Welding overheats immediately when turned on. Various malfunctions of welding inverters. How welding inverters work

Read also

Inverter welding machines are becoming increasingly popular among welders due to their compact size, low weight and reasonable prices. Like any other equipment, these devices can fail due to improper use or due to design flaws. In some cases, you can repair inverter welding machines yourself by studying the design of the inverter, but there are breakdowns that can only be repaired in a service center.

Welding inverters, depending on the model, work like household ones electrical network(220 V) and three-phase (380 V). The only thing that needs to be taken into account when connecting the device to a household network is its power consumption. If it exceeds the capabilities of the electrical wiring, then the unit will not operate if the network is drained.

So, the inverter welding machine includes the following main modules.

How does an inverter work?

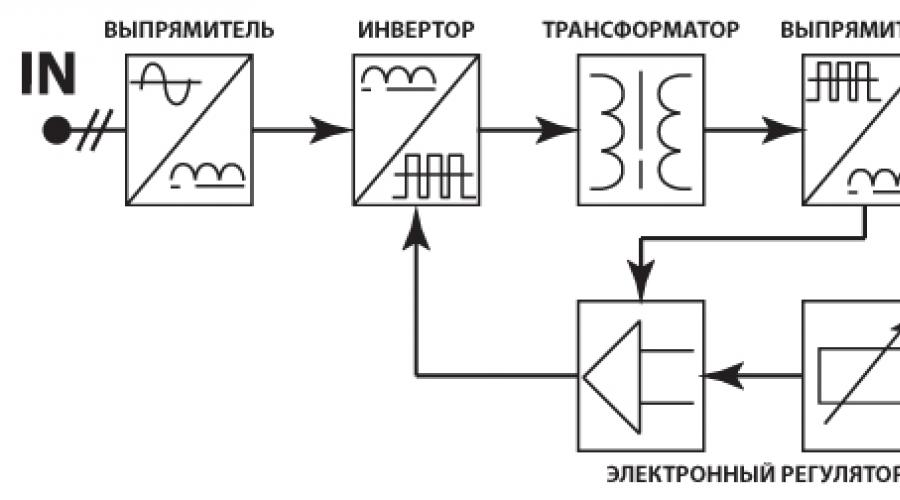

Below is a diagram that clearly shows the principle of operation welding inverter.

So, the operating principle of this welding machine module is as follows. The primary rectifier of the inverter receives voltage from the household electrical network or from generators, gasoline or diesel. The incoming current is alternating, but as it passes through the diode block, becomes permanent. The rectified current is supplied to the inverter, where it is converted back into alternating current, but with changed frequency characteristics, that is, it becomes high-frequency. Next, the high-frequency voltage is lowered by a transformer to 60-70 V with a simultaneous increase in current. At the next stage, the current again enters the rectifier, where it is converted into direct current, after which it is supplied to the output terminals of the unit. All current conversions controlled microprocessor unit management.

Causes of inverter failures

Modern inverters, especially those made on the basis of an IGBT module, are quite demanding in terms of operating rules. This is explained by the fact that when the unit is operating, its internal modules generate a lot of heat. Although radiators and a fan are used to remove heat from power components and electronic boards, these measures are sometimes not enough, especially in inexpensive units. Therefore, you need to strictly follow the rules that are indicated in the instructions for the device, which imply periodically turning off the unit to cool down.

This rule is usually called “On Duration” (DS), which is measured as a percentage. Without observing the PV, the main components of the device overheat and fail. If this happens to a new unit, then this breakdown is not subject to warranty repair.

Also, if the inverter welding machine is working in dusty rooms, dust settles on its radiators and interferes with normal heat transfer, which inevitably leads to overheating and breakdown of electrical components. If the presence of dust in the air cannot be eliminated, it is necessary to open the inverter housing more often and clean all components of the device from accumulated contaminants.

But most often inverters fail when they work at low temperatures. Breakdowns occur due to the appearance of condensation on the heated control board, resulting in a short circuit between the parts of this electronic module.

Repair features

A distinctive feature of inverters is the presence electronic board control, therefore only a qualified specialist can diagnose and fix a malfunction in this unit. In addition, diode bridges, transistor units, transformers and other parts of the electrical circuit of the device may fail. To carry out diagnostics yourself, you need to have certain knowledge and skills in working with such measuring instruments, like an oscilloscope and a multimeter.

