Timers, time relays, command devices. Basic assembly units of washing machines of various types Characteristics of the electric motor of a washing machine SMR 1 5

WASHING MACHINE “RIGA-17” TYPE SMR-1.5. This machine with two washing modes is intended for individual use at home. Tank 16 (Fig. 93, o) of the washing machine, made of stainless steel, is mounted on a cylindrical body 18. Washing and rinsing of laundry is carried out by liquid flows created by the rotation of the disk activator 19 located on the inclined bottom of the tank. The activator can rotate in two directions depending on the washing mode (normal or gentle). The normal mode (the activator rotates counterclockwise) is used for washing clothes made of cotton and linen fabrics, the gentle mode (the activator rotates clockwise) is used for washing clothes made of wool, silk, synthetic fabrics and knitwear.

A centrifugal pump 20 is installed on the same shaft with the activator, which serves to pump out liquid from the tank. The liquid enters the pump through a drain hole in the bottom of the tank, closed by a removable grille 6, through a hose 8 and is drained through a hose 9 led out of the machine body. To drain the liquid, the washing mode switch knob must be in the gentle mode position. During washing and rinsing, the bent end of the drain hose must be lowered into the tank. The activator and pump are driven from an electric motor 21 by a V-belt drive. The electric motor is mounted on an inclined frame 22, the longitudinal grooves of which allow the tension of the V-belt to be adjusted by moving the motor.

A squeezing device with two rubber-coated rollers 11 and 12 is installed and secured with screws in the tank brackets. Flat spring 13 presses the upper roller to the lower one. The pressing force is adjusted by rotating the handle 14. The rollers are rotated by a removable handle 15, which is inserted into the axis of the lower roller.

The machine is turned on by turning the time relay pointer knob. The machine turns off automatically after the set time has elapsed.

To start and protect the engine from overloads, the washing machine is equipped with an automatic start-up protection relay type 2 RTK. Connection 4, closed with screw plug 3, is intended for draining the remaining washing solution from the machine. The connecting cord 5 in the non-working position must be wound around the bracket 7.

The machine moves on two rollers 1. Bracket 24 is the support of the machine. To carry the machine there are plastic handles 17. The machine is closed at the top with a removable lid 10. At the bottom there is a machine no. 23.

The electrical circuit of the machine is shown in Fig. 93, b.

WASHING MACHINE “RUSALKA” TYPE SMR-2. Designed for washing, rinsing and spinning items made from various types of fabrics and knitwear. The machine consists of a rectangular body / (Fig. 94, a), the front part of which is removable, which simplifies assembly and facilitates repair of the machine. The lower part of the housing is made in the form of a pallet on which the motor / (Fig. 95), reversible electronic device 2, electric pump 3 and capacitor 4 are installed.

Washing tank 2 (see Fig. 94) of the machine is connected to the body using screws. There is a mark on the inner wall of the tank indicating the required water level for washing and rinsing. Washing clothes is carried out due to the reverse rotation of the activator 13, which is located on the side wall of the tank and is driven by the engine via a V-belt drive 14. During operation, the washing tank is closed with a lid.

The laundry is spun by a folding manual squeezing device 5 located in the upper part of the machine. The wrung out laundry from the wringer goes into box 10 installed on the machine body. The distance between the rollers of the squeezing device is adjusted by handle 6.

The remaining water or washing solution is drained through the removable filter cover 8 into the bath 9. At the front of the lower part of the machine there is a niche, on the hinged door of which there is a device 15 for winding the cord; There is a removable filter installed inside.

On the front wall of the machine there is a control panel with handle 3 for time relays, handle 4 for switching programs and handle 7 for turning on the electric pump. The machine can move across the floor on four rollers. When not in use, the machine is closed with a lid.

K category: Electrical questions

How do SMR type washing machines work?

