rcherd = 0.00045x6435 + 1.9 = 4.79 (m x deg/W).

- Rokna = 0.00005x6435 + 0.3 = x deg/W).

Thermal engineering calculations of the external enclosing structure are performed for all structures that close the “warm” circuit - the floor on the ground or the ceiling of a technical underground, external walls (including windows and doors), a combined covering or the ceiling of an unheated attic. Also, the calculation must be performed for internal structures if the temperature difference in adjacent rooms is more than 8 degrees.

Thermal calculation of walls

Most walls and ceilings are multi-layered and heterogeneous in design. Thermal engineering calculation of enclosing structures of a multilayer structure is as follows:

R= d1/l1 +d2/l2 +dn/ln,

where n are the parameters of the nth layer.

If we consider a brick plastered wall, we get the following design:

- outer layer of plaster 3 cm thick, thermal conductivity 0.93 W (m x deg.);

- masonry made of solid clay brick 64 cm, thermal conductivity 0.81 W (m x deg.);

- the inner layer of plaster is 3 cm thick, thermal conductivity 0.93 W (m x deg.).

The formula for thermal engineering calculation of enclosing structures is as follows:

R=0.03/0.93 + 0.64/0.81 + 0.03/0.93 = 0.85(m x deg/W).

The obtained value is significantly less than the previously determined base value of the heat transfer resistance of the walls of a residential building in Murmansk 3.65 (m x deg/W). The wall does not meet regulatory requirements and needs insulation. To insulate the wall we use a thickness of 150 mm and a thermal conductivity of 0.048 W (m x deg.).

Having selected an insulation system, it is necessary to perform a verification thermal engineering calculation of the enclosing structures. An example calculation is given below:

R=0.15/0.048 + 0.03/0.93 + 0.64/0.81 + 0.03/0.93 = 3.97(m x deg/W).

The resulting calculated value is greater than the base value - 3.65 (m x deg/W), the insulated wall meets the requirements of the standards.

The calculation of floors and combined coverings is carried out similarly.

Thermal engineering calculation of floors in contact with the ground

Often in private homes or public buildings they are carried out on the ground. The heat transfer resistance of such floors is not standardized, but at a minimum the design of the floors should not allow dew to occur. The calculation of structures in contact with the ground is carried out as follows: the floors are divided into strips (zones) 2 meters wide, starting from the outer border. There are up to three such zones; the remaining area belongs to the fourth zone. If the floor design does not provide effective insulation, then the heat transfer resistance of the zones is assumed to be as follows:

- 1 zone - 2.1 (m x deg/W);

- Zone 2 - 4.3 (m x deg/W);

- Zone 3 - 8.6 (m x deg/W);

- Zone 4 - 14.3 (m x deg/W).

It is easy to notice that the further the floor area is from the external wall, the higher its resistance to heat transfer. Therefore, they are often limited to insulating the perimeter of the floor. In this case, the heat transfer resistance of the insulated structure is added to the heat transfer resistance of the zone.

The calculation of the heat transfer resistance of the floor must be included in the general thermal engineering calculation of the enclosing structures. We will consider an example of calculating floors on the ground below. Let's take a floor area of 10 x 10 equal to 100 square meters.

- The area of zone 1 will be 64 square meters.

- The area of zone 2 will be 32 square meters.

- The area of zone 3 will be 4 square meters.

Average value of resistance to heat transfer of the floor over the ground:

Rpol = 100 / (64/2.1 + 32/4.3 + 4/8.6) = 2.6 (m x deg/W).

Having insulated the perimeter of the floor with an expanded polystyrene board 5 cm thick, a strip 1 meter wide, we obtain the average value of heat transfer resistance:

Rpol = 100 / (32/2.1 + 32/(2.1+0.05/0.032) + 32/4.3 + 4/8.6) = 4.09 (m x deg/W).

It is important to note that not only floors are calculated in this way, but also wall structures in contact with the ground (walls of a recessed floor, warm basement).

Thermal calculation of doors

The basic value of the heat transfer resistance of entrance doors is calculated somewhat differently. To calculate it, you will first need to calculate the heat transfer resistance of the wall according to the sanitary and hygienic criterion (no dew):

Rst = (Tv - Tn)/(DTn x av).

Here DTn is the temperature difference between the inner surface of the wall and the air temperature in the room, determined according to the Code of Rules and for housing is 4.0.

ab is the heat transfer coefficient of the inner surface of the wall, according to SP is 8.7.

The basic value of doors is taken equal to 0.6xРst.

For the selected door design, it is necessary to perform a verification thermal engineering calculation of the enclosing structures. An example of calculating an entrance door:

Rdv = 0.6 x (20-(-30))/(4 x 8.7) = 0.86 (m x deg/W).

This calculated value will correspond to a door insulated with a 5 cm thick mineral wool slab. Its heat transfer resistance will be R=0.05 / 0.048=1.04 (m x deg/W), which is greater than the calculated one.

Comprehensive Requirements

Calculations of walls, floors or coverings are performed to verify the element-by-element requirements of the standards. The set of rules also establishes a comprehensive requirement characterizing the quality of insulation of all enclosing structures as a whole. This value is called “specific thermal protection characteristic”. Not a single thermal engineering calculation of enclosing structures can be done without checking it. An example of a calculation for a joint venture is given below.

Kob = 88.77 / 250 = 0.35, which is less than the normalized value of 0.52. In this case, the area and volume are taken for a house with dimensions of 10 x 10 x 2.5 m. Heat transfer resistances are equal to the basic values.

The normalized value is determined in accordance with the SP depending on the heated volume of the house.

In addition to the complex requirement, to draw up an energy passport, a thermal engineering calculation of the enclosing structures is also performed; an example of how to prepare a passport is given in the appendix to SP50.13330.2012.

Uniformity coefficient

All the above calculations are applicable for homogeneous structures. Which in practice is quite rare. To take into account inhomogeneities that reduce heat transfer resistance, a correction factor for thermal homogeneity - r - is introduced. It takes into account the change in heat transfer resistance introduced by window and door openings, external corners, inhomogeneous inclusions (for example, lintels, beams, reinforcing belts), etc.

The calculation of this coefficient is quite complicated, so in a simplified form you can use approximate values from reference literature. For example, for brickwork - 0.9, three-layer panels - 0.7.

Effective insulation

When choosing a home insulation system, it is easy to see that it is almost impossible to meet modern thermal protection requirements without using effective insulation. So, if you use traditional clay bricks, you will need masonry several meters thick, which is not economically feasible. At the same time, the low thermal conductivity of modern insulation based on polystyrene foam or stone wool allows us to limit ourselves to thicknesses of 10-20 cm.

For example, to achieve a basic heat transfer resistance value of 3.65 (m x deg/W), you will need:

- brick wall 3 m thick;

- masonry made of foam concrete blocks 1.4 m;

- mineral wool insulation 0.18 m.