From the above, it becomes clear that, without the necessary skills and knowledge, it is not recommended to start repairing the device, especially electronics. Otherwise, it can be completely damaged, and repairing the welding inverter will cost half the cost of a new unit.

Main malfunctions of the unit and their diagnostics

As already mentioned, inverters fail due to the impact on the “vital” units of the device external factors. Also, malfunctions of the welding inverter can occur due to improper operation of the equipment or errors in its settings. The most common malfunctions or interruptions in the operation of inverters are:

The device does not turn on

Very often this breakdown is caused malfunction network cable apparatus. Therefore, you first need to remove the casing from the unit and ring each cable wire with a tester. But if everything is in order with the cable, then more serious diagnostics of the inverter will be required. Perhaps the problem lies in the standby power supply of the device. The method of repairing the “duty room” using the example of a Resanta brand inverter is shown in this video.

Welding arc instability or metal spattering

This malfunction may be caused incorrect setting current strength for a certain electrode diameter.

Advice! If there are no recommended current values on the packaging for the electrodes, then it can be calculated using the following formula: for each millimeter of equipment there should be a welding current in the range of 20-40 A.

It should also be taken into account welding speed. The smaller it is, the lower the current value must be set on the control panel of the unit. In addition, to ensure that the current strength corresponds to the diameter of the additive, you can use the table below.

Welding current is not adjustable

If not regulated welding current, the reason may be regulator failure or a violation of the contacts of the wires connected to it. It is necessary to remove the unit casing and check the reliability of the conductor connections, and, if necessary, test the regulator with a multimeter. If everything is in order with it, then this breakdown can be caused by a short circuit in the inductor or a malfunction of the secondary transformer, which will need to be checked with a multimeter. If a malfunction is detected in these modules, they must be replaced or rewound by a specialist.

High power consumption

Excessive power consumption, even if the device is without load, most often causes turn-to-turn short circuit in one of the transformers. In this case, you will not be able to repair them yourself. You need to take the transformer to a mechanic to rewind it.

The electrode sticks to the metal

This happens if the network voltage drops. To get rid of the electrode sticking to the parts being welded, you will need to correctly select and configure the welding mode (according to the instructions for the device). Also, the voltage in the network may sags if the device is connected to an extension cord with a small wire cross-section (less than 2.5 mm 2).

Often, a drop in voltage causing electrode sticking occurs when using a power extension cord that is too long. In this case, the problem is solved by connecting the inverter to the generator.

Overheat light on

If the indicator is on, this indicates overheating of the main modules of the unit. Also, the device may turn off spontaneously, which indicates when thermal protection is triggered. To prevent these interruptions in the operation of the unit from occurring in the future, you again need to adhere to correct mode ON duration (DS). For example, if duty cycle = 70%, then the device should operate in the following mode: after 7 minutes of operation, the unit will be given 3 minutes to cool down.

In fact, various breakdowns and there can be quite a lot of reasons that cause them, and it is difficult to list them all. Therefore, it is better to immediately understand what algorithm is used to diagnose a welding inverter in search of faults. You can find out how the device is diagnosed by watching the following tutorial.

The welding inverter provides good quality carrying out welding work, creating for the welder the maximum comfortable conditions for work. However, these advantages lead to increased complexity of its design. This can cause various malfunctions of the welding inverter and reduce its reliability.

Features of inverter repair

Unlike conventional welding machines, which are electrical products, a welding inverter is an electronic device. Consequently, diagnostics and repair of inverter welding machines are carried out by checking the operating condition of diode bridges, transistor connections, zener diodes and other parts that are included in the electronic circuits. In this case, you need to have skills in handling oscilloscopes, voltmeters, multimeters and other measuring instruments.

Home distinctive feature When repairing a welding inverter, it is difficult to determine the nature of the breakdown and detect the failed part. Therefore, it is very often necessary to diagnose all components of the electrical circuit.

Based on the foregoing, we can conclude that it is necessary to have minimal knowledge in the field of electronics and be able to understand the design electrical diagrams. If such skills and abilities are missing, then take on do-it-yourself repair Such a device is not recommended so as not to waste extra effort and time.