The general view and cross-section of a SMR-type washing machine are shown in Figure 76. A disk activator is located at the bottom of the washing tank. On the same shaft with the activator inside the housing there is a centrifugal pump that pumps liquid out of the tank. The liquid flows through a drain hole in the bottom of the tank, closed by a removable grille, through a hose into the pump and through a drain hose leading out of the machine body, it is drained back into the tank during washing, thereby ensuring the circulation of the washing liquid. After finishing the wash, the liquid is removed from the machine through the drain hose.

The activator and pump are driven by an asynchronous electric motor via a V-belt drive.

Rice. 1. Washing machine type SMR: a - general view; b - section; 1 - body; 2 - washing tank; 3 - tank fill level mark; 4 - handle for carrying the machine; 5 and 6 - rollers of the squeezing device; 7 - adjusting screw; 8 - spring; 9 and 10 - drain and connecting hoses; 11 - bracket for winding the electrical cord; 12 - handle of the squeezing device; 13 - grille; 14 - cord; 15 - relay; 16 - roller; 17 - bracket for holding the machine during spinning; 18 - frame; 19 - electric motor; 20 - pump; 21 - activator

The electric motor is mounted on an inclined frame, the longitudinal grooves of which allow you to move the motor and thereby adjust the tension of the drive belt.

A squeezing device with two rubber-coated rollers is mounted in the brackets of the machine body and secured with locking screws. A flat spring presses the upper roller against the lower one. The spring force is changed with an adjusting screw. The rollers are rotated by a removable handle, which is inserted into the axis of the lower roller. The machine is turned on by turning the time relay knob.

They carry the car by lifting it by the plastic handles. The bracket serves as a support for the machine and at the same time helps to hold it while spinning clothes. The machine can be transported on two casters. An oblong depression is pressed onto the surface of the tank, indicating the permissible liquid level. After stopping the machine, the connecting cord is wound around the bracket.

- How do SMR-type washing machines work?

The washing process involves removing various contaminants from the surfaces of products. It can be reduced to three stages: separation of dirt particles from the surface to be cleaned, to which they

stuck; transferring individual water-insoluble particles into the cleaning solution; keeping these particles in the solution until it is changed and eliminating any possibility of their re-sedimentation and adhesion to the surface being washed.

Classification of washing machines. Washing machines are divided according to various criteria: functions performed, washing method, number of tanks, degree of mechanization of laundry processing processes, degree of automation of processes, presence of liquid heating, nominal capacity.

Depending on the functions performed, they are distinguished: washing machines, machines for spinning clothes, washing machines with spinning clothes.

According to the washing method, washing machines are classified into machines with a disk activator, drum-type machines, etc. In machines with an activator, the mechanical effect on the laundry is produced by a disk with protruding ribs located along a radius or a helix. The disk rotates at high speed around its axis in one direction. Sometimes the rotation of the disc can be reversed.

Drum washing machines are machines in which the laundry is placed in a horizontal or inclined perforated drum that rotates slowly around its axis in one direction or alternately in different directions. The laundry is not completely immersed in the washing solution.

Machines for spinning clothes are either centrifugal or roller.

Washing machines can be single- or double-tank. Single-tank machines perform washing and rinsing (machines with a disk activator) and, in addition, spinning (drum machines). In two-tank machines, as a rule, one tank is used for washing and rinsing clothes, and the other is for spinning and sometimes rinsing.

According to the degree of mechanization of laundry processing processes, washing machines with spinning of clothes come with mechanization only for washing (rinsing); with mechanization of washing (rinsing) and pumping out

Chapter 14

Electrical goods

fluid machines; with mechanization of washing (rinsing), spinning and pumping out liquid.

According to the degree of process automation, laundry washing machines are divided into non-automatic, semi-automatic and automatic.

Depending on the heating of the water, washing machines are available without heating, with full heating, and with additional heating.

Depending on the nominal capacity, machines come in 1; 1.5; 2; 3 and 4 kg of laundry or more. The nominal capacity of the machine refers to the amount of dry laundry in kilograms that can be simultaneously processed in one operation or one wash cycle.

According to the current standard, washing machines have certain designations indicating the type of machine according to its functional purpose, the degree of mechanization and automation of individual operations, as well as the nominal capacity. For example, SM-1 is a washing machine for 1 kg of dry laundry; SMR-1.5 - washing machine with manual spinning of laundry for 1.5 kg of dry laundry, etc.

Washing machines without spinning clothes (SM). Washing machines without spinning clothes are usually designed for a small capacity: 0.75-1 kg of dry laundry.

The machine has a streamlined plastic body with a groove on the side wall into which a removable unit is inserted: electric motor - activator. The block in the non-working position is placed in the machine body.

Washing machines with manual spinning of clothes (SMR). These machines are characterized by incomplete mechanization of the washing processes. They spin their clothes manually.

SMR machines are available in two types: SMR-1.5 and SMR-2.

SMR-1.5 machines have a cylindrical shape and wash using a disk activator located eccentrically in the inclined bottom of the washing tank.

Machines of the SMR-2 type have a rectangular shape and are washed using a disk activator located on the side wall of the washing tank.

The main design elements of SMR-1.5 washing machines are as follows: cylindrical body; washing tank with an inclined bottom; disk activator; squeezing device; a hydraulic system, including a hose connecting the tank drain hole to the pump; pump, drain hose; frame; electric motor with protective starting equipment; cover, etc.

The squeezing device on standardized machines is detachable. When not in use, it is placed in the washing tank; for operation, it is installed in two corner brackets attached to the machine body from the outside.

The squeezing device consists of a housing, two rubber-coated rolls, a spring spring that provides the necessary pressure between the rolls, and an adjusting screw that increases or decreases the spring pressure on the roll supports.

SMR-2 machines have the same structural components as SMR-1.5 machines. The machine body is rectangular. Its upper part is occupied by a washing tank, which is made of double alloys of aluminum with manganese or magnesium. To protect against corrosion, the tanks are anodized. A plastic disk activator is placed on the side flat wall of the tank.

Semi-automatic washing machines (SMP), Such washing machines have completely mechanized all washing processes (washing, rinsing, spinning clothes, pumping out the washing solution), and some of them are automated. All machines have automatic washing (rinsing), and some, in addition, have spinning. Automation of these processes is achieved through the installation of time relays in machines. By turning the relay knob, you “set” the washing, rinsing or spinning time; after the specified time, the engine turns off.

Semi-automatic machines can be single- or double-tank.

In semi-automatic single-tank machines, washing, rinsing and spinning clothes are done by rotating the drum. The capacity of the machines is 1.5 or 2 kg of dry laundry. The main design elements of the machines are: body, washing

Chapter 14

Electrical goods

tank with perforated drum, hydraulic system, electrical equipment.

In semi-automatic double-tank machines, laundry is washed (rinsed) using a disk activator in the washing tank, and spinning is done using a centrifuge built into the machine. After washing (rinsing), the laundry is transferred from the washing tank to the centrifuge. The capacity of the machines is 1.5 or 2 kg of dry laundry. All twin-tank semi-automatic machines are rectangular in shape. The main design elements of the machines are: housing, washing tank with activator, centrifuge, hydraulic system, electrical equipment.

Automatic washing machines (AWA). Automatic washing machines began to be adopted by industry in our country in the late 60s. Such machines produce a capacity of 3-5 kg of dry laundry.

According to the washing method, automatic machines are mainly of the drum type. The working part of such a machine is a perforated drum with internal ridges. The drum is approximately ″/3 immersed in the washing solution located in the external tank-body of the machine. Drum-type machines can be top-loading or front-loading.

When loading laundry from the top, a window with a latch is made in the perforated drum. In this case, careful manufacturing of the window and valves is required, which should not have protruding corners and edges in order to avoid mechanical damage to the tissues. When loading frontally, a loading door is made in the machine body, which must close tightly.

Washing clothes in drum machines is done using the shoveling method. The laundry is caught by the combs, lifted and then dropped into the washing solution by gravity.