Operating principle of the inverter

The operating principle of inverter devices is the sequential (step-by-step) transformation of the incoming electric current signal:

- the process of rectifying incoming network currents using a special rectifier;

- the process of converting rectified currents into alternating high-frequency signals;

- the process of reducing high voltage currents to welding voltage, occurring on a power transformer;

- transformation alternating current with high frequency D.C., occurring using the output rectifier.

To perform such operations, the welding inverter design has several modules with electronic stuffing. The main module is the input current rectifier. Then there is a control board on which transistors (switches) are located, and it ends with a rectifier for the output signals.

At the same time, in devices different manufacturers having different models, the layout of the unit components can be very diverse, but the installation of the main components will always be unchanged.

Therefore, knowing the basic operating principle of such units and the location of the main modules of their design, it is possible to diagnose possible faults and carry out the necessary repairs.

Types of main faults

If the welding inverter fails, the first thing you should do is check its transistors, since they are one of the most weak points such units. Initially, you should carry out visual inspection transistors. Such a broken part is very easy to identify: it has a broken or cracked case with burnt-out leads at the solder points on the board. This part needs to be replaced immediately.

New transistors should be installed on a special thermal paste. It will ensure heat removal from the transistor to a radiator made of aluminum. But very often a visual inspection does not reveal faulty elements, then you should make a “diagnosis” using a multimeter.

Replacement faulty elements carried out according to precisely specified parameters. In some cases, it is possible to supply analogue parts, and the required parameters can be determined from the datashift. If replacing the burnt-out transistors does not help, you need to move on to further diagnostics.

IN normal mode operation, transistors cannot simply fail; most likely, this is due to the incorrect operation of other elements. Most often this is the driver. It is checked with an ohmmeter. If faulty parts are found, they must be removed and replaced with similar parts.

Then the input and output current rectifiers, which consist of diode bridges, are checked. They are installed on the radiator and are reliable components for welding inverters. But they can also fail. Their functionality is checked using a voltmeter.

Control board fault

It is best to check diode bridges by unsoldering the wires from them and then detaching them from the board. This can make everything easier further work and there will be no doubt when it happened short circuit the entire inverter circuit.

The check follows a fairly simple algorithm. It is necessary to “ring” the entire group of parts. If a “short” is detected, then you should search for a broken diode. Once it is detected, the diode should be carefully removed and replaced.

If after carrying out all the above steps the welding machine still does not work, you should test the control board. It monitors the operation (control) of the keys. The reliability of the operation of all equipment will depend on the reliability of such a board.

To carry out competent and qualified repair of the inverter, it is necessary to check for the presence of the necessary signals that produce its operation. These signals must be sent to the gate buses of the key module. You can perform a similar check using oscilloscopes.

Periodically, high heating of the inverter housing may occur. This may be due to violations of the rules for using the unit and incorrect selection of the value of the current used for welding. This can also occur when the electrodes are incorrectly selected or the unit is operated for too long. To avoid such difficulties when using the inverter, it is necessary to observe optimal modes works that are specified in the technical passport.

You can fix inverter malfunctions yourself, but this can only be done if you have the necessary diagnostic tool and experience in using it. Otherwise, it is better to seek help from specialists.

An inverter welder differs from a conventional welding machine in an easier and better welding process. However, malfunctions of the welding inverter, due to its more complex device, may be more serious and complex.

To determine the cause of a device failure, you need to diagnose it: check transistors, resistors, diodes, stabilizers, contacts, etc. Each device is supplied with detailed instructions with a description of the most common faults that you can fix yourself. However, very often repairs may require special equipment: ohmmeter, voltmeter, multimeter, oscilloscope. And you need to know how to use them. And in special cases, knowledge of electronics and the ability to work with electrical circuits are required. Therefore, if self-checking and eliminating simple faults described below did not lead to success, it is better to entrust the repair inverter device to the technicians at the service center.

What are the types of inverter malfunctions?

There are several groups of breakdowns of welding inverters:

- malfunctions arising due to non-compliance with the welding workflow standards specified in the instructions;

- malfunctions arising as a result of incorrect operation or failure of device elements;

- damage resulting from moisture, dust and foreign objects entering the device.