To automate washing processes, software devices, thermostats, washing solution level sensors, electromagnetic valves, etc. are installed in machines.

Operational characteristics of washing machines. Requirements for their quality. The main functional and ex-

The operational properties of washing machines are; washability of laundry, rinsing efficiency, spin efficiency, wear of laundry during washing, labor costs, time, consumption of detergents, water, ease of use and safety.

Laundry washability - the main property by which the quality of machines is judged.

The quality of washing depends on the design of the machine, water hardness, type of detergent, nature and degree of soiling of the laundry, type of laundry fiber, selected washing technology, etc.

In machines of different designs, it is possible to achieve the same washability of the laundry, but at the same time the wear of the fabrics will be different.

Rinse efficiency the process of which consists in removing soluble detergent substances and water-insoluble suspended and emulsified particles of contaminants remaining on the laundry from laundry, depends on the number of cycles it is carried out. Rinsing requires a lot of water. For SMR machines, three- and four-fold rinsing is required, for double-tank SMP machines - two and three times.

Spin efficiency determined by the ratio of the mass of water remaining in the laundry after spinning to the mass of the laundry in an air-dry state.

Wear and tear when washing depends on many factors. Research has established that laundry wears out less when washed in drum-type machines, more in machines with an agitator, with a side-mounted activator, and much more in machines with a bottom activator and especially with a horizontal bottom.

Physical labor costs during operation of machines are determined by the degree of mechanization of individual washing operations.

| Water consumption depends on the type of car. Washing machines with a disk activator consume about 80 liters of water per 1 kg of laundry, drum-type machines - approximately 55 l/kg.

Detergent consumption when washing by machine it depends on the type of machine, water hardness, degree of soiling of the laundry, but it is 15% less than by hand washing.

Chapter 14

Electrical goods

In addition to the noted requirements for operational properties, the quality of washing machines is influenced by water resistance in the interfaces of units in contact with liquid; corrosion resistance of all parts in contact with the washing solution; the absence of sharp edges on these parts that can cause mechanical damage to the linen; the ability to easily replace drive belts and adjust their tension; complete release of water from the hydraulic system after the end of washing and blocking of the loading hatch cover during operation of the washing machine (on drum-type washing machines).

Operating manual Washing machine Iset-8 type SMR-1.5 Sverdlovsk 1986 USSR Sverdmashpribor plant

standard description:

FOR real postage costs - the buyer pays in full.

!!! ATTENTION After purchasing the lot, contact me within 3 days, payment within 7 days. Otherwise, I will be forced to leave a negative review in order to return the trading platform commission.

Before purchasing, be sure to look at the “ABOUT ME” page, it shows in more detail how best to pay and other nuances.

Dear customers! I would like to inform you about some of the nuances that may arise when purchasing my lots. All lots are also sold on other sites. And a situation may arise when the lot will be sold on another site during the day, and I will be able to remove it from auction only in the evening. And if you buy a lot on this day, I may not have it in stock. This situation occurs extremely rarely, but it is still advisable to inquire about the availability of the lot before purchasing. I apologize in advance if this situation arises.

Everything that I sell or buy, like any person, I try to further discuss in personal correspondence, especially the conditions for sending the goods, and of course the payment itself.. So, as always, everything changes and sometimes, as you want, you may not be able to ship the goods and receive payment , as well as send money in the usual and usual way to the buyer...

Lecture ELECTRIC DRIVES OF WASHING MACHINE TYPE SMP,

DESIGN FEATURES

Main types of washing machines

Washing machines type SM. They have the simplest design, perform a minimum of laundry processing operations during washing, are characterized by small overall dimensions, low cost and are designed for washing 1..1.5 kg of dry laundry without spinning.

The washing solution circulates intensively between the layers of the material being washed and removes dirt. Under the influence of the activator, a vortex movement of the solution occurs. Continuously changing the direction of its movement improves the quality of washing clothes.

The drain pipe is located at the bottom of the washing tub. The machine kit includes an inlet hose, a stand for installing the machine on the sides of the bathtub and clothes tongs.

Washing machines type SMR. Such machines are designed for simultaneous washing of 1.5...2 kg of dry laundry under conditions of intense circulation of the washing solution created by a disk activator. The laundry is spun manually using a special device. Many models use the so-called dual-mode washing method, which takes into account the characteristics of different types of fabrics.

Washing machines type SMP. The main difference between semi-automatic washing machines (SMP type) and SMR type machines with a manual squeezing device (rubber rollers) is the presence of a function for mechanized centrifugal spinning of laundry. Thanks to this, breaking of buttons is eliminated, much less water remains in the laundry, the use of manual force is not required, and the spinning time is reduced.

Washing machines type SMA.

Currently, automatic washing machines with a perforated drum rotating about a horizontal axis are becoming increasingly popular among domestic consumers.

There are two options for loading laundry - from the top and from the end. The design principles of such machines are the same. A round drain tank and a perforated washing drum with three or four oval ridges are mounted in the upper part of the rectangular body.

In both versions of the machines, washing is carried out with reverse rotation of the drum with an angular speed of about 6.28 rad/s 1 (rotation speed 60 min~"), and spinning is carried out with its unilateral rotation with an angular speed of 41.87...62.8 rad /s (400...600 min 1). In the latest domestic models of washing machines of the SMA type, the angular speed of rotation of the drum during spinning reaches 104.67 rad/s (1000 min 4).

Washing in automatic top loading machines! the drum has two end supports. Thanks to this they improve! operating conditions of the drum itself and its drive increase the reliability and durability of the machine. Laundry is loaded through the top hatch of the drum, closed with a perforated lid. However, such loading turns out to be quite lengthy, not convenient enough, and does not allow visual control of the washing process.

Washing in automatic end-loading machines! the drum has one cantilever support; the side of the drum opposite to it is open. On this side is; loading hatch, which is closed from the outside with only one round glass lid (door) of the drain tank (reservoir). End loading is more convenient, and the glass door allows you to visually control the washing process.

Basic assembly units of washing machines of various types

The most essential assembly units of washing machines of various types are:

Housing, washing tank, activator, its drive, thermal relay and time relay (timer) - in SM type machines;

Housing, washing tank, manual squeezing device, activator, its drive, centrifugal pump, thermal relay, time relay and hydraulic system - in SMR type machines;

The housing, the washing tank, the activator, its drive, the centrifuge, its tank, the drive and suspension system, the centrifugal pump, the thermal relay, the time relay and the hydraulic system - in activator machines of the SMP type;

The housing, the washing tank, its suspension system, the washing drum, its drive, the centrifugal pump, the thermal relay, the time relay and the hydraulic system - in drum machines of the SMP type;

. housing, washing tank, its suspension system, washing drum, its drive, centrifugal pump, control device (electromechanical control - command apparatus, electronic control system), instrumentation, actuators (thermal relay, solenoid valves, temperature sensors and relays) washing solution level, control panel), electric solution heater and hydraulic system - in SMA type machines.

3. Design features of assembly units and electric drive of the SMP washing machine

Activator consists of a bladed disk (Fig. 3.1), steel or plastic, with a diameter of 140... 155 mm with small ribs 14... 16 mm high, a support and an electric drive. The activator is driven by a single-phase motor through a V-belt drive. The activator rotation speed is usually 475...750 min -1, the gap width between it and the bottom of the tank is 1...1.5 mm.

Washing machines with two washing modes - soft and hard, differing from each other in the frequency and direction of rotation of the activator disk - have become widespread. In Fig. 1, b a disk with an inclined arrangement of combs is shown, providing two washing modes: when rotating it clockwise - soft, counterclockwise - hard.