Return to contents

Common faults that you can fix yourself

Let's look at some of the most common malfunctions of welding inverters:

To identify and eliminate the cause of the malfunction, the body of the device is opened and a visual inspection of its contents is carried out.

- The welding arc burns unsteadily or the electrode spatters material heavily. The reason for this may lie in wrong choice current. The current strength must correspond to the type and diameter of the electrode and the speed of the welding process. If the current strength is not indicated on the electrode packaging, then you can start supplying current from 20-40 A for each millimeter of electrode diameter. When the welding speed is reduced, the current must also be reduced.

- The electrode sticks to the material. This often happens due to low voltage in the network, the value of which is less than the minimum permissible when working with an inverter. The cause of electrode sticking can also be poor contact in the panel sockets, which can be eliminated by fixing the boards more tightly. Using an extension cord with a wire size smaller than 2.5 mm2 or with a wire that is too long (more than 40 m) may reduce the voltage. Burnt or oxidized contacts in electrical circuit can also reduce tension.

- There is no welding process, while the device is connected to the network. In this case, you need to check the presence of mass on the part being welded. Also check the inverter cable for damage.

- The device turns off spontaneously. The device is switched off when the transformer is connected to the network, after which its protection is triggered. The reason for this may be a short circuit in the voltage circuit. The protection can be activated not only when the wires are shorted to each other or to the housing, but also when there is a short circuit between the turns of the coils or a breakdown of the capacitors. To repair a hollow part, you first need to disconnect the transformer and find the fault, and then insulate or replace the damaged element.

If there is no welding when the machine is turned on, check the connection of the electrode holder cable.

During prolonged operation, the device turned off. Most likely, this is not a breakdown, but an overheating of the inverter. You need to wait 20-30 minutes and then resume work. You should adhere to the rules for operating the device: do not overheat it, that is, take breaks in operation, connect the appropriate current values to it, do not use electrodes of too large diameters.

The transformer makes a loud noise and overheats. Perhaps the reason for this was an overload of the transformer, loosening of the bolts that tighten the sheets of the magnetic core, or a breakdown of the core fastening. Due to a short circuit between the magnetic core sheets or cables, the device can also make a loud noise. Tighten all fastening elements and restore cable insulation.

Welding current is poorly regulated. The reason for this may be a breakdown in the current regulation mechanism: a fault in the current regulation screw, a short circuit between the regulator mounts, a short circuit in the inductor, poor mobility of the secondary coils as a result of clogging, etc. Remove the casing from the inverter and examine the current regulation mechanism to identify the breakdown.

The welding arc breaks off abruptly, and it is impossible to ignite it; only sparks appear. Perhaps the problem lies in the breakdown of the winding high voltage, short circuit between the wires or poor connection with the inverter terminals.

High current consumption at no load. The reason may be short circuit of the turns on the coil. It can be eliminated either by restoring the insulation or by completely rewinding the coil.

Return to contents

If excessive spattering of the electrode metal occurs during welding, the cause may be an incorrectly selected value of the welding current.

If a burning smell and smoke appear from the device body, this may indicate a serious breakdown. IN in this case You may need qualified repairs at a service center.

To identify the malfunction, first disassemble the housing. Carry out a visual inspection of parts for damage, cracks, burnt contacts and swelling of capacitors. They also check the soldering points of parts and contacts on the inverter boards. Often the causes of malfunctions lie precisely in poor-quality soldering; they can be easily eliminated by re-soldering the parts.

All faulty parts should be removed and replaced with new ones corresponding to the given model of the device.

You can select parts in accordance with the markings indicated on the device body or in a special reference book.

You need to solder the parts using a soldering iron that has a suction, which will make the work convenient and fast.

Equipment such as a welding machine has always been in demand. Especially if he small sizes, compact, operating at a voltage of 220 volts, which is very convenient when carrying out welding work in places where it is difficult to use bulky and powerful devices. For example, on construction sites, in car repair services, household appliances etc.

But, most importantly, the welding machine, the weight of which seems ridiculous for such equipment, sometimes it does not exceed 5 kg, due to its compactness and mobility it is easy to use when repairing personal equipment, construction individual houses, construction of some metal structures on summer cottages etc. In a word, such a welding baby will come in handy everywhere.