Rice. 1. Washing machine activator discs with one (A) And

two (b) washing modes

Centrifuge, used in double-tank washing machines: SMP type, designed for centrifugal spinning of laundry after washing. It is a basket (cone-shaped

perforated rotor) with a vertical axis of rotation connected to the shaft of the centrifuge drive electric motor. Laundry is loaded from the top. Baskets with a volume of 7...9.5 dm 3 are made of AMtsM or AD-13 aluminum. The capacity of the centrifuge tank is 20...40 dm 3, its rotation frequency when spinning clothes is 2600...3270 min -1.

Drive unit in washing machines it is used to impart torque to individual executive bodies (activator disk, washing drum, centrifugal pump impeller, cam unit of the command device). It usually consists of an electric motor and a transmission device. In household washing machines, single-phase asynchronous electric motors are most often used, less often - universal collector motors, designed for rated voltages of 127 and 220 V. The rotational speed of asynchronous electric motors is 1500 and 3000 min -1, rated power 90, 120 and 180 W, rated operating mode - repeated -short-term. Reverse is allowed in the operating cycle.

Centrifugal pump serves to drain the washing solution from the washing tank upon completion of washing, as well as from the centrifuge tank of semi-automatic activator-type machines and the tank of drum-type machines during the spinning process. In some machine models, the pump operates while washing clothes, enhancing the effect of the washing solution due to its circulation and supply to the trawl tank.

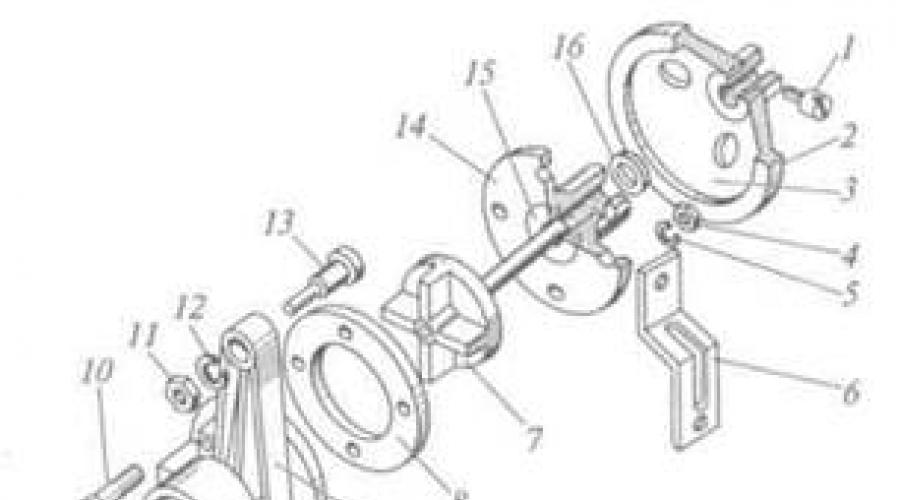

The pump (Fig. 2) consists of a housing 9, impellers 7 and covers 14. The impeller is mounted on the shaft. There is a rubber gasket between the body and the cover 8. Usually the pump is installed separately from the activator.

Sometimes in pumps the impeller is on the same axis as the activator. On the same axis, a driven pulley is attached, connected by a drive belt to the drive pulley on the axis of the electric motor.

The volumetric flow of the pump depends on the type of machine and is IK... 30 l/min. The dynamic pressure of the liquid varies within 6.8... 34.3 kPa.

Thermal relays serve to protect electric motors from unacceptable overheating during prolonged overloads and an unintended increase in current in the supply network. In washing machines, thermal relays of the RT-10 type are used, which have a normally closed contact. Manufactured relays are designed for various rated current values 1 N thermal elements: 1.2; 1.9; 2.5; 3.3 and 4.3 A. At a load of 1.1 1 N, the relay does not operate within 30 minutes; at load 1.35 1 N it operates no later than after 30 minutes, at a load of 2 1 N-in 18...60 s. The time during which the contacts self-return to the closed state occurs ranges from 30 to 10 minutes.

Rice. 2. Centrifugal pump:

/, 10 - screws; 2 - pulley tire; 3 - pulley; 4, 11 - nuts;

5, 12, 16 - washers; 6- bracket; 7 - impeller;

8 - pad; 9 - frame; 13 - axis; 14- cover;

15-cuff

Combined start-up relays designed to start an electric motor and protect its windings. In washing machines, relays of the types RTK-S, RTK-1, RTK-1-2, RTK-1-3, RTK-3-0, etc. are used. These devices consist of a solenoid-type starting relay and a thermal bimetallic relay with direct heating , mounted in one housing.

Mechanical time relay with a spring motor is designed to automatically turn off the drive of the activator (washing drum) and the centrifuge of household washing machines of types SM, SMR and SMP after a preset time for performing the laundry processing operation (washing or spinning). Depending on the design, the relay is designed for a dwell time of 1...6 or 1...10 minutes. Its permissible deviation from the specified value is 0.5 min.

A time relay with a dwell time of 6 minutes is conventionally designated as follows:

Standard version - RV-b;

Drip-proof - RV-6K.

By turning the time relay knob, the washing duration is set. At the same time, the relay contacts close and the machine turns on.

4. Double-tank (activator) washing machines and drum-type machines (SMP-B)

Double tank housing (activator) type washing machines The SMP is made of sheet steel and coated with enamel on the outside. A washing tank with an activator and a drain tank with a centrifuge are installed inside the housing. For ease of movement, the machine is equipped with running plastic or rubberized rollers. A time relay has been introduced into its electrical circuit, with the help of which it automatically turns off after a specified time has elapsed. The activator and centrifuge drive design includes one or two electric motors. The first option involves the use of an asynchronous electric motor. In the second option, an asynchronous motor is installed to drive the activator, and a commutator or asynchronous motor is installed to drive the centrifuge. To protect electric motors from overloads, thermal relays are provided in the machines, and two- or three-way taps are installed to redirect water flows into one of the sacks.

IN drum washing machines(SMP-B) rotation is transmitted to the drum from a two-speed asynchronous electric motor using a drive belt and two pulleys. The tank and drum are made of stainless steel sheet. On the back wall of the machine body, in a niche, there are two fittings for connecting hoses. At the bottom of the front wall of the housing there is a hatch for access to the filter and pump. The pump designed for pumping out the cleaning solution is equipped with its own electric motor. The control panel contains handles for the time relay and washing mode switch. The laundry is spun in the same washing drum by increasing its rotation speed.

Semi-automatic drum-type washing machines have a soft suspension and electronic control. They are designed for washing, rinsing and spinning clothes in one perforated drum with ridges on the inside. Compared to two-tank machines, the use of a drum allows you to consume less water and detergents.

The electronic control system makes it possible to select different options for washing and spin modes. Starting and switching operations are done by turning the handle of a time relay or command device, which also allows you to set the duration of any operation.

The soft drum suspension system on friction-spring shock absorbers allows you to reduce the impact of vibration on the body, reduce the weight of counterweights, increase the reliability of the machine, and reduce noise.

The hydraulic system of a drum-type machine consists of a subsystem for filling and pumping liquid from the tank.

The filling system includes a detergent dispenser and a hose for filling liquid into the machine tank.

The pumping system includes:

□ Drain hose

□ Cleaning filter

□ Electric pump

□ Drain pipes

The machine has a rectangular body that houses a washing tank, a motor-pump for draining the solution, a control unit and a two-speed electric motor with a belt drive. The drum is fixed to the machine body using springs. This ensures quiet operation and reduced vibration of the machine body.

The control panel contains:

□ Switch keys

□ Washing tank fill level scale

□ Program installation knob

□ Two warning lights

On the back wall of the machine there is a tray for washing powder and an inlet fitting with a solenoid valve for filling water. Water is drained from the tank by a motor pump through a drain hose.

©2015-2019 site

All rights belong to their authors. This site does not claim authorship, but provides free use.

Page creation date: 2017-06-12