Now modern technologies allow to manufacture in wide range and a large number of compact and mobile welding machines that are used not only in industry, but also at home. You can practically buy them in any store for the sale of equipment. Big choice and the reasonable price of welding machines allow everyone to buy them without any problems.

Currently, welding machines are very popular. different models Latvian company Resanta. This equipment High Quality. In Russia, the demand for Resanta welding machines is very high. They are convenient to transport, because their size and weight allow you to transport equipment even in the trunk passenger car. And carry it over short distances by one person.

The advantages of Resanta were appreciated not only by professional welders, but also by amateurs who do not have sufficient experience in welding work.

The company produces two types of welding equipment: Resanta welding machine and Resanta welding inverter. The difference between them is that the first type is a transformer unit, and the second is an inverter unit. Both differ from each other in various respects.

However, no matter how reliable the device is, and no matter how much safety margin it has, sooner or later some part may fail and it will need repair. Just as there is no perpetual motion machine in nature, there are no perpetual mechanisms. Breakdowns are inevitable with both the Resanta welding machine and the Resanta inverter. Let's consider general signs and the reasons for both types of welding equipment from a Latvian company, leading to repairs.

Signs and causes of welding inverter breakdowns

Signs by which you can determine that the Resanta welding inverter repair required:

- electrode sticking

- instability electric arc

- lack of arc

- device overheating

- inverter does not turn on

Causes of malfunction

Electrode sticking occurs in the following cases:

- low voltage

- using an extension cord with a cross-section of less than 2.5 mm

- burnt contacts

- poor cable contact

Arc instability is caused by:

- incorrect adjustment of welding current

- mismatch between the type and diameter of electrodes

Lack of arc in caused by the following reasons:

- cable break

- inverter overheating

- lack of "mass"

- failure of a printed circuit board, where one or even several parts have failed

Device overheating can happen when:

- he works long time at full load without interruption

- cooling fan failed

- there is a large layer of dust on the printed circuit board parts

Reasons when the inverter does not start after pressing the “Start” button. those. does not start working, may be as follows:

- absent completely or low voltage nutrition

- something is faulty: cable, socket or switch

- on printed circuit board Some element has broken down

- extension cord needs to be replaced

Welding machine breakdowns

Causes of breakdowns, because of which often welding units are being repaired:

Any manufacturer values his reputation and will not produce low-quality products. However, no matter how good the assembly of the same welding machine, during operation from vibration, constant transportation, etc., the contacts on terminal blocks, to which the welding cables are connected, weaken. And as a result, strong heating of the parts occurs at the junction points, which leads to their destruction and short circuit in the network, and therefore to repair. To prevent this, you need to regularly monitor the contacts on the terminals, and, if necessary, sort out and clean the connecting contacts, thereby ensuring tight contact of all parts.

It often happens that the welding machine suddenly he can switch off on his own. And this happens because a short circuit has occurred in the high voltage circuit. In this case, it is necessary to identify the defective location and eliminate the malfunction.

Loosening of the bolts tightening the transformer plates, overloads in the operation of the transformer unit of the welding machine, as well as loosening of the core or the mechanism for moving the coils lead to overheating of the unit’s transformer.

If the welding machine overheats, then it needs to take a “break”. Equipment overheating is possible during his intense work. In such cases, to prevent the unit from malfunctioning, it is recommended to reduce the operating current or use electrodes of a smaller diameter, otherwise the matter may end in repair.

If the machine does not “pull”, the reason should be sought in the mains voltage or the welding current regulator.

Main types of repair work

Some minor breakdowns of Resanta can be repaired yourself, without the help of specialists. But it also happens that serious repairs are required. In this case it is best contact service center

. There, for example, they can make a replacement:

Some minor breakdowns of Resanta can be repaired yourself, without the help of specialists. But it also happens that serious repairs are required. In this case it is best contact service center

. There, for example, they can make a replacement:

- fan

- inverter boards

- transformer

- diode rectifier

- capacitors

- and other details

And carry out repairs:

- control boards

- power supply

- control module

- IMS module

- main board

To reduce repairs to your welding machine, try to operate it correctly. And then you won’t need to spend money on repairs often.